piston hydraulic pump how it works pricelist

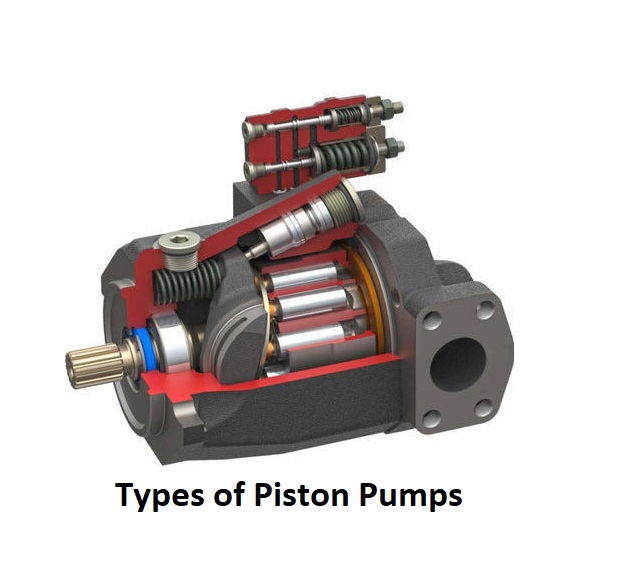

The piston pump is a type of positive displacement pump, wherein said high pressure seal with said reciprocating piston. Piston pumps can be used to transport liquids or compressed gases. They can operate over a wide range of pressures. High pressure operation can be achieved without a strong influence on the flow rate. Piston pumps can also handle viscous media and media containing solid particles. This pump type functions through a piston cup, an oscillating mechanism (where a downward stroke causes a pressure differential), and a filled pump chamber (where an upward stroke forces the pump fluid out for use). Piston pumps are typically used in scenarios where high, consistent pressure is required, as well as in water irrigation or delivery systems.

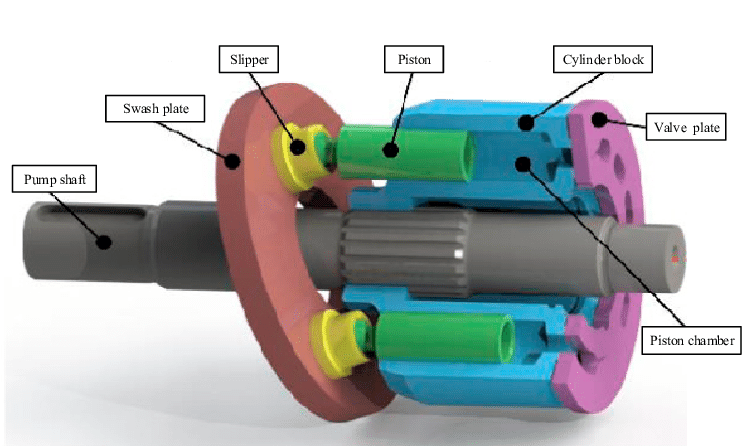

The sliding shoe of the plunger is pressed on the variable head (or swash plate). This way, the plunger moves reciprocally with the rotation of the cylinder to complete the oil absorption and pressure action.

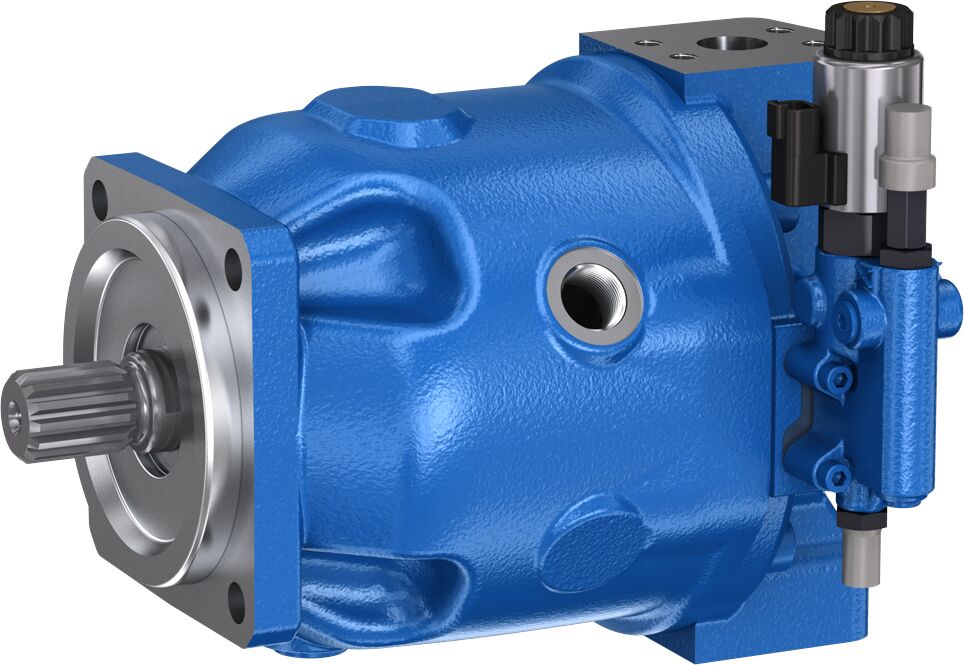

Piston pumps are widely used in machine tools, forging, metallurgy, engineering, mining and other machinery and other hydraulic transmission systems by virtue of their simple structure, small size, high efficiency and strong self-priming ability. ATO offers variable and fixed displacement axial piston pumps with power from 8 hp, 15 hp, 30 hp to 300 hp, with customization support.

The radial piston pump type R consists of valve-controlled pump elements arranged in star form around an eccentric. For large flow rates, up to 42 pump elements can be ...

... axial piston pump type V60N is designed for open circuits in mobile hydraulics and operate according to the swash plate principle. They are available with the option of a thru-shaft for ...

The K3VG series are swash-plate type axial piston pumps which give excellent performance in high flow industrial applications in a compact and cost-effective package.

... Parker’s hydraulic truck pump series F1 featuring high self-priming speed and high efficiency and is one of the leading truck pumps in the market. The F1 pump provide ...

... Piston Pumps provide fixed-displacement power in a unique miniature design. Engineered for open-circuit systems, they bring flexibility to your operation. Compact Piston ...

Parker P2/P3 High Pressure Axial Piston Pumps are variable displacement, swashplate piston pumps designed for operation in open circuit, mobile hydraulic ...

Closed circuit axial piston pumps are used as hydrostatic transmission components in self-propelled machines and for rotary drives in both fixed and mobile equipment of all kinds.

... and very compact for easier and inexpensive installations. Bent Axis pumps-motors will mount directly to virtually any Bezares PTO in our extensive line.

... displacement bent axis piston pumps were developed with spherical head pistons. This provides extremely high performance and high pressure ratings on a long life span unit. Flow rates ...

Sophisticated technology in the smallest space - this is what our Alfra electro-hydraulic pumps stand for. Due to the compact design, the powerful drive units also find room when things ...

Our hydraulic cylinder with a quick coupling has a performance up to 11 tons pressure – with a deadweight of only 2,5 kg. The SKP-1 is compatible with the ALFRA foot pump. Your advantage: Your hands are ...

... our ALFRA hydraulic cylinder SKP-1. In a team with the hydraulic pump DSP-120 it is capable to take a variety of challenges – because the SKP-1 working with a maximum operating pressure ...

... alkitronic hydraulic pumps with electric or pneumatic drive provide fast operating speed, reliability, and safety. They are designed for permanent operation. Our hydraulic ...

With their unique design, PA-PAC pumps offer a robust and durable solution to the high pressure needs of truck applications. Combining the automatic dual direction of rotation, high operating pressure (up to 500 bar peak), ...

Bent axis XPi pumps are specially designed to meet the needs of truck equipment. Their compact design allows a direct flange-mounting on the PTO. All models are of 7 piston design to ...

Lightweight two-speed hand-pump. Low hand force required at max. operating pressure. Pump housing from malleable cast iron, oil reservoir from aluminium. With pressure relief valve, factory set at max. ...

Ideal for powering single-acting cylinders and portable hydraulic tools, the Power Team PA9 series pumps are easier to operate than a hand pump, designed for efficiency. Built to be economical ...

Precision-matched cylinder and pump set for wide range of applications. Four styles of cylinders within the CPS/RPS Series with each set featuring single or two-speed hydraulic hand pumps. ...

The Power Team P-Series hand pumps come in a variety of configurations to meet the requirements of your application. Along with various oil capacities and flow rates, you can choose from the following options:

... time. Stage 1 allows rapid piston travel under no load or light load conditions. The pump automatically switches to stage 2 when the piston is loaded and a higher force is required from ...

Introducing the Axial piston hydraulic pump by Atos are designed for superior pressure application on industrial operation . It features its reduced noise operation capacity having a ...

Like all the pumps of the HP Series, it is suitable for any hydraulic application which require very high hydraulic output pressures and a moderate and controllable oil flow, to ensure ...

Air hydraulic pump, double pneumatic motor, double effect, foot operated with lock-up function, lever distributor valve (4/3), 10L tank, oil flow 8.5 / 0.26 l / min

The HP-AP pump, like all HP Series pumps, can be installed in any hydraulic applications which requires high working pressures and moderate and controllable oil flow. Our HP Series air-hydraulic ...

These pumps consist of pistons, when the pump shaft starts moving, it creates centrifugal force enough to push pistons inside piston housing to create flow.

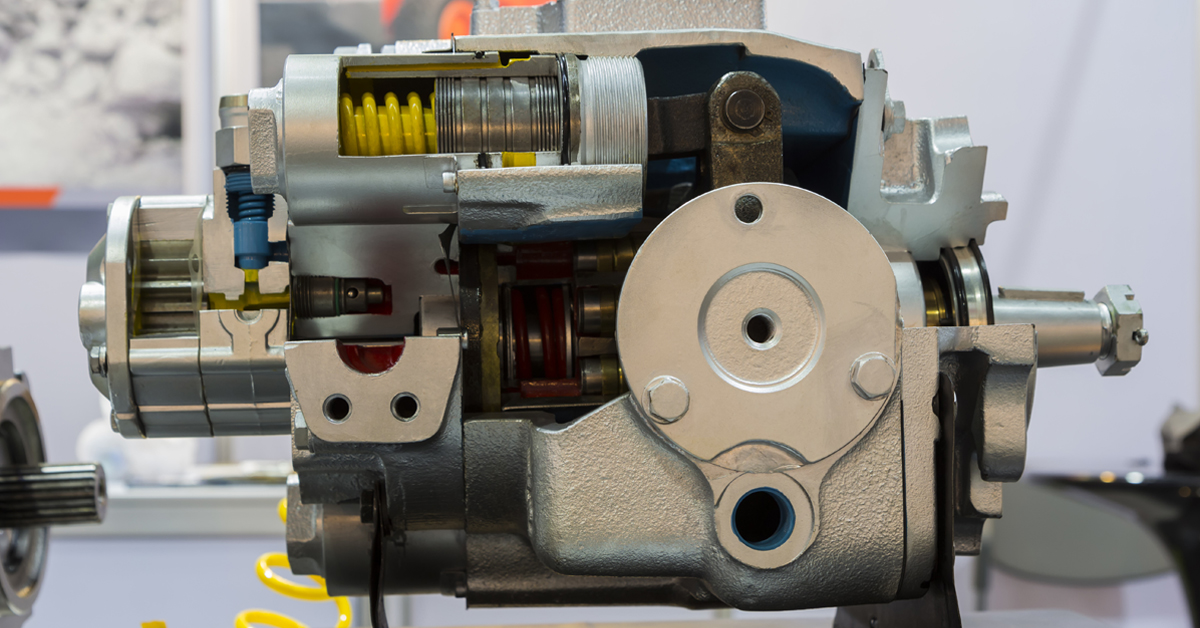

Hydraulic pumps come in different forms to accommodate a range of application requirements, from industrial die presses to heavy-duty off road equipment. One hydraulic system can vary greatly from another. For one system, a hydraulic piston pump may be the best solution, while a hydraulic gear pump may be better suited for a different one.

Powered by a hydraulic drive, a piston pump has a reciprocating positive displacement design to manage fluid flow. Pistons, or cylindrical elements within a cylinder block, create a vacuum, generated by a drive mechanism, that draws in fluid. The cylindrical chamber is pressurised by distributing energy into the fluid, compressing and forcing it towards the pump’s outlet.

Basic designs can generate about 4,000 psi, but pumps with up to 14,500 psi operating pressure are available. There are many different models that can displace a specific amount of fluid. Some allow you to adjust the displacement per revolution, which can make them more energy efficient. Piston pumps are relatively complex in design and expensive, but practical in energy-efficient applications that require high pressures and effective oil flow control.

A hydraulic gear pump is a lower-cost option, but it is quite durable, with many options available. The typical pressure rating is about 3,000 psi, but many displacement sizes and pressures can be found. Some gear pumps are rated as high as 4,500 psi, although additional valves will be needed in systems that require regular flow adjustments.

Gear pumps function by drawing fluid between their meshing gears. The adjacent gear teeth form chambers that are enclosed within the housing and pressure plates. A partial vacuum forms at the inlet where the gear teeth unmesh, allowing fluid to fill the space and be moved along the outer edge of the gears; as the gear teeth mesh again, fluid is forced out of the pump.

Both pumps use hydraulic fluid to transfer energy or generate mechanical force. Hydraulic piston pumps rely on reciprocating motion. Rotational forces are generated along an axis. Fixed and variable displacement pumps are available, as are different types, including axial, inline, bent-axis, plunger, and radial pumps, each with its own unique method of pushing fluid.

On the other hand, gear pumps move fluid via tightly aligned cogs that create suction to draw in and discharge fluid. Pumps with internal or external gears can be used, depending on the application requirements. Lobe, screw, and vane pumps are just some available types. A downside of using gear pumps is that additional devices are needed to control the desired amount of displacement, as they operate on fixed displacement only.

While gear pumps are available in a wide range of displacement sizes and pressures, and they suit various machinery applications, piston pumps offer the benefits of higher pressure ratings and are variable displacement and energy efficient. Rapid cooling means each pump is ready for the next operating cycle and can be serviced soon after shut-off.

Gear pumps typically don’t move more than 50 gallons per minute of fluid. On the other hand, some piston pumps can move hundreds of gallons per minute. Either one has advantages, depending on your hydraulic application.

Hydraulic pumps are available in different types, sizes, pressure ratings, and other specifications. It is important to choose the right pump for your hydraulic system. Gear pumps are suited for various types of machinery. Piston pumps are often found in oil field and agricultural applications, as well as in heavy-duty construction equipment. They are reliable and efficient, and they resist leakage at high speeds and pressures.

White House Products, Ltd. supplies, repairs, and maintains hydraulic gear pumps and hydraulic piston pumps from leading manufacturers. We can assist you in choosing a pump that meets your application requirements. Start browsing our catalog or register/login to view prices/availability and place an order. Contact us at +44 (0)1475 742500 for more information.

Piston pumps are durable and relatively simple devices. A basic piston pump is made up of a piston, a chamber, and two valves. The pump operates by driving the piston down into the chamber, thereby compressing the media inside. In a hand pump, this is usually air. Once the pressure of the air exceeds that of the outlet valve spring, the compressed media goes through the open outlet valve. When the piston is drawn back up, it opens the inlet valve and closes the outlet valve, thereby utilizing suction to draw in new media for compression.

Although somewhat expensive, piston pumps are among the most efficient types of pumps. They have an excellent pressure rating (as high as 10,000 psi), but their design makes them susceptible to contaminants. They provide an excellent solution for many high-pressure hydraulic oil pumping applications.

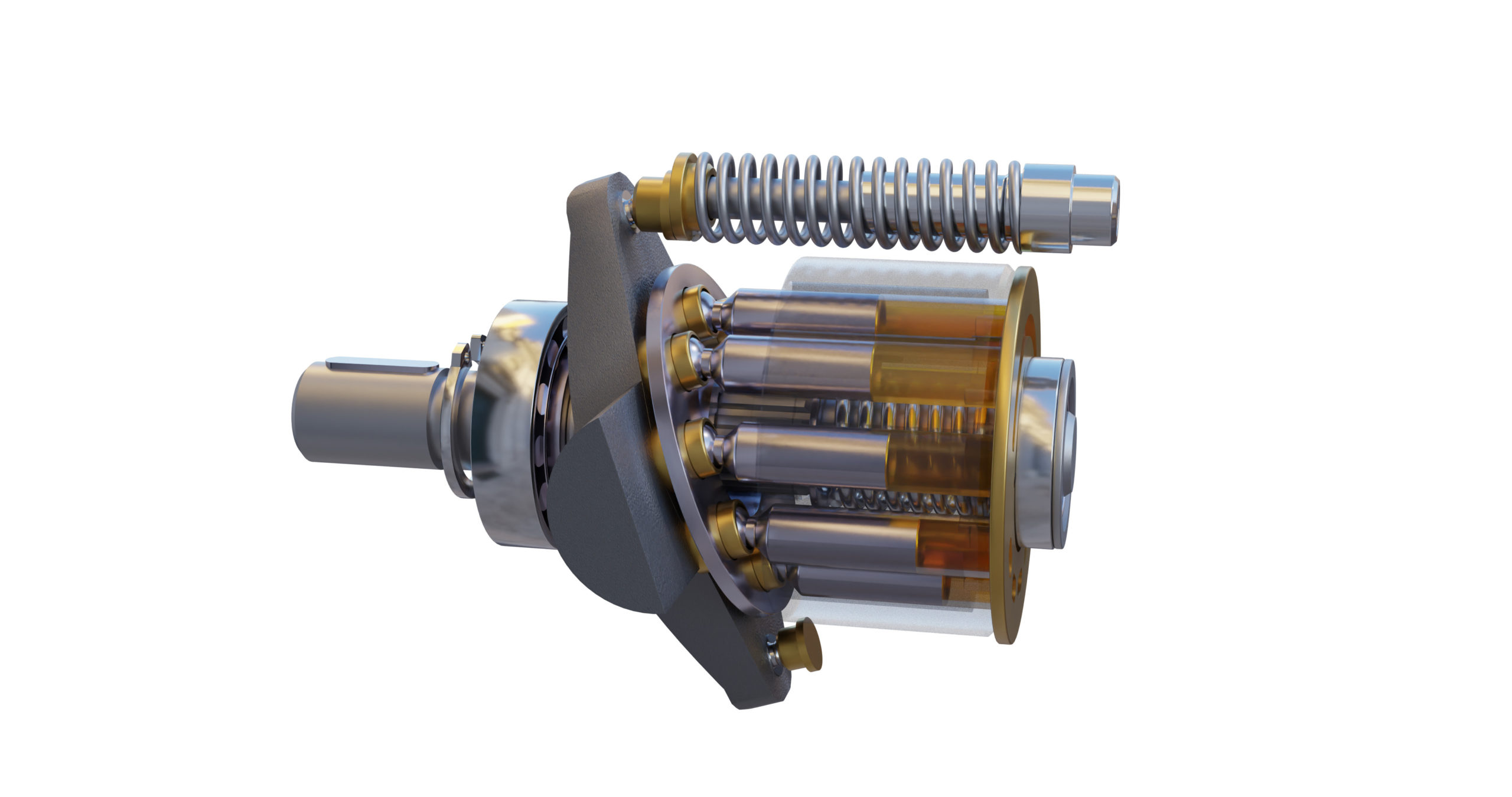

Axial piston pumps are positive displacement pumps that use multiple cylinders grouped around a central axis. The group of cylinders, usually containing an odd number, is called a cylinder block. The pistons within each cylinder are attached to a swashplate. The swashplate is also known as a cam or wobble plate and attaches to a rotating shaft. As the shaft turns, the angle of the swashplate changes, which drives the pistons in and out of their respective cylinders.

Since the swashplate is at an angle to the axis of rotation, the pistons must reciprocate axially as they orbit around the cylinder block axis. The axial motion of the pistons is sinusoidal. As a piston rises, it moves toward the valve plate. At this point in the rotation, the fluid trapped between the buried end of the piston and the valve plate is expelled to the pump"s discharge port through one of the valve plate"s semi-circular ports. As the piston moves back toward the valve plate, the fluid is pushed through the discharge port of the valve plate.

Axial piston pumps can be designed as variable displacement piston pumps, making them very useful for controlling the speeds of hydraulic motors and cylinders. In this design, a swashplate is used to vary the depth to which each piston extends into its cylinder as the pump rotates, affecting the volume of discharge. A pressure compensator piston is used in some designs to maintain a constant discharge pressure under varying loads. Cheaper pressure washers sometimes use fixed-rate designs.

In a typical pressure-compensated pump, the swashplate angle adjusts through the action of a valve using pressure feedback to make sure that the pump output flow is precisely enough to maintain a designated pressure. If the load flow increases, the pressure momentarily decreases, but the pressure-compensation valve senses the decrease and then increases the swashplate angle to increase the pump’s output flow, restoring the desired pressure.

Axial piston pumps can contain most of the necessary circuit controls intrinsically by controlling the swash-plate angle, to regulate flow and pressure. They are very reliable and can allow the rest of the hydraulic system to which they’re attached to be very simple and inexpensive.

They are used to power the hydraulic systems of jet aircrafts, being gear-driven off of the turbine engine"s main shaft, and are often used for automotive air conditioning compressors for cabin cooling. The design of these pumps meets the limited weight and space requirement in the vehicle"s engine bay and reduces vibrations.

Pressure washers also use these pumps, and axial reciprocating motors are used to power many machines. They operate on the same principles as axial piston pumps, except that the circulating fluid is provided under substantial pressure and the piston housing rotates and provides shaft power to another machine. A typical use of an axial reciprocating motor is powering small earthmoving machines such as skid loader machines.

This guide provides a basic understanding of axial piston pumps. To find out more about other types of pumps, read our guide here. For more information on related products, consult our other product guides or visit the Thomas Supplier Discovery Platform to locate potential sources or view details on specific products.

Pumps are mechanical devices used to create fluid flow. There are many different kinds of pumps, from a basic hand pump to vacuum pumps. Many pumps are identified by what they do, for example, boiler feed pumps, pressure washer pumps, and windshield washer pumps, and the intended application is a useful attribute for narrowing down pumps meant for specific applications. This article looks at a particular type of piston pump, the radial piston pump.

Piston pumps are durable and relatively simple devices. A basic piston pump is made up of a piston, a chamber, and two valves. The pump operates by driving the piston down into the chamber, thereby compressing the media inside. In a hydraulic pump, this is some sort of fluid, often water or oil. Once the pressure of the fluid exceeds that of the outlet valve spring, the compressed media goes through the open outlet valve. When the piston is drawn back up, it opens the inlet valve and closes the outlet valve, thereby utilizing suction to draw in new media for compression.

Although somewhat expensive, piston pumps are among the most efficient types of pumps. They have an excellent pressure rating (as high as 10,000 psi), but their design makes them susceptible to contaminants. They provide an excellent solution for many high-pressure hydraulic oil pumping applications. Hydraulic Pumps are any of a class of positive displacement machines used in fluid power applications to provide hydraulic flow to fluid-powered devices such as cylinders, rams, motors, and other devices.

A radial piston pump is a type of hydraulic piston pump. The working pistons extend in a radial direction symmetrically around the shaft, marking the main difference beween them and another piston pump, the axial piston pump, which has axially rotating pistons.

Radial piston pumps arrange a series of pistons radially in a cylindrical block around a rotor hub. The block consists of a pintle, a cylinder barrel with pistons, and a rotor. The pintle directs the fluid in and out of the cylinder. The rotor, mounted eccentrically in the pump housing, forces the pistons in and out of cylinders as it rotates, which cause hydraulic fluid to be sucked into the cylinder cavity and then be discharged from it. Inlets and outlets for the pump are located in a valve in a central hub. Each piston is connected to inlet port when it starts extending while it is connected to the outlet port when start retracting.

An alternative design places inlets and outlets around the perimeter of the pump housing. Radial piston pumps can be purchased as fixed- or variable-displacement models. In the variable-displacement version, the eccentricity of the rotor in the pump housing is altered to decrease or increase the stroke of the pistons.

They have many advantages, such as high efficiency, high-pressure capability up to 1,000 bar or 14000 psi, low flow and pressure ripple, low noise level, very high load at the lowest speed, and high reliability. A disadvantage is that they are bigger than axial pumps, because of the bigger radial dimensions, and so cannot always be used in applications with space constraints.

The hydrostatically balanced parts of radial piston pumps make it possible to use them with various hydraulic fluids such as mineral oil, biodegradable oil, HFC (water-glycol), HFD (synthetic ester), HFA (oil in water), and cutting emulsion. Radial pumps are used for machine tools, such as the displacement of cutting emulsion, and as a supply for hydraulic equipment like cylinders. They are also used in high-pressure units (HPU) for overload protection, and for test rigs.

The automotive sector uses them for automatic transmission and hydraulic suspension control in upper-class cars. Radial piston pumps are also used in plastic- and powder injection molding and wind energy.

This guide provides a basic understanding of radial piston pumps. To find out more about other types of pumps, read our guide here. For more information on related products, consult our other product guides or visit the Thomas Supplier Discovery Platform to locate potential sources or view details on specific products.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A busted piston pump within your company’s hydraulic system is nothing short of frustrating. Instead of stressing about downtime and replacing the entire unit, choose Global Electronic Services. Our technicians ensure quick hydraulic piston repair services to increase your operation’s uptime and keep everything working at a smooth pace.

After understanding the issues your hydraulic pistons are facing, we replace broken, damaged or worn components and repair failed parts as necessary. Once we make crucial repairs and replacements, we test the hydraulic system to ensure it runs at its highest operating level.

While some faults are more accessible to detect than others, our specialists use top-of-the-line tools in combination with their extensive line of experience to recognize a variety of piston pump complications. Delivering fast, effective and efficient piston pump repair services allows us to provide top-quality solutions.

Hydraulic piston pump repairs from Global Electronic Services help you feel confident in your company’s operations. We pinpoint the hydraulic system’s issues and make fast turnaround times to keep you moving.

Competitive pricing: Before we start any repairs, we give you an accurate estimation that’s at least 10 percent better than our competitor’s, so you can get the most value.

Quick turnarounds:Using efficient methods with our years of experience, Global Electronic Services experts can repair your hydraulic piston issues within one to five days. We help ensure your company’s uptime and productivity remain high.

Top-notch repairs:Global Electronic Services offers an 18-month, in-service warranty — giving you peace of mind that you can rely on the equipment. We can tackle any piston faults and other hydraulic concerns.

The first step of repairing your hydraulic piston pump is disassembly. We take apart the axial piston pump for inspection and measurement, recording the dimensions of each part. Once we look through the entire unit and determine its issues, we prepare a quotation to give you an idea of what to expect.

When we get the go-ahead to move on with our repairs, we start by cleaning the unit. We lap the rotary parts and end cover, then make sure the bearing and shaft fit. Our technicians also ensure the pump’s play is within tolerance.

We make the appropriate repairs and replacements of critical parts, then reinstall the rotary components. After we complete the entire process, our specialists test the hydraulic piston pump. If it’s working at peak levels, we calibrate it, then send it off to painting and finishing. If it’s still not up to par, we go back and make corrections.

Repairing and replacing these essential hydraulic piston pump parts is a more economical solution than replacing the entire unit. Although the source of a pump’s failure can come from a multitude of sources, many fall into a few areas, such as:

In many cases, wear and tear cause problems. However, excessive heat, cavitation, extreme pressure and contamination can also cause premature failure of your piston pump. Another reason for failure is from incorrect installation — all of which we can fix on the spot.

We use sophisticated software, digital controls and integrated electronics to restore your company’s piston pumps. Global Electronics Services works with the increasing complexity of hydraulic systems. Our technicians can inspect, repair, test and calibrate a range of piston pump issues.

Global Electronic Services can answer any questions you have about hydraulic piston pumps as well as our services. Here are some commonly asked questions about piston pump repair and maintenance:

Check to make sure the piston pump hasn’t lost grease lubrication in the plunger slot. A contaminated environment and water hitting the pump can also cause it to be noisy. Even inlet plumbing that results in air leaks can create a loud noise.

Hydraulic pump upkeep depends on your company’s application, so check the unit’s manual to see how long specific parts can last before needing replacement. Regular and preventative maintenance can help increase the lifespan of the pump and decrease massive overhauls down the road.

Like all parts, a cam bearing will wear over time. It can damage from a lack of lubrication, excessive pressure or overuse. Through a preventative upkeep schedule, you can catch these wear and tear issues ahead of time to keep your bearing from failing.

Many factors can cause a hydraulic piston pump to pulse. For example, abnormal inlet conditions, fixed outlet plumbing and an undersized bypass hose can contribute to the fault. Other reasons can include a non-working regulating valve or stuck/damaged pump valves.

Global Electronic Services is your go-to for hydraulic and pneumatic maintenance service and repair. We offer superior solutions at competitive prices to ensure you receive valuable and dependable repairs.

Receive a free quote online or call us at 877-249-1701 to see how we can support your company. Our experts can handle whatever’s going on with your hydraulic piston pump unit to maximize uptime.

Afghanistan Albania Algeria American Samoa Andorra Angola Anguilla Antarctica Antigua and Barbuda Argentina Armenia Aruba Australia Austria Azerbaijan Bahamas Bahrain Bangladesh Barbados Belarus Belgium Belize Benin Bermuda Bhutan Bolivia (Plurinational State of) Bonaire, Sint Eustatius and Saba Bosnia and Herzegovina Botswana Bouvet Island Brazil British Indian Ocean Territory Brunei Darussalam Bulgaria Burkina Faso Burundi Cabo Verde Cambodia Cameroon Canada Cayman Islands Central African Republic Chad Chile China Christmas Island Cocos (Keeling) Islands Colombia Comoros Congo Congo (the Democratic Republic of the) Cook Islands Costa Rica Cote d"Ivoire Croatia Cuba Curaçao Cyprus Czech Republic Denmark Djibouti Dominica Dominican Republic Ecuador Egypt El Salvador Equatorial Guinea Eritrea Estonia Ethiopia Falkland Islands (Malvinas) Faroe Islands Fiji Finland France French Guiana French Polynesia French Southern Territories Gabon Gambia Georgia Germany Ghana Gibraltar Greece Greenland Grenada Guadeloupe Guam Guatemala Guernsey Guinea Guinea-Bissau Guyana Haiti Heard Island and Mc Donald Islands Honduras Hong Kong Hungary IX Iceland India Indonesia Iran (Islamic Republic of) Iraq Ireland Isle of Man Israel Italy Jamaica Japan Jersey Jordan Kazakhstan Kenya Kiribati Korea, Democratic People"s Republic of Korea, Republic of Kuwait Kyrgyzstan Lao People"s Democratic Republic Latvia Lebanon Lesotho Liberia Libyan Arab Jamahiriya Liechtenstein Lithuania Luxembourg Macao Macedonia (the former Yugoslav Republic of) Madagascar Malawi Malaysia Maldives Mali Malta Marshall Islands Martinique Mauritania Mauritius Mayotte Mexico Micronesia (Federated States of) Moldova (the Republic of) Monaco Mongolia Montenegro Montserrat Morocco Mozambique Myanmar Namibia Nauru Nepal Netherlands New Caledonia New Zealand Nicaragua Niger Nigeria Niue Norfolk Island Northern Mariana Islands Norway Oman Pakistan Palau Palestine, State of Panama Papua New Guinea Paraguay Peru Philippines Pitcairn Poland Portugal Puerto Rico Qatar Romania Russian Federation Rwanda Réunion Saint Helena, Ascension and Tristan da Cunha Saint Kitts and Nevis Saint Lucia Saint Martin (French part) Saint Vincent and the Grenadines Saint-Barthélemy Samoa San Marino Sao Tome and Principe Saudi Arabia Senegal Serbia Seychelles Sierra Leone Singapore Sint Maarten (Dutch part) Slovakia (Slovak Republic) Slovenia Solomon Islands Somalia South Africa South Georgia and the South Sandwich Islands South Sudan Spain Sri Lanka St. Pierre and Miquelon Sudan Suriname Svalbard and Jan Mayen Islands Swaziland Sweden Switzerland Syrian Arab Republic Taiwan Tajikistan Tanzania, United Republic of Thailand Timor-Leste Togo Tokelau Tonga Trinidad and Tobago Tunisia Turkey Turkmenistan Turks and Caicos Islands Tuvalu Uganda Ukraine United Arab Emirates United Kingdom United States Minor Outlying Islands United States of America Uruguay Uzbekistan Vanuatu Vatican City State (Holy See) Venezuela (Bolivarian Republic of) Viet Nam Virgin Islands (British) Virgin Islands (U.S.) Wallis and Futuna Islands Western Sahara Yemen Zambia Zimbabwe Åland Islands

The Sprague pump develops high output pressures by applying the principle of differential areas. The pump has a large area air piston, air driven at low pressures. This air piston drives a small area liquid piston that in turn pumps liquids at high pressures.

The liquid output pressure is determined by the ratio between the area of the air drive piston, the area of the liquid driven piston and the applied operating air pressure.

The area relationship of the air piston to the liquid piston is referred to as the pump ratio. This pump ratio is indicated in the dash number which follows the pump model basic number.

In operation, an S-216-J-10 pump using 100 psi of input air pressure will produce a maximum liquid output pressure of 1000 psi; 80 psi air will produce an output pressure of 800 psi; 60 psi air . . . 600 psi output, and 40 psi air . . . 400 psi output.

Piston pumps and plunger pumps use a mechanism (typically rotational) to create a reciprocating motion along an axis, which then builds pressure in a cylinder or working barrel to force gas or fluid through the pump. The pressure in the chamber actuates the valves at both the suction and discharge points.

An axial piston pump is a positive displacement pump that has a number of pistons in a circular array within a cylinder block. It can be used as a stand-alone pump, a hydraulic motor, or an automotive air conditioning compressor.

Piston sprayers include a cylinder housing in which, when pumping, a piston moves up and down to create pressure. They are best used for distance as they generate more pressure. The increased pressure also creates finer droplets or a mist that covers well.

A hydraulic pump is a machine that uses the power of fluid to move objects. The first pumps were invented in the seventeenth century, and they were mainly used for irrigation. Over time, however, hydraulic pumps have been used for a variety of other purposes, including mining, manufacturing, and moving objects.

A hydraulic pump is a machine that uses the pressure of fluids to move things. It works by using a piston and cylinder assembly to push and pull fluid through a series of tubes. The force of the fluid moving through the tubes creates a mechanical force that can be used to do work. There are two main types of hydraulic pumps: reciprocating and impeller. A reciprocating pump has a piston that moves back and forth inside the cylinder. The force created by this motion is used to push or pull fluid through the system. An impeller is a spinning cylinder, and it can be used as a reciprocating pump or as an aerator. The main components of a hydraulic pump are pistons, cylinders, valves, and pipes. They are all connected together in order to create a system that can move fluids. A piston is a cylinder that contains one or more chambers. The air inside these chambers can be compressed, and it is able to push the fluid up through an inlet port. The piston has a rod attached to it, and this rod connects to the cylinder head on its side. The cylinder head is the end of the cylinder that contains one or more pistons. The piston is used to push the fluid up through a port. It can also be used to pull fluid down from an outlet port. In order to use pistons, all of the needed components must be connected together. The cylinder head is usually connected to a valve, which can open and close the port where the fluid can go in or out.

A hydraulic pump is a machine used to move fluid. They are incredibly important in many industries and can be found in everything from cars to the military. They work by using the pressure of water or other fluids to push objects or materials around. This can be incredibly useful for things like moving oil around or filling up containers.

The main reason hydraulic pumps are so important is that they are incredibly versatile. They can be used for a variety of purposes, which means that they are often perfect for certain jobs. For example, a hydraulic pump can be used to move something heavy around, which is perfect for things like construction sites or factories.

Furthermore, hydraulic pumps are reliable machines. This means that they are often able to work even when there is some sort of problem with them. This makes them ideal for use in critical areas, such as the military or automotive industries.

Hydraulic pumps are machines that use hydraulic fluid to move objects or fluids. They come in a variety of types, each with its own advantages and disadvantages. Here is a brief introduction to five of the most common types of hydraulic pumps:

Motor-driven pumps are the most common type of pump. They use a motor to power a screw or gear that is connected to a piston in the cylinder of the pump. A small amount of fluid is pumped by the motor and this creates a vacuum that draws more fluid through the system.

Gear pumps use gears, cams, and a series of springs to move fluid. Gear pumps can be made to pump more fluid at a faster rate than motor-driven pumps.

Piston pumps are similar in operation to gear pumps. reciprocating pumps use pistons to move fluid. The most common type of reciprocating pump is the diaphragm pump. This type of pump has a piston and a diaphragm that moves up and down within the cylinder.

Siphon Pumps are typically used in potable water applications, such as sewage pumping. They can also be found in oil field operations and other industrial settings where a pump is needed to move liquids or gases. They are also commonly called “gravity pumps” because they operate in a very similar way to the movement of a siphon. Their operation is as follows: As fluid flows through the pump by gravity, a centrifugal force is generated and pushes the fluid out of the pump. Because the pump does not have a rotating shaft, the flow of fluid is not possible. Instead, the fluid flows around a circular chamber that causes the fluid to be pushed off at an angle from the axis. The fluid then moves out of the chamber and into a channel that connects to the system it is being used in. The fluid than either enters a reservoir or flows back into the pump. This process is called flow reversal.

Rotary pump: The rotary pump is similar to the piston pump, but it uses a rotating disk to move the fluid inside a cylinder. This type of pump is faster than the piston pump, but it requires more power (and thus costs more) to operate.

Pump designs can be classified by the size of the pump and its application. Pumps can be based on the movement of a piston or gears, or they may use a combination of these two methods. A rotary pump is a type of reciprocating pump that uses a rotating shaft to move the piston. The shaft can be designed to rotate in either direction, or it will rotate in only one direction. There are two ways to classify pumps by the size of the volume they can move. The first classification is based on the size of the piston, which determines how much fluid a single pump stroke will draw in or out. The second classification is based on the size of the pump chamber and how much fluid it can hold. A pump designed to move a small amount of fluid will have a small diameter piston. A pump designed to move large amounts of fluid will have a larger diameter piston and therefore a larger volume. The volume of the pump chamber is determined by the number of pumps that can be fitted into a space. The space between each of these pumps can be filled with either liquid or gas as an alternate way to move fluid. Pumps are used in a wide range of applications, from simple low-volume pumps to large-volume high-pressure pumps. Pumps are also used in the chemical, food, and beverage industries as a way to move fluids or chemicals.

Hydraulic pumps are an important part of modern industrial and commercial life. They are used in a wide range of applications, from water pumping to hydraulic power generation. The future of hydraulic pumps is bright, with many potential applications waiting to be developed. Here are 4 examples:

Hydraulic pumps could become increasingly important in the automotive industry as engines become more efficient and fuel prices continue to rise. Hydraulic pumps could also be used in larger vehicles, such as trucks and buses, to provide extra power or increase the capacity of the engine.

Hydraulic pumps could be used more often in construction and engineering projects, where they would be useful for tasks such as lifting heavy objects or moving large amounts of water or other fluid substances.

Hydraulic pumps could be used to generate electricity by using pressurized steam or water to turn turbines, like those found in power plants and factories.

A plunger pump operates using the reciprocating motion of plungers or pistons. Depending on the design of the pump, the use of a single or multiple plungers may be used.

Action 1: The plunger or piston is pulled back. The action increases the volume of the cavity. As the cavity volume expands, fluid is drawn in through the inlet to fill the expanding cavity.

Action 2: The piston has reached it’s maximum displacement. Since it is not moving into or out of the cavity, fluid is not flowing through the inlet or the outlet.

Action 3: After reaching it’s maximum position, it is then pushed back into the cavity. During this process, the piston applies enough pressure to the fluid to overcome the pressure in the outlet of the pump. This pressure differential pushes the fluid from inside the cavity through the outlet of the pump.

Action 4: The piston reaches its maximum extension into the cavity. Here the volume of the cavity is at a minimum and fluid is not flowing through the inlet or the outlet. The next action repeats the process, starting again with action 1.

All these parts have the basic functionality of moving the liquid inside the cylinder. The piston is a lubricated sliding shaft that moves inside the cylinder and pushes the liquid in a forward and backward motion, creating a cavity and a high volume pressure at the outlet. In a diaphragm pump, the diaphragm is used to avoid leaking of the liquid since it completely seals the liquid to penetrate outside, and hence they are especially useful when the liquids are dangerous or toxic. In a plunger pump, there is a high-pressure seal that is stationary and a smooth cylindrical plunger slides through the seal.

Crank and Connecting rod: Crank is a circular disk attached to the motor and used to transfer the rotary motion of the motor to the piston. Piston, in turn, moves in a reciprocating motion with help of a connecting rod.

Reciprocating pumps are different from Centrifugal pumps on basis of its working, features, applications etc. The main difference is that Impellers are used in Centrifugal pumps whereas in reciprocating pumps piston is used to move the liquid. Centrifugal pumps continuously discharge the liquid, unlike reciprocating pumps. They are used for high viscous fluid and are lighter in weight, less expensive as compared to reciprocating pumps.

The basic Quality standards of reciprocating pumps include ISO13710, API (American Petroleum Institute) standard 674, API standard 675 “Positive Displacement Pumps- Reciprocating” and Reciprocating Pump Standards, Hydraulic Institute.

High Pressure, Low Flow Applications: Reciprocating pumps are generally designed to pump in low flow, high head applications. One of the most extreme of these applications is water jet cutting, where only a few gallons pass through the pump per minute but exceed pressures of 10,000 PSI.

Proven, Common Technology: Reciprocating pumps are one of the oldest, most proven pump types. Today, a wide variety of reciprocating pumps can be found in many different materials, types, and sizes. Reciprocating pumps range from less than 1 horsepower to over 3,000 horsepower.

Durability: Reciprocating pumps are used in some of the most abrasive and corrosive applications. Fluid ends and fluid end parts can be made of many different materials such as stainless steel, aluminum bronze, tungsten carbide, ceramic, and more. A wide selection of valve types is used in abrasive applications such as pumping cement, sand slurry, mud, etc.

Efficiency: Reciprocating pumps operate at high a higher efficiency compared to other pump designs. In most cases, at any setpoint, reciprocating pumps operate around 90%.

There are several performance indicators of a reciprocating pump which determine how effectively it works. Following are some of the key performance indicators:

High Maintenance / Short Life:The main disadvantage of a reciprocating pump is high maintenance and short life. There are many parts in the pump works, all constantly changing directions. Unless careful maintenance takes place, the lifespan of the pump is greatly reduced. While pumps such as centrifugal pumps can last 15 to 20 years with little maintenance, a reciprocating pump requires higher levels of attention and rebuilding several times within the same time frame. The cost of a reciprocating pump rebuild is usually inexpensive which still makes them cost-competitive compared to longer-lasting, higher-priced pump designs.

Pulsations:A characteristic of reciprocating pumps is the production of pressure pulsations through the pump inlet and outlets. The reciprocating motion of the pump produces these pulsations. Increasing the number of pump chambers can greatly reduce the pulsations produced, but it does not remove them completely. To negate damage to piping and surrounding systems or the pump itself, pulsation dampeners must be installed. Further system design can further decrease pulsations to nearly zero. In all cases, overall system design is important when using reciprocating pumps.

Plunger pumps come in a variety of styles, shapes, and sizes. The specific type of pump chosen for an application takes into account the pressures encountered, the flow rates needed, measurement and control systems, fluid viscosity and corrosivity, pipe material, etc. Careful attention should be given to the application before selecting a pump. Selecting the wrong pump for a job can result in damage to equipment, piping, systems, and possibly endanger personnel.

Simplex, Duplex, Triplex, Quintuplex Pumps: Many reciprocating type pumps are simplex(one), duplex (two), or triplex (three) cylinder. Duplex pumps are usually used where the two pumps can be used alternatively. Such pumps are commonly used in oil-line pumping, mine de-watering, and chemical and petroleum products transfer, but has many more applications. A triplex pump consists of three plungers, with the aim of reducing the pulsation of a single reciprocating pump. Quintuplex pumps are designed with a gear case that assists in a high-pressure task. Common applications of which are in cement slurries, sand-laden fluids, crude oil, acids, mud, and other oil well-servicing fluids. Well known manufacturers for these types of pumps are National, Gardner Denver, FMC, SPM, Oilwell, Kerr, Union, Gaso, Emsco, Aplex, and Wheatley.

Metering Pumps: A metering pump is usually used where the rate of flow of the liquid needs to be adjusted in a specific time period. Most of the metering pumps are piston-driven and are called Piston pumps. Piston pumps can pump at a constant flow rate against any kind of discharge pressure. Both Piston pumps and Plunger pumps are reciprocating positive displacement pumps that use a plunger or piston to move fluid/substance through a cylindrical chamber. Manufacturers such as

Reciprocating Pumps can also be classified according to the number of cylinders: Single cylinder and double cylinder pump. They are also sometimes classified according to their operation, known as simple hand-operated reciprocating pump & power-operated deep well reciprocating pump.

Reciprocating positive displacement pumps are highly effective, where a high degree of accuracy and reliability under different ranges of conditions that are required. Reciprocating pumps with very high efficiency are often available in a wide range of hydraulic, mechanical, and material options. They are widely used across industries such as chemical, petrochemical, refinery, pharmaceutical, cosmetic and water treatment. Typically, these types of pumps are used for applications such as Salt Water Disposal, Well Services, Descaling, Hydraulic Fracturing, and Oil & Gas Pipelines. All types of reciprocating pumps are easily available in the market to meet the diverse demands, as per different processes and applications. Piston pumps are widely used in applications such as Energy Recovery, Steam Recovery and hazardous area pumping and are available with manufacturers such as

Diaphragm Pumps are commonly used for Sludge Transfer, Acid Pumping, and Chemical Fluid Transfer and are easily available with manufacturers such as Wilden, Sandpiper, ARO, Roughneck, and Graco.

All the mentioned manufacturers in this article, offering various kinds of pumps hold a good reputation with respect to quality, price, revenue (value), and market share and are preferred by many consumers. However, a thorough check of all its features, specific to your process application, should be ideally done to buy the most suitable reciprocating pump, which can be used for a longer period of time requiring low maintenance, ease of operation, and easy availability of its spare parts.

Reciprocating pump terms are based on how the fluid is pumped (action) and the number of plungers or pistons (arrangement). For example, a Union TX-200 is a “single-acting triplex plunger pump”, a Gaso 1849 is a “double-acting duplex plunger pump”, and an Oilwell B-558 is a “single-acting quintuplex plunger pump”.

For further information on selecting the right Kawasaki Pumps for your needs, or to request a quotation, please contact us by phone or email and we’ll be pleased to assist.

We are a leading UK distributor of medium/high pressure axial piston pumps manufactured by Kawasaki Precision Machinery (UK) Ltd. Our most popular model, the medium-high pressureK3VL, has been developed for the global mobile and industrial markets.

Kawasaki offer ranges of pumps from 22.5 to 560cc/rev at pressure up to 400 bar with manual, pilot operated, solenoid operated and proportional control options.

8613371530291

8613371530291