piston hydraulic pump how it works for sale

Hydraulic piston pumps move fluids throughout professional equipment and industrial machinery. They’re known for their high efficiency and are commonly used in high-pressure applications.

There are also two major types of hydraulic piston pumps: axial and radial; both can have fixed or variable displacement; fixed displacement means that the pump is delivering the same amount of liquid or gas each time, while variable means that the amount of gas or liquid delivered may be different each time. Although both are considered piston pumps, each one operates differently.

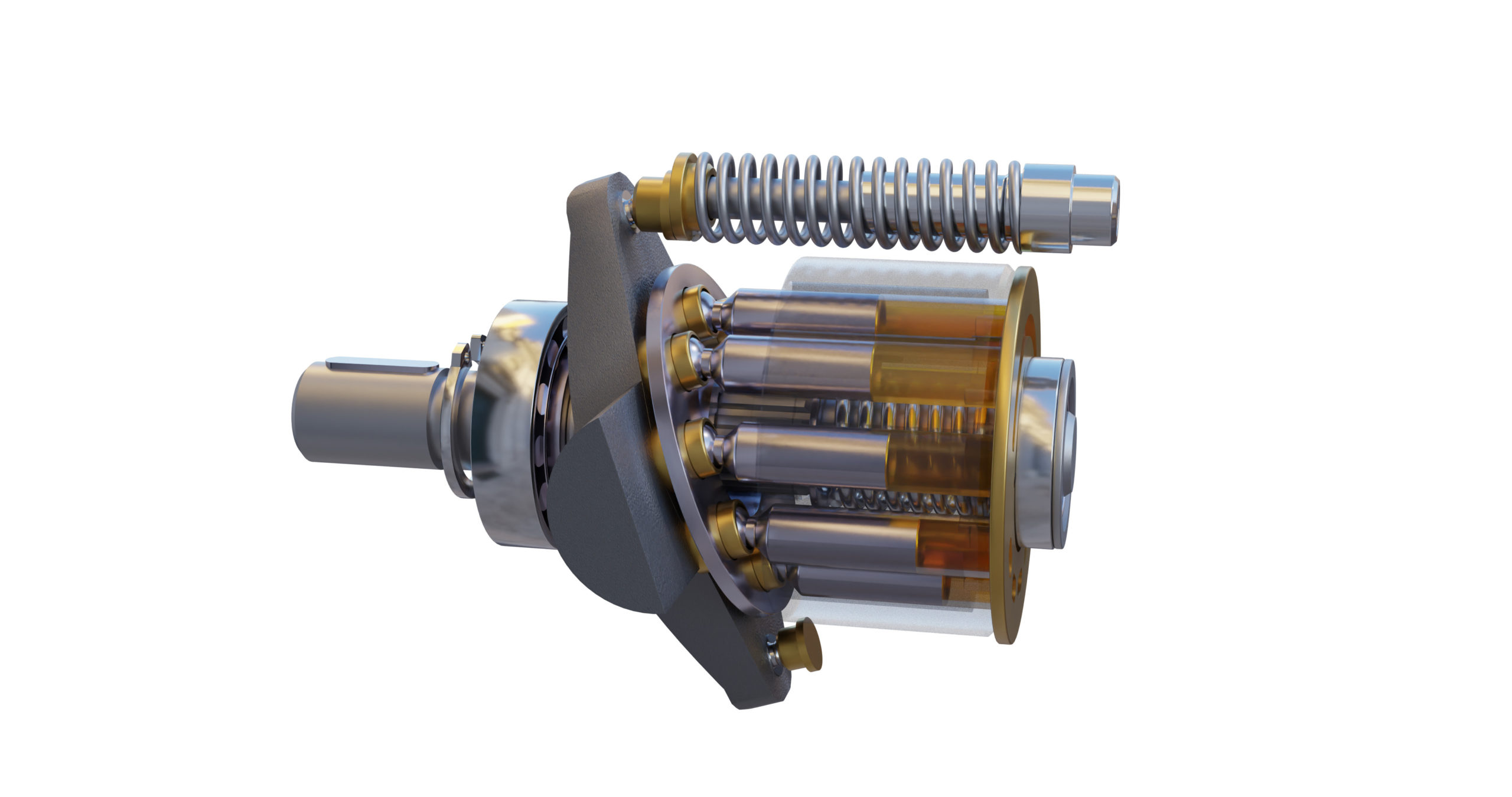

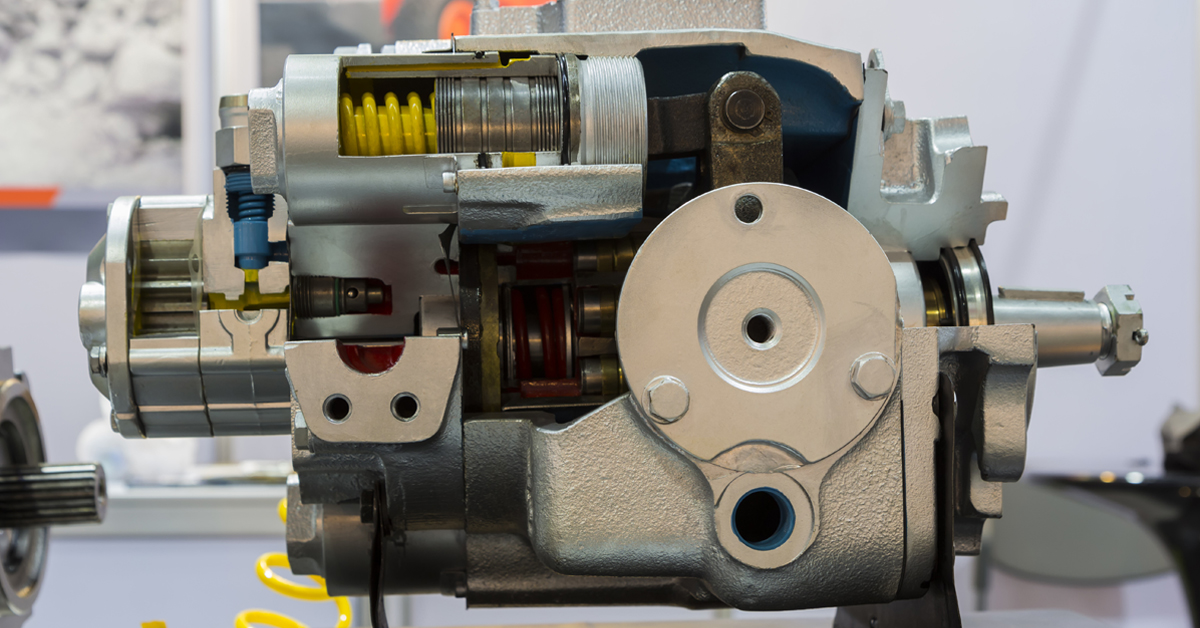

An axial piston pump features four major components: a shaft, swashplate or bent axis, cylinder block, and valve plate. The cylinder block houses the piston pumps, which are laid out cyclically around the drive shaft’s axis (thus why it is named anaxialpiston pump).

The pistons in the cylinder block pump up and down as the drive shaft rotates. The piston’s stroke will vary depending on how it is angled in the swashplate or bent axis. As the pistons move in one direction, they are connected to a suction line, and when they move in the opposite direction, they connect to a discharge channel, allowing a continuous flow of fluid.

The design of a radial piston pump is significantly different from an axial pump. The radial piston pump consists of a cylinder block, rotating camshaft, and pistons. The pistons are arranged around the cylinder block in a radial pattern and diverge from the camshaft like rays. The rotation of the cam causes the pistons to change from suction to discharge and vice versa.

In general, choosing a hydraulic pump requires an application evaluation. You’ll need to know pressure requirements, desired flow rate, speed, horsepower, and the type of fluid the pump will be dispersing.

Radial piston pumps can usually handle all fluids, including mineral oil and water-glycol hydraulic fluid, while axial piston pumps are preferred for extremely high-pressure applications.

Although piston pumps are highly efficient and reliable, contamination, over-pressurization, and inlet blockages can cause the pump to fail. If and when this happens, you’ll need to replace your pump as soon as possible.

When choosing a replacement pump, you’ll have to choose between a direct OEM replacement and a remanufactured pump. Unfortunately, direct OEM replacement pumps and services can be a significant investment. Additionally, if you have outdated equipment, you may not be able to find thepump partsneeded to restore your equipment.

If you’re looking for a quick and relatively inexpensive solution, a remanufactured pump is your best choice. However, if time and money aren’t an issue, a direct OEM replacement will most likely be the best option if the manufacturer hasn’t discontinued the pump.

Do you need help finding the right piston pump? Turn to Panagon Systems. Founded over 25 years ago, we’re an industry-leading remanufacturer of hydraulic piston pumps and motors. We specialize in remanufacturing pumps from brands like Vickers/Eaton, Rexroth, and Caterpillar, and we also carry. All pumps and motors are remanufactured in-house in the United States, guaranteed to meet OEM specifications, and are backed by a one-year warranty.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Piston pumps for spray applications, irrigation, injection, variable metering work scenarios involving water, chemicals and mixtures. Piston pumps are positive displacement pumps that use a sealed chamber and cylinder strokes in repetition to generate pressure and fluid flow. They allow constant applications rates regardless of temperature, and are designed for easy, set-point adjustment of operation specs. The piston pump type has a wide range of use within residential, commercial, agricultural and industrial setting applications involving viscous and non viscous fluids. They are compatible and commonly used with agriculture chemicals, drilling and fracking fluids, manufacturing materials, oils, lubricants and paints as well as food and beverage industry ingredients. Piston pumps are also used for industrial cleaning, water jet machining, hydraulic and coolant supply systems. Piston pumps can provide a pulsating flow rate, sometimes undesired, but makes them good choices for crop field size sprinkler systems.

We provide John Blue single rate ground drive piston pumps, double rate ground drive and hydraulic drive piston pump models. Double rate pistons allow for pumping two products at different rates with a single pump. Available piston pumps are engineered for installation in pulley, belt, direct drive flexible shaft or hollow shaft systems. Standard model piston pumps are built using heavy duty cast iron metal fitted with chemically durable, synthetic o-rings and rod packings made from Buna-N and Viton. Available piston pumps for sale offer max flow rate capacities from 10 GPM to 68 GPM. Maximum pressure output ratings range up to 120 PSI. Inlet and outlet plumbing size hookups for available piston pumps range from 1” up to 2” NPT.

Hydraulic pumps come in different forms to accommodate a range of application requirements, from industrial die presses to heavy-duty off road equipment. One hydraulic system can vary greatly from another. For one system, a hydraulic piston pump may be the best solution, while a hydraulic gear pump may be better suited for a different one.

Powered by a hydraulic drive, a piston pump has a reciprocating positive displacement design to manage fluid flow. Pistons, or cylindrical elements within a cylinder block, create a vacuum, generated by a drive mechanism, that draws in fluid. The cylindrical chamber is pressurised by distributing energy into the fluid, compressing and forcing it towards the pump’s outlet.

Basic designs can generate about 4,000 psi, but pumps with up to 14,500 psi operating pressure are available. There are many different models that can displace a specific amount of fluid. Some allow you to adjust the displacement per revolution, which can make them more energy efficient. Piston pumps are relatively complex in design and expensive, but practical in energy-efficient applications that require high pressures and effective oil flow control.

A hydraulic gear pump is a lower-cost option, but it is quite durable, with many options available. The typical pressure rating is about 3,000 psi, but many displacement sizes and pressures can be found. Some gear pumps are rated as high as 4,500 psi, although additional valves will be needed in systems that require regular flow adjustments.

Gear pumps function by drawing fluid between their meshing gears. The adjacent gear teeth form chambers that are enclosed within the housing and pressure plates. A partial vacuum forms at the inlet where the gear teeth unmesh, allowing fluid to fill the space and be moved along the outer edge of the gears; as the gear teeth mesh again, fluid is forced out of the pump.

Both pumps use hydraulic fluid to transfer energy or generate mechanical force. Hydraulic piston pumps rely on reciprocating motion. Rotational forces are generated along an axis. Fixed and variable displacement pumps are available, as are different types, including axial, inline, bent-axis, plunger, and radial pumps, each with its own unique method of pushing fluid.

On the other hand, gear pumps move fluid via tightly aligned cogs that create suction to draw in and discharge fluid. Pumps with internal or external gears can be used, depending on the application requirements. Lobe, screw, and vane pumps are just some available types. A downside of using gear pumps is that additional devices are needed to control the desired amount of displacement, as they operate on fixed displacement only.

While gear pumps are available in a wide range of displacement sizes and pressures, and they suit various machinery applications, piston pumps offer the benefits of higher pressure ratings and are variable displacement and energy efficient. Rapid cooling means each pump is ready for the next operating cycle and can be serviced soon after shut-off.

Gear pumps typically don’t move more than 50 gallons per minute of fluid. On the other hand, some piston pumps can move hundreds of gallons per minute. Either one has advantages, depending on your hydraulic application.

Hydraulic pumps are available in different types, sizes, pressure ratings, and other specifications. It is important to choose the right pump for your hydraulic system. Gear pumps are suited for various types of machinery. Piston pumps are often found in oil field and agricultural applications, as well as in heavy-duty construction equipment. They are reliable and efficient, and they resist leakage at high speeds and pressures.

White House Products, Ltd. supplies, repairs, and maintains hydraulic gear pumps and hydraulic piston pumps from leading manufacturers. We can assist you in choosing a pump that meets your application requirements. Start browsing our catalog or register/login to view prices/availability and place an order. Contact us at +44 (0)1475 742500 for more information.

Hydraulic piston pumps can handle large flows at high hydraulic system pressures. The piston pump is a hydraulic pump that delivers optimum efficiency and reliability while maintaining a compact size with a high power density. In these pumps, the pistons accurately slide back and forth inside the cylinders that are part of the hydraulic pump. The sealing properties of the pistons are excellent which makes it possible to operate at high pressures with low fluid leakage.

Hydraulic piston pumps operate at very high volumetric efficiency levels due to low fluid leakage. The plungers may consist of valves at the suction and pressure ports or with input and output channels. Piston pumps with valves at the ports are better suited to operate at higher system pressures due to better sealing characteristics. Applications are mobile and construction equipment, marine auxiliary power, metal forming and stamping, machine tools and oil field equipment.

Hydraulic pumps are manufactured depending on different functional and hydraulic system requirements, such as operating medium, required range of pressure, type of drive, etc. Our sales engineers will assist you in selecting the most appropriate hydraulic pump for your application. Contact DTA for your hydraulic pump needs today!

In an axial-piston pump, the pistons and cylinder rotate around the center, longitudinal axis. The pistons and shoes move in and out of the cylinder because they are sliding upon a stationary, variable angle, swashblock.

As the pistons rotate, they alternate between being connected to an inlet port and an outlet port. As the pistons pass over the inlet port, they suck fluid into the piston chamber. As they move over the outlet port, they expel fluid from the piston chamber.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

Quiet operation, high efficiency and compact design — all available at a competitive price. That’s what Oilgear PVWC closed-loop, hydrostatic axial-piston hydraulic pumps bring to the table. All designed around our proven rotating group.

Quiet operation, high efficiency and compact design — all available at a competitive price. That’s what Oilgear PVWC closed-loop, hydrostatic axial-piston hydraulic pumps bring to the table. All designed around our proven rotating group.

Quiet operation, high efficiency and compact design — all available at a competitive price. That’s what Oilgear PVWC closed-loop, hydrostatic axial-piston hydraulic pumps bring to the table. All designed around our proven rotating group.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids—and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Extremely effective across numerous industrial applications that require quick response in extreme environments, the XD5 series of pumps offer lightning-fast control response on both low-viscosity fluids and standard hydraulic oil. Engineered to handle the most challenging environments, they have been designed to be a high-performance solution for demanding mobile applications.

Hydraulic pumps are manufactured in a broad range of types, and among these is the hydraulic piston pump. So, what exactly is a hydraulic pump? Hydraulic piston pumps convert rotational power to hydraulic power. These pumps contain pistons cylindrical elements installed inside a cylinder block/barrel. Their motion while in operation creates a vacuum, drawing the fluid into the cylinder. The fluid is then compressed and directed to the pump outlet.

Hydraulic pumps are manufactured in a broad range of types, and among these is the hydraulic piston pump. So, what exactly is a hydraulic pump? Hydraulic piston pumps convert rotational power to hydraulic power. These pumps contain pistons cylindrical elements installed inside a cylinder block/barrel. Their motion while in operation creates a vacuum, drawing the fluid into the cylinder. The fluid is then compressed and directed to the pump outlet.

A hydraulic piston pump may be either fixed displacement (delivering a predetermined volume of fluid with each shaft revolution) or variable displacement (adjustable to deliver a different volume of fluid for each shaft revolution). Conventional hydraulic piston pump design includes a collection of rotating components, such as a rotating group and drive shaft, in addition to a swash plate/yoke and compensator, which is the pressure-and-flow-control element of the pump.

Hydraulic piston pumps can be found in a number of industrial & mobile environments, including oil fields, agriculture and construction sites. Their popularity is due to their remarkable efficiency, reliability, and performance. These pumps are capable of handling high speeds and pressures while minimizing fluid leakage.

Several types of hydraulic piston pumps are available on the market; these include axial piston pumps (a positive displacement type that features multiple pistons arranged in a circular configuration around the shaft), radial piston pumps (a positive displacement type that feature multiple pistons arranged perpendicular to the shaft). Both types are available in either variable or fixed displacement versions depending upon the requirement of the application.

White House Products offers a full repair and test facility for piston pumps and motors of all sorts. Should you wish to repair your piston unit we can supply, in many cases from stock, a broad spectrum of parts: driveshafts, valve plates, seal kits, bearings, bearing plates, charge pumps, swashplates, rotating groups etc

For the most dependable hydraulic piston pumps and piston pump parts available on the internet, you can rely on White House Products Ltd. We invite you to explore our inventory of piston pumps, which includes high-quality products from the world"s premier manufacturers.

An axial piston pump is a positive displacement pump that has a number of pistons in a circular array within a hydraulic motor or an automotive air conditioning compressor.

An axial piston pump has a number of pistons (usually an odd number) arranged in a circular array within a housing which is commonly referred to as a cylinder block, barrel. This cylinder block is driven to rotate about its axis of symmetry by an integral shaft that is, more or less, aligned with the pumping pistons (usually parallel but not necessarily).

Mating surfaces. One end of the cylinder block is convex and wears against a mating surface on a stationary valve plate. The inlet and outlet fluid of the pump pass through different parts of the sliding interface between the cylinder block and valve plate. The valve plate has two semi-circular ports that allow inlet of the operating fluid and exhaust of the outlet fluid respectively.

Protruding pistons. The pumping pistons protrude from the opposite end of the cylinder block. There are numerous configurations used for the exposed ends of the pistons but in all cases they bear against a cam. In variable displacement units, the cam is movable and commonly referred to as a yoke or hanger. For conceptual purposes, the cam can be represented by a plane, the orientation of which, in combination with shaft rotation, provides the cam action that leads to piston reciprocation and thus pumping. The angle between a vector normal to the cam plane and the cylinder block axis of rotation, called the cam angle, is one variable that determines the displacement of the pump or the amount of fluid pumped per shaft revolution. Variable displacement units have the ability to vary the cam angle during operation whereas fixed displacement units do not.

Reciprocating pistons. As the cylinder block rotates, the exposed ends of the pistons are constrained to follow the surface of the cam plane. Since the cam plane is at an angle to the axis of rotation, the pistons must reciprocate axially as they precess about the cylinder block axis. The axial motion of the pistons is sinusoidal. During the rising portion of the piston"s reciprocation cycle, the piston moves toward the valve plate. Also, during this time, the fluid trapped between the buried end of the piston and the valve plate is vented to the pump"s discharge port through one of the valve plate"s semi-circular ports - the discharge port. As the piston moves toward the valve plate, fluid is pushed or displaced through the discharge port of the valve plate.

Effect of precession. When the piston is at the top of the reciprocation cycle (commonly referred to as top-dead-center or just TDC), the connection between the trapped fluid chamber and the pump"s discharge port is closed. Shortly thereafter, that same chamber becomes open to the pump"s inlet port. As the piston continues to precess about the cylinder block axis, it moves away from the valve plate thereby increasing the volume of the trapped chamber. As this occurs, fluid enters the chamber from the pump"s inlet to fill the void. This process continues until the piston reaches the bottom of the reciprocation cylinder - commonly referred to as bottom-dead-center or BDC. At BDC, the connection between the pumping chamber and inlet port is closed. Shortly thereafter, the chamber becomes open to the discharge port again and the pumping cycle starts over.

Variable displacement. In a variable displacement pump, if the vector normal to the cam plane (swash plate) is set parallel to the axis of rotation, there is no movement of the pistons in their cylinders. Thus there is no output. Movement of the swash plate controls pump output from zero to maximum. There are two kinds of variable-displacement axial piston pumps:

direct displacement control pump, a kind of axial piston pump with a direct displacement control. A direct displacement control uses a mechanical lever attached to the swashplate of the axial piston pump. Higher system pressures require more force to move that lever, making direct displacement control only suitable for light or medium duty pumps. Heavy duty pumps require servo control.linkages and springs and in some cases magnets rather than a shaft to a motor located outside of the pump (thereby reducing the number of moving parts), keeping parts protected and lubricated and reducing the resistance against the flow of liquid.

Pressure. In a typical pressure-compensated pump, the swash plate angle is adjusted through the action of a valve which uses pressure feedback so that the instantaneous pump output flow is exactly enough to maintain a designated pressure. If the load flow increases, pressure will momentarily decrease but the pressure-compensation valve will sense the decrease and then increase the swash plate angle to increase pump output flow so that the desired pressure is restored. In reality most systems use pressure as a control for this type of pump. The operating pressure reaches, say, 200 bar (20 MPa or 2900 psi) and the swash plate is driven towards zero angle (piston stroke nearly zero) and with the inherent leaks in the system allows the pump to stabilise at the delivery volume that maintains the set pressure. As demand increases the swash plate is moved to a greater angle, piston stroke increases and the volume of fluid increases; if the demand slackens the pressure will rise, and the pumped volume diminishes as the pressure rises. At maximum system pressure the output is once again almost zero. If the fluid demand increases beyond the capacity of the pump to deliver, the system pressure will drop to near zero. The swash plate angle will remain at the maximum allowed, and the pistons will operate at full stroke. This continues until system flow-demand eases and the pump"s capacity is greater than demand. As the pressure rises the swash-plate angle modulates to try to not exceed the maximum pressure while meeting the flow demand.

Designers have a number of problems to overcome in designing axial piston pumps. One is managing to be able to manufacture a pump with the fine tolerances necessary for efficient operation. The mating faces between the rotary piston-cylinder assembly and the stationary pump body have to be almost a perfect seal while the rotary part turns at perhaps 3000 rpm. The pistons are usually less than half an inch (13 mm) in diameter with similar stroke lengths. Keeping the wall to piston seal tight means that very small clearances are involved and that materials have to be closely matched for similar coefficient of expansion.

The pistons have to be drawn outwards in their cylinder by some means. On small pumps this can be done by means of a spring inside the cylinder that forces the piston up the cylinder. Inlet fluid pressure can also be arranged so that the fluid pushes the pistons up the cylinder. Often a vane pump is located on the same drive shaft to provide this pressure and it also allows the pump assembly to draw fluid against some suction head from the reservoir, which is not an attribute of the unaided axial piston pump.

Another method of drawing pistons up the cylinder is to attach the cylinder heads to the surface of the swash plate. In that way the piston stroke is totally mechanical. However, the designer"s problem of lubricating the swash plate face (a sliding contact) is made even more difficult.

Internal lubrication of the pump is achieved by use of the operating fluid—normally called operating temperature, limited by the fluid, of about 120 °C (250 °F) so that using that fluid as a lubricant brings its own problems. In this type of pump the leakage from the face between the cylinder housing and the body block is used to cool and lubricate the exterior of the rotating parts. The leakage is then carried off to the reservoir or to the inlet side of the pump again. Hydraulic fluid that has been used is always cooled and passed through micrometre-sized filters before recirculating through the pump.

Despite the problems indicated above this type of pump can contain most of the necessary circuit controls integrally (the swash-plate angle control) to regulate flow and pressure, be very reliable and allow the rest of the hydraulic system to be very simple and inexpensive.

Axial piston pumps are used to power the hydraulic systems of jet aircraft, being gear-driven off of the turbine engine"s main shaft, The system used on the F-14 used a 9-piston pump that produced a standard system operating pressure of 3000 psi and a maximum flow of 84 gallons per minute.

Automotive air conditioning compressors for cabin cooling are nowadays mostly based around the axial piston pump design (others are based on the scroll compressor or rotary vane pump ones instead) in order to contain their weight and space requirement in the vehicle"s engine bay and reduce vibrations. They"re available in fixed displacement and dynamically adjusted variable displacement variants, and, depending upon the compressor"s design, the actual rotating swashplate either directly drives a set of pistons mated to its edges through a set of hemispherical metal shoes, or a nutating plate on which a set of pistons are mounted by means of rods.

Axial reciprocating motors are also used to power many machines. They operate on the same principle as described above, except that the circulating fluid is provided under considerable pressure and the piston housing is made to rotate and provide shaft power to another machine. A common use of an axial reciprocating motor is to power small earthmoving plant such as skid loader machines. Another use is to drive the screws of torpedoes.

MD10V series is a family of variable displacement axial piston pumps for use in closed circuits. The displacement is infinitely variable by means of a tilting swash plate; the oil flow can be reversed over the neutral point. Various controls are available: manual, servo control lever operated, on/off electric, electro proportional, hydraulic pilot, and the new automotive control. All pumps have maximum pressure relief valves and can be supplied single or tandem version. Different through drive options are available for auxiliary pump mounting as well as a wide range of options: bypass valve, pressure filter and others.

SH6V series are variable displacement, axial piston pumps, with swash plate design, for closed circuit hydrostatic transmissions and high pressure applications. SH6V pumps series are available with several control devices including manual lever, hydraulic proportional, electric proportional, and electric on/off. The pump can be supplied as single or tandem version and with through drive options for the assembly of auxiliary gear pumps.

Poclain Piston pumps closed circuitPoclain offers a proven pump technology; all models utilize the parallel axial piston/slipper concept for closed loop circuits:

Whether variable displacement, self-regulating, integrated, double- tandem or multiple pumps - All controls of our hydraulic pumps are based on a load-independent control mechanism. No matter which control is used: identical commands always result in the same response in the machine. The sensitive and precise machine control makes work easier and increases productivity. Various customer system options for mechanical, hydraulic and electric input solutions are available. Further special regulating features like torque control and pressure cut-off are also available. The reliable control of the pump can easily be integrated into any kind of vehicle management control system.

We have specialised in axial piston pumps in swash plate design. We develop and produce: variable displacement and self-regulating pumps, as well as double, tandem and multiple pumps in both closed and open circuit.

The pump pulls hydraulic oil through a suction port from a tank by moving the pistons axially and transports it into the circuit of a hydraulic system.

Designed for power and speed, the Oilgear PVV open-loop axial-piston hydraulic pumps can handle large, heavy-duty systems. Manufactured with advanced engineering and computer-optimized, the PVV pump range delivers up to 450 Bar / 560 horespower which equates to four times the horsepower at less than half the cost of other manufacturers pumps.

With it"s compact design available in several displacements, the PVV pumps offer a large selection of readily interchangeable controls. With improved response controls and reduced noise levels, its rugged cylinder design enhances performance.

The patented, pressure lubricated swashblock design offers high performance for high-cycling operations. It also contributes to the pump’s ability to run on low-viscosity fluids, including high water content, fire-resistant and other special fluids.

Zeus Hydratech fully supports the Oilgear PVV pump product line and is the only valid source for OEM parts. All Oilgear repairs are machined and tested per our original factory specifications.

8613371530291

8613371530291