pneumatic hydraulic pump high pressure supplier

... alkitronic hydraulic pumps with electric or pneumatic drive provide fast operating speed, reliability, and safety. They are designed for permanent operation. Our hydraulic ...

Compressed air operated double diaphragm pumps for the Food and Beverage, Cosmetic and Trichological sectors. The pumps are certified ATEX, CE, MOCA, FDA Compliant.

Compressed air operated double diaphragm positive displacement pumps for the Food and Beverage, Cosmetic and Trichological sectors. The pumps are certified ATEX,

Compressed air operated double diaphragm positive displacement pumps for the Food and Beverage, Cosmetic and Trichological sectors. The pumps are certified ATEX, CE, MOCA, FDA Compliant.

These mini-pumps are driven by an air-powered motor and can be connected to any supply source of compressed air. These compact low-cost pumps can operate all single-acting or double-acting ...

Like all the pumps of the HP Series, it is suitable for any hydraulic application which require very high hydraulic output pressures and a moderate and controllable oil flow, to ensure ...

The HP-AP pump, like all HP Series pumps, can be installed in any hydraulic applications which requires high working pressures and moderate and controllable oil flow. Our HP Series air-hydraulic ...

Occupying a limited workspace, the portable P801 pump runs on compressed air that has a pressure capacity ranging from 2 to 7 bar. It is commonly utilized in the supply of systems that ...

Precision-matched cylinder and pump set for wide range of applications. Four styles of cylinders within the CPS/RPS Series with each set featuring single or two-speed hydraulic hand pumps. ...

... lightweight and portable the Power Team PA6D series pumps are single-speed pumps for driving double-acting cylinders. The PA6D series pumps operate at 40-100 psi (3-8 bar) shop air ...

A two-speed pump, the Power Team PA60 series pumps are designed for rapid oil delivery at low pressure to quickly advance cylinder or tool. Equipped with air pressure regulator, air ...

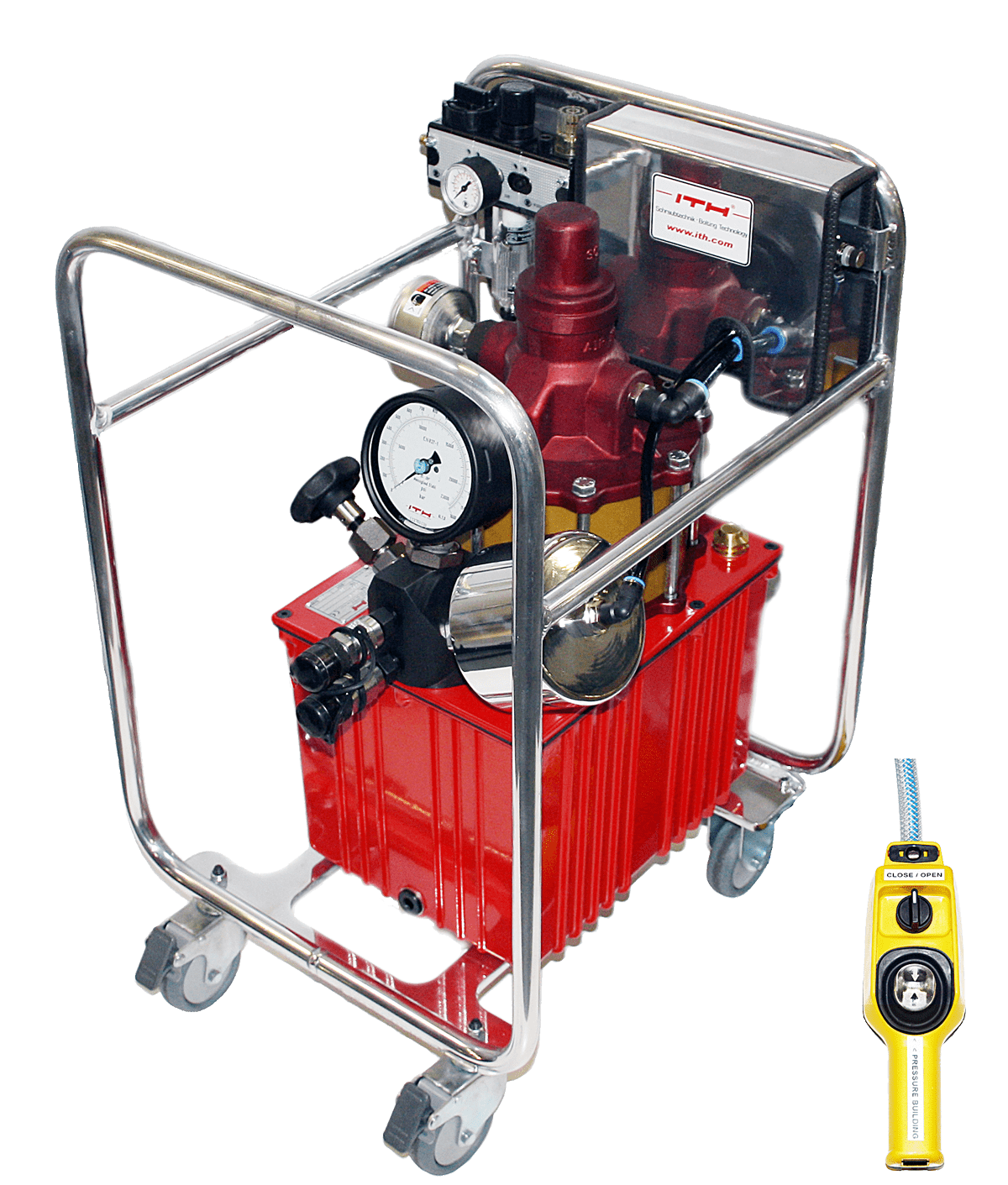

... to access. For these applications ITH developed the pneumatic pump Aero-MAX series and Travel-MAX. All the pumps can be used with standard air pressure systems. Typical ...

... electric power supplies can be difficult to access. For these applications ITH developed the pneumatic pump Aero-MAX series and Travel-MAX. All ITH pneumatic pumps ...

Double-acting, single-stage air-powered compact pump. Standard with a 3/8” NPT female thread and compressed air connector. Excluding coupler, hoses and pressure gauge.

The WL is a series of air-hydraulic pumps manufactured by Werner Weitner GmbH. Their aluminum framework operates in a single speed, and enables a pressure of up to 700bar with an air ...

• Feed by a normal compressed air line, it is the ideal solution for tensioning studs, explosion tests, mounting and dismounting bearings, hydraulic tensioning devices and anywhere very high pressure is used.

• Air consumption is approximately 2100 l/min. The feed pressure may vary from 1.8 to 7 bar. A distinctive feature of the pump is that following a drop in pressure, the hydraulic pump automatically restores the previous values.

High pressure air hydraulic pumps, the ideal solution for pressurization tests, material resistance, laboratory tests in general, stud tensioning operations, burst tests, testing of pressurized containers, bearing installation, actuation of hydraulic bolt tensioners or hydraulic nuts and anywhere you need a very high pressure. The standard version for oil circuits or in the water version on request. In the standard version the pneumohydraulic pump have pressure: 1500 bar – 2100 bar – 2500 bar – 3000 bar and 4000 bar. Air consumption is around 2,100 l / min. The supply pressure can vary from 1.8 to 7 bar. A feature of the pump is that following a pressure drop, the control unit automatically restores the pre-existing values.

Air hydraulic pumps are applied in all kinds of contexts. Although some hydraulic pumps use the momentum of moving water to continue operation, all need an initial force to begin the process. Compressors, which can be automatic or hand operated, work by increasing the amount of air in an enclosed space. This in turn increases the air pressure, which creates a force that can be used directly or as a means of powering other tools and mechanical devices such as pumps.

Compressed air is a common source of movement in hydraulic systems as it is an economical and compact option that can be installed in most pre-existing pump configurations. Construction, transportation, automotive, military, marine, excavation and manufacturing industries utilize both heavy duty and light-duty variations of air hydraulic pumps. Cranes, motors, lifts, excavators and generators all make use of these devices as they enable workers to greatly multiply workforce.

Even a small hydraulic hand pump, which uses a foot or hand pump to compress the air needed to operate the pump, can convert as little as 4.5 pounds of pedal force into 100 pounds of load moving force. Electronic air compressor pumps demonstrate capacities much greater than this.

Like all hydraulic pumps, air pumps have the same initial components. A reservoir is needed to hold the hydraulic fluids, which are usually oil or water-based composites. Hoses or tubes attached to this reservoir allow the fluid to move from the holding tank to the hydraulic cylinder, which houses a piston mechanism and two valves. An intake valve allows the hydraulic fluid to enter and then closes to trap it. The discharge valve is where the high pressure stream is released.

In addition to the hydraulic cylinder that houses one end of the piston, air hydraulic pumps also have an attached air cylinder. Compressed air in this cylinder, or air compressor, acts upon the protruding end of the piston. The air cylinder, when empty, allows a spring mechanism in the hydraulic cylinder to push the piston out. This creates a vacuum that draws the fluid from the reservoir into the hydraulic cylinder. When air is pressurized in the air compressor it engages the piston, pushing it further into the hydraulic cylinder and compressing the fluids.

This pumping action continues until the pressure in the hydraulic cylinder is great enough to force the fluid out through the discharge check valve. In some cases this is attached to hoses and a nozzle with the pressurized stream being the useful component. Other uses utilize the energy of this stream to push, pull and lift heavy loads.

Enerpac air hydraulic pumps are designed for high efficiency, proven reliability and enhanced productivity. High pressure hydraulic air driven pumps are ideal for delivering compact air over hydraulic. Constructed for safety, durability and the delivery of higher oil flow, these hydraulic power units provide high quality performance, as well as fine metering capabilities for precise control.

Enerpac Hydraulic Air Pumps provide high efficiency, proven reliability, and enhanced productivity. Choose from dozens of pneumatic hydraulic pump configurations; including single speed or 2 speed, low to high cycle, single-acting or double-acting, and various valve mount options.

Enerpac Air Over Hydraulic Pumps are rated for 10,000 psi (700 bar) and cover a multitude of different applications at locations where there’s access to a compressed air line. With so many options available for sale, there’s likely to be the ideal pump to power your application. Each offers the reassurance of trusted Enerpac high-quality, performance, and safety.

Manufacturer of air driven pumps for water and oil based fluid media. Pumps operate at 70 to 5,000 bar outlet pressure range with an automatic reciprocating differential area piston principle. Features include reduction of noise level due to less frictional resistance of air cycling valves, maintenance-friendly and robust design. Single and double acting type pumps are also offered. Pneumatic pumps are ATEX certified and used for pressurizing liquids for burst testing, charging, bolt tensioning and other high pressure purposes. Suitable for hydrostatic or pressure testing, chemical injection, dismantling of bearings, food preservation, vessel pressurization, research and development applications. Serves the automotive, gas processing, hose manufacturing, oil and gas industries.

High Pressure air operated hydraulic pumping systems are complete, self-contained units and ready to operate. Just hook up standard shop air supply (maximum 100 psi) to connection supplied on the side of the console. Discharge capacities range to 64 in3/min.

System includes hydraulic oil reservoir, oil filter, air operated hydraulic pump, pressure gauge, panel mounted high pressure valves, safety head assembly, panel mounted air regulator and gauge and air line filter and lubricator. All components are enclosed in a steel console with only the back exposed. Dimensions of standard systems are 26" wide, 24" deep and 40" high.

Pistons with O-ring seals operate in, fiberglass wrapped cylinders. The cylinder diameter is constant for a particular pump series. The driving medium pushes the piston down on the compression stroke and lifts it on the suction stroke (the M series has a spring return). No drive air lubricant is required as the piston is pre-lubricated during assembly.

In the hydraulic section, the drive piston connects to the hydraulic plunger/piston. Hydraulic pistons have different sizes depending on their nominal ratio. The higher ratio pumps can achieve higher pressures, but have smaller displacements, which translates to less flow per stroke.

During the down stroke, the inlet check valve keeps the liquid in the pump from flowing back into the suction line while it is compressed by the plunger. On the return or suction stroke, fresh liquid is drawn in through the inlet check valve, while the outlet check valve closes.

These check valves control the flow of liquid through the hydraulic section. They are spring-loaded and have a very low cracking pressure, which allows maximum flow during suction. Inlet check valves are closed by the hydraulic fluid pressure on downstrokes. At the same time, the outlet check valves open when the hydraulic pressure in the pump exceeds the pressure in the system after the pump.

This is a pilot operated, unbalanced lightweight spool that cycles the driving pressure first to the top of the driving piston and then to the bottom to cycle the piston. It is actuated through control valves at the beginning and end of stroke, causing the spool to move out of balance and the piston to move up and down.

A hydraulic seal is one of the few parts that wear out. Basically, it prevents fluid from flowing into the actuator while the hydraulic piston is moving back and forth. Seal specifications are determined by the fluid, its pressure and temperature. Most Haskel pumps can be operated without contamination by use of a vent or distance piece between the pump section and the air drive.

In a construction zone the power supply can be difficult to access. For these applications ITH developed the pneumatic pump Aero-MAX series and Travel-MAX. All the pumps can be used with standard air pressure systems. Typical applications for these pumps are bolt connections at the oil and gas industry (especially offshore) and special explosion-proof units are available as an option.

Air pressure connection ( Ø 10 mm, adaptable), air pressure gauge at the inlet, pneumatic adjusting valve, air shut-off valve, oiler and water filter with reservoir.

Hydraulic pressure adjusting valve: This provides for smooth adjustment of the max hydraulic pressure and enables a faster pressure build up since it doesn"t limit the air flow into the booster.

Two hydraulic couplings for using 1 or more bolt tensioning cylinders for simultaneously and even tensioning of 1 or more bolt connections at the same time (ITH Multi-Tensioning).

Pressure build up: Various designsHydraulic pressure adjusting valve: This provides for smooth adjustment of the max hydraulic pressure and enables a faster pressure build up since it doesn"t limit the air flow into the booster.

Without pressure adjusting valve: The hydraulic pressure output is controlled directly at the service unit (inlet pressure, primary side of the pressure cycle).

Air is used as pressure media. Especially in application areas in which wetting of the test sample is not allowed or the use of aggressive or ionising substances must be avoided, air is the ideal test medium. SIKA‘s pneumatic test pump fulfils requirements that in many cases can only be covered by several pumps from other suppliers.

Water and oil are used as pressure media. The easily operated hydraulic test pumps and pressure generators are specifically designed for the medium to high pressure range. They have a built-in reservoir for the hydraulic fluid. Pressures up to 350 bar, 700 bar or 1000 bar can be generated, depending on the model.

SIKA test pumps and pressure generators are suitable for testing, adjusting and calibrating pressure sensors, pressure gauges, pressure switches, safety valves and all types of pressure devices. They are optimised in their function and use and assist in the performance of specific tests and inspections.

MAXPRO® Technologies was founded in 1995 as the exclusive North American distributor of Maximator® products. Maximator® is globally recognized as an industry leader in high pressure solutions. Our expert team of engineers and customer service representatives will help you choose the best high pressure air-driven liquid pump for your application.

Maximator® air-driven piston style reciprocating pumps are a fast and effective pumping solution capable of delivering a wide range of pressures and flow rates. Our pumps get their power from a compressed air source and combine positive displacement with the capability to hold pressure for long periods of time. A variety of material and seal options allow almost any fluid to be pressurized. Maximator® pumps are rugged and rebuildable and can tolerate all installation positions and most environments.

Maximator® High-Pressure Air-Driven Liquid Pumps come in a variety of sizes and are useful in many industries, including oil & gas, mining, construction, aviation, aeronautics, automotive, biomedical, botanical oil extraction, alternative energy, chemical, defense, food processing, fracking, and more. Typical applications in these industries and others include:

Maximator GmbH is quality manufacturer with ISO 9001:2015 certification. CE Mark is available upon request. To learn more about any of our quality high-pressure air-driven liquid pumps, please contact us today.

MAXPRO is the exclusive supplier of Maximator pumps in North America. At MAXPRO® Technologies, we strive to offer the highest quality solutions for any high-pressure application. For more information about our high-pressure air-driven liquid pumps or any of our other high-pressure solutions, please contact us.

HPU-225 pneumatic hydraulic high pressure pump is a new type of hydraulic stretching and pressing process equipment. It converts the lower air pressure into pressure oil and becomes an ideal power source.

HPU-225 pneumatic hydraulic high pressure pump has the advantages of high output pressure, simple operation, safety and reliability, convenient carrying and so on. It can be widely used for fastening large and medium-sized mechanical screws and keyless matching of large transmission parts and structural parts in manufacturing industries such as metallurgy, mining, petrochemical industry, shipbuilding industry, locomotive and rolling stock. It is time-saving, labor-saving, uniform force distribution and reliable sealing. It is an ideal tool for the assembly and matching of various large and medium-sized machinery

Werner Weitner air hydraulic pumps can be used effectively in much case where high pressure is necessary and do not need much maintenance that means lower operating costs. WL series pumps produce 700 bar hydraulic output with only 5 bar air input. WL pumps can be used securely in several fields such as; operating hydraulic cylinders, pullers, presses...

These pumps are controlled by a foot pedal. When pedal is pressed from back side, the air engine starts to pump oil until you release the pedal to stop pumping. When pedal is pressed from front side, pressure relief operation could be completed. For security conditions, WL series hydro-pneumatic pumps are equipped with pressure relief valve just as other Weitner pumps. When pressure reaches the adjusted value, exceeding oil is discharged to tank due to reduce risks.

Air hydraulic pumps work more silently according to electrical or gasoline power units and can be used securely at any gaseous or flammable places. WL pumps also can be used as double acting with the help of a way control valve.

8613371530291

8613371530291