permco hydraulic pump manual manufacturer

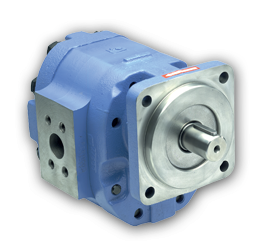

Permco is a leading manufacturer of high-pressure hydraulic gear/vane pumps and motors, flow dividers, intensifiers, and accessories. Available in a wide variety of sizes and configurations to suit your application needs.

The Perfection Machining Company was founded in 1964 to design and manufacture replacement parts for the mining industry. Renamed Permco 4 years later, the family-owned business developed a wide array of replacement hydraulic parts and eventually expanded its manufacturing capabilities to include cast iron parts and the resulting complete units. Today, we maintain our focus on customer service and continue a decades-long tradition of developing fluid power systems that meet each of our customer’s specific needs. Permco’s product offering now includes gear and vane pumps/motors, flow dividers, intensifiers and a variety of accessories and components.

Permco offers the highest quality product possible to our wide customer base of OEMs and distributors. Because we understand that our success depends on the success of our customers, we are committed to reducing customers’ costs and increasing the simplicity of doing business with us.

Not only do such differences matter in design and manufacturing, they hold for how pumps are assembled, too. Building a high-quality pump is meticulous work, stressed Shell. “Our people do prep work very similar to what you would see in a good engine rebuild shop.” For instance, they might take a honing stone or emery cloth and kiss a few areas on the gear before installation. That’s because when gears are pulled from a warehouse shelf and moved to the assembly station, it’s not unheard of to accidentally bump and nick a gear. If that gear gets assembled as is, and it subsequently rides on the soft bronze plate, the burr will cut a groove and create a leak path. Left unchecked, that pump will run inefficiently and underperform. Few manufacturers take such a hands-on approach to quality, emphasized Shell.

“But probably the biggest thing that differentiates us is we test every pump that goes out of this building. For peace of mind from the customer’s standpoint, that’s huge,” he stressed. Each pump gets assembled with new parts to create a tight package. Then it’s run up to 2,000 psi pressure, where the components flex and the gears will take a take a slight wipe—removing perhaps 0.0005 to 0.001 in. of material from the housing. That’s acceptable, notes Shell, because filters on the test benches trap the wear particles, instead of remaining behind to contaminate a customer’s hydraulic system.

Finally, the approved product is assigned a serial number that includes the initials of the assembler—as a further sign of the workmanship that stands behind a high-quality pump.

Permco is a leading manufacturer of high-pressure hydraulic gear pumps and motors, flow dividers, intensifiers, and accessories. Both roller bearing and sleeve bushing series are available in a wide variety of sizes and configurations.

Starting as the Perfection Machining Company in 1964, Permco hydraulic pumps began designing and manufacturing replacement parts for the mining industry. In 1968 the name was officially changed to Permco and the development of replacement hydraulic parts was under way.

In 1974 Permco hydraulic pumps expanded its manufacturing capabilities to include cast iron parts, which enabled us to offer complete units. We later developed our sleeve bushing pumps, which have recently been rounded out with the introduction of the P124 series.

Permco, working with The Torrington Company, developed the patented "controlled stress" roller bearing, which increases pump and motor life by up to 30%. As a result, we recently extended our warranty from one year to two years.

Our commitment is to continue to develop and offer the highest quality product possible to our wide customer base, which includes both OEM"s and distribution. We are also committed to working with our customers to supply them in such a way as to reduce their cost and to make their interface with Permco hydraulic pumps as seamless as possible. We are determined to do business the old fashioned way, while incorporating as much technology as makes sense to keep up with today"s fast pace in business.

At Northern Hydraulics we manufacture your Permco Hydraulic Pump on-site in our full service Machine Shop.Permco products are available in a variety of sizes and configurations to meet your specific needs. Give us a call at 1-800-823-4937, we have the Permco hydraulic components to build you the Permco Hydraulic Pumps or Motors you need.

Permco offers quality gear pumps at a fair price. Beiler Hydraulics is a distributor and authorized build center for Permco Gear Pumps and Motors. We stock hundreds of replacement parts as well as the components needed to assemble new pumps. If you are in a breakdown situation and need a fast turn around let our experienced staff work for you. Permco Gear pumps can easily replace many manufacturer"s units. In our past 30 years of experience we have successfully crossed over name brand cast iron gear pumps and motors such as Materis, Parker/Commercial, Muncie, and Hydreco.

Northern Hydraulics offers a complete line of Permco hydraulic pumps and replacement Permco parts. We are a Permco distributor and an authorized Permco Pump Build Center. Permco hydraulic products are available in a variety of shaft styles (spline, keyed) and displacements. We can build and customize your Permco hydraulic pump on site in our full service machine shop. Do you need to repair your Permco pump? We stock Permco repair parts to help you with that too. Permco gear housings, thrust plates, seal kits, relief valves, detent kits, and more are on the shelf. Contact our knowledgable hydraulic pump sales representatives for assistance in replacing any Permco Dump Pump. We stock many direct mount Permco DMD-512, DMD-20 and DMD-25 pump models fully assembled and ready to ship. Ask us about our Wet Line Kits for dump applications. We can install and/or supply the parts for these as well. Permco Gemini Series Pumps for fleet operations and Permco Versa-Pak pumps for use in the refuse industry are also available. Are you searching for a bushing pump in the Permco P124, P197, P257 or P360 Series? We have these gear pumps and hydraulic pump repair parts ready for you to browse. Do you need an electric cluth pump for your snowplow, dump body, wrecker, or agricultural equipment? We have Permco Clutch Pumps with electric clutches for 12VDC operation. Check out our CP124 Series of Permco dump pumps to browse available 2 groove v-belt, 6 groove, and 8 groove clutches and choose your Permco hydraulic pump from a variety of measured flow ratings.

Permco continues a long tradition of developing fluid power systems that meet customers� specific needs. Its products include gear and vane pumps/motors, flow dividers, intensifiers and a variety of accessories and components.

The Perfection Machining Company was founded in 1964 to design and manufacture replacement parts for the mining industry. Renamed Permco 4 years later, the family-owned business developed a wide array of replacement hydraulic parts and eventually expanded its manufacturing capabilities to include cast iron parts and the resulting complete units. Today, we maintain our focus on customer service and continue a decades-long tradition of developing fluid power systems that meet each of our customer’s specific needs. Permco’s product offering now includes gear and vane pumps/motors, flow dividers, intensifiers and a variety of accessories and components. Permco offers the highest quality product possible to our wide customer base of OEMs and distributors. Because we understand that our success depends on the success of our customers, we are committed to reducing customers’ costs and increasing the simplicity of doing business with us.

We are committed to ensuring that our customers are more profitable by choosing Permco rather than anyone else. As a leading manufacturer of precision-engineered fluid power products, we design and build the best-value solutions that uniquely fit our customers’ needs. We operate the company by striving for profitable growth, increasing shareholder value, and providing opportunities for our employees to develop and grow. Permco understands the central role business plays in society and will always strive to be an example of Integrity, Service to our customers, employees, shareholders, and local communities

For more than 40 years Permco has grown and prospered through lasting partnerships with our customers. We will continue to grow by understanding that our success is entirely dependent on the success of our customers.

Flint Hydraulics, Inc. offers high-pressure gear pumps & motors, accessories & parts from respected industry leader, Permco, Inc. Browse our extensive selections here: http://www.laurenc60.sg-host.com/permco-product-catalog.html and call us today at 901-794-4884 or email sales@laurenc60.sg-host.com.

Flint Hydraulics’ inventory of Permco high-pressure gear pumps and motors, accessories and parts allows us to supply a large range of replacement parts and configure Permco units for same day shipment from our … Read more

Permco high-pressure hydraulic gear pumps and motors, accessories and parts will answer the demands of your toughest applications. Browse our online catalog here: http://www.laurenc60.sg-host.com/permco-product-catalog.html and call Flint Hydraulics today at 901-794-4884 or email … Read more

High-pressure gear pumps and motors from industry leader Permco, Inc. provide quality & reliability at affordable costs. Our inventory includes an extensive variety of products; browse it here: http://www.laurenc60.sg-host.com/permco-product-catalog.html, and call Flint Hydraulics, … Read more

Flint Hydraulics, Inc. offers high-pressure hydraulic gear pumps and motors, accessories and parts from respected industry leader Permco, Inc. Browse our extensive catalog here: https://flinthyd.com and call us today at 901-794-4884 or email … Read more

Flint Hydraulics’ inventory of Permco high-pressure gear pumps and motors includes an extensive variety of products, accessories and parts. Browse our online catalog here: http://www.laurenc60.sg-host.com/permco-product-catalog.html and call us today at 901-794-4884 or email … Read more

Flint Hydraulics, Inc. offers high-pressure gear pumps and motors, accessories and parts from respected industry leader Permco, Inc. Browse our extensive inventory here: http://www.laurenc60.sg-host.com/permco-product-catalog.html and call us today at 901-794-4884 or email sales@laurenc60.sg-host.com.

Flint Hydraulics, Inc. offers high-pressure gear pumps and motors, accessories and parts from respected industry leader Permco, Inc. Browse our extensive inventory here: http://www.laurenc60.sg-host.com/permco-product-catalog.html, and call us today at 901-794-4884 or email sales@laurenc60.sg-host.com.

Flint Hydraulics, Inc. offers high-pressure gear pumps and motors, accessories and parts from respected industry leader Permco, Inc. Our inventory includes an extensive variety of products, and we can supply a large range … Read more

Flint Hydraulics, Inc. offers original and replacement parts available for many manufacturers such as Comatrol, Cross, Danfoss, Eaton-Cessna, Eaton-CharLynn, Eaton-Vickers, Geartek, Kawasaki-Staffa, Parker-Commercial-Intertech, Parker-Denison, Permco, Poclain, Turolla, Webster, and many more. Browse our … Read more

186 permco hydraulic pump parts products are offered for sale by suppliers on Alibaba.comAbout 3% % of these are hydraulic pumps, 1%% are construction machinery parts, and 1%% are other construction machinery attachments.

A wide variety of permco hydraulic pump parts options are available to you, You can also choose from gear pump, permco hydraulic pump parts,as well as from 1 year, 6 months, and 3 months permco hydraulic pump parts,And whether permco hydraulic pump parts is fittings, {2}, or {3}.

Rotary flow dividers provide many useful functions from a single pump source. Synchronised operation of multiple cylinders or motors. Proportional division of pumps output among several circuits. Intensified flow pressure when pressures higher than pump capacity is needed. The rotary gear flow divider consists of 2 or more gear sections connected by a common shaft. Because a common shaft connects the gear sections, the rotation speed is the same for each gear and the flow division is exactly proportional to the displacement of each of the sections.

8613371530291

8613371530291