pipe bender hydraulic pump free sample

However, when we initially designed it in the mid 1980"s it was a mechanical bender targeted at racecar builders who wanted an affordable bender which still produced high quality bends. Hydraulics wasn"t added until years later.

Differences between the two benders are:Frame strength has been more than doubled and the 7/8" diameter 100,000 psi alloy pins were upgraded to 1 1/4" diameter.

A die locking mechanism was designed that both helps bend thin wall tubing as well as very heavy walled tubing by preventing the die from relaxing when not bending. Springback is the #1 cause of wrinkling thin walled tubing.The Model 32 has been designed for mechanical or hydraulic operation from day one. Its hydraulic swivel block rotates on the cylinders true center axis thereby eliminating side load on the ram during bending. This greatly extends the life of the cylinder. A one piece steel ram yoke with quick disconnect pin is now incorporated as well. An anti- springback ratchet is now included free with the bender. This allowed us to design a new ratchet lever system with more than a 20% reduction in bending effort.Geometry of the bender itself was altered to take better advantage of the new generation 3 followbars thus yielding better bends.

LARGE CAPACITY - Bends round tubing and pipe from 1/2" to 2 1/2" O.D. and square tubing from 1/2" to 2". This bender is rated to bend 2" o.d. x .250" wall DOM steel tubing. Also capable of solid steel up to 1 1/2" diameter.NOTE: To bend round tubing over 2" o.d. x .120" wall, square tubing over 1 1/2" or solids over 1" diameter requires hydraulics.

EASY OPERATION - The Model 32 uses a high-ratio ratchet mechanism to allow you to bend larger tubing sizes comfortably without assistance. For example, the average operator can bend 1 3/4" x .095" wall round mild steel tubing with one hand and 1" x .065" wall tubing with ONE finger. Dies can be changed in under 30 seconds. Bend times are typically in the 30-60 second range for 1" O.D. and above tubing using the ratchet mechanism. Hydraulics may be slightly slower or faster depending on the power unit chosen.

DIE LOCKING MECHANISM - Standard on every Model 32 is the die locking mechanism. As the die rotates while bending the drive holes in the forming die pass under the lock pin. When the drive hole is below the lock pin, it drops into the drive hole and when pressure is removed from the bender the die"s rotation is locked at that position. When bending resumes the ramp machined into the lock pin will automatically lift the pin out of the drive hole. This mechanism combined with the included anti-springback ratchet allows the Model 32 to better bend thin wall tubing as well as the heavier sizes of tubing such as 2" o.d. x .250" wall DOM tubing.

36" TELESCOPING HANDLE - Included free with manual version of the bender. The new design has twice the bearing area of the old style for longer life and provides ample leverage for tube sizes up to 1 3/4".However, if more leverage is desired for tougher to bend applications, you now can simply obtain a longer piece of standard 1" schedule 40 pipe and insert it into the ratchet lever. Comes standard with a pull pin so the handle may be retracted out of the way when not in use saving valuable floor space.

CENTER PIVOT HYDRAULIC CYLINDER - The hydraulic swivel block rotates on the cylinders true center axis thereby eliminating side load on the ram during bending. This greatly extends the life of the cylinder. A one piece steel ram yoke with quick disconnect pin is now incorporated as well.

However, when we initially designed it in the mid 1980"s it was a mechanical bender targeted at racecar builders who wanted an affordable bender which still produced high quality bends. Hydraulics wasn"t added until years later.

Differences between the two benders are:Frame strength has been more than doubled and the 7/8" diameter 100,000 psi alloy pins were upgraded to 1 1/4" diameter.

A die locking mechanism was designed that both helps bend thin wall tubing as well as very heavy walled tubing by preventing the die from relaxing when not bending. Springback is the #1 cause of wrinkling thin walled tubing.The Model 32 has been designed for mechanical or hydraulic operation from day one. Its hydraulic swivel block rotates on the cylinders true center axis thereby eliminating side load on the ram during bending. This greatly extends the life of the cylinder. A one piece steel ram yoke with quick disconnect pin is now incorporated as well. An anti- springback ratchet is now included free with the bender. This allowed us to design a new ratchet lever system with more than a 20% reduction in bending effort.Geometry of the bender itself was altered to take better advantage of the new generation 3 followbars thus yielding better bends.

LARGE CAPACITY - Bends round tubing and pipe from 1/2" to 2 1/2" O.D. and square tubing from 1/2" to 2". This bender is rated to bend 2" o.d. x .250" wall DOM steel tubing. Also capable of solid steel up to 1 1/2" diameter.NOTE: To bend round tubing over 2" o.d. x .120" wall, square tubing over 1 1/2" or solids over 1" diameter requires hydraulics.

EASY OPERATION - The Model 32 uses a high-ratio ratchet mechanism to allow you to bend larger tubing sizes comfortably without assistance. For example, the average operator can bend 1 3/4" x .095" wall round mild steel tubing with one hand and 1" x .065" wall tubing with ONE finger. Dies can be changed in under 30 seconds. Bend times are typically in the 30-60 second range for 1" O.D. and above tubing using the ratchet mechanism. Hydraulics may be slightly slower or faster depending on the power unit chosen.

DIE LOCKING MECHANISM - Standard on every Model 32 is the die locking mechanism. As the die rotates while bending the drive holes in the forming die pass under the lock pin. When the drive hole is below the lock pin, it drops into the drive hole and when pressure is removed from the bender the die"s rotation is locked at that position. When bending resumes the ramp machined into the lock pin will automatically lift the pin out of the drive hole. This mechanism combined with the included anti-springback ratchet allows the Model 32 to better bend thin wall tubing as well as the heavier sizes of tubing such as 2" o.d. x .250" wall DOM tubing.

36" TELESCOPING HANDLE - Included free with manual version of the bender. The new design has twice the bearing area of the old style for longer life and provides ample leverage for tube sizes up to 1 3/4".However, if more leverage is desired for tougher to bend applications, you now can simply obtain a longer piece of standard 1" schedule 40 pipe and insert it into the ratchet lever. Comes standard with a pull pin so the handle may be retracted out of the way when not in use saving valuable floor space.

CENTER PIVOT HYDRAULIC CYLINDER - The hydraulic swivel block rotates on the cylinders true center axis thereby eliminating side load on the ram during bending. This greatly extends the life of the cylinder. A one piece steel ram yoke with quick disconnect pin is now incorporated as well.

A hydraulic pipe bender is a device that uses hydraulic pressure to bend various metal pipes to specific angles. Hydraulic pipe benders work the same way as hydraulic car jacks and can perform multiple bends on the same pipe. Although they aren"t as effective as electric pipe benders, making bends using hydraulic pipe benders takes less time and effort than manual benders. This article discusses more about what hydraulic pipe benders are, their design and operation, and compares them with other pipe benders.

A hydraulic pipe bender requires less effort to bend pipe than manual pipe benders. It uses hydraulic pressure to bend pipes of different sizes and material types (e.g., copper and stainless steel). Hydraulic pipe benders use the ram bending method to bend pipes to specific angles. This method uses a bending die (Figure 2 labeled A), which controls the inside radius of the bend. The die presses the pipe against two stationary rollers (Figure 2 labeled B) to achieve the bend.

Hydraulic machines take advantage of Pascal’s principle, which states that an increase of pressure at one point in a confined space filled with incompressible fluid will lead to an equal increase at all other points. Hydraulic machines typically use water or oil as the incompressible fluid. An example of hydraulics is if two cylinders containing pistons are filled with oil and connected to one another with a pipe, any force that one piston applies to the oil will act upon the other piston.

In hydraulic systems, it"s possible to multiply the force on the second piston or cylinder in the above example based on Pascal"s principle and the pressure definition. Pressure is the force acting per unit area. Thus, with a constant pressure value, an increase of the second piston’s surface area results in an increase of force acting upon that piston. Most hydraulic systems have valves connecting cylinders and pistons to a high-pressure oil pump. Therefore, by applying a small force on the hydraulic pipe bender"s pump, a larger force is created to make bends in pipes of various sizes and materials.

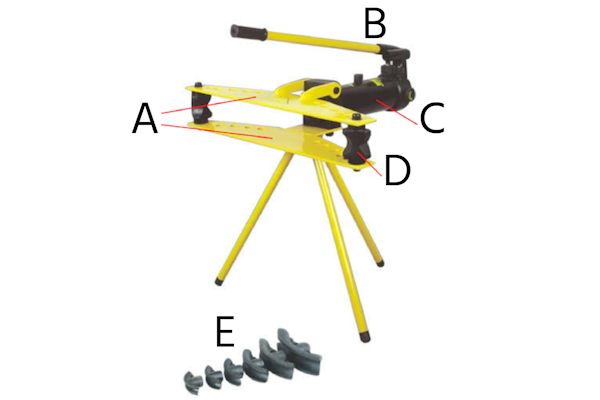

Figure 3: A hydraulic pipe bender mounted on a tripod with the following components: hand pump (A), cylinder (B), frame plates (C), pivot assembly (D), dies (E).

Hand Pump: The pump (Figure 3 labeled A) supplies high-pressure oil to the entire cylinder through the release knob valve and the hydraulic hose. It has a handle that facilitates the opening and closing of the valve to release the oil as required. The pump has an oil filler screw for refilling or replacing the oil.

Cylinder: Pressure, force created in the hand pump, is transmitted to the cylinder (Figure 3 labeled B) via the hydraulic hose. Given that the cylinder has a higher surface area than the pump, the force is multiplied there, making it possible to bend pipes of various sizes and materials to the required degrees.

Pivot Assembly: This is an assembly of rollers (Figure 3 labeled D) placed between the upper and lower frame plates and secured in applicable holes with pins and snap pins. The pivot assembly allows the pipe to roll through as the bending occurs, making it possible to achieve the required bending degree.

Operate the pump slowly, monitoring the bend until achieving the desired bend angle.Don"t force the pipe to bend. If it doesn"t bend, stop, release the hydraulic pressure and remove it from the bender.

When finished, turn the hydraulic pipe bender off and retract the cylinder by slowly turning the release valve knob counterclockwise. Release the left side pivot pin and the pivot assembly.

Hydraulic pipe benders are useful for various uses, such as wall returns, handrails, roll cages, car chassis, rail elbows, furniture frames, and pipeline construction and repair. They are suitable for more robust pipes like those made of iron and steel. These machines are also ideal for producing tubes and pipes that require precision.

Readiness:Hydraulic pipe benders need a little more time to set up than manual pipe benders. Electric pipe benders vary in set up time depending on the type.

The choice of a pipe bending machine depends on budget, use, and requirements. A hydraulic pipe bender is ideal for small-scale uses, where high precision and quality don"t matter much.

Tired of cranking the handle on your tubing bender? Are you using a 6" cheater bar slid over the factory handle to gain mechanical leverage, while trying to read the degree wheel that is ~8 feet away? This kit is designed out of pure necessity and built to be the best kit out on the market.

Designed to fit the JD-2 Model 3, JD-2 Model 32, Pro Tools 105, 105HD, Woodward Fab WFB2, Eastwood 21115, and JMR manual tubing benders. The brackets are laser cut out of high strength 1/4" steel and formed on a CNC press brake. Sold in two configurations, welded or unwelded. Material thickness and bending capacity vary from tube bender to tube bender please consult your user manual for technical information. Rule of thumb if you can bend it manually then the SWAG air/hydraulic bender can bend the same material with ease.

Please note that this kit is 100% complete, however it does not come painted. The tube bender as well as the 8 ton ram is not included. The 8 Ton Air/Hydraulic ram must have an outside diameter of 80mm. There are dozens of 8 ton rams that are sold on Ebay & Amazon, however a majority of them have an outside diameter of 84mm or 78mm which will not work for this application. The Vevor Ram is not compatible with either of our mounts.

Imagine how much easier your job is going if you"re not having to manually retract your tube bender every time you need to re-pin your die set. The 100 pounds of resistance offered by this return spring is backwards compatible with our Air/Hydro tube bender ram mount. No tools required for installation, just hook it up to your bender and the back side of your 8 ton ram and you"re done.

E-Z Bend 90 Hydraulic Tubing-Pipe Bender for metalworking, makes smooth wrinkle-free bends in a variety of tubing and pipe. Bending capacity .049 to .180 wall electric weld, d.o.m, & chrome moly tubing (some restrictions tubing diameter versus radius of bend may apply). Utilizes a 10 ton power pump and is offered in a manual pump version (MA01HP) and air/hydraulic foot pump (MA01FP) as well as bender less any pump (MA01). Range of dies radius and sizes are offered for the bender: 4” die radius ¾”-1”-1-1 1/8”-1 ¼”tubing & ½”& ¾” pipe, 5” die radius ¾”-7/8”-1”-1- 1/8”-1 ¼” tubing -3/4"pipe, 6” die radius 1 3/8”-1 ½”-1 5/8”-1 ¾” tubing & 1/2" -1" - 1 ¼” -1 ½”pipe, 7” die radius 1 ½”-1 5/8”-1 ¾”-2” tubing, Square tubing set for 3/4"-1" -1 1/4" . Bender requires 6” x 6.5” of bench space. All dies are cast, machined and heat treated. Includes: 4 standard dies included with bender: 5" radius,1" -1 1/4" / 6" radius 1 1/2"-1 3/4" ), “How to” instructional video, “Bend-It” computer software bending program. This tubing bender is unique and no horizontal style bender in the market can compete with this bender for speed, accuracy, and range of bending options.

Tired of pulling on that ratchet arm? No worries. Our hydraulic upgrade kits are easy-to-install; most taking only a couple of minutes! Be sure to call our technical sales team at +1 (813) 986-9000 if you have any questions.

8613371530291

8613371530291