pneumatic powered hydraulic pump free sample

Pistons with O-ring seals operate in, fiberglass wrapped cylinders. The cylinder diameter is constant for a particular pump series. The driving medium pushes the piston down on the compression stroke and lifts it on the suction stroke (the M series has a spring return). No drive air lubricant is required as the piston is pre-lubricated during assembly.

In the hydraulic section, the drive piston connects to the hydraulic plunger/piston. Hydraulic pistons have different sizes depending on their nominal ratio. The higher ratio pumps can achieve higher pressures, but have smaller displacements, which translates to less flow per stroke.

During the down stroke, the inlet check valve keeps the liquid in the pump from flowing back into the suction line while it is compressed by the plunger. On the return or suction stroke, fresh liquid is drawn in through the inlet check valve, while the outlet check valve closes.

These check valves control the flow of liquid through the hydraulic section. They are spring-loaded and have a very low cracking pressure, which allows maximum flow during suction. Inlet check valves are closed by the hydraulic fluid pressure on downstrokes. At the same time, the outlet check valves open when the hydraulic pressure in the pump exceeds the pressure in the system after the pump.

A hydraulic seal is one of the few parts that wear out. Basically, it prevents fluid from flowing into the actuator while the hydraulic piston is moving back and forth. Seal specifications are determined by the fluid, its pressure and temperature. Most Haskel pumps can be operated without contamination by use of a vent or distance piece between the pump section and the air drive.

This application note explores the basic principle of pneumatic pumps and flow control system based on the basic principle of pneumatic pumps, known as piezoelectric regulation technology of pressure driven flow control makes it better suited in terms of responsiveness and accuracy. It also demonstrates the applications of pressure driven flow control in a range of industrial & research fields.

As an introduction to pneumatic pumps, it’s important to understand that pneumatics is a branch of technology that uses the force of compressed gases to create mechanical effects. Pneumatics pumps use these mechanical forces to manipulate the movement of fluids within microfluidic channels.

Pneumatic pumps basically use air in the same method, that a hydraulic pump would employ fluids. Both these pumps are capable of producing amplified levels of mechanical force which translates into a high source of power.

The basic principle of a pneumatic pump is focused on the use of pressurized gas or air to move media. When pneumatic pumps are utilized for industrial applications, it involves the use of compressed inert gases or compressed air.

These pumps utilize a double piston system. One of these pistons have a much smaller diameter than the other, and they are separated by an airtight chamber filled with a liquid or a compressed gas.

Pneumatic pumps are well known aspositive displacement pumpsthat are double-acting with no return spring. They are capable of utilizing many pressurized gases or fluids as drivers. There are many different types of pneumatic pumps, but here are the ones that are popular for industrial applications:

Pneumatic Diaphragm Pumps (both piston and plunger types) – It uses a plunger/piston mechanism to facilitate the movement of media through a cylindrical chamber. This mechanism is powered by a pneumatic, electric, hydraulic, or steam drive.

Pressure-driven flow control was introduced as a proprietary technology by Elveflow, based on the basic principle of a pneumatic pump. The introduction of peizoelectric technology opens the door to many integration use-cases for industrial applications, from droplet generation to even sensor calibration. These features makes the pressure-driven flow controller capable of offering unrivalled flow regulation accuracy & responsiveness.

Other types of pneumatic pumps are cost-effective and have been used for a long period. Nevertheless, performance proves to be the bottleneck (response time, accuracy & pulses). It can be critical when the setup is complex or when a fine control is requested as it is usually the case in microfluidics.

Pressure driven flow control is becoming much more widely accepted pump system, because it was developed specifically for microfluidics. It meets users expectations with its performances (responsiveness, stability, reproducibility). Thepiezoelectric regulation technology is adapted to most microfluidic applications (97%*).

Pressure driven flow control proves to be one of the best pneumatic pump systems for various reasons. It allows pulseless flow with a sub-second response time. It consists in using a gas input pressure within a hermetic liquid tank, in order to flow liquid from the tank to your microfluidic device.

This technology ensures fine handling of large fluid volumes (several liters) and allowing long-term experiments. The fast responsiveness & high stability of pressure-driven flow control offer critical features compared to peristaltic pumps for several applications from droplet generation, flow focusing, flow chemistry or synthesis.

EngMatTec"s Air operated hydraulic piston pumps use the principle of intensification to generate up to 10,000 psi of hydraulic oil pressure with only 100 psi of compressed air.

Supplied with a 6 foot 6 inch (80") long extra heavy duty jacking hose rated to 17,600 psi. the Pump is assembled with a bigger 2.5 quart Oil Storage tank for Lager Tools and Attachments.

This 10,000 psi Pump and 6 foot long 17,600 psi Hose set is just what you"ll need on those Tough and Demanding Jobs that will need more oil to Push Harder, Pull Longer or Bend Further.

The ESCO Air Reducer, for Air/Hydraulic Pumps, is designed to regulate the air pressure that is received by the hydraulic pump, that is then used to power all ESCO Hydraulic Tools.

Maintaining air pressure when using Hydraulic Equipment will increase the Proper Functioning of Hydraulic Equipment, Protect Air/Hydraulic Pumps from Over-Flow of Air, and Keep ESCO Hydraulic Products in their PRIME.

The ESCO Air Reducer, for Air/Hydraulic Pumps, is designed to regulate the air pressure that is received by the hydraulic pump, that is then used to power all ESCO Hydraulic Tools.

Maintaining air pressure when using Hydraulic Equipment will increase the Proper Functioning of Hydraulic Equipment, Protect Air/Hydraulic Pumps from Over-Flow of Air, and Keep ESCO Hydraulic Products in their PRIME.

Simply put, applications of hydraulic devices are best for when higher force and heavy lifting is needed. Use pneumatics for mechanical and lighter engineering needs. Here are some examples of how each is used:

The most important reason is safety. Pressurized hydraulic fluid that suddenly escapes presents the threat of explosive velocity. Another hydraulic safety issue concerns the harm that faults can cause with unexpected movement by sharp, heavy equipment, injuring those nearby.

Keep in mind that fluid power hydraulic and pneumatic systems are low maintenance, with pneumatics even more so. Pneumatic safety precautions involve ensuring hoses are free from damage. Old or fraying hoses leak air, which causes equipment to malfunction. That, in turn, can cause serious harm to users. To learn more about protecting hoses, don’t miss Hydraulic hose protection to ensure safe designs and Quick Guide: hydraulics and pneumatics protection in specialist vehicles.

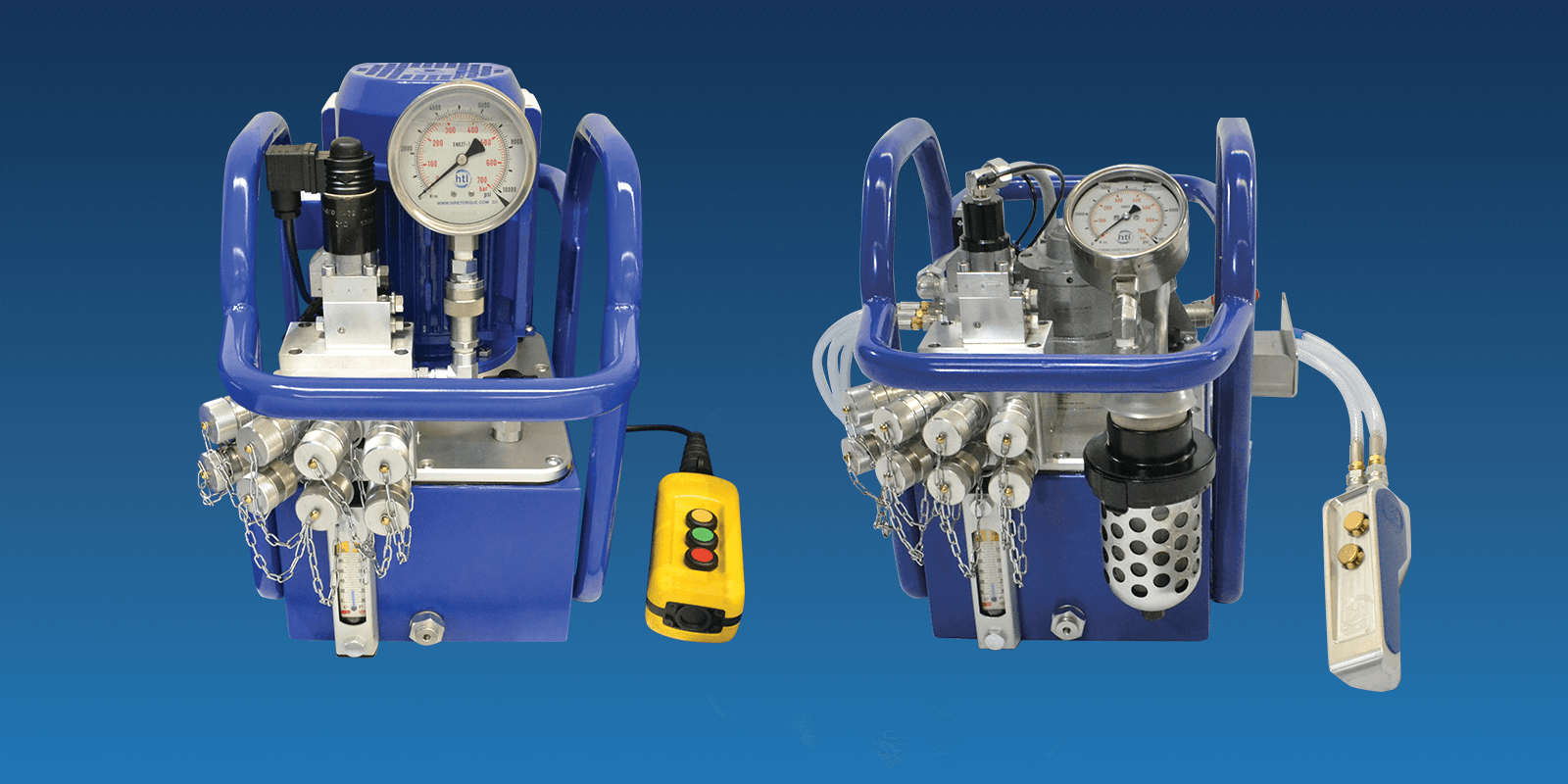

The Enerpac LAT Torque Wrench Pump combines compact design and high productivity for bolting applications in areas hard to access with larger air powered pumps. Whether on an offshore platform, refinery, or mine anywhere in the world, the pump is built for the toughest worksite environments. Featuring a proven Enerpac piston design, reinforced FRL support and air supply connection, the LAT will provide years of reliable service with fastening and breakout speeds to keep you on schedule and under budget.

The many types of hydraulic pumps available today mean there’s one to suit just about any hydraulic application imaginable. But with so many features to consider, for anyone choosing a pump for the first time the choices may seem overwhelming.

Before you can select the right pump, first of all, you should understand the basics, and also the features that can be configured. Answering a few key questions about your intended applications will help you narrow the options.

A key consideration is how you want the pump to be powered. What drives this decision is the location where you will be carrying out the work. For example, if you are working in a hazardous environment, a ‘spark free’ (ATEX certified) air-driven hydraulic pump will offer a safer solution.

If working at a remote location without access to compressed air or electric power, a battery-powered pump is the way to go. Manually powered pumps, such as foot pumps and hand pumps, offer a simple solution for smaller jobs. Especially those where the operation doesn’t need to be repeated many times or when a very slow level of force is needed in a testing environment.

Most hydraulic pump manufacturers categorize their pumps by the intended pairing to the hydraulic tool and application. It’s worth noting there are key differences that make them suited to each hydraulic application.

Do you plan to use a pump with a hydraulic cylinder? The major consideration is whether you need a pump designed for a single or double-acting application. If the cylinder is double-acting, the pump will need at least two ports. One for the advance line – to extend the cylinder, the other for the return line – to retract it.

Pumps for hydraulic torque wrenches include a user-adjustable relief valve that allows the operator to easily set the correct torque pressure. They usually also include an onboard pressure gauge which can be either analog or digital.

By nature, pumps are generally very heavy, but lighter models are available which are easier to lift and carry to the work location. Roll cages are also a good feature to provide extra durability.

Hydraulic tensioner pumps are available in manual, air, and electric powered configurations. What makes a tensioner pump different is the capacity to work at very high pressures up to 21,750 psi (1500 bar). Pro Tip: Because these pumps operate at very high pressures you must always use fittings and hoses designed for these pressures.

Machinery used in manufacturing plants often include built-in hydraulics to operate workholding setups. However, where there isn’t such a system, (or if the hydraulic pressure needs increasing), a separate pump can be added.

These types of fixed bench application types of hydraulic pumps are powered by compressed air or electricity. Air-operated hydraulic pumps are powered by workshop air and are best suited to low or medium-duty cycles. Electric powered pumps are recommended for high-duty cycle applications and automation. They offer great versatility, low noise and provide the highest level of performance and durability.

For multi-point lifts, a controlled lifting pump offers a better solution than independently operated pumps. High precision movement of large objects requires synchronization of multiple lifting points. This can be achieved using a controlled lifting pump. By regulating the oil flow to each cylinder, these pumps provide incredibly accurate positional control. Manual intervention is minimized, the structural integrity of the load is maintained, and productivity and safety is assured.

Controlled lifting pumps feature both single and synchronized multiple outlet control either through joystick or pendant operation. More sophisticated models such as the EVO Synchronous Lifting System use stroke sensors. These can provide accuracy of up to 0.040 in (1 mm) between leading and lagging cylinders.

Technical and performance considerations can be examined in great detail and will be covered in a pump series of blog posts. But for overview purposes consider the following checklist to match your intended use.

For specifications of all types of hydraulic pumps visit the Enerpac website. If you need guidance get in touch with your nearest Enerpac distributor.

Hydraulic pumps are mechanisms in hydraulic systems that move hydraulic fluid from point to point initiating the production of hydraulic power. Hydraulic pumps are sometimes incorrectly referred to as “hydrolic” pumps.

They are an important device overall in the hydraulics field, a special kind of power transmission which controls the energy which moving fluids transmit while under pressure and change into mechanical energy. Other kinds of pumps utilized to transmit hydraulic fluids could also be referred to as hydraulic pumps. There is a wide range of contexts in which hydraulic systems are applied, hence they are very important in many commercial, industrial, and consumer utilities.

“Power transmission” alludes to the complete procedure of technologically changing energy into a beneficial form for practical applications. Mechanical power, electrical power, and fluid power are the three major branches that make up the power transmission field. Fluid power covers the usage of moving gas and moving fluids for the transmission of power. Hydraulics are then considered as a sub category of fluid power that focuses on fluid use in opposition to gas use. The other fluid power field is known as pneumatics and it’s focused on the storage and release of energy with compressed gas.

"Pascal"s Law" applies to confined liquids. Thus, in order for liquids to act hydraulically, they must be contained within a system. A hydraulic power pack or hydraulic power unit is a confined mechanical system that utilizes liquid hydraulically. Despite the fact that specific operating systems vary, all hydraulic power units share the same basic components. A reservoir, valves, a piping/tubing system, a pump, and actuators are examples of these components. Similarly, despite their versatility and adaptability, these mechanisms work together in related operating processes at the heart of all hydraulic power packs.

The hydraulic reservoir"s function is to hold a volume of liquid, transfer heat from the system, permit solid pollutants to settle, and aid in releasing moisture and air from the liquid.

Mechanical energy is changed to hydraulic energy by the hydraulic pump. This is accomplished through the movement of liquid, which serves as the transmission medium. All hydraulic pumps operate on the same basic principle of dispensing fluid volume against a resistive load or pressure.

Hydraulic valves are utilized to start, stop, and direct liquid flow in a system. Hydraulic valves are made of spools or poppets and can be actuated hydraulically, pneumatically, manually, electrically, or mechanically.

The end result of Pascal"s law is hydraulic actuators. This is the point at which hydraulic energy is transformed back to mechanical energy. This can be accomplished by using a hydraulic cylinder to transform hydraulic energy into linear movement and work or a hydraulic motor to transform hydraulic energy into rotational motion and work. Hydraulic motors and hydraulic cylinders, like hydraulic pumps, have various subtypes, each meant for specific design use.

The essence of hydraulics can be found in a fundamental physical fact: fluids are incompressible. (As a result, fluids more closely resemble solids than compressible gasses) The incompressible essence of fluid allows it to transfer force and speed very efficiently. This fact is summed up by a variant of "Pascal"s Principle," which states that virtually all pressure enforced on any part of a fluid is transferred to every other part of the fluid. This scientific principle states, in other words, that pressure applied to a fluid transmits equally in all directions.

Furthermore, the force transferred through a fluid has the ability to multiply as it moves. In a slightly more abstract sense, because fluids are incompressible, pressurized fluids should keep a consistent pressure just as they move. Pressure is defined mathematically as a force acting per particular area unit (P = F/A). A simplified version of this equation shows that force is the product of area and pressure (F = P x A). Thus, by varying the size or area of various parts inside a hydraulic system, the force acting inside the pump can be adjusted accordingly (to either greater or lesser). The need for pressure to remain constant is what causes force and area to mirror each other (on the basis of either shrinking or growing). A hydraulic system with a piston five times larger than a second piston can demonstrate this force-area relationship. When a force (e.g., 50lbs) is exerted on the smaller piston, it is multiplied by five (e.g., 250 lbs) and transmitted to the larger piston via the hydraulic system.

Hydraulics is built on fluids’ chemical properties and the physical relationship between pressure, area, and force. Overall, hydraulic applications allow human operators to generate and exert immense mechanical force with little to no physical effort. Within hydraulic systems, both oil and water are used to transmit power. The use of oil, on the other hand, is far more common, owing in part to its extremely incompressible nature.

Pressure relief valves prevent excess pressure by regulating the actuators’ output and redirecting liquid back to the reservoir when necessary. Directional control valves are used to change the size and direction of hydraulic fluid flow.

While hydraulic power transmission is remarkably useful in a wide range of professional applications, relying solely on one type of power transmission is generally unwise. On the contrary, the most efficient strategy is to combine a wide range of power transmissions (pneumatic, hydraulic, mechanical, and electrical). As a result, hydraulic systems must be carefully embedded into an overall power transmission strategy for the specific commercial application. It is necessary to invest in locating trustworthy and skilled hydraulic manufacturers/suppliers who can aid in the development and implementation of an overall hydraulic strategy.

The intended use of a hydraulic pump must be considered when selecting a specific type. This is significant because some pumps may only perform one function, whereas others allow for greater flexibility.

The pump"s material composition must also be considered in the application context. The cylinders, pistons, and gears are frequently made of long-lasting materials like aluminum, stainless steel, or steel that can withstand the continuous wear of repeated pumping. The materials must be able to withstand not only the process but also the hydraulic fluids. Composite fluids frequently contain oils, polyalkylene glycols, esters, butanol, and corrosion inhibitors (though water is used in some instances). The operating temperature, flash point, and viscosity of these fluids differ.

In addition to material, manufacturers must compare hydraulic pump operating specifications to make sure that intended utilization does not exceed pump abilities. The many variables in hydraulic pump functionality include maximum operating pressure, continuous operating pressure, horsepower, operating speed, power source, pump weight, and maximum fluid flow. Standard measurements like length, rod extension, and diameter should be compared as well. Because hydraulic pumps are used in lifts, cranes, motors, and other heavy machinery, they must meet strict operating specifications.

It is critical to recall that the overall power generated by any hydraulic drive system is influenced by various inefficiencies that must be considered in order to get the most out of the system. The presence of air bubbles within a hydraulic drive, for example, is known for changing the direction of the energy flow inside the system (since energy is wasted on the way to the actuators on bubble compression). Using a hydraulic drive system requires identifying shortfalls and selecting the best parts to mitigate their effects. A hydraulic pump is the "generator" side of a hydraulic system that initiates the hydraulic procedure (as opposed to the "actuator" side that completes the hydraulic procedure). Regardless of disparities, all hydraulic pumps are responsible for displacing liquid volume and transporting it to the actuator(s) from the reservoir via the tubing system. Some form of internal combustion system typically powers pumps.

While the operation of hydraulic pumps is normally the same, these mechanisms can be split into basic categories. There are two types of hydraulic pumps to consider: gear pumps and piston pumps. Radial and axial piston pumps are types of piston pumps. Axial pumps produce linear motion, whereas radial pumps can produce rotary motion. The gear pump category is further subdivided into external gear pumps and internal gear pumps.

Each type of hydraulic pump, regardless of piston or gear, is either double-action or single-action. Single-action pumps can only pull, push, or lift in one direction, while double-action pumps can pull, push, or lift in multiple directions.

Vane pumps are positive displacement pumps that maintain a constant flow rate under varying pressures. It is a pump that self-primes. It is referred to as a "vane pump" because the effect of the vane pressurizes the liquid.

This pump has a variable number of vanes mounted onto a rotor that rotates within the cavity. These vanes may be variable in length and tensioned to maintain contact with the wall while the pump draws power. The pump also features a pressure relief valve, which prevents pressure rise inside the pump from damaging it.

Internal gear pumps and external gear pumps are the two main types of hydraulic gear pumps. Pumps with external gears have two spur gears, the spurs of which are all externally arranged. Internal gear pumps also feature two spur gears, and the spurs of both gears are internally arranged, with one gear spinning around inside the other.

Both types of gear pumps deliver a consistent amount of liquid with each spinning of the gears. Hydraulic gear pumps are popular due to their versatility, effectiveness, and fairly simple design. Furthermore, because they are obtainable in a variety of configurations, they can be used in a wide range of consumer, industrial, and commercial product contexts.

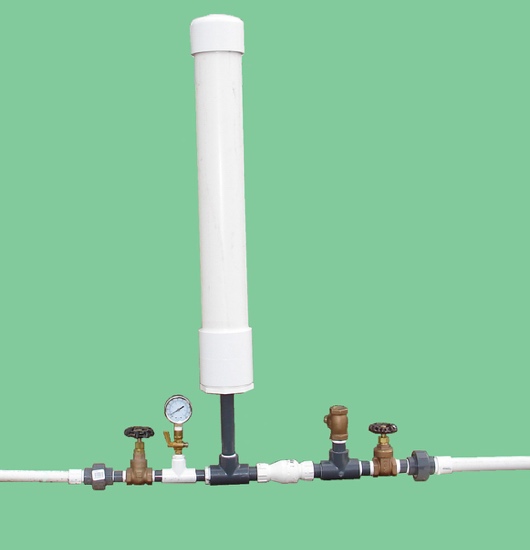

Hydraulic ram pumps are cyclic machines that use water power, also referred to as hydropower, to transport water to a higher level than its original source. This hydraulic pump type is powered solely by the momentum of moving or falling water.

Ram pumps are a common type of hydraulic pump, especially among other types of hydraulic water pumps. Hydraulic ram pumps are utilized to move the water in the waste management, agricultural, sewage, plumbing, manufacturing, and engineering industries, though only about ten percent of the water utilized to run the pump gets to the planned end point.

Despite this disadvantage, using hydropower instead of an external energy source to power this kind of pump makes it a prominent choice in developing countries where the availability of the fuel and electricity required to energize motorized pumps is limited. The use of hydropower also reduces energy consumption for industrial factories and plants significantly. Having only two moving parts is another advantage of the hydraulic ram, making installation fairly simple in areas with free falling or flowing water. The water amount and the rate at which it falls have an important effect on the pump"s success. It is critical to keep this in mind when choosing a location for a pump and a water source. Length, size, diameter, minimum and maximum flow rates, and speed of operation are all important factors to consider.

Hydraulic water pumps are machines that move water from one location to another. Because water pumps are used in so many different applications, there are numerous hydraulic water pump variations.

Water pumps are useful in a variety of situations. Hydraulic pumps can be used to direct water where it is needed in industry, where water is often an ingredient in an industrial process or product. Water pumps are essential in supplying water to people in homes, particularly in rural residences that are not linked to a large sewage circuit. Water pumps are required in commercial settings to transport water to the upper floors of high rise buildings. Hydraulic water pumps in all of these situations could be powered by fuel, electricity, or even by hand, as is the situation with hydraulic hand pumps.

Water pumps in developed economies are typically automated and powered by electricity. Alternative pumping tools are frequently used in developing economies where dependable and cost effective sources of electricity and fuel are scarce. Hydraulic ram pumps, for example, can deliver water to remote locations without the use of electricity or fuel. These pumps rely solely on a moving stream of water’s force and a properly configured number of valves, tubes, and compression chambers.

Electric hydraulic pumps are hydraulic liquid transmission machines that use electricity to operate. They are frequently used to transfer hydraulic liquid from a reservoir to an actuator, like a hydraulic cylinder. These actuation mechanisms are an essential component of a wide range of hydraulic machinery.

There are several different types of hydraulic pumps, but the defining feature of each type is the use of pressurized fluids to accomplish a job. The natural characteristics of water, for example, are harnessed in the particular instance of hydraulic water pumps to transport water from one location to another. Hydraulic gear pumps and hydraulic piston pumps work in the same way to help actuate the motion of a piston in a mechanical system.

Despite the fact that there are numerous varieties of each of these pump mechanisms, all of them are powered by electricity. In such instances, an electric current flows through the motor, which turns impellers or other devices inside the pump system to create pressure differences; these differential pressure levels enable fluids to flow through the pump. Pump systems of this type can be utilized to direct hydraulic liquid to industrial machines such as commercial equipment like elevators or excavators.

Hydraulic hand pumps are fluid transmission machines that utilize the mechanical force generated by a manually operated actuator. A manually operated actuator could be a lever, a toggle, a handle, or any of a variety of other parts. Hydraulic hand pumps are utilized for hydraulic fluid distribution, water pumping, and various other applications.

Hydraulic hand pumps may be utilized for a variety of tasks, including hydraulic liquid direction to circuits in helicopters and other aircraft, instrument calibration, and piston actuation in hydraulic cylinders. Hydraulic hand pumps of this type use manual power to put hydraulic fluids under pressure. They can be utilized to test the pressure in a variety of devices such as hoses, pipes, valves, sprinklers, and heat exchangers systems. Hand pumps are extraordinarily simple to use.

Each hydraulic hand pump has a lever or other actuation handle linked to the pump that, when pulled and pushed, causes the hydraulic liquid in the pump"s system to be depressurized or pressurized. This action, in the instance of a hydraulic machine, provides power to the devices to which the pump is attached. The actuation of a water pump causes the liquid to be pulled from its source and transferred to another location. Hydraulic hand pumps will remain relevant as long as hydraulics are used in the commerce industry, owing to their simplicity and easy usage.

12V hydraulic pumps are hydraulic power devices that operate on 12 volts DC supplied by a battery or motor. These are specially designed processes that, like all hydraulic pumps, are applied in commercial, industrial, and consumer places to convert kinetic energy into beneficial mechanical energy through pressurized viscous liquids. This converted energy is put to use in a variety of industries.

Hydraulic pumps are commonly used to pull, push, and lift heavy loads in motorized and vehicle machines. Hydraulic water pumps may also be powered by 12V batteries and are used to move water out of or into the desired location. These electric hydraulic pumps are common since they run on small batteries, allowing for ease of portability. Such portability is sometimes required in waste removal systems and vehiclies. In addition to portable and compact models, options include variable amp hour productions, rechargeable battery pumps, and variable weights.

While non rechargeable alkaline 12V hydraulic pumps are used, rechargeable ones are much more common because they enable a continuous flow. More considerations include minimum discharge flow, maximum discharge pressure, discharge size, and inlet size. As 12V batteries are able to pump up to 150 feet from the ground, it is imperative to choose the right pump for a given use.

Air hydraulic pumps are hydraulic power devices that use compressed air to stimulate a pump mechanism, generating useful energy from a pressurized liquid. These devices are also known as pneumatic hydraulic pumps and are applied in a variety of industries to assist in the lifting of heavy loads and transportation of materials with minimal initial force.

Air pumps, like all hydraulic pumps, begin with the same components. The hydraulic liquids, which are typically oil or water-based composites, require the use of a reservoir. The fluid is moved from the storage tank to the hydraulic cylinder via hoses or tubes connected to this reservoir. The hydraulic cylinder houses a piston system and two valves. A hydraulic fluid intake valve allows hydraulic liquid to enter and then traps it by closing. The discharge valve is the point at which the high pressure fluid stream is released. Air hydraulic pumps have a linked air cylinder in addition to the hydraulic cylinder enclosing one end of the piston.

The protruding end of the piston is acted upon by a compressed air compressor or air in the cylinder. When the air cylinder is empty, a spring system in the hydraulic cylinder pushes the piston out. This makes a vacuum, which sucks fluid from the reservoir into the hydraulic cylinder. When the air compressor is under pressure, it engages the piston and pushes it deeper into the hydraulic cylinder and compresses the liquids. This pumping action is repeated until the hydraulic cylinder pressure is high enough to forcibly push fluid out through the discharge check valve. In some instances, this is connected to a nozzle and hoses, with the important part being the pressurized stream. Other uses apply the energy of this stream to pull, lift, and push heavy loads.

Hydraulic piston pumps transfer hydraulic liquids through a cylinder using plunger-like equipment to successfully raise the pressure for a machine, enabling it to pull, lift, and push heavy loads. This type of hydraulic pump is the power source for heavy-duty machines like excavators, backhoes, loaders, diggers, and cranes. Piston pumps are used in a variety of industries, including automotive, aeronautics, power generation, military, marine, and manufacturing, to mention a few.

Hydraulic piston pumps are common due to their capability to enhance energy usage productivity. A hydraulic hand pump energized by a hand or foot pedal can convert a force of 4.5 pounds into a load-moving force of 100 pounds. Electric hydraulic pumps can attain pressure reaching 4,000 PSI. Because capacities vary so much, the desired usage pump must be carefully considered. Several other factors must also be considered. Standard and custom configurations of operating speeds, task-specific power sources, pump weights, and maximum fluid flows are widely available. Measurements such as rod extension length, diameter, width, and height should also be considered, particularly when a hydraulic piston pump is to be installed in place of a current hydraulic piston pump.

Hydraulic clutch pumps are mechanisms that include a clutch assembly and a pump that enables the user to apply the necessary pressure to disengage or engage the clutch mechanism. Hydraulic clutches are crafted to either link two shafts and lock them together to rotate at the same speed or detach the shafts and allow them to rotate at different speeds as needed to decelerate or shift gears.

Hydraulic pumps change hydraulic energy to mechanical energy. Hydraulic pumps are particularly designed machines utilized in commercial, industrial, and residential areas to generate useful energy from different viscous liquids pressurization. Hydraulic pumps are exceptionally simple yet effective machines for moving fluids. "Hydraulic" is actually often misspelled as "Hydralic". Hydraulic pumps depend on the energy provided by hydraulic cylinders to power different machines and mechanisms.

There are several different types of hydraulic pumps, and all hydraulic pumps can be split into two primary categories. The first category includes hydraulic pumps that function without the assistance of auxiliary power sources such as electric motors and gas. These hydraulic pump types can use the kinetic energy of a fluid to transfer it from one location to another. These pumps are commonly called ram pumps. Hydraulic hand pumps are never regarded as ram pumps, despite the fact that their operating principles are similar.

The construction, excavation, automotive manufacturing, agriculture, manufacturing, and defense contracting industries are just a few examples of operations that apply hydraulics power in normal, daily procedures. Since hydraulics usage is so prevalent, hydraulic pumps are unsurprisingly used in a wide range of machines and industries. Pumps serve the same basic function in all contexts where hydraulic machinery is used: they transport hydraulic fluid from one location to another in order to generate hydraulic energy and pressure (together with the actuators).

Elevators, automotive brakes, automotive lifts, cranes, airplane flaps, shock absorbers, log splitters, motorboat steering systems, garage jacks and other products use hydraulic pumps. The most common application of hydraulic pumps in construction sites is in big hydraulic machines and different types of "off-highway" equipment such as excavators, dumpers, diggers, and so on. Hydraulic systems are used in other settings, such as offshore work areas and factories, to power heavy machinery, cut and bend material, move heavy equipment, and so on.

Fluid’s incompressible nature in hydraulic systems allows an operator to make and apply mechanical power in an effective and efficient way. Practically all force created in a hydraulic system is applied to the intended target.

Because of the relationship between area, pressure, and force (F = P x A), modifying the force of a hydraulic system is as simple as changing the size of its components.

Hydraulic systems can transfer energy on an equal level with many mechanical and electrical systems while being significantly simpler in general. A hydraulic system, for example, can easily generate linear motion. On the contrary, most electrical and mechanical power systems need an intermediate mechanical step to convert rotational motion to linear motion.

Hydraulic systems are typically smaller than their mechanical and electrical counterparts while producing equivalents amounts of power, providing the benefit of saving physical space.

Hydraulic systems can be used in a wide range of physical settings due to their basic design (a pump attached to actuators via some kind of piping system). Hydraulic systems could also be utilized in environments where electrical systems would be impractical (for example underwater).

By removing electrical safety hazards, using hydraulic systems instead of electrical power transmission improves relative safety (for example explosions, electric shock).

The amount of power that hydraulic pumps can generate is a significant, distinct advantage. In certain cases, a hydraulic pump could generate ten times the power of an electrical counterpart. Some hydraulic pumps (for example, piston pumps) cost more than the ordinary hydraulic component. These drawbacks, however, can be mitigated by the pump"s power and efficiency. Despite their relatively high cost, piston pumps are treasured for their strength and capability to transmit very viscous fluids.

Handling hydraulic liquids is messy, and repairing leaks in a hydraulic pump can be difficult. Hydraulic liquid that leaks in hot areas may catch fire. Hydraulic lines that burst may cause serious injuries. Hydraulic liquids are corrosive as well, though some are less so than others. Hydraulic systems need frequent and intense maintenance. Parts with a high factor of precision are frequently required in systems. If the power is very high and the pipeline cannot handle the power transferred by the liquid, the high pressure received by the liquid may also cause work accidents.

Even though hydraulic systems are less complex than electrical or mechanical systems, they are still complex systems that should be handled with caution. Avoiding physical contact with hydraulic systems is an essential safety precaution when engaging with them. Even when a hydraulic machine is not in use, active liquid pressure within the system can be a hazard.

Inadequate pumps can cause mechanical failure in the place of work that can have serious and costly consequences. Although pump failure has historically been unpredictable, new diagnostic technology continues to improve on detecting methods that previously relied solely on vibration signals. Measuring discharge pressures enables manufacturers to forecast pump wear more accurately. Discharge sensors are simple to integrate into existing systems, increasing the hydraulic pump"s safety and versatility.

Hydraulic pumps are devices in hydraulic systems that move hydraulic fluid from point to point, initiating hydraulic power production. They are an important device overall in the hydraulics field, a special kind of power transmission that controls the energy which moving fluids transmit while under pressure and change into mechanical energy. Hydraulic pumps are divided into two categories namely gear pumps and piston pumps. Radial and axial piston pumps are types of piston pumps. Axial pumps produce linear motion, whereas radial pumps can produce rotary motion. The construction, excavation, automotive manufacturing, agriculture, manufacturing, and defense contracting industries are just a few examples of operations that apply hydraulics power in normal, daily procedures.

Wilson Company carries a deep inventory of pneumatic and hydraulic parts and supplies. We’re your one-stop source for motion control products, systems solutions. Whatever components or designs you need for your business or project, Wilson Company has all the answers you’re looking for.

Family owned and operated since 1965, Wilson Company has expanded to six locations in Dallas, Fort Worth, Houston, Texarkana, Austin, and San Antonio. In addition to designing and installing fluid power systems and components, we’ve also offered education programs about hydraulic and pneumatic principles and system design.

When your business needs a safe and effective power source, systems that use pneumatic parts may be the answer. Pneumatic tools use compressed air or gases to generate sufficient mechanical energy in several industrial implementations, including blow guns, air tools, and pick-and-place applications.

Pneumatic systems are ideal for situations that don’t require the same force that hydraulic pumps and systems typically generate. Since they don’t have a lot of complex moving parts or rely on electricity, pneumatic tools are safer and easier to maintain than electric sources of energy, and usually much less expensive.

When a project needs an energy source with more force or one that allows for better accuracy, many companies turn to hydraulic power. Hydraulics use pressurized liquids and fluids to generate and transfer energy, moving liquids through tubes, actuators, filters, and pressurizers to help move and activate automated components and mechanisms.

Hydraulic systems are frequently used in heavy construction applications. Hydraulic pumps are powered by large equipment like bulldozers, cranes, and diggers to pressurize incoming fluids, which in turn put arms, blades, and lifting devices in motion. Industrial companies also use hydraulic power to operate robotic arms, lathes, and presses.

Wilson Company’s services go beyond supplying and installing equipment. We offer hands-on training courses in hydraulic technology and pneumatic operations, in which classmates build, adjust, inspect and analyze energy circuits from schematic designs. Students with technical backgrounds or basic aptitude learn all about the maintenance and operation of heavy industrial equipment through textbooks and laboratory work.

Hydraulic and pneumatic power systems are suitable for a broad range of companies, industries, and businesses. With Wilson Company"s vast experience and technical know-how, we give our customers power solutions that are efficient and cost-effective, along with extensive product support and customer service.

Mining: Hydraulic mining systems including lifters, excavators, and rock movers, as well as pneumatic power for drills, wrenches, loaders, and mining equipment

Government defense & security: Hydraulic lifting of jets for construction, integrated systems for intrusion detection, power for unmanned vehicles, fluid purification, and more

Transportation: Moving natural resources, hydraulic systems for aircraft, spike drivers and ballast regulators for railroad companies, pneumatic couplers for rail cars and vehicles, and more

Knowledge. Our engineering specialists know all about traditional hydraulic and pneumatic equipment and are always on top of the latest trends and technologies that can help your business.

Convenience. With offices in Houston, Dallas, Fort Worth, Austin, San Antonio, and Texarkana, Wilson Company easily handles the hydraulic and pneumatic power needs for all of Eastern Texas.

To find out more about what Wilson Company does and how we can help you take advantage of hydraulic or pneumatic power solutions, contact us using our online form, or call us toll-free at 1-800-580-1212. Our certified experts will guide you through all your options, help you decide what solution is right for you, and get started ordering the supplies and installation for hydraulic or pneumatic power.

Pneumatics is more cost-effective than Hydraulics as air is free and can useable generally n flammable environments. Pneumatics offers more power in a smaller and lighter unit compared to most other technology systems, as well as being a much cleaner technology.

Some prefer electric drive over the pneumatic and hydraulic system, as electric drive actuators generally have better point-of-interest accuracy and repeatability than an equivalent pneumatic or hydraulic actuator.

Like pneumatics, hydraulic actuators comprise pistons that move inside a hollow cylinder. Incompressible liquid coming from a pump moves the cylinder. As the pressure increases, the cylinder is likewise moved along the axis of that piston and creates a linear force.

Both hydraulic and electrical systems have their advantages. Still, you can count on hydraulic actuators to be more suited for high-force applications as these rugged actuators can produce a force that is 25 times more powerful than pneumatic cylinders the same size.

They can operate in pressures as high as 4,000 psi. They can even hold torque and force constant without requiring a pump to supply more fluid or pressure because it uses incompressible fluids. You can put the motors and pumps away at a certain distance without much power loss.

They are smooth, network-friendly, reprogrammable, repeatable, and quieter compared to Hydraulics and can give you diagnostics or maintenance feedback immediately.

This course covers the fundamentals of hydraulic power and hydraulic system safety. It also covers theoretical and hands-on training with hydraulic systems, specifically hydraulic pressure, force and flow. Hands-on training includes hydraulic system components, power units, basic schematics, actuators, pumps and metering.

This course covers hydraulic relief valves, check valves and flow control valves, with sequencing and pressure reducing valve operation and use. Hands-on training includes hydraulic system and circuit activities.

This course covers the fundamentals of pneumatic power and compressed air safety. Theoretical and hands-on training with pneumatic systems, covering pneumatic pressure, force and flow. This course also covers pressure regulators, air filters and lubricators. Hands-on training includes basic schematics, common pneumatic fittings, actuators and speed control.

Examples of customized fluid power training include, but are not limited to, fluid power pump fundamentals, rebuilds, troubleshooting, and systems troubleshooting.

Check that the pump shaft is rotating. Even though coupling guards and C-face mounts can make this difficult to confirm, it is important to establish if your pump shaft is rotating. If it isn’t, this could be an indication of a more severe issue, and this should be investigated immediately.

Check the oil level. This one tends to be the more obvious check, as it is often one of the only factors inspected before the pump is changed. The oil level should be three inches above the pump suction. Otherwise, a vortex can form in the reservoir, allowing air into the pump.

What does the pump sound like when it is operating normally? Vane pumps generally are quieter than piston and gear pumps. If the pump has a high-pitched whining sound, it most likely is cavitating. If it has a knocking sound, like marbles rattling around, then aeration is the likely cause.

Cavitation is the formation and collapse of air cavities in the liquid. When the pump cannot get the total volume of oil it needs, cavitation occurs. Hydraulic oil contains approximately nine percent dissolved air. When the pump does not receive adequate oil volume at its suction port, high vacuum pressure occurs.

This dissolved air is pulled out of the oil on the suction side and then collapses or implodes on the pressure side. The implosions produce a very steady, high-pitched sound. As the air bubbles collapse, the inside of the pump is damaged.

While cavitation is a devastating development, with proper preventative maintenance practices and a quality monitoring system, early detection and deterrence remain attainable goals. UE System’s UltraTrak 850S CD pump cavitation sensor is a Smart Analog Sensor designed and optimized to detect cavitation on pumps earlier by measuring the ultrasound produced as cavitation starts to develop early-onset bubbles in the pump. By continuously monitoring the impact caused by cavitation, the system provides a simple, single value to trend and alert when cavitation is occurring.

The oil viscosity is too high. Low oil temperature increases the oil viscosity, making it harder for the oil to reach the pump. Most hydraulic systems should not be started with the oil any colder than 40°F and should not be put under load until the oil is at least 70°F.

Many reservoirs do not have heaters, particularly in the South. Even when heaters are available, they are often disconnected. While the damage may not be immediate, if a pump is continually started up when the oil is too cold, the pump will fail prematurely.

The suction filter or strainer is contaminated. A strainer is typically 74 or 149 microns in size and is used to keep “large” particles out of the pump. The strainer may be located inside or outside the reservoir. Strainers located inside the reservoir are out of sight and out of mind. Many times, maintenance personnel are not even aware that there is a strainer in the reservoir.

The suction strainer should be removed from the line or reservoir and cleaned a minimum of once a year. Years ago, a plant sought out help to troubleshoot a system that had already had five pumps changed within a single week. Upon closer inspection, it was discovered that the breather cap was missing, allowing dirty air to flow directly into the reservoir.

A check of the hydraulic schematic showed a strainer in the suction line inside the tank. When the strainer was removed, a shop rag was found wrapped around the screen mesh. Apparently, someone had used the rag to plug the breather cap opening, and it had then fallen into the tank. Contamination can come from a variety of different sources, so it pays to be vigilant and responsible with our practices and reliability measures.

The electric motor is driving the hydraulic pump at a speed that is higher than the pump’s rating. All pumps have a recommended maximum drive speed. If the speed is too high, a higher volume of oil will be needed at the suction port.

Due to the size of the suction port, adequate oil cannot fill the suction cavity in the pump, resulting in cavitation. Although this rarely happens, some pumps are rated at a maximum drive speed of 1,200 revolutions per minute (RPM), while others have a maximum speed of 3,600 RPM. The drive speed should be checked any time a pump is replaced with a different brand or model.

Every one of these devastating causes of cavitation threatens to cause major, irreversible damage to your equipment. Therefore, it’s not only critical to have proper, proactive practices in place, but also a monitoring system that can continuously protect your valuable assets, such as UE System’s UltraTrak 850S CD pump cavitation senor. These sensors regularly monitor the health of your pumps and alert you immediately if cavitation symptoms are present, allowing you to take corrective action before it’s too late.

Aeration is sometimes known as pseudo cavitation because air is entering the pump suction cavity. However, the causes of aeration are entirely different than that of cavitation. While cavitation pulls air out of the oil, aeration is the result of outside air entering the pump’s suction line.

Several factors can cause aeration, including an air leak in the suction line. This could be in the form of a loose connection, a cracked line, or an improper fitting seal. One method of finding the leak is to squirt oil around the suction line fittings. The fluid will be momentarily drawn into the suction line, and the knocking sound inside the pump will stop for a short period of time once the airflow path is found.

A bad shaft seal can also cause aeration if the system is supplied by one or more fixed displacement pumps. Oil that bypasses inside a fixed displacement pump is ported back to the suction port. If the shaft seal is worn or damaged, air can flow through the seal and into the pump’s suction cavity.

As mentioned previously, if the oil level is too low, oil can enter the suction line and flow into the pump. Therefore, always check the oil level with all cylinders in the retracted position.

If a new pump is installed and pressure will not build, the shaft may be rotating in the wrong direction. Some gear pumps can be rotated in either direction, but most have an arrow on the housing indicating the direction of rotation, as depicted in Figure 2.

Pump rotation should always be viewed from the shaft end. If the pump is rotated in the wrong direction, adequate fluid will not fill the suction port due to the pump’s internal design.

A fixed displacement pump delivers a constant volume of oil for a given shaft speed. A relief valve must be included downstream of the pump to limit the maximum pressure in the system.

After the visual and sound checks are made, the next step is to determine whether you have a volume or pressure problem. If the pressure will not build to the desired level, isolate the pump and relief valve from the system. This can be done by closing a valve, plugging the line downstream, or blocking the relief valve. If the pressure builds when this is done, there is a component downstream of the isolation point that is bypassing. If the pressure does not build up, the pump or relief valve is bad.

If the system is operating at a slower speed, a volume problem exists. Pumps wear over time, which results in less oil being delivered. While a flow meter can be installed in the pump’s outlet line, this is not always practical, as the proper fittings and adapters may not be available. To determine if the pump is badly worn and bypassing, first check the current to the electric motor. If possible, this test should be made when the pump is new to establish a reference. Electric motor horsepower is relative to the hydraulic horsepower required by the system.

For example, if a 50-GPM pump is used and the maximum pressure is 1,500 psi, a 50-hp motor will be required. If the pump is delivering less oil than when it was new, the current to drive the pump will drop. A 230-volt, 50-hp motor has an average full load rating of 130 amps. If the amperage is considerably lower, the pump is most likely bypassing and should be changed.

Figure 4.To isolate a fixed displacement pump and relief valve from the system, close a valve or plug the line downstream (left). If pressure builds, a component downstream of the isolation point is bypassing (right).

The most common type of variable displacement pump is the pressure-compensating design. The compensator setting limits the maximum pressure at the pump’s outlet port. The pump should be isolated as described for the fixed displacement pump.

If pressure does not build up, the relief valve or pump compensator may be bad. Prior to checking either component, perform the necessary lockout procedures and verify that the pressure at the outlet port is zero psi. The relief valve and compensator can then be taken apart and checked for contamination, wear, and broken springs.

Install a flow meter in the case drain line and check the flow rate. Most variable displacement pumps bypass one to three percent of the maximum pump volume through the case drain line. If the flow rate reaches 10 percent, the pump should be changed. Permanently installing a flow meter in the case drain line is an excellent reliability and troubleshooting tool.

Ensure the compensator is 200 psi above the maximum load pressure. If set too low, the compensator spool will shift and start reducing the pump volume when the system is calling for maximum volume.

Performing these recommended tests should help you make good decisions about the condition of your pumps or the cause of pump failures. If you change a pump, have a reason for changing it. Don’t just do it because you have a spare one in stock.

Conduct a reliability assessment on each of your hydraulic systems so when an issue occurs, you will have current pressure and temperature readings to consult.

Al Smiley is the president of GPM Hydraulic Consulting Inc., located in Monroe, Georgia. Since 1994, GPM has provided hydraulic training, consulting and reliability assessments to companies in t...

The Power Team P-Series hand pumps come in a variety of configurations to meet the requirements of your application. Along with various oil capacities and flow rates, you can choose from the following options:

Compact design ensures that the Power Team PA6 series pump is lightweight and portable. The PA6 series consists of single-speed pumps designed to drive single-acting cylinders. The power unit of choice for major manufacturers of auto body, frame straighteners and other equipment. Operates at 40-100 psi (3-8 bar) shop air pressure at the pump, dBA 85 at 10,000 psi (700 bar). Serviceable pump motor is not a “throwaway”, providing economical repair. Permanently vented reservoir cap. Internal relief valve protects circuit components, air inlet filter protects motor.

Compact, lightweight and portable the Power Team PA6D series pumps are single-speed pumps for driving double-acting cylinders. The PA6D series pumps operate at 40-100 psi (3-8 bar) shop air pressure at the pump. Designed with longevity in-mind the PA6D series feature internal relief valve protects circuit components, air inlet filter protects motor. Serviceable pump motor is not a “throw away”, providing economical repair. Permanently vented reservoir cap. dBA 85 at 10,000 psi (700 bar) for all PA6 pump.

Ideal for powering single-acting cylinders and portable hydraulic tools, the Power Team PA9 series pumps are easier to operate than a hand pump, designed for efficiency. Built to be economical in service; the PA9 series is not a “throwaway” unit. Unique bladder design for all-position operation and storage. Operates on 40-120 psi (3-8 bar) shop air, at 20 cfm (570 l). Hard-coat anodized aluminum housing. Oil filler with integral safety relief minimizes chance of damage to reservoir bladder if overfilling occurs.

A two-speed pump, the Power Team PA60 series pumps are designed for rapid oil delivery at low pressure to quickly advance cylinder or tool. Equipped with air pressure regulator, air filter and lubricator. Serviceable air motor for economical repair. Internal relief valve protects circuit components. Permanently vented reservoir cap.

Focused on single-speed and low pressure the Power Team PA50 series pump outputs 3,200 PSI / 220 BAR, fitting serviceable requirements for air motor for economical repair. Integrated air inlet filter protects motor. The PA50 series also features a filter in outlet port protects against contaminated systems Assorted reservoirs to suit your application"s requirements.

Rotary-Style Air Motor. Use where air is the preferred source of energy. 3 hp motor starting under full load. Two-speed operation for rapid cylinder advance. Models available with full remote control over advance and return, except PA554. Tandem center valve holds the load when pump is shut-off.

Compact, Portable, Cordless Hydraulic Pump for MRO Applications. Compact, Li-ion 18VDC, 9.0 Ah battery-powered pump provides extended run-time. Two-stage, high-pressure hydraulic pump offers quick tool advancement in the first stage. Extremely compact, lightweight with an ergonomic handle grip and transport strap to ease portability. Self-contained, rubber bladder reservoir allows pump usage in most positions with an impressive capacity of 70 cu. in. usable. Quiet, smooth-running, serviceable brushed 18VDC motor. High-impact, fiberglass reinforced shroud protects your investment in the most demanding and harsh applications. Interchangeable valve configuration accommodates a vast array of applications. CSA rated for intermittent duty, CE compliant.

The 10 series Power Team hydraulic pumps are designed to have a maximum of 690 bar (10,000 psi) at a flow rate of 164 cc/min (10 cu. in/min). All Power Team pumps come fully assembled, and each with the ability to be valved for either single- or double acting cylinders. Designed to be compact can easily mobile, the power team 10 series includes a portable power source is included for hydraulic cylinders, and tools. The permanent magnet motor is strategically constructed to easily start under load, even with reduced voltage conditions. Battery-operated models have 8 foot (2,4 m) power cord with alligator clips to connect to any 12 volt battery, optional rechargeable battery pack with shoulder strap are alternatives for maximum portability. The Power Team 10 series pump typically delivers 15 minutes of continuous operation at 10,000 psi (700 bar) on a single battery. Built to withstand High-impact, shielded with a flame retardant construction.

The Power Team 17 series pump is delibertly designed for maintenance and construction applications up to 55 Ton. For use with single-acting or double-acting cylinders at operating pressures to 10,000 psi (700 bar). For intermittent duty; starts under full load. Equipped with 1⁄2 hp (0,37 kW), 3,450 rpm, single-phase, thermal protected induction motor; 10 ft. remote control cord (PE172S has 25 ft. (7,6 m) cord) Low amperage draw; small generators and low amperage circuits can be used as power source. Extremely quiet noise level (67-81 dBA).

Vanguard Jr. + Power Team 18 series pumps provide two-speed high performance in a light-weight, compact package. Designed to provide a gauge port and metal reservoir on all pump models. Equipped with a 1⁄2 hp (0,37 kW), 115 volt, 60/50 Hz single phase motor that starts under load, even at reduced voltage. Low amperage draw permits use with smaller generators and low amperage circuits. All pumps have a 10 foot (3 m) remote control. CSA rated for intermittent duty. Noise level of 85-90 dBA. For operating hydraulic crimping, cutting or other tools: No. PE184C - Allows you to alternately operate a spring-return cutting and/or crimping tool without disconnecting either tool. Select a port connection with a manual 4-way valve, start the pump with a remote control hand switch and extend the connected tool. When the hand switch is switched to off, the pump stops and the automatic valve opens, allowing the tool to return. In the center (neutral) position, a manual control valve holds the tool in position at the time valve is shifted.

The 21 series Power Team pump and RD5513 cylinder used in a special press that produces pharmaceutical-grade extracts for herbal medicines. Totally enclosed, fan cooled induction motor: 1 hp (0,75 kW), 1,725 rpm, 60 Hz, single phase. Designed intentional for thermal overload protection. Remote co

8613371530291

8613371530291