oliver 1800 hydraulic pump pricelist

All BrandsAGCO AllisAllis-ChalmersAriensCase/Case IHDavid BrownDeutz/Deutz-AllisDixie ChopperEncoreExmarkFord/New HollandGleanerHesston-FiatHydro-GearInternational HarvesterJohn DeereLong/UniversalMassey-FergusonMcCormickMinneapolis-MolineOliverParkerScagTOROWhite/AGCO WhiteWright

Brake Actuator Assembly, Used - For Oliver tractor models 1750 (after s/n 180537), 1800 (after s/n 90525), 1850 (after s/n 150421), 1900 (after s/n 90525), 1950 (after s/n 150421) Replaces Oliver OEM number 105725AS, , Compatible with White tractor models 4-150, 4-180, For a new version of this item use Item #: 105801, Used items are not always in stock. If we are unable to ship this part we will contact you within one business day., (Item #: 435374) $131.01

Clutch Disc - For Oliver tractor models 950, 990, 995, 1800, 1900 Replaces Oliver OEM number 105635AS, , Compatible with White tractor models 2-115, 4-115, Replaces White OEM number 105635AS, 14" Diameter, 1-3/4", 27 Spline, Additional Handling and Oversize Fees Apply To This Item, (Item #: 166084) $157.22

Spark Plug - For tractor models White 2-78, White 4-78, 1650, 1655, 1750, 1755, 1800, 1850, 1855, 1900. Replaces 157803A, Autolite AL65 and Champion N12YC. Verify correct spark plug size and type. Price is for one plug. (Item #: 172892, Ref: 834236M1) $4.09

PTO Drive Hub - For Oliver tractor models 1750 (s/n 180537-190957), 1800, 1850 (s/n 150421-198393), 1900, 1950, Replaces Oliver OEM number 103966A, 164309A, Size: 6-1/4", Hub Size: 1-1/8", Splines: 17, Center: Spring, (Item #: 176830) $174.30Engine Gaskets

Conversion Gasket Set - Converts head gasket set into overhaul gasket set. For tractor models (1650, 1655, White 2-70 diesel up to SN# 187585), (1750, 1755 gas or diesel), (1800 from SN# 124396 gas or diesel), (1850, 1855, 1950 with 310 Waukesha gas). (Item #: 131602, Ref: CS3809) $100.01

Bare Block, Remanufactured, 106085A - For Oliver tractor model 1800, Replaces Oliver Casting number 106085A, 221020D, Our remanufactured bare blocks have been; cleaned, inspected, align bored, and pressure checked, (Item #: 204878) $1100.01

Bare Block, Remanufactured, 155720A - For Oliver tractor models 1800, 1850, Replaces Casting number 155720A, 221120, Our remanufactured bare blocks have been; cleaned, inspected, align bored, and pressure checked, (Item #: 204880) $1225.01

Bare Block, Used - For Oliver tractor model 1800, Replaces Oliver Casting number 106085A, 221020D, Our used bare blocks are inspected for cracks. This requires 7 to 10 working day lead time, Block may require further cleaning, inspection, or machining before use, For a Remanufactured version of this part use Item #: 204878, Used items are not always in stock. If we are unable to ship this part we will contact you within one business day., (Item #: 443837) $625.01

Crankshaft, Remanufactured, 221211 - For Oliver tractor model 1800 (Gas or Diesel with 1-3/4 thrust), Replaces Casting number 221211, Our remanufactured crankshafts are cleaned, magnafluxed, measured and reground if necessary, the journals are then polished., (Item #: 200611) $930.01

Cylinder Head, Remanufactured - For Oliver tractor model 1800 (Early Gas), Cylinders: 6, Our remanufactured cylinder heads are reconditioned and ready for assembly, with both valve guides and valve seats installed, Cleaned and tested for cracks, (Item #: 200580) $710.01

Cylinder Head, Remanufactured - For Oliver tractor model 1800 (Late Gas), Cylinders: 6, Our remanufactured cylinder heads are reconditioned and ready for assembly, with both valve guides and valve seats installed, Cleaned and tested for cracks, (Item #: 200581) $710.01

Cylinder Head, Remanufactured, 221502 - For Oliver tractor models 1650, 1750, 1800 (Diesel), Replaces Oliver Casting number 221502, Cylinders: 6, Casting No. 221502, Our remanufactured cylinder heads are reconditioned and ready for assembly, with both valve guides and valve seats installed, Cleaned and tested for cracks, (Item #: 200577) $1325.01

Cylinder Head, Remanufactured, 221802 - For Oliver tractor models 1650, 1750, 1800 (Diesel), Replaces Oliver Casting number 221802, 157163A, Cylinders: 6, Casting No. 221802, 157163A, Our remanufactured cylinder heads are reconditioned and ready for assembly, with both valve guides and valve seats installed, Cleaned and tested for cracks, (Item #: 200576) $1900.01

Cylinder Head, Remanufactured, 221902B-157081A - For Oliver tractor models 1650, 1800, Replaces Oliver Casting number 221902B-157081A, Engine 283D, Casting No. 221902B-157081A, Our remanufactured cylinder heads are reconditioned and ready for assembly, with both valve guides and valve seats installed, Cleaned and tested for cracks, (Item #: 204520) $1375.01

Cylinder Head, Remanufactured, 222202 - For Oliver tractor model 1800 (Gas), Replaces Oliver Casting number 222202, Cylinders: 6, Casting Number 222202, Not a welded head, Our remanufactured cylinder heads are reconditioned and ready for assembly, with both valve guides and valve seats installed, Cleaned and tested for cracks, (Item #: 205526) $1000.01

Cylinder Head, Remanufactured, 222302 - For Oliver tractor models 1800, 1900 (Gas), Replaces Oliver Casting number 222302, Cylinders: 6, Casting No. 222302, Our remanufactured cylinder heads are reconditioned and ready for assembly, with both valve guides and valve seats installed, Cleaned and tested for cracks, (Item #: 205601) $1325.01

Cylinder Head, Used - For Oliver tractor model 1800 (Gas), Replaces Oliver Casting number 222202, Cylinders: 6, Our used cylinder heads have been visually inspected for cracks, Cylinder head may require further cleaning, inspection, or machining before use, For a Remanufactured version of this part use Item #: 205526, Used items are not always in stock. If we are unable to ship this part we will contact you within one business day., (Item #: 405526) $435.01

Cylinder Head, Used - For Oliver tractor models 1800, 1900 (Gas), Replaces Oliver Casting number 222302, Cylinders: 6, Our used cylinder heads have been visually inspected for cracks, Cylinder head may require further cleaning, inspection, or machining before use, For a Remanufactured version of this part use Item #: 205601, Used items are not always in stock. If we are unable to ship this part we will contact you within one business day., (Item #: 405601) $710.01

Cylinder Head with Valves, Remanufactured, 221902H-158792A - For Oliver tractor models 1650, 1800, Replaces Oliver Casting number 221902H-158792A, Engine 283D, Casting No. 221902H-158792A, Our remanufactured cylinder heads are reconditioned and ready for assembly, with valves installed, Cleaned and tested for cracks, (Item #: 207042) $2325.01

Rear Coupler Sprocket, Used - For Oliver tractor models 1750, 1755, 1800, 1850, 1855, 1900, 1950, 1955, Replaces Oliver OEM number 107416A, Splines: 27, For a new version of this item use Item #: 110748, Used items are not always in stock. If we are unable to ship this part we will contact you within one business day., (Item #: 435507) $48.01

Exhaust Stack, Chrome, Curved - Double walled, 36 inches tall (not including base), 5 1/2 inch base, 2 15/16 inch inside diameter, 5 inch outside diameter. For tractor models (1650 diesel), 1655, 1750, 1755, 1800, 1850, (1855 gas). (Item #: 178570, Ref: R5903) $391.40

Carburetor, Rebuilt - This rebuilt carburetor is a direct replacement for OEM numbers matching: 13750. For the following tractor models: 1750, 1755, 1800, 1850. Add $100.00 core charge to price - you will receive instructions for returning your core for a refund if you have one available. (Item #: 205388, Ref: 1929-CARB) $510.01

Hydraulic Pump Drive Shaft Seal - For Oliver tractor models 1600, 1650, 1750, 1800, 1850, 1950 Replaces Oliver OEM number 303047059, , Compatible with White tractor models 2-70, Replaces White OEM number 303047059, Outside Diameter: 1.125", Shaft Diameter: 0.750", (Item #: 173773) $3.70

Tractor Canopy Headliner - For Oliver tractor models 1550, 1555, 1600, 1650, 1655, 1750, 1755, 1800, 1850, 1855, 1900, 1950, 1955, 2050, 2055, 2150, 2155, 2255, Tractor Canopy use Item #: 162500, (Item #: 167695) $320.00Oil System

Oliver, 101324AS, Used - For Oliver tractor model 1800, Replaces Oliver OEM nos 101324AS, Used items are not always in stock. If we are unable to ship this part we will contact you within one business day., (Item #: 457194) $11.01

Oliver, 1MS1711B, Used - For Oliver tractor model 1800, Replaces Oliver OEM nos 1MS1711B, Used items are not always in stock. If we are unable to ship this part we will contact you within one business day., (Item #: 457196) $11.01

Oliver, 1MS1711C, Used - For Oliver tractor model 1800, Replaces Oliver OEM nos 1MS1711C, Used items are not always in stock. If we are unable to ship this part we will contact you within one business day., (Item #: 457195) $11.01PTO / Driveline

PTO Drive Shaft - 67.125" long. For tractor models (1750 SN# 180537 to 190957), 1800, (1850 SN# 150421 to 194007), 1900, 1950. (Item #: 173446, Ref: 103897A) $550.00Seats

Seat Back - For 660, 750, 770, 880, 990, 1500, 1555, 1600, 1700, 1800, 1900, White 2-78, White 4-78. Seat Back is Green and White Vinyl on Wood. (Item #: 182156, Ref: R1005) $76.08

Paint, Oliver Yellow, 1 Gallon - This Oliver Yellow was used on Oliver models from 1960 through 1970 and also on some Fleetline models. High Strength air dry enamel with Alkyd resins to assure durability. Fade resistant, smooth uniform film characteristics. Paint cannot be shipped to California due to California Regulations. All Paint can only ship UPS Ground. (Item #: 108392, Ref: TP224GAL) $130.00

Paint, Oliver Yellow, 1 Quart - This Oliver Yellow was used on Oliver models from 1960 through 1970 and also on some Fleetline models. High Strength air dry enamel with Alkyd resins to assure durability. Fade resistant, smooth uniform film characteristics. Paint cannot be shipped to California due to California Regulations. All Paint can only ship UPS Ground. (Item #: 108391, Ref: TP224QT) $45.00

Paint, Oliver Yellow, Spray Can - This Oliver Yellow was used on Oliver models from 1960 through 1970 and also on some Fleetline models. High Strength air dry enamel with Alkyd resins to assure durability. Fade resistant, smooth uniform film characteristics. Paint cannot be shipped to California due to California Regulations. All Paint can only ship UPS Ground. (Item #: 108390, Ref: TP224SP) $9.00

The pump must be a tapered-bearing style piston piston pump with a good housing. These pumps are found on Ford NAA, Jubilee, 600, 700, 800, 900, 2000 (4 cylinder only) and 4000 (4 cylinder only) tractors.

Upon receipt of your pump, we will rebuild your pump for you. All pumps get new seals, wobble shaft, roller bearing, race, plug(s), needle bearing and internal gaskets. Many pumps also get new gears, balls, springs, rollers, pistons, plates, etc. based on what is needed for each individual pump. The turn around time is 2-weeks. We"ll rebuild your pump, test your pump, and then send it back to you.

Please note that flat/standard bearing pumps are not rebuildable. If our rebuilder discovers that any housings are damaged, we will call you and at that point you can decide to replace a housing (additional cost) or not have your pump rebuilt.

-When mounted, the shaft of the pump faces towards the front of the tractor. Original pump is marked PRD14S. This is the small capacity pump, we also carry the large 42 L per minute pump

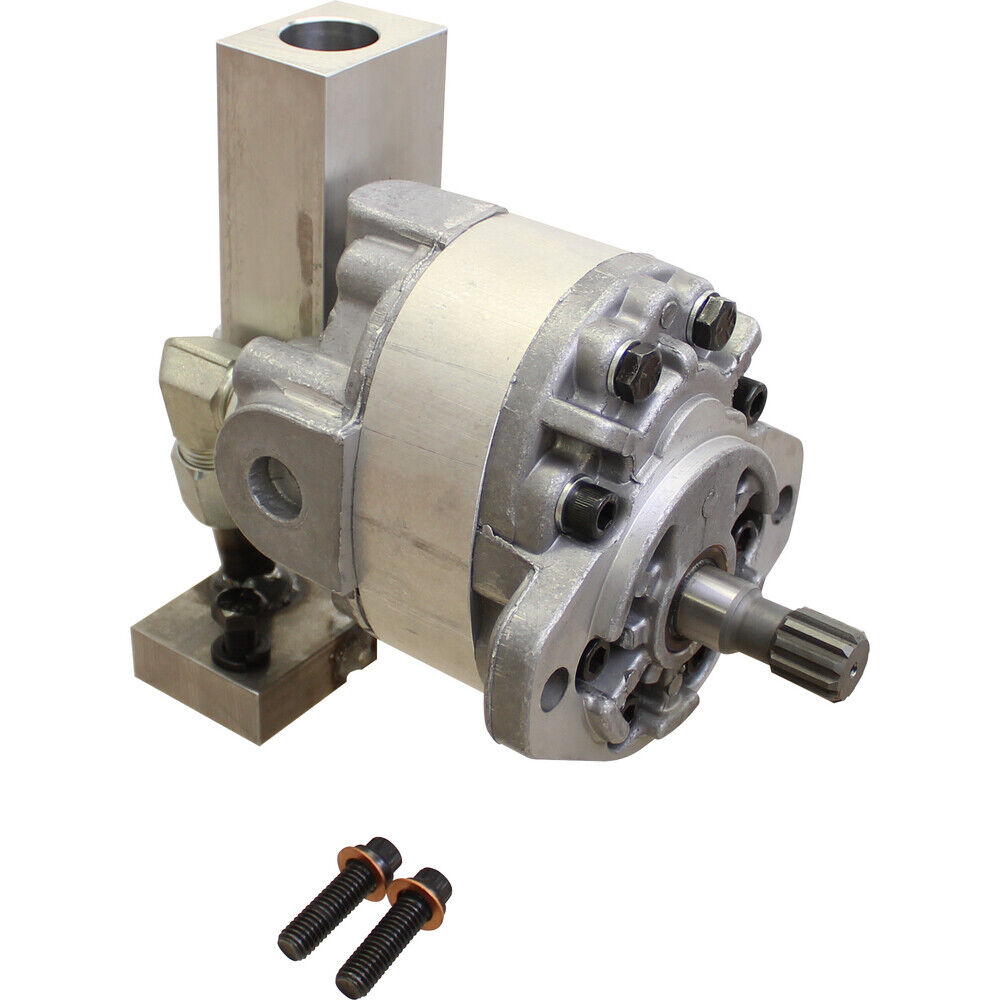

Hydraulic Pump, 15 GPM, Non-Serialized8 piston, non-serialized pump. Built using all new components. Pressure set to OEM specifications, flow tested at operating temperature & assembled in the USA, at our facility in Iowa.Everyone knows how important hydraulics are. Read our blog post, "What Makes Hy-Capacity Hydraulic Pumps so Great?" here.The R94657N Hydraulic Pump - New fits equipment brands such as: John DeereThe R94657N is a substitute for the following discontinued products: R94657NH, R94657

Agriculture has always been changing. From using hand tools, to horses, then steam and the internal combustion engine, perhaps the thing that changed the most was the power of the tools that the farmer used. The 2255 could be considered an icon of this kind of change, as it was the most powerful production tractor to wear meadow green paint and to bear the name Oliver.

The 2255 was introduced in the fall of 1972 as “New for 1973”. It essentially replaced the 2055 and 2155 models, and returned to more of a traditional Oliver design. The 2055 and 2155 were Minneapolis Moline tractors with green and white paint and Oliver decals. They didn’t use the cast iron front main frame as most Olivers do, and had fewer transmission speeds. That wasn’t the case with the 2255. But first, let’s discuss where this giant of the Oliver tractor line got its power.

It wasn’t uncommon for Oliver to outsource the engines for their higher horsepower tractors. They had worked with Continental, General Motors and Perkins in the past to get power plants for their tractors. This time around, they went with Caterpillar. Cat, as the company has become commonly referred to, has been around since the merger of Holt Manufacturing and Best Tractor Company in 1925. Manufacturing crawlers and industrial equipment, Cat was easily once one of Oliver’s biggest competitors. That had changed by the 1970s, as Oliver and its parent company White were no longer making crawlers.

The engine of choice for the 2255 was the Cat 3150 V8 diesel engine. Competitive tractor manufacturers tried their hand at using V8 power in their tractors, but without much success. The Cat 3150 wasn’t the perfect engine, but it did seem to stand the test of time better than other makes of V8 diesel. And all it takes is one look of the banks of that massive engine protruding from each side of the tractor to make just about any Oliver collector fall in love. Let’s face it; this is one tough looking tractor.

Cat 3150 had a bore and stroke of 4.5 inches, giving it a total displacement of 573 cubic inches. When the naturally aspirated Cat 3150 equipped Oliver 2255 was tested in 1973 at the University of Nebraska, it produced 146.72 horsepower at the PTO. This was three more horsepower than the 2655 and five more than the 2155.

That mighty V8 diesel required a new frame and new sheet metal. The cast iron tub was drastically wider than other Oliver models, to accommodate the banks of the Cat 3150. The cast frame also had a hole in the left front side to allow access to the engine oil filters that were mounted on the lower part of the engine block. Apparently, the first prototype versions didn’t have this access hole. It didn’t take long for the guys at Oliver to realize that the oil filters were going to be about impossible to reach without this access point.

There was more than one reason to outsource the engine for the 2255. Production numbers were going to be low enough that designing and tooling up for a new engine would have been cost prohibitive. Another reason was the engine speed of the 3150. Unlike the straight six engines that ran at around 2200 rpm for their rated horsepower in other Oliver tractors, the Cat 3150 ran at a rated speed of 2600 rpm, and a no-load speed of 2800 rpm.

Upon closer inspection, you could start to see the difference. The 3208 was just about a complete redesign of the engine. One of the major differences was the injection pump. The 3150 used a long in-line injection pump, with a rather large governor on the back of it. The 3208 used an injection pump that was arranged in a V, just like the cylinders of the engine. It had a much smaller governor, and took up less space between the two banks of the engine. Both pumps used cam driven plungers, one for each cylinder.

Most injection pumps on Oliver tractors used a single plunger, with the fuel being directed to the correct cylinder at the right time. There were other external changes on the 3208, but inside is where the big change took place. The stroke was increased from 4.5 inches to 5 inches. The bore remained at 4.5 inches. This increased the displacement to 636 cubic inches, 63 more than the 3150 engine.

By the next year, the new White 4-150 was about ready to hit the fields, and the decision had already been made to phase out Oliver and the meadow green. Would this model have become the Oliver 2355? We’ll probably never know.

The Oliver engineers were used to getting 5000 or more hours out of a set of bearings. Replacement of the bearings required removal of the oil pan, then you just took the caps off the crank and rods and rolled the old bearings out and the new bearings in. Sounds easy enough, until you figure in that the front axle and exhaust were in the way, and so the best option was to pull the engine out of the frame.

The over/under transmission in the 2255 tractor used what is called a trunnion mount where it attached to the main transmission. Most other Oliver tractors at the time used the chain coupler, but the higher horsepower of the 2255 was a little more than the chain and sprockets could reliably handle. The trunnion mount consisted of a flange on the rear of the over/under sliding inside a large flange on the front of the main transmission. The trunnion was sealed by an o-ring, allowing transmission oil to lubricate the coupler that connected the two shafts inside. Shaft alignment problems were all but eliminated with this setup.

We have already mentioned that the main transmission consisted of six forward and two reverse speeds. In actuality, it was really a three speed forward and one speed reverse setup, with high and low ranges. While many other manufacturers would have two or three shift levers, Oliver had combined transmission shifting into a single lever 40 years prior to the 2255 tractor. So when you shift your Oliver through its middle neutral gate, you are actually shifting from high to low range, or vice-versa. All shafts, bearings and gears were lubricated by either splash oil or pressurized and filtered oil. A spin-on filter on the outside on the rear main frame provided for easy service.

The main transmission is a constant mesh, helical gear setup. Constant mesh means that the gears are always engaged to each other. Older sliding spur gear transmissions had gears that would move to select speeds, so some gears would not be in contact with their corresponding gear, depending on which speed you had selected. A constant mesh transmission uses a shifting collar to connect a shaft to a gear. The gears and shafts all stay in the same position, only the shift collar moves. Helical gears have their teeth cut into them at an angle to the direction of rotation. This makes for longer teeth, giving more surface area on the same gear, allowing for more power to be transmitted through it. It also has a quieting effect, since the gear teeth mesh together smoother, instead of striking each other as they do in a spur gear transmission like an Oliver 88.

The final drives were quite similar to other models of Oliver tractors. The pinion shaft turns the differential, which turns the bull pinions, which then turn the bull gears. On the 2255 there were a couple of changes. The brakes on an Oliver are almost always mounted on the bull pinion shaft, and from the days of the Fleetline tractors, almost always used two discs on each side of the tractor. The 2255 used a triple disc brake setup, which of course gave much more friction surface to stop and steer the tractor with. To further increase braking power, a hydraulic piston actuated by the brake pedals provided the pressure against the brake disc that made them do their job.

A mechanical linkage connected to the parking brake lever would manually hold the brakes when the operator parked the tractor. The brakes on the 2255 are supposed to be a dry brake, so if you have poor braking and oil coming out of the brake housings, you have a leak that is lubricating your brake discs, and keeping them from doing their job. The oil can come from two places, either the brake piston that is in the brake cover, or the oil seal on the bull pinion shaft. If you are getting hydraulic oil on the brakes, especially the outer disc, then it is the brake piston. If you getting transmission oil on the inner discs, then it is the bull pinion shaft seal. The seals aren’t too expensive to replace, but usually the discs need replacing as well, since they will never be the same if they are soaked with oil.

On most Oliver tractors, the bull gear drives the axle that the rear wheel is bolted to. The high revving 2255 had the extra speed and power that needed to be slowed down to usable field speeds. To reduce the torque load on the transmission, and slow things down a bit, Oliver used an outboard planetary final drive on the 2255. This final drive was built by Clark transmission, and had its own separate oil. It proved to be a very reliable unit, but did limit the adjustability of wheel spacing on the rear wheels. Power adjust wheels were an option that helped with this dilemma.

Like the 1755 and larger Olivers, the 2255 had a closed center hydraulic system. Closed center hydraulics had some definite advantages over the older open center hydraulics. In an open center system, the pump is always moving oil, and so the oil always needs somewhere to go. A pump on a closed center system is what is known as a variable displacement pump, and can actually pump no oil, even though it is turning a full speed. How it does it is quite simple, once you have seen one taken apart.

The oil is pumped by a group of pistons, no bigger than your finger, nine of them in the case of the 2255. Instead of connecting to a crankshaft like a piston does in an engine, each piston in the pump has a flat head that can pivot. A metal cage, not unlike one on a bearing, holds the pistons together in a circular group. A good way to picture what this group looks like is to imagine the six bullets of a revolver. They are grouped in the same way, and if you spin the cylinder that has the bullets in it, they are going around in the same fashion as the pistons in the pump. Obviously, this isn’t going to pump any oil, and is actually a good representation of what happens when the pump goes into a neutral mode.

To pump the oil, each piston is attached to a cage that holds it against what is called the swash plate. The swash plate is shaped like a flat doughnut, with an ear on each side that it pivots on. One flat side of the swash plate is very smooth, and this is the side that the heads of those pistons slide in a circle on. If we go back to our example of the revolver, imagine each bullet sticking only halfway into its hole. The head of each bullet is attached to a flat plate that it can slide on, allowing the cylinder of the revolver to be spun, and the bullets to go around in a circle.

When we spin the cylinder on our imaginary revolver, the whole group of bullets goes around in a circle. Now if we tilt our flat plate that the bullets are on at a bit of an angle, half of the bullets will come farther out of their holes, and the other half will move farther into their holes. Without changing the position or angle of the flat plate, we’ll give the imaginary revolver another spin. This time as each bullet goes around in the circle, it moves in and out of its hole. Put oil in each of those holes, and the bullets will push it in and out. We now have a variable displacement pump.

Back to the real pump on the tractor. There is a spring that pushes against the swash plate at all times, tilting it at sharpest angle it is able to, making the pistons travel inside their bores the farthest possible distance, and pumping the most oil possible. Fighting against this spring is a plunger that is pushed by hydraulic pressure. The higher the pressure gets, the farther the plunger moves, and the more the swash plate returns to a flat position. When the pressure in the system reaches 2200 psi, the plunger will have moved the swash plate so that it is in its neutral position, and all the pistons will do is rotate in a circle, but not move in and out of their holes, just like the bullets in the spinning cylinder of the revolver.

What this all boils down to is that the pump is always creating 2200 psi of hydraulic pressure, but is only pumping enough oil to do just that. When the operator operates a remote valve, the pressure in the system drops, the plunger moves back against the pressure of the spring, and the swash plate tilts at angle, allowing the pistons to move further in and out of their holes, pumping more oil until the pressure returns to normal. When everything is working as it should, the closed center pump uses less power when the hydraulics aren’t being used. An open center pump at full speed is pumping the most oil it can, and using the power it takes to do that.

The closed center pump is a precision piece of equipment. All of those little pistons have a machine fit, and the swash plate has a mirror finish. It’s all metal on metal, with hydraulic oil to lubricate. Throw in the smallest bit of dirt, and all of these polished surfaces get scratched. Every scratch is a place for oil to leak by. And every internal leak decreases the flow of the pump, and generates extra heat. So you can see why clean oil and regular filter changes are so important to a closed center hydraulic system.

The power take off is a hydraulically engaged clutch pack, powered by a shaft that goes from the PTO unit to the engine flywheel. This same shaft provides power for the hydraulic pump. To engage the PTO, the operator just needed to move the lever ahead to the on position. Moving it slowly would allow the operator to ‘feather’ the engagement, instead of it turning on all at once, and possibly breaking whatever was hooked to it. The PTO unit also had a hydraulically engaged brake that kept the shaft from turning, a common problem with older Oliver tractors. When the tractor is shut off, the PTO lever automatically returns to the brake position, preventing the tractor from being started with the PTO engaged.

One of the main problems a 2255 owner might have with the PTO is worn out seals. The PTO clutch is activated by hydraulic oil, but transmission oil lubricates the rest of the parts. If the o-ring seals on the PTO clutch piston begin to leak, the oil goes into the transmission. Since the hydraulics have a separate reservoir from the transmission, and use a lighter hydraulic oil as opposed to the heavy 80w-90 used in the transmission, this isn’t a good thing. The transmission will get over full, and its oil will get thinned out. So if your hydraulic oil goes down, and your tranny oil goes up, chances are that you have this problem.

A common option was the factory installed cab. Even though it was factory installed, it was not made by Oliver. A company by the name of Crenlo Inc. of Rochester, Minnesota built the cabs, and then shipped them to Oliver. This cab, unlike prior cabs, had a roll over protective structure (ROPS) built into it. The cab came with a windshield wiper, dome light, built in fenders and upholstery, but only a fan with an air filter to pressurize the operator area, which helped keep dust out and provided minimal cooling. Optional for the cab was a heater, or a heater/air conditioning combination. If you’ve ever run a tractor with a cab and no air conditioning, you’ll understand why most of the 2255s with cabs also had air. Since the fender fuel tanks could not be used with the cab, there was a set of fuel tanks that were an option that would mount under the built-in fenders of the cab.

One of the more expensive options was the front wheel assist. It added almost $4,000 to the list price of the tractor, but that’s not all it added. The axle, manufactured by Clark, provided extra weight, and more importantly extra pulling power, especially in tough conditions. This axle was a true mechanical front wheel assist. There were no torque limiters or clutches. Once the axle was engaged, it was geared to the same pinion shaft that drove the differential. The Clark axle and front wheel assist Olivers were featured in the November/December 2004 issue of the Hart-Parr Oliver Collector if you are looking for more information on this setup.

The three-point hitch on the 2255 was the beefy Category II and III hitch. It used two external hydraulic cylinders to provide for 6,000 pounds of lifting capacity 24 inches past the end of the lift arms. Draft control was sensed on the lower links, and used external leaf springs to measure the draft load against. It too was an option, and replaced the wide swinging drawbar that was in the base price.

Weights, hydraulic valves, hydraulic cylinders were other options available for the 2255. Tires could be ordered in several different sizes and combinations. Even little accessories like a cigarette lighter, a coolant heater and an additional backrest for the seat were available, but were not installed at the factory.

Oliver promoted the massive 2255 starting with a two-page piece of literature in 1972. There were at least five different pieces printed that featured the 2255.

Brochure # 3 was form P-135, and was printed in March of 1973. It is an eight-page, color brochure on the OLIVER 2255 CAT-Powered V-8 with 145 PTO Horsepower. This is with the Cat 3150 engine.

Of course Oliver advertised in many of the farm related publications as well. There was also sales and service bulletins, plus the owner’s manuals, parts manuals and service manuals that would be produced with any tractor. Service and parts for the Cat engines were somewhat limited through Oliver, as Cat wanted to sell these parts through their dealer network. Both the 3150 and the 3208 needed their fair share of special service tools, which of course could be purchased at your local Cat dealer.

The 2255 was manufactured from 1972 until 1976. During those years there were two different versions of the same tractor that rolled off the assembly line. The version that was the most common was the one we know as the Oliver 2255. It was painted with meadow green paint with clover white paint on the wheels, grille and trim. The second version was the White 2255. It was painted Cockshutt’s Vermillion red, with white trim. Other Oliver models of the early 1970s were painted with the same colors, but were labeled as Cockshutt tractors. Perhaps as a sign of things to come, the 2255 did not have the name Cockshutt on it, but was instead called the White 2255.

Tractors painted red and labeled as Cockshutt or White were intended for sale in Canada. There was an exception to this rule. A distributor known as Co-op Federee in Quebec, Canada would import tractors from Oliver for sale in that providence. They either didn’t want to, or couldn’t use the red paint and Cockshutt name in Quebec. The instead imported the tractors with the green paint and Oliver name, just as they appeared in the United States.

Production was higher for 1973, undoubtedly due to a whole year of production time instead of the one month 1972 got. The first tractor for 1973 was made on February 6 with the serial number 237 210-705. Production of the 2255 for 1973 ended on December 11 with serial number 244 214-713. That transmission code makes it a front wheel assist tractor, or a two-wheel drive tractor with the front wheel assist pinion shaft installed. In this case, it was indeed a front wheel assist tractor. There was a total of 671 units made during 1973. Of that, 508 were two-wheel drive with the Oliver name on them.

There is a note next to the production for August 8, 1973 indicating that of the 32 two-wheel drive tractors made that day, that one or maybe all 32 were made as industrial tractors. It depends on how you read it as to how many, but guess is that all 32 were. The industrial tractor(s) would have been painted yellow. There were 124 front wheel assist units with Oliver decals on them. 1973 was also the first year that any of the White 2255s were made. That year there were 33 made as two-wheel drive, and only 6 made with front wheel assist.

The first serial number was 244 825-705, made on January 21. On May 7, 1974 the first Cat 3208 equipped 2255 came off the line with serial number 248 722-705. The last 2255 for the year was made on October 2, serial number 252 714-713. Not only did this year see the highest number of units at a total of 956, but the most variations as well. Both the Cat 3150 and the Cat 3208 were used, and the first 2255s were exported to a country other than Canada. Of the 956, there were 678 two-wheel drive, and 164 front wheel assist Olivers made for the domestic market.

The White version came in at 96 two-wheel drive, and 9 with front wheel assist. Co-op Federee of Quebec, Canada took 2 two-wheel drive and 2 front wheel assist tractors. Those four were the only 2255s recorded as going to them. Finally, there were 5 front wheel assist Olivers that went out as export tractors. 1974 also saw the last White 2255 roll off the line with serial number 252 133-713. Even though this tractor had the transmission code for front wheel assist, it was a two-wheel drive tractor with the long pinion shaft.

By 1975, the consolidation of Oliver, Cockshutt, and Minneapolis Moline into the silver and gray painted White line was well under way. All of the 2255 tractors made in 1975 were made during a one-week period, starting on March 4 with serial number 258 472-705 and ending on March 8 with serial number 258 571-705. There were only 100 units made that year, and only 15 of those were two-wheel drive Olivers for the domestic market. Of the remainder, 21were two-wheel drive Olivers, and 64 were front wheel assist Olivers, all destined for export. No other versions of the 2255 were made in 1975.

The last year for the 2255 was 1976. Production was very similar to the previous year with exactly 100 tractors built. This time they were all built during a week in February, starting on the ninth with serial number 266 683-705, and ending with serial number 266 782-705 on the thirteenth. Of the 100 made, 20 were two-wheel drive Olivers for the domestic market, 15 were two-wheel drive Olivers for export, and 65 were front wheel assist Olivers for export. No other versions of the 2255 were made that year.

Here are some things to consider with these production numbers. The Cat 3150 and Cat 3208 trade places easily, so a 2255 may have had its engine swapped at some point with a different version. It also wasn’t unheard of for Oliver to send a domestic tractor out as an export, or keep an export tractor in the United States in order to fill an order, or because an order was cancelled. And finally, since some tractors were made with a front wheel assist pinion shaft and a two-wheel drive axle it may be possible that they are now front wheel assist tractors. The opposite could happen as well.

It has long been assumed that the 1976 production was all bound for export and that the last 2255 left the country. I wasn’t really fond of hearing such news, knowing in my mind that that tractor was beaten and broke, and rusting away in some far away land whose name I’m sure I couldn’t pronounce, never to be seen again. This tractor was more than just the last 2255 made; it was the last production tractor to wear the meadow green paint and to bear the name of Oliver.

That last 2255 is a piece of history and deserves a better fate than that. During my research for this article I found some good news. It appears from the records that I got from the Floyd County Museum that the last 20 Oliver 2255s made were destined for the domestic market. That last 2255, the last Oliver, should be somewhere in the United States. So check those serial number tags, because if you have serial number 266 782-705, then you truly have an icon. The last 2255, and the last Oliver ever made.

The Hart-Parr/Oliver Collectors Association, a nonprofit organization, was founded in 1989 for the historical and educational benefit of Hart-Parr and Oliver collectors and the general public. It now includes nearly 4,500 members and consists of 21 chapters. In its effort to collect, preserve and distribute information on the Hart-Parr/Oliver and related companies.

8613371530291

8613371530291