parker 108 hydraulic pump manufacturer

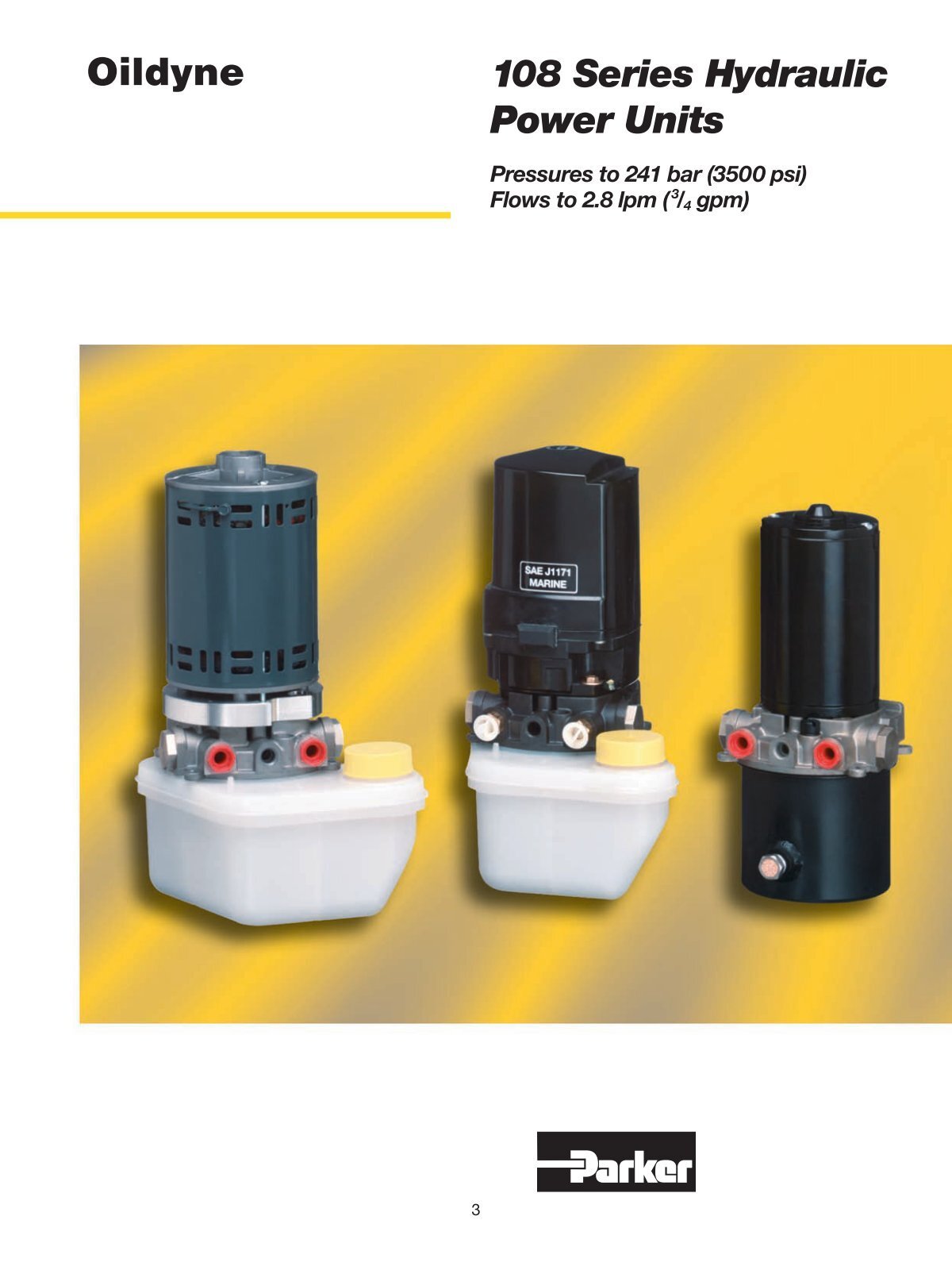

The 108 Series offers versatile compact hydraulic power units engineered to let you put the power where you need it. Featuring an AC or DC motor, gear pump, reservoir, internal valving, load hold checks and relief valves, the 108 Series delivers an efficient, completely self-contained power solution in a compact footprint. Designed by Parker for intermittent service, these units come in four standard pump sizes.

The compact hydraulic power packs in this series are available with single- or bi-directional rotation. Single direction units are commonly used to charge accumulators, power uni-directional hydraulic motors and cylinders, provide pilot flow to servo valves, pressurize lube systems, and supply multifunction circuits through external valving. Bi-directional, reversible units operate double-acting cylinders and bi-rotational motors.

Parker Compact Piston Pumps deliver up to 276 bar (4,000) operating pressures, along with versatility, efficiency and speed. They also feature a significantly reduced footprint and quiet operation.

Reliable and highly efficient, Parker Compact Piston Pumps provide fixed-displacement power in a unique miniature design. Engineered for open-circuit systems, they bring flexibility to your operation. Compact Piston Pumps handle a variety of fluids including hydraulic oil, brake fluid, low viscosity fluids and non-water-based fluids. They also feature cast iron and aluminum construction for added durability. Multiple pumps, special configurations and bidirectional pumps are available upon request.

These radial piston fixed displacement hydraulic motors have been specifically engineered for high mechanical and volumetric efficiency over a wide range of speed and torque. MR motors are combined into 11 different frame sizes, corresponding to 41 standard displacements available, from 33 cc/rev to 9000 cc/rev.Markets:• Industrial• Material handling• Marine• Oil & Gas• MobileFeatures/Benefits:• High reliability and long lifetime thanks to the high mechanical efficiency of up to 96% and the starting torque of up to 95% of the theoretical value• Highly customizable• Outstanding volumetric efficiency: up to 99%• Very low operating noise levels• Smooth rotation at very low speed (minimum speed: 0,5-1 rpm)• High accuracy in positioning control• High resistance to thermal shocks• Wide range of operating temperature• Wide range of operating fluids• Reversible operation (motor and pump)• Full range of parking brakes availableApplications:• Winches• Wheel drive• Shredders (Recycling)• Mooring (Constant tensioning)• Steerable Thrusters

Do you need Parker hydraulic pump repair, rebuild, or replacement? We specialize in Parker pump repair and rebuilds. If you need a free estimate for any Parker pump, get in touch with us today to find out how much it will cost for repairs.

We provide fast, reliable hydraulic pump repair service on all Parker models. We are guarantee all repair work will be done with genuine OEM parts, so you know that you aren’t getting gray market or counterfeit parts.

Our team of skilled technicians will give your pump the attention it needs, and put it through our detailed inspection and repair process. Once the pump has been reassembled, we’ll test it thoroughly with our state-of-the-art-test equipment.

When you get your pump back, it will meet or exceed factory specs. Once you work with us, we think that you will keep coming back to us for all of your Parker hydraulic repair needs, including Parker hydraulic motors and Parker hydraulic cylinders.

If you don’t see your model number listed below, don’t hesitate to call or contact us. We service just about every model of pump that is available from Parker Hannifin and other manufacturers.

When you are on the job and under a deadline and equipment fails, you need fast, reliable repair. We can send in our field technicians to get your Parker pump back up and running as soon as possible. Our reliable, experienced team can perform diagnostic services and minor repairs for equipment and machinery used in many industries. Our team can travel throughout the United States and many international locations, including North America and South America.

If repairs cannot be made on-site to your Parker pump, you can ship it to our facility. If you’re close enough, you can drop it off. We know how important it is to get your hydraulic systems back up and running. So you can trust us to get your pump repaired and back to you as fast as possible, and working properly.

Parker Hannifin HPD produces a wide array of hydraulic components and systems for a variety of industries. Their commitment to research and development and the integration of leading-edge technology allows the company to continually upgrade and add to its product line.

Don’t see your Parker Hannifin hydraulic pump model number? Not a problem. Call 800-800-6971 or send us an email. Chances are we’ve worked on it before and have parts for it, even if it’s not listed on our website.

Parker or its subsidiaries or authorized distributors. To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user, the user is responsible for determining that such data and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the components or systems.

1. Name & address of manufacturer 2. WARNING - see page 4 3. WARNING - see page 4 Parker Hannifin - Oildyne Division 4. CE Mark (if applicable) 5520 Hwy 169 North 5. Year of product manufacture (if CE marked) New Hope, MN 55428 USA 6.

Oildyne Division. Any additional information may be obtained available. The gear pump is driven through a coupling located from Parker by referencing the unit part number stamped on between the electric motor shaft and the pump drive shaft. the product label or by contacting your local authorized Parker These power units are designed to be operated with an integral Oildyne Distributor.

HIGH DENSITY POLYETHYLENE WITH UV ADDITIVE Series Power Units have the 754 CC (46 CU. IN.) 22.2 same dimensions. (.875) 265.2 (10.44) RESERVOIR F Note: All dimensions in mm (inches). STEEL 2000 CC (122 CU. IN.) Parker Hannifin HPS Division New Hope, MN 55428 USA...

(1.15) 2X 5/16-18 UNC-2A (5.00) 144.5 (5.69) 30.7 (1.21) 321.8 (12.67) MOUNTING HOLES 3/8-16 UNC-2B X 177.4 164.1 (6.98) (6.46) 101.6 112.8 Ø (4.00) (4.44) Note: All dimensions in mm (inches). Parker Hannifin HPS Division New Hope, MN 55428 USA...

152.4 (6.00) 1 QUART 1/2 GALLON 3 QUART 1 GALLON (1 LITER) (2 LITER) (3 LITER) (4 LITER) 143.4 (5.65) (8.70) 313.2 (12.33) 403.9 (15.90) Note: All dimensions in mm (inches). Parker Hannifin HPS Division New Hope, MN 55428 USA...

108/118 and 165/175 Series NN Circuit 108/118 and 165/175 Series WW Circuit N.C. N.O. 108/118 and 165/175 Series S1 - S4 Circuit (NC valve) 108/118 and 165/175 Series S5 - S8 Circuit (NO valve) Parker Hannifin HPS Division New Hope, MN 55428 USA...

Back Pressure Valve Back Pressure Valve LPRV LPRV HPRV HPRV 108/118 and 165/175 Series RB Circuit 108/118 and 165/175 Series LB Circuit (Reversible with Back Pressure) (Reversible Locking with Back Pressure) Parker Hannifin HPS Division New Hope, MN 55428 USA...

Locating Power Unit Storage: -7 to +60°C (+20 to +140°F) Please contact Parker Oildyne for usage outside of this range. The unit should preferably be installed indoors in a clean, dry environment with an ambient temperature of 16 to 37°C (60 to 108/118 and 165/175 Series Power Units should be installed 100°F).

Refer to the performance data on pages 17 - 20 for your L - 2 WHITE particular model to determine the current ratings needed BLACK for your electrical controls. Parker Oildyne does not supply MOTOR 161 - 193 MFD/125V GREEN/YEL. controls for the 108/118 and 165/175 Series Power Units.

BLACK MOTOR LEAD NOTE: AM Motor has an internal 100 amp thermal breaker; BI Motor has an internal 50 amp thermal breaker; IC Motor has an internal 33 amp thermal breaker Parker Hannifin HPS Division New Hope, MN 55428 USA...

32 cSt (150 SSU) and 64 cSt (300 SSU) at 38°C (100°F). For fluids other than these, contact Parker Oildyne with the details. If users wish to use alternative oil, hydraulic fluid or ATF, they are warned to check that they have the same properties as those recommended.

Please provide a hydraulic schematic of your circuit to assist The pump is now primed. When using an externally mounted Parker Oildyne. directional control valve (DCV), connect the tank port of the DCV to the ‘DN’ port of the power unit. Connect the ‘UP’ port of Additional Testing the power unit to the inlet port of the DCV.

It is strongly recommended that the customer have available the drawing less than 12.6 A MSDS for the fluid chosen for use in the Parker Oildyne power 2. The 108/118 Series 24 vdc Permanent Magnet motor is unit. Follow all instructions should the fluid be spilled or come in drawing less than 9.6 A.

10 minute cycle. S2 (12 V) S2 (12 V) S2 (24 V) Time at constant load followed by off time to allow the motor to cool to ambient Current Draw - Amps Parker Hannifin HPS Division New Hope, MN 55428 USA...

Percentage of "on" time in a repetitive 10 minute cycle S3 (12 V) S3 (24 V) Time at constant load followed by "off" time to allow motor to cool to ambient temperature. Current Draw - Amps Parker Hannifin HPS Division New Hope, MN 55428 USA...

Pressure - bar (psi) Pressure - bar (psi) NOTE: S2 = 5 Maximum recommended ON time for the HA/HD motors is 5 minutes, afterwhich the motors must be OFF until cooled to ambient temperature Parker Hannifin HPS Division New Hope, MN 55428 USA...

10 minute cycle. S2 (12 V) S2 (24 V) Time at constant load followed by "off" time to allow the motor to cool to ambient temperature. Current Draw - Amps Parker Hannifin HPS Division New Hope, MN 55428 USA...

(500 – 999 psi) (+/- 100 psi) 70 – 137.9 bar +/- 10.3 bar (1000 – 1999 psi) (+/- 150 psi) 138+ bar +/- 13.8 bar (2000+ psi) (+/- 200 psi) Parker Hannifin HPS Division New Hope, MN 55428 USA...

Remove the ‘B’ reservoir screw using a 4 mm (5/32 in) hex key. Retain the screw for reassembly. It is recommended that the bonded washer/rubber seal is replaced. It is Parker Oildyne part number 415067. ‘B’ reservoir screw The ‘C’, ‘D’, ‘P’, ‘Q’, ‘R’...

With the reservoir vertical, ensure the ‘V-lip’ seal is in place on the reservoir mouth. The reservoir wall is positioned inside the 8. Parker Hannifin offers an oil sampling kit which can be ‘V’. Orient the power unit over the reservoir so the reservoir used to ascertain the condition of the system fluid.

Oil temperature too high/viscosity too low oil is thick enough for application conditions Motor or voltage is incorrect Ensure motor and voltage are right Solenoid valve is open Ensure solenoid valve is closed Parker Hannifin HPS Division New Hope, MN 55428 USA...

Torque screw to spec Not properly mounted Check for incorrect mounting Solenoid not releasing Coil not energized (if N.C.) Apply proper voltage to coil Coil not de-energized (if N.O.) De-energize coil Parker Hannifin HPS Division New Hope, MN 55428 USA...

Instruction Manual Oildyne 108/118 and 165/175 Series Bulletin HY22-3210A/US Hydraulic Power Units Notes Parker Hannifin HPS Division New Hope, MN 55428 USA...

Bulletin HY22-3210A/US Hydraulic Power Units Declaration of Incorporation EC Declaration of Incorporation. Manufacturer’s Name: Parker Hannifin Corporation Manufacturer’s Address: Oildyne Division 5520 Highway 169 North New Hope, MN 55428 USA Declare that the partially complete machinery described below conforms to applicable health and safety requirements of Part 1 of Annex 1 of Machinery Directive 2006/42/EC taking full account of requirements for pressure equipment.

Tel: +358 (0)20 753 2500 parker.portugal@parker.com Free phone: 00 800 27 27 5374 parker.finland@parker.com www.parker.com © 2011 Parker Hannifin Corporation. All rights reserved. Bulletin HY22-3210A/US .25M, 11/11 BG Parker Hannifin Corporation Hydraulic Pump and Power Systems Division Oildyne Business Unit...

Whether you’re local or farther away you can ship your hydraulic unit in for repair to our Hydraulic Repair facility. Contact us today at 800-728-5168 and check out the Shipping Info link below for more information on how to mail in your Hydraulic unit for repair at our Oklahoma City facility.

8613371530291

8613371530291