piston type hydraulic pump factory

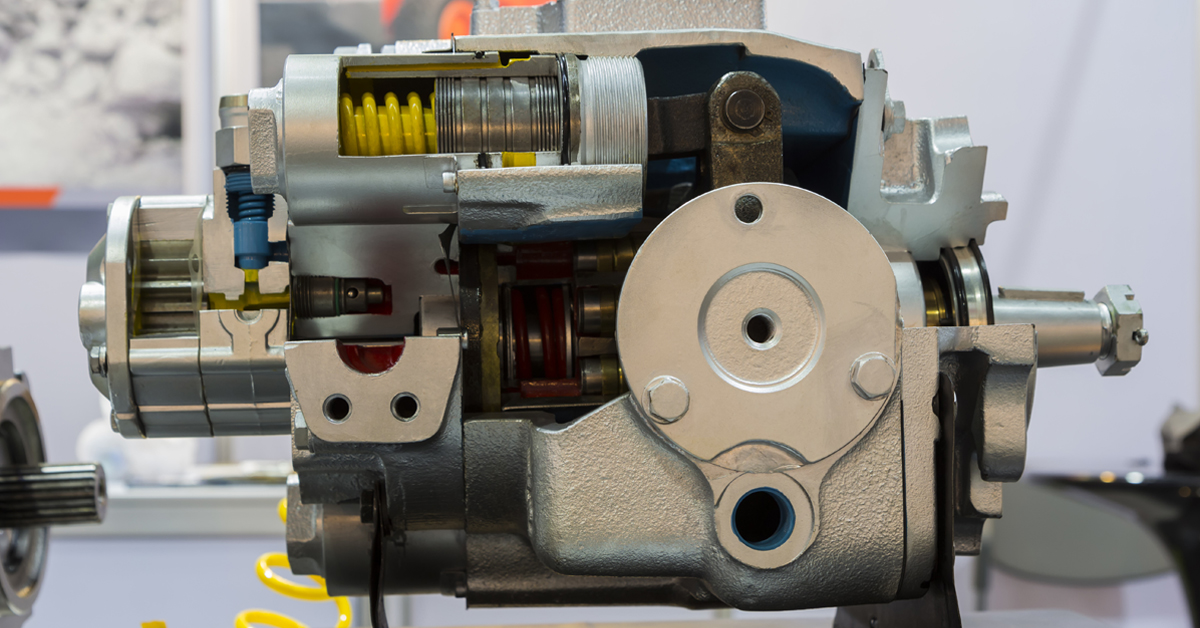

Piston pumps are typically much more complicated and are often available in wither fixed or, commonly, variable displacement configurations and with pressure compensation. These are big words that mean that piston pumps can usually adapt to the system pressure, providing maximum efficiency and flexibility. They are often used in “closed center” systems where the pump displacement varies to meet the needs of the work being done. Piston pumps use a “swashplate” to move the pistons and the angle of the swashplate & bore of the pistons determines the displacement. Pressure compensation regulates outputs in response to variations in the system. Piston pumps are typically the most efficient type of hydraulic pumps.

Hydraulic piston pumps use a plunger-like apparatus to move hydraulic fluids through a cylinder in order to effectively raise the pressure for machinery, allowing it to push, pull and lift heavy loads. This particular style of hydraulic pump is the driving force behind heavy-duty machines such as cranes, loaders, backhoes, diggers, and excavators. Piston pumps are not limited to construction work and are also found in aeronautic, automotive, power generation, marine, military, and manufacturing industries, to name a few.

The popularity of hydraulic piston pumps stems from their ability to maximize energy use and productivity. Even a hydraulic hand pump powered by a foot or hand pedal can convert as little as 4.5 pounds of force into 100 pounds of load-moving force. Electric hydraulic pumps can reach pressure ranges up to 4,000 PSI. As capacities show such variability, the intended use of a pump should be carefully considered. Several other variables should also be taken into account. Task-specific power sources, operating speeds, maximum fluid flows, and pump weights are widely available in standard and custom configurations. Measurements such as diameter, rod extension length, height, and width should also be considered, especially when a hydraulic piston pump is to be fitted to a pre-existing hydraulic system.

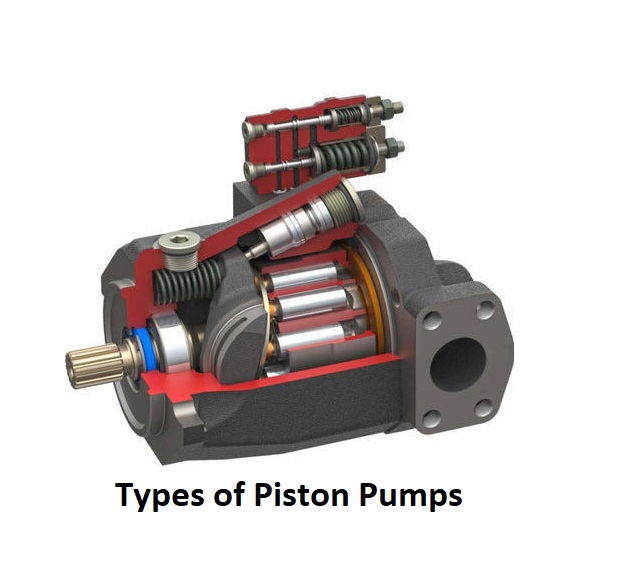

There are two basic variations of hydraulic piston pumps: axial and radial pistons. The essential difference between the two is the placement of the pistons within the hydraulic cylinder and the directionality of the movement. Axial pistons run parallel to the cylinder, while radial pistons are perpendicular to an inner column running through the cylinder. The latter provides a rotary movement. Axial pistons provide linear motion and are more popular in heavy machinery contexts. Both can be single action or double action pumps. Despite the differing piston placements, both systems function in a similar fashion. Hydraulic fluids, usually oil or water composites, are housed in a reservoir connected to the main cylinder by tubes or hoses. The cylinder houses the pistons and one or more intake check valves and an equal number of discharge check valves. When the piston is withdrawn, it creates a vacuum, and the liquid solution is pulled into the cylinder. The piston is then returned to its original position and the intake valve is sealed. This creates pressure within the enclosed space and compresses the fluids. The plunger-like action is repeated until enough pressure is accumulated to force the hydraulic fluids out through the discharge valve. This creates the energy needed to work the attached machinery and move the intended load.

The radial piston pump type R consists of valve-controlled pump elements arranged in star form around an eccentric. For large flow rates, up to 42 pump elements can be ...

... axial piston pump type V60N is designed for open circuits in mobile hydraulics and operate according to the swash plate principle. They are available with the option of a thru-shaft for ...

The K3VG series are swash-plate type axial piston pumps which give excellent performance in high flow industrial applications in a compact and cost-effective package.

... Parker’s hydraulic truck pump series F1 featuring high self-priming speed and high efficiency and is one of the leading truck pumps in the market. The F1 pump provide ...

... Piston Pumps provide fixed-displacement power in a unique miniature design. Engineered for open-circuit systems, they bring flexibility to your operation. Compact Piston ...

Parker P2/P3 High Pressure Axial Piston Pumps are variable displacement, swashplate piston pumps designed for operation in open circuit, mobile hydraulic ...

Closed circuit axial piston pumps are used as hydrostatic transmission components in self-propelled machines and for rotary drives in both fixed and mobile equipment of all kinds.

... and very compact for easier and inexpensive installations. Bent Axis pumps-motors will mount directly to virtually any Bezares PTO in our extensive line.

... displacement bent axis piston pumps were developed with spherical head pistons. This provides extremely high performance and high pressure ratings on a long life span unit. Flow rates ...

Sophisticated technology in the smallest space - this is what our Alfra electro-hydraulic pumps stand for. Due to the compact design, the powerful drive units also find room when things ...

Our hydraulic cylinder with a quick coupling has a performance up to 11 tons pressure – with a deadweight of only 2,5 kg. The SKP-1 is compatible with the ALFRA foot pump. Your advantage: Your hands are ...

... our ALFRA hydraulic cylinder SKP-1. In a team with the hydraulic pump DSP-120 it is capable to take a variety of challenges – because the SKP-1 working with a maximum operating pressure ...

... alkitronic hydraulic pumps with electric or pneumatic drive provide fast operating speed, reliability, and safety. They are designed for permanent operation. Our hydraulic ...

With their unique design, PA-PAC pumps offer a robust and durable solution to the high pressure needs of truck applications. Combining the automatic dual direction of rotation, high operating pressure (up to 500 bar peak), ...

Bent axis XPi pumps are specially designed to meet the needs of truck equipment. Their compact design allows a direct flange-mounting on the PTO. All models are of 7 piston design to ...

Lightweight two-speed hand-pump. Low hand force required at max. operating pressure. Pump housing from malleable cast iron, oil reservoir from aluminium. With pressure relief valve, factory set at max. ...

Ideal for powering single-acting cylinders and portable hydraulic tools, the Power Team PA9 series pumps are easier to operate than a hand pump, designed for efficiency. Built to be economical ...

Precision-matched cylinder and pump set for wide range of applications. Four styles of cylinders within the CPS/RPS Series with each set featuring single or two-speed hydraulic hand pumps. ...

The Power Team P-Series hand pumps come in a variety of configurations to meet the requirements of your application. Along with various oil capacities and flow rates, you can choose from the following options:

... time. Stage 1 allows rapid piston travel under no load or light load conditions. The pump automatically switches to stage 2 when the piston is loaded and a higher force is required from ...

Introducing the Axial piston hydraulic pump by Atos are designed for superior pressure application on industrial operation . It features its reduced noise operation capacity having a ...

Like all the pumps of the HP Series, it is suitable for any hydraulic application which require very high hydraulic output pressures and a moderate and controllable oil flow, to ensure ...

Air hydraulic pump, double pneumatic motor, double effect, foot operated with lock-up function, lever distributor valve (4/3), 10L tank, oil flow 8.5 / 0.26 l / min

The HP-AP pump, like all HP Series pumps, can be installed in any hydraulic applications which requires high working pressures and moderate and controllable oil flow. Our HP Series air-hydraulic ...

The axial piston pump type V60N is designed for open circuits in mobile hydraulics and operate according to the swash plate principle. They are available with the option ...

Variable displacement axial piston pumps operate according to the bent axis principle. They adjust the geometric output volume from maximum to zero. As a result they vary the flow rate ...

The K3VG series are swash-plate type axial piston pumps which give excellent performance in high flow industrial applications in a compact and cost-effective package.

Closed circuit axial piston pumps are used as hydrostatic transmission components in self-propelled machines and for rotary drives in both fixed and mobile equipment of all kinds.

Twin flow axial piston pumps offers two different flows. In addition, we find several advantages such as lower weight or standar system solutions. BZT are available in ISO and SAE version.

Our variable volume, pressure compensated axial piston pumps continuously match output flow to the system demands. They’re designed to closely match the Eaton-Vickers PVB and PVQ and ...

The PFBA is a fixed displacement pump, axial-piston pump. It’s proven itself in a variety of operations—including die casting and injection molding machines, high-pressure ...

PMH high pressure axial piston pumps for closed loop are specifically designed to be used on heavy duty machines for traction and auxiliary functions, providing efficiency and durability.

Variable displacement pumps in closed loop; 3 basic design units and 8 max. displacement sizes of 14, 18, 21, 28, 35, 46, 56, 64 cc/rev; various control options; max. nominal pressure 300 bar, 350 bar peak; driving speed: ...

"C"" Axial Piston Pumps for high accuracy fluid metering with precision flow controls and high-pressure capability. Specifically designed for the Polyurethane Industry. Capacities from ...

Rotork offers a range of high quality hydraulic pumps for applications in the upstream and downstream oil and gas industries. These include an extensive range of axial piston ...

... Parker’s hydraulic truck pump series F1 featuring high self-priming speed and high efficiency and is one of the leading truck pumps in the market. The F1 pump provide ...

Parker P2/P3 High Pressure Axial Piston Pumps are variable displacement, swashplate piston pumps designed for operation in open circuit, mobile hydraulic ...

... Series pump offers variable displacement axial piston pumps for open-circuit applications. Featuring a compact footprint and continuous operating pressure ...

PROPISTON Hydraulics Co., Ltd established in 1979, stands out as a piston pump manufacturer. Here you can find various types of piston pump including AR series, pressure compensator series, propotional electro-hydraulic series and pilot pressure control series. Our products feature variable displacement single pumps and we also have a strong R&D team to keep improving piston pumps to meet the highest demand of our clients.

Hydraulic piston pumps move fluids throughout professional equipment and industrial machinery. They’re known for their high efficiency and are commonly used in high-pressure applications.

There are also two major types of hydraulic piston pumps: axial and radial; both can have fixed or variable displacement; fixed displacement means that the pump is delivering the same amount of liquid or gas each time, while variable means that the amount of gas or liquid delivered may be different each time. Although both are considered piston pumps, each one operates differently.

An axial piston pump features four major components: a shaft, swashplate or bent axis, cylinder block, and valve plate. The cylinder block houses the piston pumps, which are laid out cyclically around the drive shaft’s axis (thus why it is named anaxialpiston pump).

The pistons in the cylinder block pump up and down as the drive shaft rotates. The piston’s stroke will vary depending on how it is angled in the swashplate or bent axis. As the pistons move in one direction, they are connected to a suction line, and when they move in the opposite direction, they connect to a discharge channel, allowing a continuous flow of fluid.

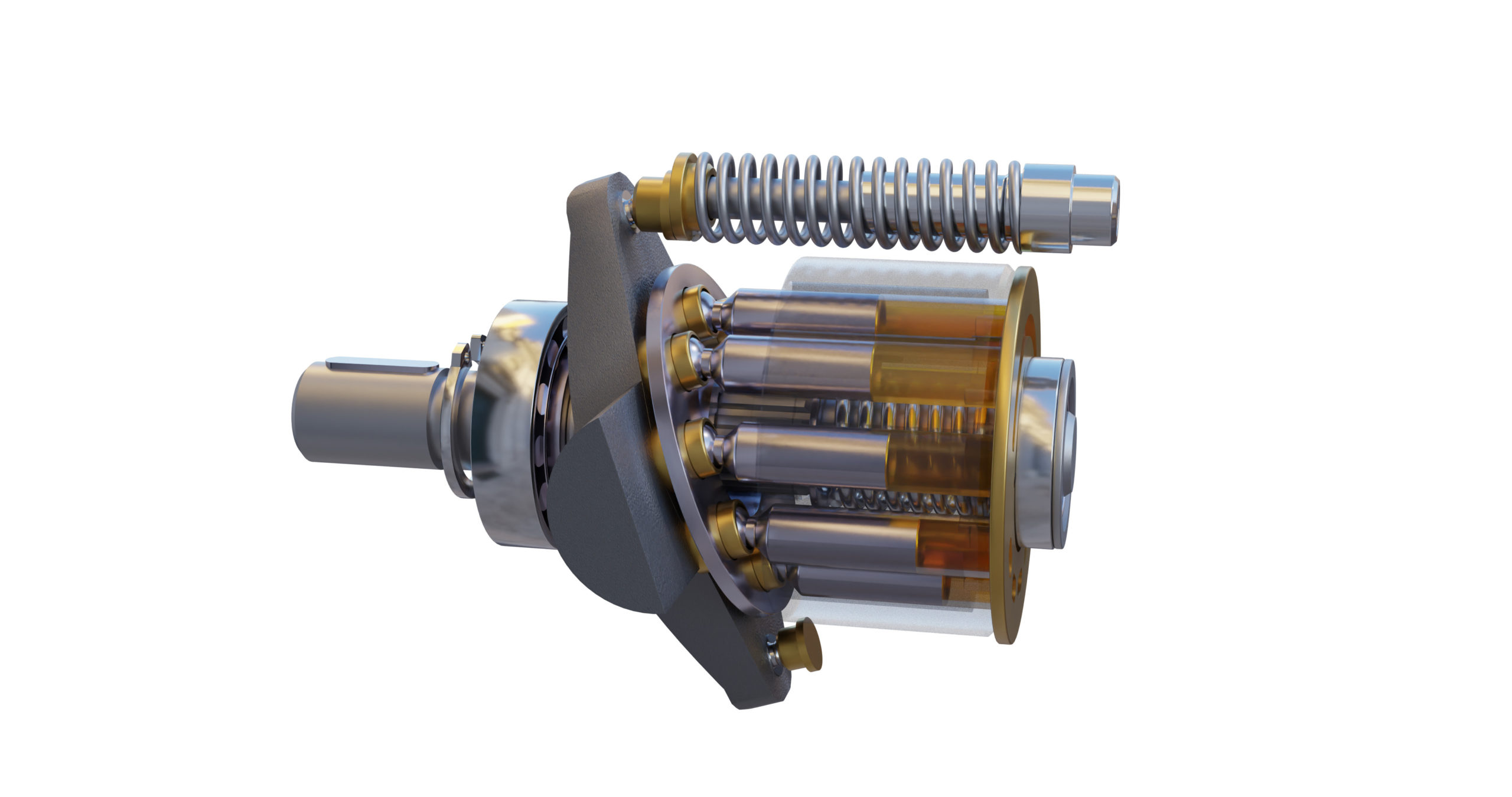

The design of a radial piston pump is significantly different from an axial pump. The radial piston pump consists of a cylinder block, rotating camshaft, and pistons. The pistons are arranged around the cylinder block in a radial pattern and diverge from the camshaft like rays. The rotation of the cam causes the pistons to change from suction to discharge and vice versa.

In general, choosing a hydraulic pump requires an application evaluation. You’ll need to know pressure requirements, desired flow rate, speed, horsepower, and the type of fluid the pump will be dispersing.

Radial piston pumps can usually handle all fluids, including mineral oil and water-glycol hydraulic fluid, while axial piston pumps are preferred for extremely high-pressure applications.

Although piston pumps are highly efficient and reliable, contamination, over-pressurization, and inlet blockages can cause the pump to fail. If and when this happens, you’ll need to replace your pump as soon as possible.

When choosing a replacement pump, you’ll have to choose between a direct OEM replacement and a remanufactured pump. Unfortunately, direct OEM replacement pumps and services can be a significant investment. Additionally, if you have outdated equipment, you may not be able to find thepump partsneeded to restore your equipment.

If you’re looking for a quick and relatively inexpensive solution, a remanufactured pump is your best choice. However, if time and money aren’t an issue, a direct OEM replacement will most likely be the best option if the manufacturer hasn’t discontinued the pump.

Do you need help finding the right piston pump? Turn to Panagon Systems. Founded over 25 years ago, we’re an industry-leading remanufacturer of hydraulic piston pumps and motors. We specialize in remanufacturing pumps from brands like Vickers/Eaton, Rexroth, and Caterpillar, and we also carry. All pumps and motors are remanufactured in-house in the United States, guaranteed to meet OEM specifications, and are backed by a one-year warranty.

Hydraulic systems are in general members of the fluid power branch of power transmission. Hydraulic pumps are also members of the hydraulic power pack/hydraulic power unit family. Hydraulic units are encased mechanical systems that use liquids for hydraulics.

The hydraulic systems that hydraulic pumps support exist in a range of industries, among them agriculture, automotive manufacturing, defense contracting, excavation, and industrial manufacturing. Within these industries, machines and applications that rely on hydraulic pumps include airplane flaps, elevators, cranes, automotive lifts, shock absorbers, automotive brakes, garage jacks, off-highway equipment, log splitters, offshore equipment, hydraulic motors/hydraulic pump motors, and a wide range of other hydraulic equipment.

When designing hydraulic pumps, manufacturers have many options from which to choose in terms of material composition. Most commonly, they make the body of the pump–the gears, pistons, and hydraulic cylinders–from a durable metal material. This metal is one that that can hold up against the erosive and potentially corrosive properties of hydraulic fluids, as well as the wear that comes along with continual pumping. Metals like this include, among others, steel, stainless steel, and aluminum.

First, what are operating specifications of their customer? They must make sure that the pump they design matches customer requirements in terms of capabilities. These capabilities include maximum fluid flow, minimum and maximum operating pressure, horsepower, and operating speeds. Also, based on application specifications, some suppliers may choose to include discharge sensors or another means of monitoring the wellbeing of their hydraulic system.

Next, what is the nature of the space in which the pump will work? Based on the answer to this question, manufacturers will design the pump with a specific weight, rod extension capability, diameter, length, and power source.

Manufacturers must also find out what type of substance does the customer plan on running through the pumps. If the application calls for it, manufacturers can recommend operators add other substances to them in order to decrease the corrosive nature of certain hydraulic fluids. Examples of such fluids include esters, butanol, pump oils, glycols, water, or corrosive inhibitors. These substances differ in operating temperature, flash point, and viscosity, so they must be chosen with care.

All hydraulic pumps are composed in the same basic way. First, they have a reservoir, which is the section of the pump that houses stationary fluid. Next, they use hydraulic hoses or tubes to transfer this fluid into the hydraulic cylinder, which is the main body of the hydraulic system. Inside the cylinder, or cylinders, are two hydraulic valves and one or more pistons or gear systems. One valve is located at each end; they are called the intake check/inlet valve and the discharge check/outlet valve, respectively.

Hydraulic pumps operate under the principle of Pascal’s Law, which states the increase in pressure at one point of an enclosed liquid in equilibrium is equally transferred to all other points of said liquid.

To start, the check valve is closed, making it a normally closed (NC) valve. When the check is closed, fluid pressure builds. The piston forces the valves open and closes repeatedly at variable speeds, increasing pressure in the cylinder until it builds up enough to force the fluid through the discharge valve. In this way, the pump delivers sufficient force and energy to the attached equipment or machinery to move the target load.

When the fluid becomes pressurized enough, the piston withdraws long enough to allow the open check valve to create a vacuum that pulls in hydraulic fluid from the reservoir. From the reservoir, the pressurized fluid moves into the cylinder through the inlet. Inside the cylinder, the fluid picks up more force, which it carries over into the hydraulic system, where it is released through the outlet.

Piston pumps create positive displacement and build pressure using pistons. Piston pumps may be further divided into radial piston pumps and axial piston pumps.

Radial pumps are mostly used to power relatively small flows and very high-pressure applications. They use pistons arranged around a floating center shaft or ring, which can be moved by a control lever, causing eccentricity and the potential for both inward and outward movement.

Axial pumps, on the other hand, only allow linear motion. Despite this, they are very popular, being easier and less expensive to produce, as well as more compact in design.

Gear pumps, or hydraulic gear pumps, create pressure not with pistons but with the interlocking of gear teeth. When teeth are meshed together, fluid has to travel around the outside of the gears, where pressure builds.

External gear pumps facilitate flow by enlisting two identical gears that rotate against each other. As liquid flows in, it is trapped by the teeth and forced around them. It sits, stuck in the cavities between the teeth and the casing, until it is so pressurized by the meshing of the gears that it is forced to the outlet port.

Internal gear pumps, on the other hand, use bi-rotational gears. To begin the pressurizing process, gear pumps first pull in liquid via a suction port between the teeth of the exterior gear, called the rotor, and the teeth of the interior gear, called the idler. From here, liquid travels between the teeth, where they are divided within them. The teeth continue to rotate and mesh, both creating locked pockets of liquid and forming a seal between the suction port and the discharge port. Liquid is discharged and power is transported once the pump head is flooded. Internal gears are quite versatile, usable with a wide variety of fluids, not only including fuel oils and solvents, but also thick liquids like chocolate, asphalt, and adhesives.

Various other types of hydraulic pumps include rotary vane pumps, centrifugal pumps, electric hydraulic pumps, hydraulic clutch pumps, hydraulic plunger pumps, hydraulic water pumps, hydraulic ram pumps, portable 12V hydraulic pumps, hydraulic hand pumps, and air hydraulic pumps.

Rotary vane pumps are fairly high efficiency pumps, though they are not considered high pressure pumps. Vane pumps, which are a type of positive-displacement pump, apply constant but adjustable pressure.

Centrifugal pumps use hydrodynamic energy to move fluids. They feature a rotating axis, an impeller, and a casing or diffuser. Most often, operators use them for applications such as petroleum pumping, sewage, petrochemical pumping, and water turbine functioning.

Electric hydraulic pumps are hydraulic pumps powered by an electric motor. Usually, the hydraulic pump and motor work by turning mechanisms like impellers in order to create pressure differentials, which in turn generate fluid movement. Nearly any type of hydraulic pump can be run with electricity. Most often, operators use them with industrial machinery.

Hydraulic clutch pumps help users engage and disengage vehicle clutch systems. They do so by applying the right pressure for coupling or decoupling shafts in the clutch system. Coupled shafts allow drivers to accelerate, while decoupled shafts allow drivers to decelerate or shift gears.

Hydraulic ram pumps are a type of hydraulic pump designed to harness hydropower, or the power of water, to elevate it. Featuring only two moving hydraulic parts, hydraulic ram pumps require only the momentum of water to work. Operators use hydraulic ram pumps to move water in industries like manufacturing, waste management and sewage, engineering, plumbing, and agriculture. While hydraulic ram pumps return only about 10% of the water they receive, they are widely used in developing countries because they do not require fuel or electricity.

Hydraulic water pumps are any hydraulic pumps used to transfer water. Usually, hydraulic water pumps only require a little bit of energy in the beginning, as the movement and weight of water generate a large amount of usable pressure.

Air hydraulic pumps are hydraulic pumps powered by air compressors. In essence, these energy efficient pumps work by converting air pressure into hydraulic pressure.

Hydraulic pumps are useful for many reasons. First, they are simple. Simple machines are always an advantage because they are less likely to break and easier to repair if they do. Second, because fluid is easy to compress and so quick to create pressure force, hydraulic pumps are very efficient. Next, hydraulic pumps are compact, which means they are easy to fit into small and oddly shaped spaces. This is especially true in comparison to mechanical pumps and electrical pumps, which manufacturers cannot design so compactly. Speaking of design, another asset of hydraulic pumps is their customizability. Manufacturers can modify them easily. Likewise, hydraulic pumps are very versatile, not only because they are customizable, but also because they can work in places where other types of pump systems can’t, such as in the ocean. Furthermore, hydraulic pumps can produce far more power than similarly sized electrical pumps. Finally, these very durable hydraulic components are much less likely to explode than some other types of components.

To make sure that your hydraulic pumps stay useful for a long time, you need to treat them with care. Care includes checking them on a regular basis for problems like insufficient fluid pressure, leaks, and wear and tear. You can use diagnostic technology like discharge sensors to help you with detect failures and measure discharge pressure. Checking vibration signals alone is often not enough.

To keep yourself and your workers safe, you need to always take the proper precautions when operating or performing maintenance and repairs on your hydraulic pumps. For example, you should never make direct contact with hydraulic fluid. For one, the fluid made be corrosive and dangerous to your skin. For two, even if the pump isn’t active at that moment, the fluid can still be pressurized and may potentially harm you if something goes wrong. For more tips on hydraulic pump care and operation, talk to both your supplier and OSHA (Occupational Safety and Health Administration).

Pumps that meet operating standards are the foundation of safe and effective operations, no matter the application. Find out what operating standards your hydraulic pumps should meet by talking to your industry leaders.

The highest quality hydraulic pumps come from the highest quality hydraulic pump manufacturers. Finding the highest quality hydraulic pump manufacturers can be hard, which is why we have we listed out some of our favorites on this page. All of those whom we have listed come highly recommended with years of experience. Find their information nestled in between these information paragraphs.

Once you have put together you list, get to browsing. Pick out three or four hydraulic pump supply companies to which you’d like to speak, then reach out to each of them. After you’ve spoken with representatives from each company, decide which one will best serve you, and get started on your project.

Variable displacement axial piston pumps adjust the geometric output volume from maximum to zero. As a result they vary the flow rate that is provided to the consumers.

The RKP-D family of products has an intelligent control mechanism that allows the user to optimize the usage of control entities within a hydraulic system, often making the need for central control hardware redundant

Moog is the leading supplier for Radial Piston Pumps (RKP) worldwide. This mature and robust product has been used for decades and runs today in over 100,000 machines in various applications around the globe. It is widely known for its robust and reliable design.

The Moog Radial Piston pump comes in 8 pump sizes between 19 cc and 140 cc per revolution (19, 32, 45, 63, 80,100, 140 and 250) and has a maximum speed range of 1,800 to 2,900 rpm

Large selection of controls, including standard pressure compensator (Type F), remote pressure compensator (Type H), pressure and flow control (Type J,R) and digital electro-hydraulic control (RKP-D)

There are typically three types of hydraulic pump constructions found in mobile hydraulic applications. These include gear, piston, and vane; however, there are also clutch pumps, dump pumps, and pumps for refuse vehicles such as dry valve pumps and Muncie Power Products’ Live PakTM.

The hydraulic pump is the component of the hydraulic system that takes mechanical energy and converts it into fluid energy in the form of oil flow. This mechanical energy is taken from what is called the prime mover (a turning force) such as the power take-off or directly from the truck engine.

With each hydraulic pump, the pump will be of either a uni-rotational or bi-rotational design. As its name implies, a uni-rotational pump is designed to operate in one direction of shaft rotation. On the other hand, a bi-rotational pump has the ability to operate in either direction.

For truck-mounted hydraulic systems, the most common design in use is the gear pump. This design is characterized as having fewer moving parts, being easy to service, more tolerant of contamination than other designs and relatively inexpensive. Gear pumps are fixed displacement, also called positive displacement, pumps. This means the same volume of flow is produced with each rotation of the pump’s shaft. Gear pumps are rated in terms of the pump’s maximum pressure rating, cubic inch displacement and maximum input speed limitation.

Generally, gear pumps are used in open center hydraulic systems. Gear pumps trap oil in the areas between the teeth of the pump’s two gears and the body of the pump, transport it around the circumference of the gear cavity and then force it through the outlet port as the gears mesh. Behind the brass alloy thrust plates, or wear plates, a small amount of pressurized oil pushes the plates tightly against the gear ends to improve pump efficiency.

A cylinder block containing pistons that move in and out is housed within a piston pump. It’s the movement of these pistons that draw oil from the supply port and then force it through the outlet. The angle of the swash plate, which the slipper end of the piston rides against, determines the length of the piston’s stroke. While the swash plate remains stationary, the cylinder block, encompassing the pistons, rotates with the pump’s input shaft. The pump displacement is then determined by the total volume of the pump’s cylinders. Fixed and variable displacement designs are both available.

With a fixed displacement piston pump, the swash plate is nonadjustable. Its proportional output flow to input shaft speed is like that of a gear pump and like a gear pump, the fixed displacement piston pump is used within open center hydraulic systems.

As previously mentioned, piston pumps are also used within applications like snow and ice control where it may be desirable to vary system flow without varying engine speed. This is where the variable displacement piston pump comes into play – when the hydraulic flow requirements will vary based on operating conditions. Unlike the fixed displacement design, the swash plate is not fixed and its angle can be adjusted by a pressure signal from the directional valve via a compensator.

Vane pumps were, at one time, commonly used on utility vehicles such as aerial buckets and ladders. Today, the vane pump is not commonly found on these mobile (truck-mounted) hydraulic systems as gear pumps are more widely accepted and available.

Within a vane pump, as the input shaft rotates it causes oil to be picked up between the vanes of the pump which is then transported to the pump’s outlet side. This is similar to how gear pumps work, but there is one set of vanes – versus a pair of gears – on a rotating cartridge in the pump housing. As the area between the vanes decreases on the outlet side and increases on the inlet side of the pump, oil is drawn in through the supply port and expelled through the outlet as the vane cartridge rotates due to the change in area.

Input shaft rotates, causing oil to be picked up between the vanes of the pump which is then transported to pump outlet side as area between vanes decreases on outlet side and increases on inlet side to draw oil through supply port and expel though outlet as vane cartridge rotates

A clutch pump is a small displacement gear pump equipped with a belt-driven, electromagnetic clutch, much like that found on a car’s air conditioner compressor. It is engaged when the operator turns on a switch inside the truck cab. Clutch pumps are frequently used where a transmission power take-off aperture is not provided or is not easily accessible. Common applications include aerial bucket trucks, wreckers and hay spikes. As a general rule clutch pumps cannot be used where pump output flows are in excess of 15 GPM as the engine drive belt is subject to slipping under higher loads.

What separates this pump from the traditional gear pump is its built-in pressure relief assembly and an integral three-position, three-way directional control valve. The dump pump is unsuited for continuous-duty applications because of its narrow, internal paths and the subsequent likelihood of excessive heat generation.

Dump pumps are often direct mounted to the power take-off; however, it is vital that the direct-coupled pumps be rigidly supported with an installer-supplied bracket to the transmission case with the pump’s weight at 70 lbs. With a dump pump, either a two- or three-line installation must be selected (two-line and three-line refer to the number of hoses used to plumb the pump); however, a dump pump can easily be converted from a two- to three-line installation. This is accomplished by inserting an inexpensive sleeve into the pump’s inlet port and uncapping the return port.

Many dump bodies can function adequately with a two-line installation if not left operating too long in neutral. When left operating in neutral for too long however, the most common dump pump failure occurs due to high temperatures. To prevent this failure, a three-line installation can be selected – which also provides additional benefits.

Pumps for refuse equipment include both dry valve and Live Pak pumps. Both conserve fuel while in the OFF mode, but have the ability to provide full flow when work is required. While both have designs based on that of standard gear pumps, the dry valve and Like Pak pumps incorporate additional, special valving.

Primarily used on refuse equipment, dry valve pumps are large displacement, front crankshaft-driven pumps. The dry valve pump encompasses a plunger-type valve in the pump inlet port. This special plunger-type valve restricts flow in the OFF mode and allows full flow in the ON mode. As a result, the horsepower draw is lowered, which saves fuel when the hydraulic system is not in use.

In the closed position, the dry valve allows just enough oil to pass through to maintain lubrication of the pump. This oil is then returned to the reservoir through a bleed valve and small return line. A bleed valve that is fully functioning is critical to the life of this type of pump, as pump failure induced by cavitation will result if the bleed valve becomes clogged by contaminates. Muncie Power Products also offer a butterfly-style dry valve, which eliminates the bleed valve requirement and allows for improved system efficiency.

It’s important to note that with the dry valve, wear plates and shaft seals differ from standard gear pumps. Trying to fit a standard gear pump to a dry valve likely will result in premature pump failure.

Encompasses plunger-type valve in the pump inlet port restricting flow in OFF mode, but allows full flow in ON mode lowering horsepower draw to save fuel when not in use

Wear plates and shaft seals differ from standard gear pumps – trying to fit standard gear pump to dry valve likely will result in premature pump failure

Live Pak pumps are also primarily used on refuse equipment and are engine crankshaft driven; however, the inlet on a Live Pak pump is not outfitted with a shut-off valve. With a Live Pak pump, the outlet incorporates a flow limiting valve. This is called a Live Pak valve. The valve acts as an unloading valve in OFF mode and a flow limiting valve in the ON mode. As a result, the hydraulic system speed is limited to keep within safe operating parameters.

Outlet incorporates flow limiting valve called Live Pak valve – acts as an unloading valve in OFF mode and flow limiting valve in ON mode restricting hydraulic system speed to keep within safe operating parameters

Designed for power and speed, the Oilgear PVV open-loop axial-piston hydraulic pumps can handle large, heavy-duty systems. Manufactured with advanced engineering and computer-optimized, the PVV pump range delivers up to 450 Bar / 560 horespower which equates to four times the horsepower at less than half the cost of other manufacturers pumps.

With it"s compact design available in several displacements, the PVV pumps offer a large selection of readily interchangeable controls. With improved response controls and reduced noise levels, its rugged cylinder design enhances performance.

The patented, pressure lubricated swashblock design offers high performance for high-cycling operations. It also contributes to the pump’s ability to run on low-viscosity fluids, including high water content, fire-resistant and other special fluids.

Zeus Hydratech fully supports the Oilgear PVV pump product line and is the only valid source for OEM parts. All Oilgear repairs are machined and tested per our original factory specifications.

Designed for power and speed, the Oilgear PVV open-loop axial-piston hydraulic pumps can handle large, heavy-duty systems. Manufactured with advanced engineering and computer-optimized, the PVV pump range delivers up to 450 Bar / 560 horespower which equates to four times the horsepower at less than half the cost of other manufacturers pumps.

With it"s compact design available in several displacements (200-540cc/rev), the PVV pumps offer a large selection of readily interchangeable controls. With improved response controls and reduced noise levels, its rugged cylinder design enhances performance.

The patented, pressure lubricated swashblock design offers high performance for high-cycling operations. It also contributes to the pump’s ability to run on low-viscosity fluids, including high water content, fire-resistant and other special fluids.

Zeus Hydratech fully supports the PVV pump product line and is the only valid source for OEM parts. All Oilgear repairs are machined and tested per our original factory specifications.

For small sewage treatment plants, biogas plants, ponds For water treatment in small sewage treatment plants For desulfurization in biogas plants For aeration of ponds e.g. koi ponds Air delivery 200l/min with proven linear piston principle

Elephant Fluid Power: Provide SAUER series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Persisting in "High quality, Prompt Delivery, Aggressive Price", we have established long-term cooperation with clientele from both equally overseas and domestically and get new and old clients" higher comments for Yuken Pump A 100 Pump, Hawe Pump Si...

Elephant Fluid Power: Provide Good Quality P80 Valve - Control valve for CAT series piston pump,guarantee quality and appropriate prices.owing to good service, a variety of high quality products, competitive prices and efficient delivery, we enjoy a good reputation among our customers. We are an energetic company with wide market for Dakin P36-A3, Linde Pump Hpv, Kayaba Gear Pump Krp4...

Elephant Fluid Power: Provide Paker series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We always get the job done to be a tangible staff to ensure that we can easily offer you the best high-quality and the greatest value for Denison Hydraulic pump parts, Yuken Pump A3h 16 Pump, Uchida A8v, We are going to empower people by communicatin...

Elephant Fluid Power: Provide Nabtesco Pump Parts - Yuken Series Hydraulic Pump Parts,original OEM pump parts and auxiliary factory pump parts.The key to our success is "Good Product Excellent, Reasonable Rate and Efficient Service" for Piston Type Hydraulic Pump Animation, Pump K3v180, Italy Sam Pump H2v 75 H1c108, If you are interested in any of our products or would like to discuss a cus...

Elephant Fluid Power: Provide Dakin series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for Italy Sam Pump H2v 226 H1c55, Hpv 118 Pump, Toshiba Sg, We put genuine and health a...

Elephant Fluid Power: Provide Uchida series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Our solutions are broadly acknowledged and dependable by users and may meet consistently developing economic and social requires for Caterpillar Pump, Oilgear Pvv 250 Pump, Danfoss Orbital Motors Pdf, If you are interested in our products, please fee...

Elephant Fluid Power: Provide SAUER series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Always customer-oriented, and it"s our ultimate goal to get not only by far the most reputable, trustable and honest supplier, but also the partner for our customers for Hydraulic Spare Parts For Construction Machine, Kawasaki K7v Pump, Directional C...

Elephant Fluid Power: Provide Nabtesco Pump Parts - NACHI series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Our staff through skilled training. Skilled skilled knowledge, potent sense of company, to satisfy the provider requirements of consumers for Kayaba Gear Pump Catalogue, Komatsu Pc300-6 Hydraulic Pump, Hydraulic Spare Parts For Construction Machine, ...

Elephant Fluid Power: Provide Paker series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Sticking for the belief of "Creating items of top of the range and creating buddies with people today from all over the world", we normally put the interest of shoppers in the first place for Heavy Equipment Parts Edmonton, Heavy Equipment Parts Trin...

Elephant Fluid Power: Provide Linde series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts."Based on domestic market and expand overseas business" is our development strategy for Foton Ft150, Piston Type Hydraulic Pump Animation, Eaton Orbital Motors, With superb service and quality, and an enterprise of foreign trade featuring validity an...

Elephant Fluid Power: Provide Komatsu series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We consistently carry out our spirit of ""Innovation bringing development, Highly-quality ensuring subsistence, Management promoting benefit, Credit attracting customers for Liebherr Grease Pump, Kayaba Gear Pump Seal Kit, Directional Control Valve, ...

Elephant Fluid Power: Provide Dakin series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Our goods are broadly recognized and reliable by users and can meet consistently switching financial and social demands of Linde Pump Hpv, 083 Hmt125ac/Ae Travel, Hydraulic Piston Kayaba Pumps Psv2-55t, We sincerely count on exchange and cooperation ...

Elephant Fluid Power: Provide Komatsu series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We have been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Denison Pv6 10 Pump, Italy Sam Pump H2v 160 H1c108, Hitachi 1100 Hitachi 1800 Pump, We warmly welcome you to build cooperation and genera...

Elephant Fluid Power: Provide JEIT series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.The purchaser fulfillment is our primary focus on. We uphold a consistent level of professionalism, high quality, credibility and service for Kato 311 Walking Travel, Korea Hydraulic Jmf 80 S, Axial Piston Type Hydraulic Pump, Our products enjoy good...

Elephant Fluid Power: Provide Kayaba series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We pursue the management tenet of "Quality is remarkable, Company is supreme, Name is first", and will sincerely create and share success with all clientele for Hydraulic pump parts, Yuken Pump A 70 Pump, Oilgear Pvv 200 Pump, Trust us, you will find...

Elephant Fluid Power: Provide Uchida series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We stay with our company spirit of "Quality, Performance, Innovation and Integrity". We goal to create more value for our clients with our abundant resources, advanced machinery, experienced workers and superb solutions for Komatsu Pump Factory China...

Elephant Fluid Power: Provide Paker series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts."Based on domestic market and expand overseas business" is our improvement strategy for Sauer Danfoss 90 Series 75cc Pump Parts Manual, Hydraulic Piston Kayaba Pumps Msg-10/33vp, Rexroth A10vg Pump, We welcome new and previous buyers from all walks o...

Elephant Fluid Power: Provide Komatsu series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We insist on offering premium quality creation with very good company concept, honest product sales along with the finest and fast assistance. it will bring you not only the premium quality item and huge profit, but the most significant is to occupy ...

Elephant Fluid Power: Provide Kawasaki series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We will devote ourselves to giving our esteemed buyers using the most enthusiastically thoughtful services for Korea Hydraulic Jmv 275/172 Travel, Kayaba Pump Hydraulic, Toshiba Sg, We are also frequently hunting to determine relationship with new su...

Elephant Fluid Power: Provide Liebherr series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Gaining purchaser gratification is our firm"s intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services fo...

Elephant Fluid Power: Provide Kayaba series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we"re devoted to supplying the top benefit for our customers for Vickers Vane Pump Catalog...

Elephant Fluid Power:Provide Cat OEM pump piston pump spare parts 9T series,guarantee quality and appropriate prices, and perfect after-sales service.Our items are commonly identified and trusted by customers and may fulfill continuously switching economic and social wants of Foton 39 Excavator Rotary Swing, Liebherr Boom Pump, Piston Hydraulic Pump, Our tenet is "Reasonable prices, efficient prod...

Elephant Fluid Power: Provide Cat OEM pump piston pump spare parts 9T series,guarantee quality and appropriate prices, and perfect after-sales service.We normally believe that one"s character decides products" quality, the details decides products" high-quality ,while using the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Rexroth A10vso Series Piston Pump, Continental Hpv Pump, Yuken Pump A3...

Elephant Fluid Power: Provide Denison Pv6 10 Pump - Liebherr series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for Hydraulic Piston Linde Pumps Hmf50, Dakin V50 Vd2-15a Vd5-15a Mf18 Pump, Komatsu Pump Adjustment, Welcome all custo...

Elephant Fluid Power: Provide Paker series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Italy Sam Pump H2v 75 H1c55, Pump K3v140, Heavy Equipment Spare Parts Suppli...

Elephant Fluid Power: Provide Linde series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Heavy Equipment Used Parts Near Me, Hpv 102 Hydraulic Pump, Sauer Pumps Hydraulic, Winning customers" trust is d...

Elephant Fluid Power: Provide Komatsu series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Always customer-oriented, and it"s our ultimate target to be not only the most reliable, trustable and honest supplier, but also the partner for our customers for Hmgc16 Travel, Pump K3v, Hydraulic Piston Pump For Sale, Through our hard work, we have...

Elephant Fluid Power: Provide JEIT series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts."Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm to the long-term to develop together with consumers for mutual reciprocity and mutual advantage for Korea Hydraulic Jmv 53/34 Travel, Piston Shoe Hydraulic...

Elephant Fluid Power: Provide Teijin Seiki series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.With a sound enterprise credit history, exceptional after-sales services and modern production facilities, we"ve earned an outstanding track record amongst our consumers across the whole world for Hmgc16 Travel, Kawasaki Pump Shoe, Yuken Pump A 70 Pu...

Elephant Fluid Power: Provide Kayaba series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts."Based on domestic market and expand overseas business" is our development strategy for Toshiba Shibaura Lucus400 Hd450v-2 Pump, Komatsu Pump Controller, Denison Pv6 15 Pump, We have now ISO 9001 Certification and qualified this item .in excess of 16...

Elephant Fluid Power: Provide Denison Pv6 10 Pump - JEIT series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Hmt36fa Ex200 Travel, Eaton Vickers Pump Distributors, Oilgear Pvk 140 Pump, We aim at Ongoing system innovation...

Elephant Fluid Power: Provide Yuken Series Hydraulic Pump Parts,original OEM pump parts and auxiliary factory pump parts.We have been experienced manufacturer. Wining the majority of your crucial certifications of its market for Italy Sam Pump H1v 160, Linde Pump Repair, Sauer Pumps Hydraulic, With us your money in safe your business in safe . Hope we can be your trust...

Elephant Fluid Power: Provide Kawasaki series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts."Quality 1st, Honesty as base, Sincere company and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for Sauer Danfoss Pump Model Code, Italy Sam Pump H2v 75 H1c75, Korea Hydraulic Jmf 36 S, With our rules of "...

Elephant Fluid Power: Provide Eaton Vickers series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.The client satisfaction is our primary concentrate on. We uphold a consistent level of professionalism, top quality, credibility and service for Kayaba Pump, Kawasaki Pump K3vi80, Main Pump Pc300 Komatsu, Our aim is to help customers realize their go...

Elephant Fluid Power: Provide Paker series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts."Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our corporation to the long-term to establish collectively with customers for mutual reciprocity and mutual benefit for Cat Pump Parts, Hpv 135 Pump, Heavy Eq...

Elephant Fluid Power: Provide Liebherr series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We believe that prolonged expression partnership is really a result of top of the range, value added support, rich encounter and personal contact for Italy Sam Pump H2v 226 H1c55, Yuken Pump A3h 56 Pump, Heavy Equipment Parts Canada, Welcome your enq...

Elephant Fluid Power: Provide Dakin series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Using a complete scientific high quality management program, superior high quality and superior faith, we acquire great reputation and occupied this industry for Rexroth A10vso Series Piston Pump, Orbital Motors Danfoss, Hmgf36 Travel, We welcome buy...

Elephant Fluid Power: Provide Kawasaki series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Fast and great quotations, informed advisers to help you choose the correct solution that suits all your requirements, a short creation time, responsible top quality manage and distinct providers for paying and shipping affairs for Hydraulic Piston L...

Elephant Fluid Power: Provide K3v280dtp Main Pump - Sauer piston pump series Seal kit,guarantee quality and appropriate prices.Our primary intention should be to offer our clientele a serious and responsible enterprise relationship, delivering personalized attention to all of them for Piston Axial Hydraulic Pump, Korea Hydraulic Jmf 151 S, Vickers Vane Pump V210 Pdf, We neve...

Elephant Fluid Power: Provide K3v280dtp Main Pump - Nachi series pump seal kit,guarantee quality and appropriate prices.To be able to ideal satisfy client"s requirements, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Price tag, Fast Service" for Cat Pump 240, A4vg56 Rexroth Pump, Kawasaki Pump Distributors, Our Ent...

Elephant Fluid Power: Provide K3v280dtp Main Pump - Kawasaki Series Pump Seal kit,guarantee quality and appropriate prices.We have been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Oilgear Pvv 540 Pump, Linde Pump Hpv, Vickers Vane Pump Identification, Welcome all prospects of residence and abroad to visit our organi...

Elephant Fluid Power: Provide K3v280dtp Main Pump - Eton Vickers series pump Seal kit,guarantee quality and appropriate prices.Persisting in "High high quality, Prompt Delivery, Aggressive Price", we"ve established long-term cooperation with clients from the two overseas and domestically and get new and old clients" superior comments for Kayaba Gear Pump Krp4, Rexroth Pump P...

Elephant Fluid Power: Provide Cat Series pump parts seal kit,original OEM pump parts and auxiliary factory pump parts.High-quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is constantly observed and pursued by our business for Rexroth Pump Pdf, Kayaba Pump Hydraulic, Sauer Danfoss 90 Series Pu...

Elephant Fluid Power: Provide NACHI series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Dedicated to strict top quality command and considerate purchaser support, our experienced staff customers are always available to discuss your necessities and be certain full client gratification for Ap-12 Cat320 Pump, Sauer Pump Pu, Italy Sam Pump ...

Elephant Fluid Power: Provide Liebherr series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for Korea Hydraulic Jmf 53 S, Hitachi Pump Manual, Uchida Gear Pump Gsp2, With a wide range, top...

Elephant Fluid Power: Provide Kawasaki series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Our personnel are always in the spirit of "continuous improvement and excellence", and with the superior quality products, favorable price and good after-sales services, we try to win every customer"s trust for Korea Hydraulic Jmf 80 S, Dakin Opv1-23...

Elephant Fluid Power: Provide Eaton Vickers series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We strive for excellence, services the customers", hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for Toshiba Pvb 80/92 Pump, Directional Control Valv...

8613371530291

8613371530291