pneumatic hydraulic pump high pressure free sample

Pistons with O-ring seals operate in, fiberglass wrapped cylinders. The cylinder diameter is constant for a particular pump series. The driving medium pushes the piston down on the compression stroke and lifts it on the suction stroke (the M series has a spring return). No drive air lubricant is required as the piston is pre-lubricated during assembly.

In the hydraulic section, the drive piston connects to the hydraulic plunger/piston. Hydraulic pistons have different sizes depending on their nominal ratio. The higher ratio pumps can achieve higher pressures, but have smaller displacements, which translates to less flow per stroke.

During the down stroke, the inlet check valve keeps the liquid in the pump from flowing back into the suction line while it is compressed by the plunger. On the return or suction stroke, fresh liquid is drawn in through the inlet check valve, while the outlet check valve closes.

These check valves control the flow of liquid through the hydraulic section. They are spring-loaded and have a very low cracking pressure, which allows maximum flow during suction. Inlet check valves are closed by the hydraulic fluid pressure on downstrokes. At the same time, the outlet check valves open when the hydraulic pressure in the pump exceeds the pressure in the system after the pump.

This is a pilot operated, unbalanced lightweight spool that cycles the driving pressure first to the top of the driving piston and then to the bottom to cycle the piston. It is actuated through control valves at the beginning and end of stroke, causing the spool to move out of balance and the piston to move up and down.

A hydraulic seal is one of the few parts that wear out. Basically, it prevents fluid from flowing into the actuator while the hydraulic piston is moving back and forth. Seal specifications are determined by the fluid, its pressure and temperature. Most Haskel pumps can be operated without contamination by use of a vent or distance piece between the pump section and the air drive.

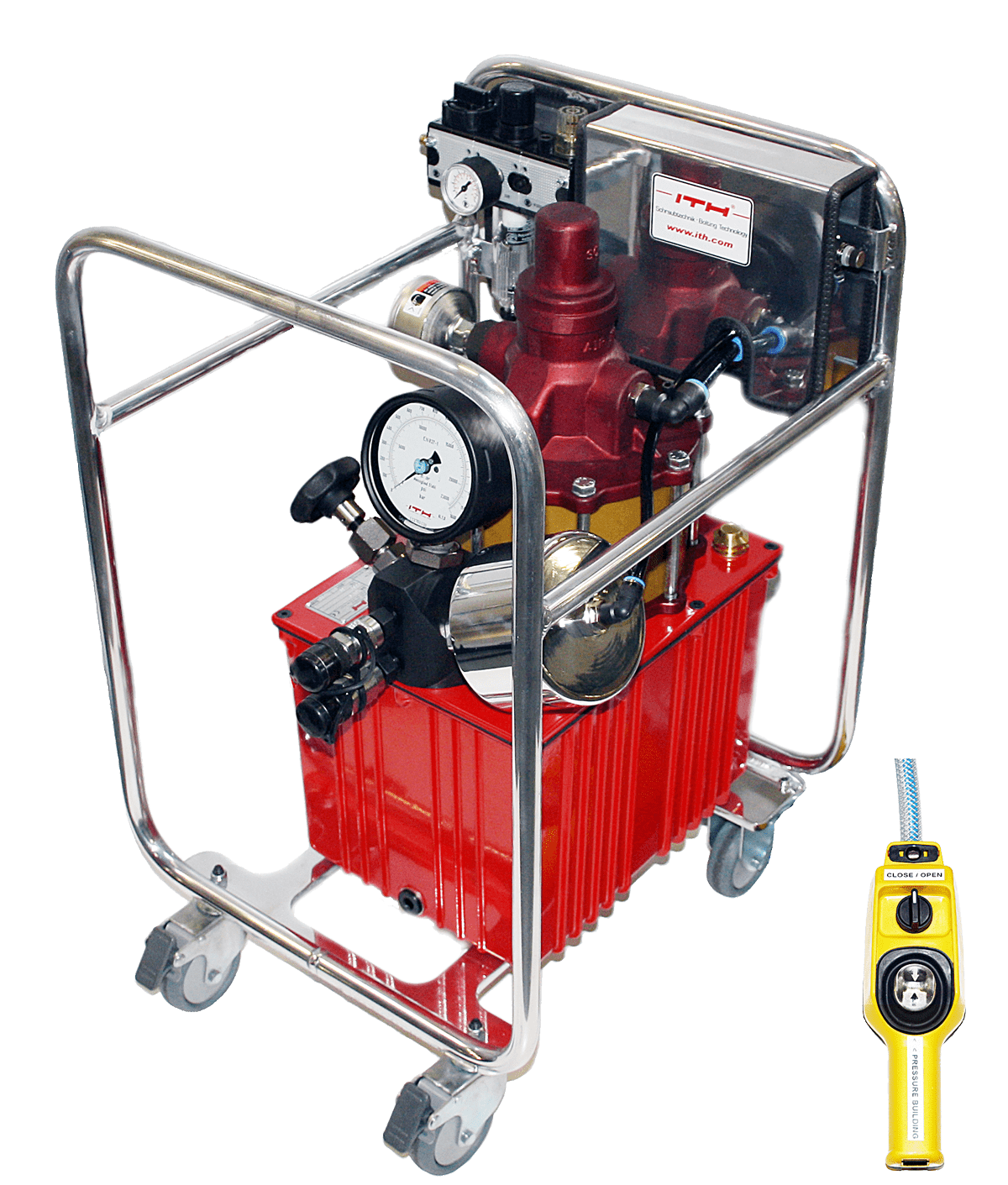

In a construction zone the power supply can be difficult to access. For these applications ITH developed the pneumatic pump Aero-MAX series and Travel-MAX. All the pumps can be used with standard air pressure systems. Typical applications for these pumps are bolt connections at the oil and gas industry (especially offshore) and special explosion-proof units are available as an option.

Air pressure connection ( Ø 10 mm, adaptable), air pressure gauge at the inlet, pneumatic adjusting valve, air shut-off valve, oiler and water filter with reservoir.

Hydraulic pressure adjusting valve: This provides for smooth adjustment of the max hydraulic pressure and enables a faster pressure build up since it doesn"t limit the air flow into the booster.

Two hydraulic couplings for using 1 or more bolt tensioning cylinders for simultaneously and even tensioning of 1 or more bolt connections at the same time (ITH Multi-Tensioning).

Pressure build up: Various designsHydraulic pressure adjusting valve: This provides for smooth adjustment of the max hydraulic pressure and enables a faster pressure build up since it doesn"t limit the air flow into the booster.

Without pressure adjusting valve: The hydraulic pressure output is controlled directly at the service unit (inlet pressure, primary side of the pressure cycle).

EngMatTec"s Air operated hydraulic piston pumps use the principle of intensification to generate up to 10,000 psi of hydraulic oil pressure with only 100 psi of compressed air.

Supplied with a 6 foot 6 inch (80") long extra heavy duty jacking hose rated to 17,600 psi. the Pump is assembled with a bigger 2.5 quart Oil Storage tank for Lager Tools and Attachments.

Can also be supplied without the 6 foot long 17,600 psi hose and screw together high-pressure couplers. Each item is sold separately or as this cost-effective set.

This 10,000 psi Pump and 6 foot long 17,600 psi Hose set is just what you"ll need on those Tough and Demanding Jobs that will need more oil to Push Harder, Pull Longer or Bend Further.

A 3-inch diameter aluminium piston with 100 psi of air pressure behind it, pushes a solid 1/4 inch diameter high tensile steel piston into an oil filled forged steel barrel.

As there is 100 time less surface area on the 1/4 inch piston all the force from the 3 inch piston is concentrated and the pressure generated is "intensified" to 10,000 psi.

With higher pump pressures and flow rates, Graco priming piston pumps handle a broad range of inks and high viscosity fluids with ease. These Graco designed pumps offer durability, power and reliability for any ink manufacturing or printing application. Choose from two reliable motor options: pneumatic or hydraulic, each capable of generating high pressures to meet your manufacturing demands.

Hydraulic pumps are mechanisms in hydraulic systems that move hydraulic fluid from point to point initiating the production of hydraulic power. Hydraulic pumps are sometimes incorrectly referred to as “hydrolic” pumps.

They are an important device overall in the hydraulics field, a special kind of power transmission which controls the energy which moving fluids transmit while under pressure and change into mechanical energy. Other kinds of pumps utilized to transmit hydraulic fluids could also be referred to as hydraulic pumps. There is a wide range of contexts in which hydraulic systems are applied, hence they are very important in many commercial, industrial, and consumer utilities.

“Power transmission” alludes to the complete procedure of technologically changing energy into a beneficial form for practical applications. Mechanical power, electrical power, and fluid power are the three major branches that make up the power transmission field. Fluid power covers the usage of moving gas and moving fluids for the transmission of power. Hydraulics are then considered as a sub category of fluid power that focuses on fluid use in opposition to gas use. The other fluid power field is known as pneumatics and it’s focused on the storage and release of energy with compressed gas.

"Pascal"s Law" applies to confined liquids. Thus, in order for liquids to act hydraulically, they must be contained within a system. A hydraulic power pack or hydraulic power unit is a confined mechanical system that utilizes liquid hydraulically. Despite the fact that specific operating systems vary, all hydraulic power units share the same basic components. A reservoir, valves, a piping/tubing system, a pump, and actuators are examples of these components. Similarly, despite their versatility and adaptability, these mechanisms work together in related operating processes at the heart of all hydraulic power packs.

The hydraulic reservoir"s function is to hold a volume of liquid, transfer heat from the system, permit solid pollutants to settle, and aid in releasing moisture and air from the liquid.

Mechanical energy is changed to hydraulic energy by the hydraulic pump. This is accomplished through the movement of liquid, which serves as the transmission medium. All hydraulic pumps operate on the same basic principle of dispensing fluid volume against a resistive load or pressure.

Hydraulic valves are utilized to start, stop, and direct liquid flow in a system. Hydraulic valves are made of spools or poppets and can be actuated hydraulically, pneumatically, manually, electrically, or mechanically.

The end result of Pascal"s law is hydraulic actuators. This is the point at which hydraulic energy is transformed back to mechanical energy. This can be accomplished by using a hydraulic cylinder to transform hydraulic energy into linear movement and work or a hydraulic motor to transform hydraulic energy into rotational motion and work. Hydraulic motors and hydraulic cylinders, like hydraulic pumps, have various subtypes, each meant for specific design use.

The essence of hydraulics can be found in a fundamental physical fact: fluids are incompressible. (As a result, fluids more closely resemble solids than compressible gasses) The incompressible essence of fluid allows it to transfer force and speed very efficiently. This fact is summed up by a variant of "Pascal"s Principle," which states that virtually all pressure enforced on any part of a fluid is transferred to every other part of the fluid. This scientific principle states, in other words, that pressure applied to a fluid transmits equally in all directions.

Furthermore, the force transferred through a fluid has the ability to multiply as it moves. In a slightly more abstract sense, because fluids are incompressible, pressurized fluids should keep a consistent pressure just as they move. Pressure is defined mathematically as a force acting per particular area unit (P = F/A). A simplified version of this equation shows that force is the product of area and pressure (F = P x A). Thus, by varying the size or area of various parts inside a hydraulic system, the force acting inside the pump can be adjusted accordingly (to either greater or lesser). The need for pressure to remain constant is what causes force and area to mirror each other (on the basis of either shrinking or growing). A hydraulic system with a piston five times larger than a second piston can demonstrate this force-area relationship. When a force (e.g., 50lbs) is exerted on the smaller piston, it is multiplied by five (e.g., 250 lbs) and transmitted to the larger piston via the hydraulic system.

Hydraulics is built on fluids’ chemical properties and the physical relationship between pressure, area, and force. Overall, hydraulic applications allow human operators to generate and exert immense mechanical force with little to no physical effort. Within hydraulic systems, both oil and water are used to transmit power. The use of oil, on the other hand, is far more common, owing in part to its extremely incompressible nature.

Pressure relief valves prevent excess pressure by regulating the actuators’ output and redirecting liquid back to the reservoir when necessary. Directional control valves are used to change the size and direction of hydraulic fluid flow.

While hydraulic power transmission is remarkably useful in a wide range of professional applications, relying solely on one type of power transmission is generally unwise. On the contrary, the most efficient strategy is to combine a wide range of power transmissions (pneumatic, hydraulic, mechanical, and electrical). As a result, hydraulic systems must be carefully embedded into an overall power transmission strategy for the specific commercial application. It is necessary to invest in locating trustworthy and skilled hydraulic manufacturers/suppliers who can aid in the development and implementation of an overall hydraulic strategy.

The intended use of a hydraulic pump must be considered when selecting a specific type. This is significant because some pumps may only perform one function, whereas others allow for greater flexibility.

The pump"s material composition must also be considered in the application context. The cylinders, pistons, and gears are frequently made of long-lasting materials like aluminum, stainless steel, or steel that can withstand the continuous wear of repeated pumping. The materials must be able to withstand not only the process but also the hydraulic fluids. Composite fluids frequently contain oils, polyalkylene glycols, esters, butanol, and corrosion inhibitors (though water is used in some instances). The operating temperature, flash point, and viscosity of these fluids differ.

In addition to material, manufacturers must compare hydraulic pump operating specifications to make sure that intended utilization does not exceed pump abilities. The many variables in hydraulic pump functionality include maximum operating pressure, continuous operating pressure, horsepower, operating speed, power source, pump weight, and maximum fluid flow. Standard measurements like length, rod extension, and diameter should be compared as well. Because hydraulic pumps are used in lifts, cranes, motors, and other heavy machinery, they must meet strict operating specifications.

It is critical to recall that the overall power generated by any hydraulic drive system is influenced by various inefficiencies that must be considered in order to get the most out of the system. The presence of air bubbles within a hydraulic drive, for example, is known for changing the direction of the energy flow inside the system (since energy is wasted on the way to the actuators on bubble compression). Using a hydraulic drive system requires identifying shortfalls and selecting the best parts to mitigate their effects. A hydraulic pump is the "generator" side of a hydraulic system that initiates the hydraulic procedure (as opposed to the "actuator" side that completes the hydraulic procedure). Regardless of disparities, all hydraulic pumps are responsible for displacing liquid volume and transporting it to the actuator(s) from the reservoir via the tubing system. Some form of internal combustion system typically powers pumps.

While the operation of hydraulic pumps is normally the same, these mechanisms can be split into basic categories. There are two types of hydraulic pumps to consider: gear pumps and piston pumps. Radial and axial piston pumps are types of piston pumps. Axial pumps produce linear motion, whereas radial pumps can produce rotary motion. The gear pump category is further subdivided into external gear pumps and internal gear pumps.

Each type of hydraulic pump, regardless of piston or gear, is either double-action or single-action. Single-action pumps can only pull, push, or lift in one direction, while double-action pumps can pull, push, or lift in multiple directions.

Vane pumps are positive displacement pumps that maintain a constant flow rate under varying pressures. It is a pump that self-primes. It is referred to as a "vane pump" because the effect of the vane pressurizes the liquid.

This pump has a variable number of vanes mounted onto a rotor that rotates within the cavity. These vanes may be variable in length and tensioned to maintain contact with the wall while the pump draws power. The pump also features a pressure relief valve, which prevents pressure rise inside the pump from damaging it.

Internal gear pumps and external gear pumps are the two main types of hydraulic gear pumps. Pumps with external gears have two spur gears, the spurs of which are all externally arranged. Internal gear pumps also feature two spur gears, and the spurs of both gears are internally arranged, with one gear spinning around inside the other.

Both types of gear pumps deliver a consistent amount of liquid with each spinning of the gears. Hydraulic gear pumps are popular due to their versatility, effectiveness, and fairly simple design. Furthermore, because they are obtainable in a variety of configurations, they can be used in a wide range of consumer, industrial, and commercial product contexts.

Hydraulic ram pumps are cyclic machines that use water power, also referred to as hydropower, to transport water to a higher level than its original source. This hydraulic pump type is powered solely by the momentum of moving or falling water.

Ram pumps are a common type of hydraulic pump, especially among other types of hydraulic water pumps. Hydraulic ram pumps are utilized to move the water in the waste management, agricultural, sewage, plumbing, manufacturing, and engineering industries, though only about ten percent of the water utilized to run the pump gets to the planned end point.

Despite this disadvantage, using hydropower instead of an external energy source to power this kind of pump makes it a prominent choice in developing countries where the availability of the fuel and electricity required to energize motorized pumps is limited. The use of hydropower also reduces energy consumption for industrial factories and plants significantly. Having only two moving parts is another advantage of the hydraulic ram, making installation fairly simple in areas with free falling or flowing water. The water amount and the rate at which it falls have an important effect on the pump"s success. It is critical to keep this in mind when choosing a location for a pump and a water source. Length, size, diameter, minimum and maximum flow rates, and speed of operation are all important factors to consider.

Hydraulic water pumps are machines that move water from one location to another. Because water pumps are used in so many different applications, there are numerous hydraulic water pump variations.

Water pumps are useful in a variety of situations. Hydraulic pumps can be used to direct water where it is needed in industry, where water is often an ingredient in an industrial process or product. Water pumps are essential in supplying water to people in homes, particularly in rural residences that are not linked to a large sewage circuit. Water pumps are required in commercial settings to transport water to the upper floors of high rise buildings. Hydraulic water pumps in all of these situations could be powered by fuel, electricity, or even by hand, as is the situation with hydraulic hand pumps.

Water pumps in developed economies are typically automated and powered by electricity. Alternative pumping tools are frequently used in developing economies where dependable and cost effective sources of electricity and fuel are scarce. Hydraulic ram pumps, for example, can deliver water to remote locations without the use of electricity or fuel. These pumps rely solely on a moving stream of water’s force and a properly configured number of valves, tubes, and compression chambers.

Electric hydraulic pumps are hydraulic liquid transmission machines that use electricity to operate. They are frequently used to transfer hydraulic liquid from a reservoir to an actuator, like a hydraulic cylinder. These actuation mechanisms are an essential component of a wide range of hydraulic machinery.

There are several different types of hydraulic pumps, but the defining feature of each type is the use of pressurized fluids to accomplish a job. The natural characteristics of water, for example, are harnessed in the particular instance of hydraulic water pumps to transport water from one location to another. Hydraulic gear pumps and hydraulic piston pumps work in the same way to help actuate the motion of a piston in a mechanical system.

Despite the fact that there are numerous varieties of each of these pump mechanisms, all of them are powered by electricity. In such instances, an electric current flows through the motor, which turns impellers or other devices inside the pump system to create pressure differences; these differential pressure levels enable fluids to flow through the pump. Pump systems of this type can be utilized to direct hydraulic liquid to industrial machines such as commercial equipment like elevators or excavators.

Hydraulic hand pumps are fluid transmission machines that utilize the mechanical force generated by a manually operated actuator. A manually operated actuator could be a lever, a toggle, a handle, or any of a variety of other parts. Hydraulic hand pumps are utilized for hydraulic fluid distribution, water pumping, and various other applications.

Hydraulic hand pumps may be utilized for a variety of tasks, including hydraulic liquid direction to circuits in helicopters and other aircraft, instrument calibration, and piston actuation in hydraulic cylinders. Hydraulic hand pumps of this type use manual power to put hydraulic fluids under pressure. They can be utilized to test the pressure in a variety of devices such as hoses, pipes, valves, sprinklers, and heat exchangers systems. Hand pumps are extraordinarily simple to use.

Each hydraulic hand pump has a lever or other actuation handle linked to the pump that, when pulled and pushed, causes the hydraulic liquid in the pump"s system to be depressurized or pressurized. This action, in the instance of a hydraulic machine, provides power to the devices to which the pump is attached. The actuation of a water pump causes the liquid to be pulled from its source and transferred to another location. Hydraulic hand pumps will remain relevant as long as hydraulics are used in the commerce industry, owing to their simplicity and easy usage.

12V hydraulic pumps are hydraulic power devices that operate on 12 volts DC supplied by a battery or motor. These are specially designed processes that, like all hydraulic pumps, are applied in commercial, industrial, and consumer places to convert kinetic energy into beneficial mechanical energy through pressurized viscous liquids. This converted energy is put to use in a variety of industries.

Hydraulic pumps are commonly used to pull, push, and lift heavy loads in motorized and vehicle machines. Hydraulic water pumps may also be powered by 12V batteries and are used to move water out of or into the desired location. These electric hydraulic pumps are common since they run on small batteries, allowing for ease of portability. Such portability is sometimes required in waste removal systems and vehiclies. In addition to portable and compact models, options include variable amp hour productions, rechargeable battery pumps, and variable weights.

While non rechargeable alkaline 12V hydraulic pumps are used, rechargeable ones are much more common because they enable a continuous flow. More considerations include minimum discharge flow, maximum discharge pressure, discharge size, and inlet size. As 12V batteries are able to pump up to 150 feet from the ground, it is imperative to choose the right pump for a given use.

Air hydraulic pumps are hydraulic power devices that use compressed air to stimulate a pump mechanism, generating useful energy from a pressurized liquid. These devices are also known as pneumatic hydraulic pumps and are applied in a variety of industries to assist in the lifting of heavy loads and transportation of materials with minimal initial force.

Air pumps, like all hydraulic pumps, begin with the same components. The hydraulic liquids, which are typically oil or water-based composites, require the use of a reservoir. The fluid is moved from the storage tank to the hydraulic cylinder via hoses or tubes connected to this reservoir. The hydraulic cylinder houses a piston system and two valves. A hydraulic fluid intake valve allows hydraulic liquid to enter and then traps it by closing. The discharge valve is the point at which the high pressure fluid stream is released. Air hydraulic pumps have a linked air cylinder in addition to the hydraulic cylinder enclosing one end of the piston.

The protruding end of the piston is acted upon by a compressed air compressor or air in the cylinder. When the air cylinder is empty, a spring system in the hydraulic cylinder pushes the piston out. This makes a vacuum, which sucks fluid from the reservoir into the hydraulic cylinder. When the air compressor is under pressure, it engages the piston and pushes it deeper into the hydraulic cylinder and compresses the liquids. This pumping action is repeated until the hydraulic cylinder pressure is high enough to forcibly push fluid out through the discharge check valve. In some instances, this is connected to a nozzle and hoses, with the important part being the pressurized stream. Other uses apply the energy of this stream to pull, lift, and push heavy loads.

Hydraulic piston pumps transfer hydraulic liquids through a cylinder using plunger-like equipment to successfully raise the pressure for a machine, enabling it to pull, lift, and push heavy loads. This type of hydraulic pump is the power source for heavy-duty machines like excavators, backhoes, loaders, diggers, and cranes. Piston pumps are used in a variety of industries, including automotive, aeronautics, power generation, military, marine, and manufacturing, to mention a few.

Hydraulic piston pumps are common due to their capability to enhance energy usage productivity. A hydraulic hand pump energized by a hand or foot pedal can convert a force of 4.5 pounds into a load-moving force of 100 pounds. Electric hydraulic pumps can attain pressure reaching 4,000 PSI. Because capacities vary so much, the desired usage pump must be carefully considered. Several other factors must also be considered. Standard and custom configurations of operating speeds, task-specific power sources, pump weights, and maximum fluid flows are widely available. Measurements such as rod extension length, diameter, width, and height should also be considered, particularly when a hydraulic piston pump is to be installed in place of a current hydraulic piston pump.

Hydraulic clutch pumps are mechanisms that include a clutch assembly and a pump that enables the user to apply the necessary pressure to disengage or engage the clutch mechanism. Hydraulic clutches are crafted to either link two shafts and lock them together to rotate at the same speed or detach the shafts and allow them to rotate at different speeds as needed to decelerate or shift gears.

Hydraulic pumps change hydraulic energy to mechanical energy. Hydraulic pumps are particularly designed machines utilized in commercial, industrial, and residential areas to generate useful energy from different viscous liquids pressurization. Hydraulic pumps are exceptionally simple yet effective machines for moving fluids. "Hydraulic" is actually often misspelled as "Hydralic". Hydraulic pumps depend on the energy provided by hydraulic cylinders to power different machines and mechanisms.

There are several different types of hydraulic pumps, and all hydraulic pumps can be split into two primary categories. The first category includes hydraulic pumps that function without the assistance of auxiliary power sources such as electric motors and gas. These hydraulic pump types can use the kinetic energy of a fluid to transfer it from one location to another. These pumps are commonly called ram pumps. Hydraulic hand pumps are never regarded as ram pumps, despite the fact that their operating principles are similar.

The construction, excavation, automotive manufacturing, agriculture, manufacturing, and defense contracting industries are just a few examples of operations that apply hydraulics power in normal, daily procedures. Since hydraulics usage is so prevalent, hydraulic pumps are unsurprisingly used in a wide range of machines and industries. Pumps serve the same basic function in all contexts where hydraulic machinery is used: they transport hydraulic fluid from one location to another in order to generate hydraulic energy and pressure (together with the actuators).

Elevators, automotive brakes, automotive lifts, cranes, airplane flaps, shock absorbers, log splitters, motorboat steering systems, garage jacks and other products use hydraulic pumps. The most common application of hydraulic pumps in construction sites is in big hydraulic machines and different types of "off-highway" equipment such as excavators, dumpers, diggers, and so on. Hydraulic systems are used in other settings, such as offshore work areas and factories, to power heavy machinery, cut and bend material, move heavy equipment, and so on.

Fluid’s incompressible nature in hydraulic systems allows an operator to make and apply mechanical power in an effective and efficient way. Practically all force created in a hydraulic system is applied to the intended target.

Because of the relationship between area, pressure, and force (F = P x A), modifying the force of a hydraulic system is as simple as changing the size of its components.

Hydraulic systems can transfer energy on an equal level with many mechanical and electrical systems while being significantly simpler in general. A hydraulic system, for example, can easily generate linear motion. On the contrary, most electrical and mechanical power systems need an intermediate mechanical step to convert rotational motion to linear motion.

Hydraulic systems are typically smaller than their mechanical and electrical counterparts while producing equivalents amounts of power, providing the benefit of saving physical space.

Hydraulic systems can be used in a wide range of physical settings due to their basic design (a pump attached to actuators via some kind of piping system). Hydraulic systems could also be utilized in environments where electrical systems would be impractical (for example underwater).

By removing electrical safety hazards, using hydraulic systems instead of electrical power transmission improves relative safety (for example explosions, electric shock).

The amount of power that hydraulic pumps can generate is a significant, distinct advantage. In certain cases, a hydraulic pump could generate ten times the power of an electrical counterpart. Some hydraulic pumps (for example, piston pumps) cost more than the ordinary hydraulic component. These drawbacks, however, can be mitigated by the pump"s power and efficiency. Despite their relatively high cost, piston pumps are treasured for their strength and capability to transmit very viscous fluids.

Handling hydraulic liquids is messy, and repairing leaks in a hydraulic pump can be difficult. Hydraulic liquid that leaks in hot areas may catch fire. Hydraulic lines that burst may cause serious injuries. Hydraulic liquids are corrosive as well, though some are less so than others. Hydraulic systems need frequent and intense maintenance. Parts with a high factor of precision are frequently required in systems. If the power is very high and the pipeline cannot handle the power transferred by the liquid, the high pressure received by the liquid may also cause work accidents.

Even though hydraulic systems are less complex than electrical or mechanical systems, they are still complex systems that should be handled with caution. Avoiding physical contact with hydraulic systems is an essential safety precaution when engaging with them. Even when a hydraulic machine is not in use, active liquid pressure within the system can be a hazard.

Inadequate pumps can cause mechanical failure in the place of work that can have serious and costly consequences. Although pump failure has historically been unpredictable, new diagnostic technology continues to improve on detecting methods that previously relied solely on vibration signals. Measuring discharge pressures enables manufacturers to forecast pump wear more accurately. Discharge sensors are simple to integrate into existing systems, increasing the hydraulic pump"s safety and versatility.

Hydraulic pumps are devices in hydraulic systems that move hydraulic fluid from point to point, initiating hydraulic power production. They are an important device overall in the hydraulics field, a special kind of power transmission that controls the energy which moving fluids transmit while under pressure and change into mechanical energy. Hydraulic pumps are divided into two categories namely gear pumps and piston pumps. Radial and axial piston pumps are types of piston pumps. Axial pumps produce linear motion, whereas radial pumps can produce rotary motion. The construction, excavation, automotive manufacturing, agriculture, manufacturing, and defense contracting industries are just a few examples of operations that apply hydraulics power in normal, daily procedures.

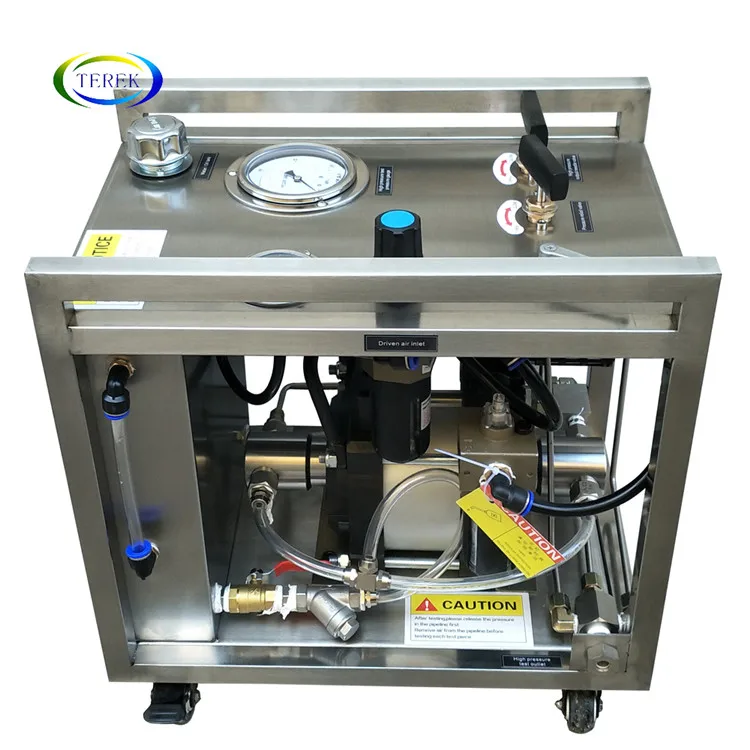

Pressure is one of the most commonly measured quantities in engineering, which is why exact and reliable pressure measurement is especially important. However, the characteristics of the even best sensor or transducer can be altered by a wide variety of factors. This drift cannot be prevented, and it leads to incorrect readings. Calibration allows these deviations to be measured and documented in a certificate. All pressure measuring devices that significantly affect processes or activities should be calibrated before being used. SIKA‘s mobile test and calibration devices are effective aids for performing the necessary test and calibration tasks quickly.

Air is used as pressure media. Especially in application areas in which wetting of the test sample is not allowed or the use of aggressive or ionising substances must be avoided, air is the ideal test medium. SIKA‘s pneumatic test pump fulfils requirements that in many cases can only be covered by several pumps from other suppliers. SIKA test pumps and pressure generators are suitable for testing, adjusting and calibrating pressure sensors, pressure gauges, pressure switches, safety valves and all types of pressure devices. They are optimised in their function and use and assist in the performance of specific tests and inspections.

Water and oil are used as pressure media. The easily operated hydraulic test pumps and pressure generators are specifically designed for the medium to high pressure range. They have a built-in reservoir for the hydraulic fluid. Pressures up to 350 bar, 700 bar or 1000 bar can be generated, depending on the model. SIKA test pumps and pressure generators are suitable for testing, adjusting and calibrating pressure sensors, pressure gauges, pressure switches, safety valves and all types of pressure devices. They are optimised in their function and use and assist in the performance of specific tests and inspections.

The latest generation of comparison test pumps combines precision – also with high pressures – and high manufacturing quality. Depending on the model, air, distilled water and / or hydraulic fluid can be used as the test medium.

The sophisticated design of these comparison test pumps allows effortless installation of test sample including those with big nominal diameters. The integrated adapters at the pressure connections additionally allow free adjustment of the reference pressure gauge and the test sample. Filling the pressure vessel and test pressure generation are easily carried out by means of a revolving spindle. The standard pressurising medium tank installed on the test pump allows smooth filling of large volumes. Pressure fluctuations due to air and gas particles, compensation of thermodynamic effects as well as the exact setting of the desired test pressure are carried out by means of the fine adjustment (optional). Distilled water is excellently suited as calibration medium, as it can be removed without problems and without residue. For test pressures above 1000 bar (approx. 14,500 psi), hydraulic fluid is recommended since its higher viscosity allows easier test pressure generation. All parts coming in touch with the medium are made of stainless steel thus ensuring wear-free operation.

Although the lightweight high-pressure hydraulic table top pumps are compactly built, they provide a big nylon tank with a usable tank volume of 327 cm3. In combination with a delivery volume of 0.9 cm3 per piston stroke, they provide the opportunity of testing multiple test samples in parallel. They are installed directly on the delivered pressure hose or via a separate distributor block therefore saving time and making your test tasks very efficient. The integrated check valve within the pressure vessel very quickly leads to stable pressure states. The integrated safety valve protects from overloading.

Pneumatics is more cost-effective than Hydraulics as air is free and can useable generally n flammable environments. Pneumatics offers more power in a smaller and lighter unit compared to most other technology systems, as well as being a much cleaner technology.

Some prefer electric drive over the pneumatic and hydraulic system, as electric drive actuators generally have better point-of-interest accuracy and repeatability than an equivalent pneumatic or hydraulic actuator.

Like pneumatics, hydraulic actuators comprise pistons that move inside a hollow cylinder. Incompressible liquid coming from a pump moves the cylinder. As the pressure increases, the cylinder is likewise moved along the axis of that piston and creates a linear force.

Both hydraulic and electrical systems have their advantages. Still, you can count on hydraulic actuators to be more suited for high-force applications as these rugged actuators can produce a force that is 25 times more powerful than pneumatic cylinders the same size.

They can operate in pressures as high as 4,000 psi. They can even hold torque and force constant without requiring a pump to supply more fluid or pressure because it uses incompressible fluids. You can put the motors and pumps away at a certain distance without much power loss.

They are smooth, network-friendly, reprogrammable, repeatable, and quieter compared to Hydraulics and can give you diagnostics or maintenance feedback immediately.

Enerpac Hydraulic Air Pumps provide high efficiency, proven reliability, and enhanced productivity. Choose from dozens of pneumatic hydraulic pump configurations; including single speed or 2 speed, low to high cycle, single-acting or double-acting, and various valve mount options.

Enerpac Air Over Hydraulic Pumps are rated for 10,000 psi (700 bar) and cover a multitude of different applications at locations where there’s access to a compressed air line. With so many options available for sale, there’s likely to be the ideal pump to power your application. Each offers the reassurance of trusted Enerpac high-quality, performance, and safety.

When it comes to operating heavy machinery and equipment, a hydraulic system likely does the heavy lifting. These powerful pieces of equipment are capable of moving impressive weights and are behind some of the most vital tasks of many businesses. With all the work they do, proper hydraulic system care is critical. Without it, you risk damaging the components, losing efficiency and injuring workers by creating safety hazards.

Many maintenance tasks need to be done regularly, so it helps to keep a list handy. We"ve compiled a hydraulic system maintenance checklist, so you can ensure your system stays clean and healthy.

A hydraulic system is a critical component of most heavy machinery. The fluid power a hydraulic system generates enables the force needed to lift and move heavy parts.

Hydraulic systems themselves feature numerous intricate components that must operate efficiently for the system to function. Keeping each assembly in working order requires a regular maintenance routine.

Your employees are the heart and soul of your organization — ensuring their safety allows you to continue doing what you do. Working around hydraulic equipment is dangerous, especially when the equipment malfunctions or breaks down. Instituting a regular maintenance routine will help you notice and repair potentially hazardous issues to minimize the chances of a harmful incident occurring.

Time is money, so you do everything you can to keep your crew on schedule. Regular equipment maintenance is a critical aspect of workplace efficiency, as servicing your equipment will help prevent breakdowns and injuries that could halt your operations. Rather than falling behind due to unforeseen incidents, work regular maintenance into your schedule to maximize uptime. The comparatively small amount of time you dedicate to hydraulic equipment maintenance will increase your organization"s productivity in the long run.

Your organization spent a lot of money purchasing hydraulic equipment, so it is wise to preserve that investment through consistent maintenance. A breakdown could cause you to spend even more money repairing or replacing those resources. Maintenance technicians clear the clogs and corrosion that could damage your system"s critical components. By investing a small amount in hydraulic servicing, you will save your business from the high costs of repairing components, replacing your entire system or covering employee medical bills.

Check your hydraulic oil on a consistent schedule — it needs to remain clean and free of any contaminants. You should empty and replace the hydraulic oil after every 1,000 hours of work or per the manufacturer"s instructions.

Read the manufacturer specifications to confirm how often you should change the fluid and other factors of hydraulic fluid care. It is essential to use the same type of hydraulic fluid every time you top off your levels. If possible, use the same brand each time as well.

Filters take on the task of removing even the most minuscule particles that could clog your hydraulic system. However, the process of keeping particulates out of the system causes the filters themselves to become clogged over time. Your filters will lose efficacy as they accumulate pollutants, so replace them often. If applicable, make sure to clean the filter bowl as well.

Visually inspect the rod for wear, such as corrosion and pitting. These issues can lead to moisture within the fluid, which compounds and can cause many problems for your hydraulic system, like increased wear and inadequate lubrication.

If rod corrosion occurs, it can damage the seal from excess friction. Other dangers to seals include excess pressure and fluid contaminants. A worn seal may leak, causing equipment hazards and environmental health and safety concerns. If there are signs the seal is damaged, check with your equipment manufacturer about proper replacement.

Fluctuations in pressure or line thickness can lead to equipment damage. For example, excessive pressure from the cylinder can cause ballooning, where the line dilates and allows too much high-pressure fluid to pass, thus wearing out the seals. Regularly inspect the condition of the lines and make sure they are not ballooning.

For optimal functioning, you must watch your fluid levels, adding to them as needed. Too little hydraulic fluid can damage your pumps. Just like when replacing contaminated oil, be sure to follow the specifications given by the manufacturer and take care to avoid mixing oils.

Breathers must be kept clean or risk contaminating the hydraulic system. Clean the breather regularly and inspect it for holes or tears. Different types of breathers may have additional requirements, so check the manufacturer"s instructions. Spring types, for instance, may need to be replaced annually to avoid tension loss that allows contaminants. Others can have indicators that tell you when to replace filters or caps. Be aware of any additional steps such as these.

If hoses are pinched, kinked, frayed, bubbling, stretched or otherwise damaged, they can restrict the flow of fluid or lead to pressure leaks. Most of these problems are visible from the outside, but others occur internally, so inspect the inside for damage that could cause a clog.

Similar to aeration, cavitation is the result of gas bubbles experiencing rapid changes in pressure. The gas bubbles implode, causing miniature shock waves. The shock waves generate repeated stress on the metal surfaces, damaging the components.

Scan electrically controlled Servo valves using an infrared thermometer and check the temperature of these valves. If it is higher than 150℉, you may have a problem with the valve. Slow or errant operation at the valve points can be a sign of contaminated fluid.

Keep your infrared thermometer out and use it on the electric drive motor to detect any areas of high heat. These areas could be on the housing or rotor bearings and require servicing to avoid further damage to the equipment.

As with any maintenance task, it"s important to approach it the right way. Here are some hydraulic system troubleshooting tips that can make the process easier and faster for your employees:

Watch your access points and pressure readings:When setting up your system, place frequently accessed components, like filters and gauges, in easy-to-reach places.

Safety first:Always remember how much power a hydraulic system is capable of. Only allow skilled, trained technicians to perform maintenance on them to avoid injury or damage.

York Precision Machining & Hydraulics is leading the way in precision fluid power components and systems. York Precision is home to the renowned Bear-Loc® and Bear-Loc® Hydraulic Locking Actuator, the most reliable locking solution available. More information about Bear-Loc and York Precision products and capabilities is available here.

Proper hydraulic maintenance and a quality hydraulic locking actuator can help protect the longevity of your system and the safety of your employees. For more information about hydraulic systems and how Bear-Loc® can improve yours, reach out to a representative today.

8613371530291

8613371530291