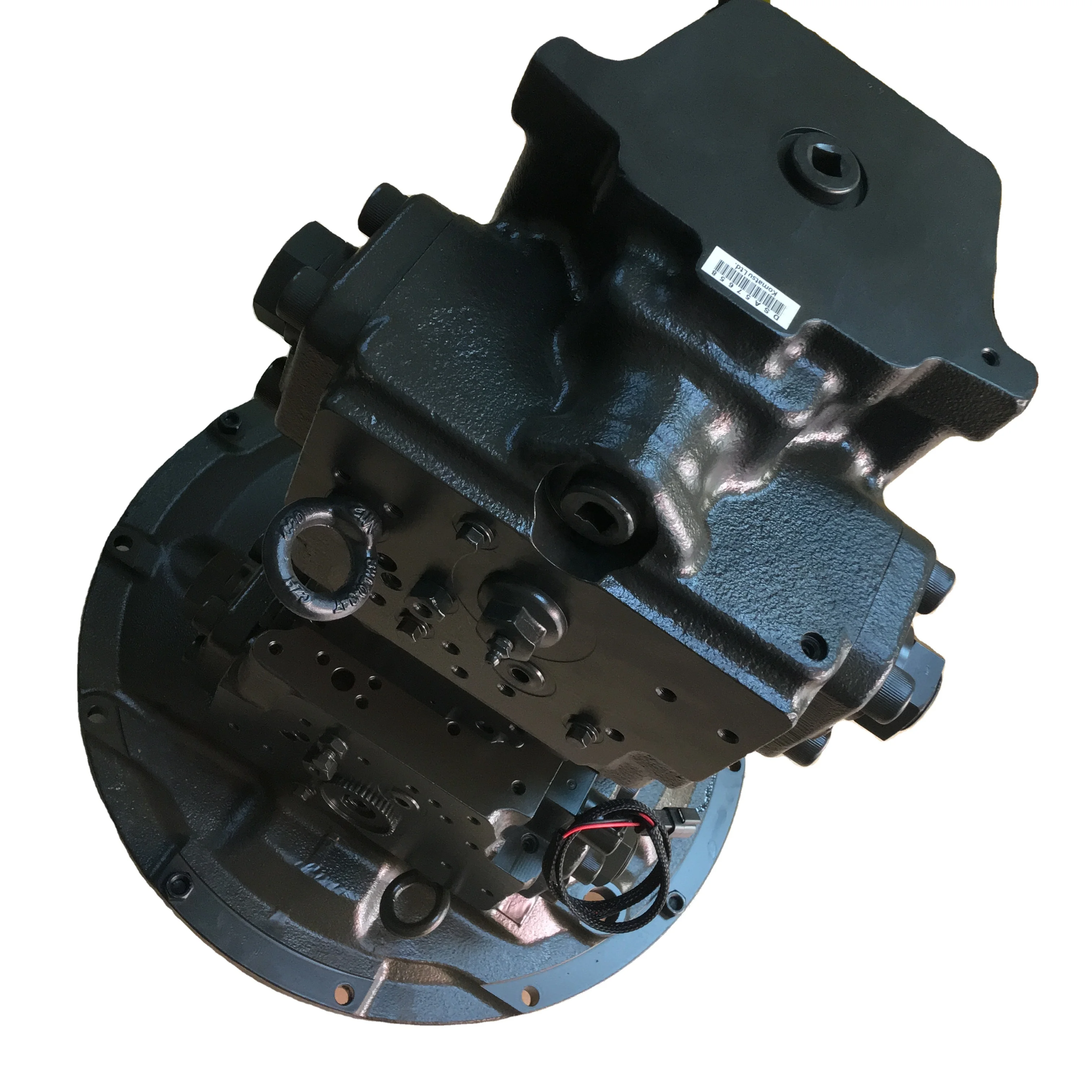

pc300 hydraulic pump free sample

There are a number of different komatsu hydraulic pumps available in the market, among them. The komatsu PC 300 hydraulic pumps are available in various sizes, shapes. Hydraulic pumps usually such as piston pumps, one are piston pumps and one of the most commonly used hydraulic pumps is the type of piston pumps, which are commonly used in two series of pipes.

The hydraulic pumps varies depending on the model of the pump, for example, they are normally used, one-stage, three-stage, and four-stage hydraulic pumps. The price of komatsu hydraulic pumps varies depending on the model, the type, and the source of the pump.

The hydraulic pump is one of the most important components of any komatsu hydraulic pump. In PC 300 7 they are equipped with a series of piston pumps, that are between to press aize and pressurize.

2 BR350JG-1 3 3 PC128uu-1 and –2 9 4 PC228USLC-3 13 5 PC150-6LK Pre and Minor Change 21 6 PC200 to 250-6 PRE Minor Change 27 7 PC200 to 270-6 Minor Change 33 8 PC300 and 400-6 Minor Change 39 9 PC300 and 400-6 PRE - Minor Change 45 10 PC600/750/1100-6 (E-OLSS) 51 11 PC200/220/270 as 53 TimberJack 635SL/735SL/835SL 12 PC200Z-6LE (no monitor panel) 59 13 D39Ex / Px – 21 KomStat Dozer Coming Soon2 … from loose Sheets to a Book!

Begun in the 1990’s as an aid to Komatsu Hydraulic Excavator Shop Manual’s Te sting & Adjusting sections, these popular documents have also been widely used as training aids and exercises to teach the proper methods and sequence for H/E T&A. Due to their wide use in initial and recurrent training, their convenience and purposeful organization toward product PERFORMANCE, these documents are now popularly used to perform and document product performance at ALL stages of product life. These ‘sheets’ are used from PDI to PM Tune Up’s to Repair and Troubleshooting. In Training, no machine can be understood properly without first “MEASURING” the product’s condition and performance according to its intended design. Consolidating elements of Structure, Function, STD Values, Testing, Adjusting & Troubleshooting this format is brief yet complete – to OUR BEST KNOWLEDGE! Watch for revisions as we STRIVE TO IMPROVE in both PRODUCT KNOWLEDGE and COMMUNICATION of same.

1. Engine Speeds – vital health criteria in a diesel powered hydraulically operated product such as Hyd/Exc etc. Failure to verify proper Diesel performance wastes time on ANY further element (in operational diagnostics).2. Cycle Times – these confirm the “FLOW” constituent of Hydraulic HP while “PRESSUR ES” usually remain constant. Therefore, any +/- in flow is a direct Hyd.HP result. Be certain to benchmark these BOTH prior to and AFTER any adjusting.3. PPC or ‘pilot’ pressure – confirming the controls work before use!4. Main Pressures – While adjustable, these must be verified and ‘balanced’ (multi-pump product) before adjusting other ‘pressure’ sensitive control devices (such as LS or PC/TCC/TVC).5. LS-EPC (if equipped) – must verify operation correct PRIOR to any attempt to verify or adjust the LS Valve(s).6. Servo In Pressure Ratio (to main) is only a TEST. Nothing can be adjusted here because the very items being tested (LS & PC/TCC/TVC) are, in subsequent elements, going to be TESTED & ADJUSTED, provided this step reveals they are operating as designed, in GENERAL.7. LS Valve(s) adjustment – resulting in proper LS Differential Pressure(s) and that multi- pump product have as CLOSE a BALANCE as possible, giving product best possible pump synergy for best Hyd. HP and best possible combination of POWER and FINE CONTROL.8. PC-EPC (if equipped) operation verified prior to PC adjusting.9. HP Valve (PC/TCC/TVC) adjustment – results in BEST ENGINE USE for both power and most efficient use of fuel. This sets pump(s) limits.10. RECHECK Cycle times (Element 2). This documents performance results or reveals any error(s) in adjusting which may be corrected for the best possible product.

Mobile Crusher TESTING & ADJUSTMENT PROCEDUREUse the following procedure as a supplement to the Shop Manual when testing & adjusting the Komatsu BR350JG-1machines serial number 1005 & higher. NOTE! Hydraulic adapters must be FITTED prior to using thisprocedure. See diagrams on last pages.Always ensure that any known abnormalities are resolved and are normal before continuing with this procedure. Seethe “Points to Remember when Troubleshooting and Troubleshooting Procedure” section in the Shop manual forinstructions. Follow this procedure in order from 1-9 because skipping one step will affect the measurements in the following steps..

BR350JG-1 Crusher 07/ 06/ 014 4) Measure the Main Relief and Unload valve pressures using a 400 kg/cm2 gauge connected to the test ports on top of the main pump assembly. Compare with the standard values listed below, and adjust if necessary. Note - BR350JG-1 remains “Pumps DIVIDED” all the time.

Item Measurement conditions Front pump Rear pump Standard value kg/cm2 Unload Pressure Hi Idle, Neutral 30 - 50 Conveyor Lift Hi Idle, Relief Unload Pres 170 - 180 Magnetic Sep. Hi Idle, Blocked/Uncoupled Unload Pres 170 - 180 OPT 2 Hi Idle, Uncoupled Unload Pres 170 - 180 OPT 3 Hi Idle, Uncoupled Unload Pres 170 - 180 OPT 4 Hi Idle, Uncoupled Unload Pres 170 - 180 Travel Left Hi Idle, Relief Unload Pres 345 - 370 LH relief Travel Right Hi Idle, Relief Unload Pres 345 - 370 RH relief

Measurement Front Pump Front Pump Rear Pump Rear Pump Standard Value Conditions Servo Input Main Servo Input Main Servo vs. Main Pressure Pressure Neutral Almost the same Crusher set at Unload Unload Servo 1/2 of HALF DIAL Pressure pressure main GRIZZLY at Unload Unload Servo 1/2 of HALF DIAL Pressure Pressure main

6) Measure the LS Differential pressure using the functions with EPC Dial at FULL. Adjust LS Valve if the Difference between the Load Sense pressure and the Main pressure is outside the standard value. ( Main – LS ) Kg / CM2 Measurement conditions Actual Value Standard Value Hi Idle, Neutral, Front Pump 20 - 40 Hi Idle, CRUSHER rotating at FULL DIAL, Front Pump 21 - 23 Hi Idle, Neutral, Rear Pump 20 - 40 Hi Idle, GRIZZLY rotating at FULL DIAL, Rear Pump 21 - 23

8) PC Valve adjustment: The PC valve functions similar to the previous TVC valve. You can use engine rpm over relief to determine if the PC valves are adjusted correctly. If the rpm with the track over relief is not within the standard value range, adjust the PC valve on each pump (DIVIDED!) to give you the correct rpm. Use the Travel over relief to inform you if the PC valve for each pump is adjusted within 20 rpm of the other.

LH Track 2000 – 2200 (within 20 rpm of rear Relief (Front pump) pump) RH Track 2000 – 2200 (within 20 rpm of Relief front pump) (Rear Pump)Note: Adjust the PC valves to the midpoint of this range. If you adjust to the low end of the range the machine will not go muchfaster, but will use a lot more fuel.

The Self-Pressure Reducing Valve is located on the rear of the main control valve. The outlet hose for the front pump attaches tothis valve. To access the Control Pressure Relief valve remove the partition between the engine and the main control valve. Asyou can see below, the relief valve is located on the bottom of the Self-Pressure Reducing valve.

3) Measure, record (and re-record, if adjusted) the Pilot Oil pressure at the solenoid block. Adjust charge pump relief if necessary on -1. Dash 2 – adjust self-pressure reducing valve.

Charge Pump Relief Actual value Adjusted Value Standard Value, kg/cm2 Pilot Oil Pressure 31 - 35

5) ** NOT used on uu-2**LS EPC input voltage: Using the harness checker, breakout box and multimeter, check for controllerinput voltage at the EPC connector at the pump.

8) PC Valve adjustment: The PC valve functions similar to the previous TVC valve. You use engine rpm over relief todetermine if the PC valves are adjusted correctly. Test rpm with the Arm over relief at high idle. If not within the standard valuerange, adjust the PC valve on the main pump to give you the correct rpm over relief using the arm or bucket over relief.

Measurement Actual value After Adjustment PC128uu-1 PC128uu-2 conditions RPM RPM High Idle, Arm 1880 - 1920* 2120 - 2320* Relief• Note: Adjust the PC valve to the midpoint of this range. If you adjust to the low end of the range the machine will not go much faster, but will use a lot more fuel. PC Valves can “hide” a sick engine! Always ensure the engine care and health is verified prior to making hydraulic system adjustments.

Item Measurement condi tions Front pump Rear pump standard value (code 11) (code 12) kg/cm2 PC228 Unload Pressure A, Hi Idle, Neutral 30 – 50 Boom Up A, Hi Idle, Relief (PMax) NO 345 - 365 (370 - 390) BOOM UP CUSHION Arm In A, Hi Idle, Relief (PMax) 345 - 365 (370 - 390) Arm Out A, Hi Idle, Relief (PMax) 345 - 365 (370 - 390) Bucket Dump A, Hi Idle, Relief (PMax) 345 - 365 (370 - 390) Bucket Curl A, Hi Idle, Relief (PMax) 345 - 365 (370 - 390) Swing Left A, Hi Idle, Swing Lock, Relief 300 – 330 Swing Right A, Hi Idle, Swing Lock, Relief 300 – 330 Travel Left A, Hi Idle, Relief Unload Pres 380 - 400 LH relief Travel Right A, Hi Idle, Relief Unload Pres 380 – 400 RH relief

6) Measure the (Servo Input Pressure), and compare with the main pressure at the same time. (This test verifies that the LS circuit, LS valve, and the PC valve are working properly.) Measurement Front Pump Front Pump Rear Pump Rear Pump Approx.STD Ratio Conditions Servo Input Main Servo Input Main Servo vs. Main Neutral Almost the same Arm Relief Servo 3/5 of main Arm Relief + Pmax Servo 3/5 of main RH Travel , Hi, half Unload Unload Servo 3/5 of main stroke - SPINNING Pressure pressure LH Travel, Hi, half Unload Unload Servo 3/5 of main stroke - SPINNING Pressure Pressure

7) LS Differential - TIME Method: Using LOW TRAVEL (Std. 5 turn spec with NO tolerances); A mode; Hi Idle; Raise track, set travel lever at FULL STROKE Measurement conditions Actual Value After Adjusting Standard Value, Seconds A MODE, Hi Idle, Lo Travel speed, Right 56.0 Track rotating at Full PPC stroke,Front pump +/- 0.5 sec A MODE, Hi Idle, Lo Travel speed, Left 56.0 Track rotating at Full PPC stroke, Rear Pump +/- 0.5 secAdjust LS Valve on each pump separately to achieve NO MORE than ½ second difference in Lo TVL cycle time. Each FLAT will change cycle approximately 2 seconds (5 turns, running start).LS Differential - PRESSURE Method: Consult LAST PAGE

8) PC EPC output pressure: Connect the coupler nipple to the PC EPC pressure check port on top of rear pump. Attach a 60kg/cm2 gauge to the nipple. Bring up monitoring code 13 on the monitor panel to view the current flowing to the solenoid while testing. Start the engine, A mode, High Idle, Auto Decel “OFF”, arm over relief, Power Max, and measure the oil pressure at the outlet of the valve at this time. The pressure and current should be within the standard values below. Item Actual value Std value PC228USLC-3 PC EPC current (code 13) * 480 - 680 mA PC EPC output pressure 5-10 kg/cm2

9) PC Valve adjustment: The PC valve functions similar to the previous TVC valve. You use engine rpm over relief to determine if the PC valves are adjusted correctly. Test rpm with the Arm over relief Power Max “ON”. If not within the standard value range, adjust the PC valve on each pump to give you the correct rpm over relief using the stalled track (ensures both high relief pressure and divided pumps when travel operated WITHOUT any other function). Use the Travel over relief to inform you if the PC valve for each pump is adjusted within 20 rpm of the other. Measurement Actual value After Adjustment Standard Value conditions PC228USLC-6, rpm Arm Relief, 1800 - 2000* H/O+P/Max RH Track Relief, 1800 - 2000 (within 20 Hi Travel speed rpm of rear pump) (Front pump) LH Track Relief 1800 - 2000 (within 20 Hi Travel speed rpm of front pump) (Rear Pump)• Note: Adjust the PC valves to the midpoint of this range. If you adjust to the low end of the range the machine will not go much faster, but will use a lot more fuel. PC Valves can “hide” a sick engine! Always ensure the engine care and health is verified prior to making hydraulic system adjustments. Divided pump target RPM’s will need to be about 50 – 100 higher than the merged, 2 pump values.

LS Differential - PRESSURE Method: Measure and adjust the LS Differential Pressure using the tracks as outlined in the Shop Manual. Raise one side of the machine, (A mode, HI travel speed, Full Throttle) and move the travel lever of the raised track Partial - Lever Stroke (easily held steady at a chosen value such as 85 kg/cm2 of Main Pressure). At this point the Main pressure should be 80 - 100 kg/cm2. Adjust the LS Differential pressure to within standard values. Repeat this procedure for the opposite track and pump. Measurement conditions Actual Value After Adjusting Standard Value, kg/cm2 A, Hi Idle, Neutral, Front Pump 30 - 50 A, Hi Idle, Hi Travel speed, Right Track 23 - 25 rotating at half stroke, Front Pump A, Hi Idle, Neutral, Rear Pump 30 – 50 A, Hi Idle, Hi Travel speed, Left Track 23 - 25 rotating at half stroke, Rear Pump * LS Verification: Since track operation may cause erratic readings on the more sensitive digital DIFFERENTIAL PRESSURE GUAGES, another method of final verification is to use BOOM UP or ARM OUT functions to get a “final, steady LSDifferential” reading. Operate the chosen function at a steady speed roughly at 50-80% as long as main pressure (codes 11, 12) is kept steady for the most repeatable and reliable reading of MAIN – LS = LS Differential.

4) Measure the Main Relief and Unload valve pressures using the machine monitor panel code 11. Compare with the standard values listed below, and adjust if necessary. Item Measurement Conditions Main Pump After Standard Value (code 11) Adjusting kg/cm2 Unload Pressure H/O, Hi Idle, Neutral not 30 - 50 adjustable Boom Up H/O, Hi Idle, Relief (PMax) 315-335 (345-370) Arm In H/O, Hi Idle, Relief (PMax) 315-335 (345-370) Arm Out H/O, Hi Idle, Relief (PMax) 315-335 (345-370) Bucket Dump H/O, Hi Idle, Relief (PMax) 315-335 (345-370) Bucket Curl H/O, Hi Idle, Relief (PMax) 315-335 (345-370) Swing Left H/O, Hi Idle, Swing Lock, Relief 315 – 335 Swing Right H/O, Hi Idle, Swing Lock, Relief 315 – 335 Travel Left H/O, Hi Idle, Relief 345-370 LH relief Travel Right H/O, Hi Idle, Relief 345-370 RH reliefWHEN SETTING THE RELIEF PRESSURE: Set the high pressure setting (345-370) with the lower portion of the reliefvalve FIRST, then set the low pressure setting (315-335) second.

Measurement Main Pump Main Pump Standard Value Conditions Servo Input Main Pressure Servo vs. Main Neutral Servo 1/2 of main Arm Relief Servo 1/3 of main Arm Relief + Pmax Servo 1/3 of main Travel , Hi, half Servo 1/2 of main stroke Travel, Hi, full Servo 1/2 of main stroke

4) Measure the Main Relief and Unload valve pressures using the machine monitor panel codes 11 & 12. Compare with the standard values listed below, and adjust if necessary. Item Measurement conditions Front pump Rear pump Standard value (code 11) (code 12) kg/cm2 Unload Pressure H/O, Hi Idle, Neutral 30 - 50 non-adjustable Boom Up H/O, Hi Idle, Swing Accel ON, 315-335 LS Relief (345-370) Relief then (PMax) RH Main Relief or Safety Arm In H/O, Hi Idle, Swing Accel ON, 315-335 LS Relief (345-370) Relief then (PMax) LH Main Relief or Safety Arm Out H/O, Hi Idle, Swing Accel ON, 315-335 LS Relief (345-370) Relief then (PMax) LH Main Relief or Safety Bucket Dump H/O, Hi Idle, Swing Accel ON, 315-335 LS Relief (345-370) Relief then (PMax) RH Main Relief or Safety Bucket Curl H/O, Hi Idle, Swing Accel ON, 315-335 LS Relief (345-370) Relief then (PMax) RH Main Relief or Safety Swing Left H/O, Hi Idle, Swing Lock, Relief 305 - 330 Swing relief Swing Right H/O, Hi Idle, Swing Lock, Relief 305 - 330 Swing relief Travel Left H/O, Hi Idle, Relief Right 345 - 370 Left Main relief Sub-Unload Travel Safety valve Pressure 50-70 Travel Right H/O, Hi Idle, Relief Left 345 - 370 Right Main relief Sub-Unload Travel Safety valve Pressure 50-70Adjust the Main Relief valves using the travel, then adjust the LS Relief using the work equipment. It is normal to see a 2-6kg/cm2 difference between the pressures of the work equipment.

6) Measure the (Servo Input Pressure), and compare with the main pressure at the same time. (This test verifies that the LScircuit, LS valve, and the TVC valve are working properly.) Measurement Front Pump Front Pump Rear Pump Rear Pump Standard Value Servo Conditions Servo Input Main Servo Input Main vs. Main Pressure Pressure Neutral Almost the same Arm Relief Almost the same Left Track Unload Unload Servo approximately Relief Pressure pressure 1/2of main Right Track Unload Unload Servo approximately Relief Pressure Pressure 1/2of main

PC200 to 250-6 Pre-m/c 07/ 06/ 2001 297) Measure the LS Differential pressure using the tracks. Adjust if the Difference between the Load Sense pressure and the Main pressure is outside the standard value while rotating the raised track in Hi travel speed at half stroke. Measurement conditions Actual Value Standard Value H/O, Hi Idle, Neutral, Front Pump 30 - 50 kg/cm2 H/O, Hi Idle, Hi Travel speed, Left Track rotating at half 21 - 23 kg/cm2 stroke, Front Pump H/O, Hi Idle, Neutral, Rear Pump 30 -50 kg/cm2 H/O, Hi Idle, Hi Travel speed, Right Track rotating at half 21 - 23 kg/cm2 stroke, Rear Pump

8) TVC Valve adjustment: You can use engine rpm over relief to determine if the TVC valves are adjusted correctly. If the rpmwith the Arm over relief Power Max “ON” is not within the standard value range, adjust the TVC valve on each pump to give youthe correct rpm. Use the Travel over relief to inform you if the TVC valve for each pump is adjusted within 20 rpm of theother. Measurement Actual After Standard Standard Standard Standard conditions value Adjustment Value Value Value Value PC200,210 PC200,210 PC220, 250 PC220,250 Komatsu, Cummins, Komatsu, Cummins, rpm rpm rpm rpm Arm Relief, 2100 - 2300 2050 -2250 2200 - 2400 2150 - 2350 H/O+P/Max ** ** ** ** LH Track Must be Must be Must be Must be Relief (Front within 20 within 20 within 20 within 20 pump) rpm of the rpm of the rpm of the rpm of the RH track RH track RH track RH track RH Track Must be Must be Must be Must be Relief (Rear within 20 within 20 within 20 within 20 Pump) rpm of the rpm of the rpm of the rpm of the LH track LH track LH track LH track

Item Measurement conditions Front pump Rear pump standard value (code 11) (code 12) kg/cm2

6) Measure the (Servo Input Pressure), and compare with the main pressure at the same time. (This test verifies that the LS circuit, LS valve, and the PC valve are working properly.) Measurement Front Pump Frnt Front Rear Pump Rear Rear Pump Approx.STD Conditions Servo Input LS Pump Main Servo Input LS Main Ratio Servo vs. Main Neutral Almost the same Arm Relief Servo 1/2 of main Arm Relief + Pmax Servo 1/2 of main LH Travel , Hi, Unload Unload Servo 1/2 of half stroke Pressure pressure main RH Travel, Hi, half Unload Unload Servo 1/2 of stroke Pressure Pressure main

7) LS Differential - TIME Method: Using MEDIUM TRAVEL (Std. 5 turn spec with NO tolerances); H/O; Hi Idle; ActiveOFF; Raise track, set travel lever at FULL STROKE: PC200 (PC220)[250]<270> Measurement conditions Actual Value After Adjusting Standard Value, Seconds H/O, Hi Idle, Mi Travel speed, Left Track 39.5 (41.5)[45]<44.5> rotating at Full stroke, Front Pump max diff to opposite 0.5 H/O, Hi Idle, Mi Travel speed, Right Track 39.5 (41.5)[45]<44.5> rotating at Full stroke, Rear Pump max diff to opposite 0.5Adjust LS Valve on each pump separately to achieve NO MORE than ½second difference in Mi TVL cycle time. Each FLA T will change cycle approximately 2 seconds (5 turns, running start).LS Differential - PRESSURE Method: Consult LAST PAGE

9) PC Valve adjustment: The PC valve functions similar to the previous TVC valve. You use engine rpm over relief to determine if the PC valves are adjusted correctly. Test rpm with the Arm over relief Power Max “ON”. If not within the standard value range, adjust the PC valve on each pump to give you the correct rpm over relief using the stalled track (ensures both high relief pressure and divided pumps when travel operated WITHOUT any other function). Use the Travel over relief to inform you if the PC valve for each pump is adjusted within 20 rpm of the other. Measurement Actual value After Standard Value Standard Value Standard Value conditions Adjustment PC200LC-6, rpm PC220/250LC-6, PC270LC-6, rpm rpm Arm Relief, 1900 - 2100* 2000 - 2200* 2100 – 2300* H/O+P/Max LH Track Relief, 1900 - 2100 (within 20 2000 - 2200 2100 – 2300 Hi Travel speed rpm of rear pump) (within 20 rpm of (within 20 rpm of rear (Front pump) rear pump) pump) RH Track Relief 1900 - 2100 (within 20 2000 - 2200 2100 - 2300 Hi Travel speed rpm of front pump) (within 20 rpm of (within 20 rpm of (Rear Pump) front pump) front pump)• Note: Adjust the PC valves to the midpoint of this range. If you adjust to the low end of the range the machine will not go much faster, but will use a lot more fuel. PC Valves can “hide” a sick engine! Always ensure the engine care and health is verified prior to making hydraulic system adjustments. Divided pump target RPM’s will need to be about 50 – 100 higher than the merged, 2 pump values.10) Recheck all cycle times, and note in the table under #2 the new measurements.

PC200 to 270-6 m/c 07/06/2001 37CONTROL SIDE VIEW OF THE MAIN HYDRAULIC PUMP

The Self-Pressure Reducing Valve is located on the rear of the main control valve. The outlet hose for the front pump attaches tothis valve. To access the Control Pressure Relief valve remove the partition between the engine and the main control valve. Asyou can see below, the relief valve is located on the bottom of the Self-Pressure Reducing valve. ** PC300 to 450-6 Installation is90 Degrees Rotated CCW from this!!**

LS Differential - PRESSURE Method: Measure and adjust the LS Differential Pressure using the tracks as outlined in the Shop Manual. Raise one side of the machine, (HO mode, HI travel speed, Full Throttle) and move the travel lever of the raised track Partial - Lever Stroke (easily held steady at a chosen value such as 85 kg/cm2 of Main Pressure). At this point the Main pressure should be 80 - 100 kg/cm2. Adjust the LS Differential pressure to within standard values. Repeat this procedure for the opposite track and pump. Measurement conditions Actual Value After Adjusting Standard Value, kg/cm2 H/O, Hi Idle, Neutral, Front Pump 30 - 50 H/O, Hi Idle, Hi Travel speed, Left Track 21 – 23 rotating at half stroke, Front Pump H/O, Hi Idle, Neutral, Rear Pump 30 – 50 H/O, Hi Idle, Hi Travel speed, Right Track 21 – 23 rotating at half stroke, Rear Pump• LS Verification: Since track operation may cause erratic readings on the more sensitive digital DIFFERENTIAL PRESSURE GUAGES, another method of final verification is to use BOOM UP or ARM OUT functions to get a “final, steady LS Differential” reading. Operate the chosen function at a steady speed roughly at 50-80% as long as main pressure (codes 11, 12) is kept steady for the most repeatable and reliable reading of MAIN – LS = LS Differential.

PC300/400-6LK TESTING & ADJUSTMENT PROCEDUREUse the following procedure as a supplement to the Shop Manual when testing & adjusting the Komatsu PC300 &PC400-6”LK” machines. (Minor Change ) s/n A83001 & up.

Actual After Standard Value Standard Value Measurement conditions RPM Adjusting PC300LC-6mc PC400LC-6LK a. High Idle, H/O mode 1900-2000 2000-2100 b. High Idle, H/O (+Touch) 2000-2100 2100-2200 c. High Idle, Active (+Touch) 2100-2200 2200-2300 d. Low Idle, H/O mode 850-950 610-710 e. Low Idle, H/O mode(+Touch) N/A 900-1080 f. Arm in relief 1830-2030 1920-2120 g. Arm in relief & P. max 1690-1790 1850-2050 h. Auto-Decel ON 1300-1500 1300-1500 i. RH Track Relief, H/O 1690 - 1790 1850 - 2050 j. LH Track Relief, H/O 1690 - 1790 1850 - 2050 k. Low Idle @ Track Relief PEMC Test PEMC Test operation to close PPC switch.

2) Measure and record all of the Cycle Times listed below. See the Shop Manual for procedural details. Measurement conditions Actual Values After Adjusting Standard Value Standard Value H/O mode, High Idle Seconds PC300LC-6mc PC400LC-6LK Boom Raise 3.5 - 4.3 3.8 - 4.6 Arm In 3.5 - 4.3 4.4 - 5.2 Arm Out 3.1 - 3.7 3.5 - 4.3 Bucket Curl 2.9 - 3.5 3.2 - 4.0 Bucket Dump 2.0 - 2.6 2.5 - 3.1 LH Swing, 5 turns 28.5 - 31.5 31.0 - 35.0 RH Swing, 5 turns 28.5 - 31.5 31.0 - 35.0 LH Travel, Hi, 5 turns 30.4 - 37.8 32.8 - 40.2 LH Travel, Mi, 5 turns 37.3 - 45.9 38.0 - 50.0 LH Travel, Lo, 5 turns 44.8 - 56.6 57.0 - 70.0 RH Travel, Hi, 5 turns 30.4 - 37.8 32.8 - 40.2 RH Travel, Mi, 5 turns 37.3 - 45.9 38.0 - 50.0 RH Travel, Lo, 5 turns 44.8 - 56.6 57.0 - 70.0

Item Measurement conditions Rear pump Front pump Standard Value Standard Value (code 12) (code 11) PC 300LC-6 PC 400LC-6 Kg/cm2 kg/cm2 Unload Pressure H/O, Hi Idle, Neutral Divided 30 - 50 30 - 50 non-adjustable non-adjustable Boom Up H/O, Hi Idle, Relief (PMax) 335-355 (345-365) 335-355 (345-365) Boom DOWN(Low) Machine “Push-Up” feature 175 - 195 175 - 195 Arm In H/O, Hi Idle, Relief (PMax) 335-355 (345-365) 335-355 (345-365) Arm Out H/O, Hi Idle, Relief (PMax) 335-355 (345-365) 335-355 (345-365) Bucket Dump H/O, Hi Idle, Relief (PMax) 335-355 (345-365) 335-355 (345-365) Bucket Curl H/O, Hi Idle, Relief (PMax) 335-355 (345-365) 335-355 (345-365) Swing Left H/O, Hi Idle, Swing Lock, Relief 300 - 325 295 – 320 Swing Right H/O, Hi Idle, Swing Lock, Relief 300 - 325 295 – 320 Travel Left H/O, Hi Idle, Relief Unload Pres 345-365 LH relief 345-365 LH relief Travel Right H/O, Hi Idle, Relief Unload Pres 345-365 RH relief 345-365 RH relief

WHEN SETTING THE RELIEF PRESSURE: Stall each track individually and measure the pressure (HO mode, Full Throttle,Swing Lock “OFF.”) This will give you the power max pressure setting with the pumps divided. The left track is using the rearpump and left main relief valve and the right track is using the front pump and right main relief valve. Adjust to 355 +/- 10kg/cm2 using the track. Verify the settings using the work equipment independently in HO mode, Swing Lock “OFF,” over relief.Readings should be 345 +/- 10 kg/cm2.

Measurement Front Pump Frnt Front Rear Pump Rear Rear Pump Approx. Ratio Conditions Servo Input LS Pump Main Servo Input LS Main Servo vs. Main Neutral Almost the same Arm Relief + Pmax Servo 2/5 of main RH Travel , Hi, Unload Unload Servo 2/5 of main half stroke Pressure pressure LH Travel, Hi, half Unload Unload Servo 2/5 of main stroke Pressure Pressure

PC300 to 400-6 m/c 07/06/2001 417) LS Differential - TIME Method: Using MEDIUM TRAVEL (Std. 5 turn spec with N O tolerances); H/O; Hi Idle; Active OFF; Raise track, set travel lever at FULL STROKE: [300]<400> Measurement conditions Actual Value After Adjusting Standard Value, Seconds H/O, Hi Idle, Mi Travel speed, Left Track Med [42]<44.5> rotating at Full stroke, Rear Pump max diff to opposite 0.5 H/O, Hi Idle, Mi Travel speed, Right Track Med [42]<44.5> rotating at Full stroke, Front Pump max diff to opposite 0.5Adjust LS Valve on each pump separately to achieve NO MORE than ½second difference in Mi TVL cycle time. Each FLAT will change cycle approximately 2 seconds (5 turns, running start).LS Differential - PRESSURE Method: Consult LAST PAGE

8) TVC Valve adjustment: Measure the TVC valve adjustment using engine RPM. The engine RPM at 2-pump relief and power max is the best judge of how well the TVC’s are loading the engine (Step A below). If the 2-pump/power max relief RPM is not within specifications, use the following procedure to adjust them. Note: See “EXAMPLE” below Measurement Conditions Actual Value After Standard Value Standard Value (engine rpm) Adjusting PC300LC-6mc PC400LC-6LK (rpm) (rpm) A) Arm Relief, H/O+ 1690 - 1790 1850 - 2050 P/Max (2 pumps) B) Arm Relief, H/O, Move Within 20 rpm of Within 20 rpm of Travel pedal slightly front pump front pump (Rear Pump) C) Boom Up Relief, H/O, Within 20 rpm of Within 20 rpm of Move Travel pedal slightly rear pump rear pump (Front Pump)

NOTE: The Pump Merge/Divide valve is not actuated with the Active Mode switch, so you cannot divide the pumps withthis switch to set the TVC valves individually.

To set the TVC valves individually, check the RPM drop of each by doing Steps B & C above. Adjust each pump to within 20rpm of each other, and to give you a 2 pump rpm within the Standard Value.

A) Switch the connector (CN-VO5) for the Boom High/Low solenoid with the connector (CN-VO3) for the pump Merge/Divide solenoid. Then you can turn the Boom High/Low switch “ON” to activate the merge/divide valve, and divide the pumps.

EXAMPLE: PC 300LC-6, RPM at 2-pump power max relief 1850. Spec is 1690 - 1790. 8A) Rear pump rpm drop 1870, adjust rear pump TVC to 1830. 8B) Front pump rpm drop 1880, adjust front pump TVC to 1830. RECHECK 2 PUMP / POWER MAX RELIEF, after adjustment it is 1730 (within spec.)

LS Differential – Pressure Method Using the tracks as outlined in the Shop Manual. Raise one side of the machine, (HO mode, HI travel speed, Full Throttle) and move the travel lever of the raised track Half - Lever Stroke (easily held steady at a chosen value such as 85 kg/cm2 of Main Pressure). At this point the Main pressure should be 80 - 100 kg/cm2. Adjust the LS Differential pressure to within standard values. Repeat this procedure for the opposite track and pump.

Measurement conditions Actual Value After Adjusting Standard Value, kg/cm2 H/O, Hi Idle, Neutral, Front Pump 30 – 50 H/O, Hi Idle, Hi Travel speed, Right Track 24 – 26 rotating at half stroke, Front Pump H/O, Hi Idle, Neutral, Rear Pump 30 – 50 H/O, Hi Idle, Hi Travel speed, Left Track 24 – 26 rotating at half stroke, Rear Pump LS Verification: Since track operation may cause erratic readings on the more sensitive digital DIFFERENTIAL PRESSURE GUAGES, another method of final verification is to use BOOM UP or ARM OUT functions to get a “final, steady LS Differential” reading. Operate the chosen function at some steady speed roughly at ½or less as long as main pressure (codes 11, 12) is kept steady for the most repeatable and reliable reading of MAIN – LS = LS Differential.

PC300 to 400-6 m/c 07/06/2001 45 Date Customer

PC300/400-6 TESTING & ADJUSTMENT PROCEDUREUse the following procedure as a supplement to the Shop Manual when testing & adjusting the Komatsu PC300 &PC400-6 machines. **( Pre-Minor Change )

1) Warm the machine up to operating temperature, and record all of the following Engine Speeds using the machine monitor panel code 10. Compare these with the specified values. Adjust the engine speed if necessary. Actual After Standard Value Standard Value Measurement conditions RPM Adjusting PC300LC-6 PC400LC-6 a. High Idle, H/O mode 2000 - 2100 2050 - 2150 b. High Idle, G/O mode 1790 - 1930 1810 - 1990 c. High Idle, F/O mode 1790 - 1930 1810 - 1990 d. High Idle, L/O mode 1590 - 1730 1500 - 1700 e. Low Idle, H/O mode 850 - 950 650 - 750 f. Arm in relief 1830 - 2030 1910 - 2060 g. Arm in relief & P. max 1690 - 1790 1940- 2030 h. Auto-Decel ON 1300 - 1500 1300 - 1400

2) Measure and record all of the Cycle Times listed below. See the Shop Manual for procedural details. Measurement conditions Actual Values After Adjusting Standard Value Standard Value H/O mode, High Idle seconds PC300LC-6 * PC400LC-6 * Boom Raise 3.5 - 4.3 3.8 - 4.6 Arm In 3.5 - 4.3 4.4 - 5.2 Arm Out 3.1 - 3.7 3.5 - 4.3 Bucket Curl 2.9 - 3.5 3.4 - 4.2 Bucket Dump 2.0 - 2.6 2.6 - 3.2 LH Swing, 5 turns 28.5 - 31.5 32.0 - 35.4 RH Swing, 5 turns 28.5 - 31.5 32.0 - 35.4 LH Travel, Hi, 5 turns 30.4 - 37.8 32.8 - 40.2 LH Travel, Mi, 5 turns 37.3 - 45.9 39.7 - 49.3 LH Travel, Lo, 5 turns 44.8 - 56.6 56.0 - 69.0 RH Travel, Hi, 5 turns 30.4 - 37.8 32.8 - 40.2 RH Travel, Mi, 5 turns 37.3 - 45.9 39.7 - 49.3 RH Travel, Lo, 5 turns 44.8 - 56.6 56.0 - 69.0* See the Shop Manual for the cycle times of the PC300HD-6 and PC400HD-6.

Item Measurement conditions Rear pump Front pump Standard Value Standard Value (code 12) (code 11) PC 300LC-6 PC 400LC-6 Kg/cm2 kg/cm2 Unload Pressure H/O, Hi Idle, Neutral 30 - 50 30 - 50 non-adjustable non-adjustable Boom Up H/O, Hi Idle, Relief (PMax) 335-355 (345-365) 335-355 (345-365) Arm In H/O, Hi Idle, Relief (PMax) 335-355 (345-365) 335-355 (345-365) Arm Out H/O, Hi Idle, Relief (PMax) 335-355 (345-365) 335-355 (345-365) Bucket Dump H/O, Hi Idle, Relief (PMax) 335-355 (345-365) 335-355 (345-365) Bucket Curl H/O, Hi Idle, Relief (PMax) 335-355 (345-365) 335-355 (345-365) Swing Left H/O, Hi Idle, Swing Lock, Relief 300 - 325 295 - 320 Swing Right H/O, Hi Idle, Swing Lock, Relief 300 - 325 295 - 320 Travel Left H/O, Hi Idle, Relief Unload Pres 345-365 LH relief 345-365 LH relief Travel Right H/O, Hi Idle, Relief Unload Pres 345-365 RH relief 345-365 RH relief

WHEN SETTING THE RELIEF PRESSURE: Stall each track individually and measure the pressure (HO mode, Full Throttle,Swing Lock “OFF.”) This will give you the power max pressure setting with the pumps divided. The left track is using the rearpump and left main relief valve and the right track is using the front pump and right main relief valve. Adjust to 355 +/- 10kg/cm2 using the track. Verify the settings using the work equipment independently in HO mode, Swing Lock “OFF,” over relief.Readings should be 345 +/- 10 kg/cm2.

Measurement Front Pump Front Pump Rear Pump Rear Pump Standard Value Conditions Servo Input Main Servo Input Main Servo vs. Main Pressure Pressure Neutral Almost the same Arm Relief Servo 2/5 of main Arm Relief + Pmax Servo 2/5 of main RH Travel , Hi, half Unload Unload Servo 2/5 of main stroke Pressure pressure LH Travel, Hi, half Unload Unload Servo 2/5 of main stroke Pressure Pressure

PC300 to 400-6 PRE - m/c 07/06/2001 47

7) Measure and adjust the LS Differential Pressure using the tracks as outlined in the Shop Manual. Raise one side of the machine, (HO mode, HI travel speed, Full Throttle) and move the travel lever of the raised track Half - Lever Stroke (easily held steady at a chosen value such as 85 kg/cm2 of Main Pressure). At this point the Main pressure should be 80 - 100 kg/cm2. Adjust the LS Diffe rential pressure to within standard values. Repeat this procedure for the opposite track and pump.

Measurement conditions Actual Value After Adjusting Standard Value, kg/cm2 H/O, Hi Idle, Neutral, Front Pump 30 - 50 H/O, Hi Idle, Hi Travel speed, Right Track 24 - 26 rotating at half stroke, Front Pump H/O, Hi Idle, Neutral, Rear Pump 30 - 50 H/O, Hi Idle, Hi Travel speed, Left Track 24 - 26 rotating at half stroke, Rear Pump• LS Verification: Since track operation may cause erratic readings on the more sensitive digital DIFFERENTIAL PRESSURE GUAGES, another method of final verification is to use BOOM UP or ARM OUT functions to get a “final, steady LS Differential” reading. Operate the chosen function at some steady speed roughly at ½or le ss as long as main pressure (codes 11, 12) is kept steady for the most repeatable and reliable reading of MAIN – LS = LS Differential.

8) TVC Valve adjustment: Measure the TVC valve adjustment using engine RPM. The engine RPM at 2-pump relief and power max is the best judge of how well the TVC’s are loading the engine (Step A below). If the 2-pump/power max relief RPM is not within specifications, use the following procedure to adjust them. Note: See “EXAMPLE” below Measurement Conditions Actual Value After Standard Value Standard Value (engine rpm) Adjusting PC300LC-6 PC400LC-6 (rpm) (rpm) A) Arm Relief, H/O+ 1690 - 1790 1940 - 2040 P/Max (2 pumps) B) Arm Relief, H/O, Move Within 20 rpm of Within 20 rpm of Travel pedal slightly front pump front pump (Rear Pump) C) Boom Up Relief, H/O, Within 20 rpm of Within 20 rpm of Move Travel pedal slightly rear pump rear pump (Front Pump)

NOTE: The Pump Merge/Divide valve is not actuated with the Swing Accel (Priority) switch, so you cannot divide thepumps with this switch to set the TVC valves individually.

To set the TVC valves individually, check the RPM drop of each by doing Steps B & C above. Adjust each pump to within 20rpm of each other, and to give you a 2 pump rpm within the Standard Value.

A) Switch the connector (CN-VO5) for the Boom High/Low solenoid with the connector (CN-VO3) for the pump Merge/Divide solenoid. Then you can turn the Boom High/Low switch “ON” to activate the merge/divide valve, and divide the pumps.

EXAMPLE: PC 300LC-6, RPM at 2-pump power max relief 1850. Spec is 1690 - 1790. 8A) Rear pump rpm drop 1870, adjust rear pump TVC to 1830. 8B) Front pump rpm drop 1880, adjust front pump TVC to 1830. RECHECK 2 PUMP / POWER MAX RELIEF, after adjustment it is 1730 (within spec.)

PC300 to 400-6 PRE - m/c 07/06/2001 51 Date Customer

3) Measure, record (and re-record, if adjusted) the (Control Pump) PILOT pressure, and adjust if necessary. Step 3 Actual value Adjusted Value Standard Value, kg/cm2 Pilot Oil Pressure 32.0 – 35.5

WHEN SETTING THE RELIEF PRESSURE: Relieve and measure the pressure (DH mode, Full Throttle, Swing Lock“OFF.”) Heavy Lift ON will give you the HIGH RELIEF for each valve and pump group. Then, set the LOW RELIEF withHeavy LIFT turned OFF. Always do HIGH first.

6) Test and Adjust ALL “CO VALVES” (Front & Rear Pumps – Remember on PC1100 #3 pump, the CO Valve is there, but isnon-adjustable.) G Mode, Swing Lock OFF, High Idle Item Measurement conditions Front/R4 Rear/L5 #3 / S4 Standard Value Standard Value Right 4 Left 5 Swing 4 PC 600LC-6 [PC750]PC 1100LC-6 Kg/cm2 kg/cm2

7) Test and Adjust NC OUT pressures, DH Mode, HIGH Idle, Swing Lock OFF Item Measurement conditions Front/R4 Rear/L5 #3 / S4 Standard Value Standard Value Right 4 Left 5 Swing 4 PC 600LC-6 [PC750]/1100LC-6 Kg/cm2 kg/cm2 Pump #3 Swing, NO Load N/A N/A [N/A] MIN 17 FRONT Pair RIGHT TRACK – No load N/A N/A MIN 18 MIN 17 REAR Pair LEFT TRACK – No Load N/A N/A MIN 18 MIN 17

Item Actual Adjusted Standard Value Standard Value

8613371530291

8613371530291