positive displacement hydraulic pump supplier

Distributor of positive displacement pumps. Other products include high and low viscosity, gear, general purpose water, reverse osmosis, boiler feed, condensate, sump, submersible, air operated, drum, machine tool coolant, multi-stage booster, vacuum, centrifugal, air operated diaphragm, magnetic drive, seamless, metering, piston, progressing cavity, self-priming, solid handling, turbine, and vertical pumps. Repair, testing, and inspection services are available. Value-added pump services include design and application consulting, engineering, research and recommendations, project and individual pump quotations, pick-up and delivery, and rebuilding. Industries served include industrial, HVAC, commercial, biomedical, and chemical sectors. 24-hour shipping available.

DXP represents several world class lobe pump suppliers and applies lobe pumps in multiple markets including food & beverage, pharmaceutical, biotechnology, chemical, municipal and other industrial markets. Typically lobe pumps are used in sanitary or ultraclean applications but they can also be applied when transporting various forms of sludge, bio-solids or greases. Unlike other rotary positive displacement pumps, lobe pump use timing gears to prevent the two rotors from contacting one another, allowing them to be more tolerant of solids and also to be more shear sensitive.

Product degradation is a costly consequence of improper pump selection, which can lead to product losses, missed deliveries and decreased margins. Anderson Process offers an expansive line of Positive Displacement Pumps specifically engineered to provide consistent product transfer for challenging media.

With decades of experience in fluid dynamics, Anderson Process’s team of pump experts and engineers know that, in the long run, faster pumping isn’t always the right choice for all applications. For example, the transfer of high-viscosity fluids commonly found in the food or pulp and paper industries, or variable-viscosity fluids commonly found in chemical processing, requires a highly efficient pump that is capable of consistent flow rates. And fluids with suspended or fragile solids, such as those found in paints and pigments, need a pump that will minimize shear. Anderson Process’s offerings of Positive Displacement Pumps combine mechanical efficiency with steady flow rates to deliver fluid transfer capabilities that are both cost-effective and consistent.

Anderson Process is proud to partner with longtime pump manufacturers who are leading the industry in positive displacement pump technology. Our brands include Wilden®, Blackmer, Tuthill Pumps, Liquiflo, CAT Pumps, Ampco, and Graco. These brands are known within the process equipment industry for their quality craftsmanship, durability and superior reliability. Our comprehensive selection of diaphragm pumps and rotary pumps are designed to withstand the most demanding applications. Our sanitary pumps are engineered for easy cleaning and minimize contamination risks.

Whether you ultimately need a vane pump or a gear pump, or a piston pump or a lobe pump, Anderson Process’s pump experts will ensure your positive displacement pump is ideally specified and configured for the needs of your application, something warehouse pump suppliers can’t do. As an authorized service center for many of our brands, we can provide the hands-on service required to keep your equipment — and your process — running as efficiently as possible for as long as possible.

AGI Industries represents Positive Displacement pumps from industry leading companies like IMO, Colfax, Watson Marlow / Bredel, FMC Fluid Technologies, Roper Pumps, Hydroplex, Ingersoll-Rand ARO, Allweiler, Warren, Houttuin, WiWa, Masosine, and SC Hydraulic Engineering. These brands offer a wide range of PD pump options including rotary gear, peristaltic (hose and tube) piston, plunger, double diaphragm, two and three screw, progressive cavity, and sinusoidal rotor design to serve the onshore and offshore Oil and Gas Industry, the Chemical Process and Hydrocarbon Process Industries, Power Generation, Water and Wastewater, Pulp, Paper and Wood Products industries and most, other markets where reliable operation in low, medium and high pressure pumping of thin to viscous fluid is required.

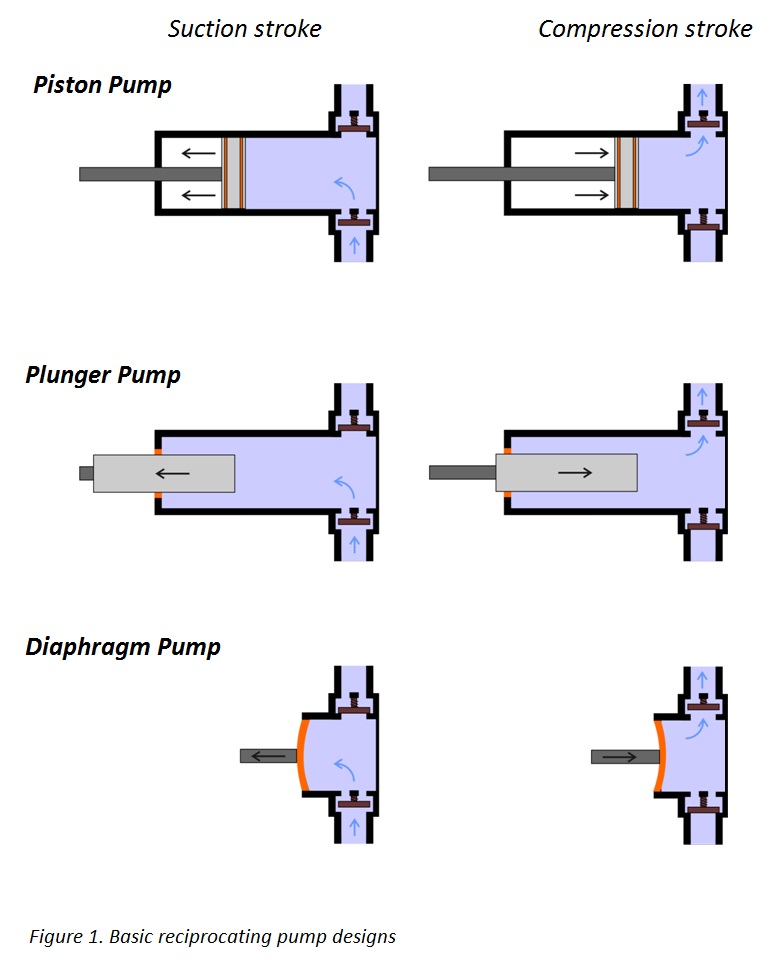

Gear pumps are one of the most common types of positive displacement pumps. They provide a constant volume of fluid that passes between the teeth of two meshing gears and the casing. The rotating gears and separation of teeth create a suction that pulls fluid in through the inlet. The gears then trap the liquid and move it around the casing to the discharge or outlet. Each revolution creates consistency in the flow of fluid.

There are two main types of rotary gear pumps, internal and external. Both types use similar principles for pumping fluids. Two gears are inside a casing in a way that the teeth lock together. As a motor turns one of the gears the locking teeth turn the other. The difference in the two designs is that an external gear pump uses side-by-side gears (typically the same size), so when the motor turns one gear, the other rotates in the opposite direction. The internal gear pump design uses two different size gears. A motor turns the small gear, which is inside the larger gear, rotating it in the same direction.

DAE Pumps offers economical rotary gear pumps of both types in a variety of sizes. No other gear pumps can match the performance and durability of our pumps. Because of the close tolerance between the gears and casing, most gear pumps are highly susceptible to wear, but DAE Pumps gear pumps outperform all others. Our pumps process a wide range of viscosities and are ideal for handling fluids at high pressures and low flow rates. DAE Pumps rotary gear pumps are widely used in chemical installations to pump high viscosity fluids. They are one of the most common types of pumps for moving corrosive liquids and hydraulic fluid power applications.

DAE pumps gear pumps provide consistency in moving a variety of slurry materials and are suitable for several industries like paints, food processing, chemicals, oil & gas, and others. Our rotary gear pumps are available in duplex steel, cast steel, and cast iron, among other materials. Contact DAE Pumps to customize a pump to your specific needs.

Positive displacement pumps create suction lift to push fluid mechanically through the system at a constant speed, regardless of inlet pressure. Positive displacement pumps are popular in water treatment, oil and gas, chemical and food and beverage industries due to their ability to operate effectively under high viscosity, high pressure, and differential flow operations.

Flo-Line is a proud partner of industry leading positive displacement pump manufacturers such as Pulsafeeder, Netzsch, Circor, Yamada, Abel, and more. Depending on the solid content or toxicity of the fluid, our extensive range of pumps offers a solution for every process need. Contact us for more information or request a quote on the positive displacement pump you need.

Along with centrifugal pumps, positive displacement pumps are one of the main types of pumping and fluid transfer solutions available for commercial applications. These pumps are typically used in cases where a constant flow rate is required.

The chambers within positive displacement pumps hold a fixed volume of liquid dependent on the requirements of your application, allowing them to transfer fluid at a constant pressure. We offer several variations of positive displacement pumps, including diaphragm pumps, progressive cavity pumps, rotary lobe pumps, gear pumps, and more.

Positive displacement pumps are used in a variety of applications. They function by trapping a specific amount of fluid inside a cavity and then pushing the fluid to the exit port of the pump. Typically, users elect to use positive displacement pumps when they want consistent flows and viscosities are too high to be handled by centrifugal pumps. Glauber Equipment is a premier supplier of positive displacement pumps. A more detailed explanation of how displacement pumps can work for your specific application is outlined below.

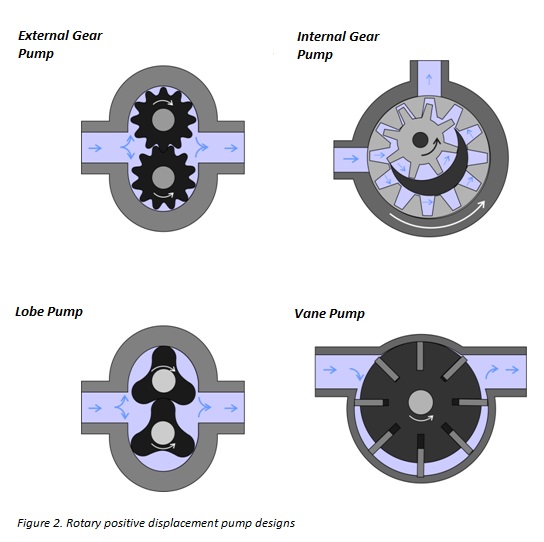

With a positive displacement pump, liquid flows into the pumps as the cavity on the suction side expands and the liquid flows out of the discharge as the cavity collapses. The volume is a constant given each cycle of operation. The positive displacement pumps can be divided in two main classes, reciprocating and rotary.

A positive displacement pump moves liquids by pressurizing the fluid, allowing it to pass through the system and be drawn into an expanding chamber. Once the specified volume of liquid is in the chamber, it then contracts and forces the fluid out of the pump. Its design ensures a consistent discharge of fluid at the pressure required to move it through the system’s piping. Positive displacement pumps provide constant flow with changing pressure. Also, its efficiency increases with increasing viscosity and increasing pressure.

The liquid is drawn into the pump by creating negative pressure at the inlet port, making the pump self-priming and ensuring a continuous flow regardless of pressure. Typically, these pumps operate at lower speeds and produce more pressure than a centrifugal pump. They are a common component of hydraulic systems and other applications that require high pressure and low flow rates.

Positive displacement pumps shouldn’t operate against closed valves on the discharge side of the pump. There is no shut off head on them like on centrifugal pumps. If so, operating against closed discharge valves continues to produce flow until the pressure in the discharge line is increased until the line bursts or the pump is severely damaged – or both.

Rotary positive displacement pumps move fluid through the use of a rotating element. The element develops a liquid seal with the pump casing, creating suction at the inlet port and displacing the fluid from the reservoir to the outlet.

In a reciprocating pump, the repeated backward and forward movement of a diaphragm, piston or plunger transports the fluid from the reservoir. The reciprocation or cycle of the driving element creates suction at the inlet port and compression at the outlet.

A linear pump moves the fluid in a straight line by using a mechanical element to capture the liquid and move it through a tube to the outlet port. The volume capacity of a linear pump is limited, but because this type of pump is set in a static location, calibrations are not necessary.

Glauber Equipment specializes in producing a wide range of positive displacement pumps designed to meet the specific applications of our clients. They meet the needs of many applications, including:

Also known as gear pumps, these have few moving parts so they"re less prone to wear than other hydraulic pumps. Combine with an electric motor to generate flow in a hydraulic system. To mount to a NEMA C-face motor, use a Pump-to-Motor Mount (sold separately).

Viking Pump, a Unit of IDEX Corporation, leads the world in the design and manufacture of rotary Positive Displacement Pumps for use in some of the toughest applications. Since 1911, our innovative products have been key contributors to successful operations in virtually every industry—from military, to food and beverage, to chemicals, fuels, and plastics—reliably pumping materials that are thin, thick, hot, cold, liquid, solid, etc.

ProcessFlo offers a variety of positive displacement pumps, including air operated diaphragm (AODD), rotary lobe, progressive cavity, internal and external gear, diaphragm, metering, sliding vane, and peristaltic pumps for hygienic and industrial applications.

A Positive Displacement pump (PD pump) is a mechanical device which displaces a known quantity of liquid for every revolution or cycle that the pump completes. The flow rate through a positive displacement pump is directly proportional to its speed and number of cycles over a given time.

A positive displacement pump works by using a screw, a blade, a vane, a lobe, a gear or diaphragm. It creates a chamber or cavity between the pumping elements and the cavity in which the fluid is temporarily stored is moved by the reciprocating or rotary motion along the pipe to its destination.

Progressive Cavity Pump has a rotor rotating within a housing called a stator. The rotor is always metallic and the stator is made up of a rubber type of material. It looks somewhat like a screw thread – the fluid is between the cavities and the rotary motion of the rotor forces the fluid through from one end to the other. It has a low to moderate capacity, low to high pressure, good solids handling capability, one seal, low shear, constant flow and a low pulsation.

Rotary Lobe Pumphas moderate to high capacity, low to moderate pressure, good solids handling capability, two/four seals, a constant flow and moderate pulsation.

Screw Pump –the screw pump has multi versions known as multi screw pumps featuring moderate to high capacity, high pressures, only lubricative liquids, no solids handling capability, one seal and a constant flow.

Diaphragm Pump – Air Operated Diaphragm Pump has low to moderate capacity, low to moderate pressure, very low efficiencies, no seal and high pulsation.

Positive Displacement pumps are generally used for fluids with a relatively high viscosity. They can be used where high accuracy is required e.g metering or dosing. They can also be used where high pressures are required i.e high pressure washing. Waste Water Treatment is another application e.g Netzsch Tornado Rotary Lobe Pump

The main advantages of a Positive Displacement Pump is that it can handle highly viscous fluids whereas a Centrifugal Pump would be inefficient and require high driver powers. PD pumps also have a good volumetric efficiency & driver power is kept to a minimum. The flow rate is easily adjustable via a speed control because the flow rate is directly proportional to its speed. Driver sizing is not as critical as with a Centrifugal pump because the pump will deliver the known quantity of fluids regardless of system back pressure (losses). A Positive Displacement Pump can produce a very low shear action in the case of sensitive fluids.

The main disadvantages of a Positive Displacement Pump vs a Centrifugal pump is that dry running can be catastrophic due to either close clearances of parts or in the case of progressive cavity pumps the interference fit between the rotor and stator. All PD pumps require the installation of a pressure relief valve to prevent failure of the pump or piping in case of accident or closure of the delivery valve or blockage in the piping. Main pd pumps will produce pulsations which can lead to undesirable effects i.e vibration, product damage & water hammer. PD pumps have a limited flow range ~1000m³/hr vs 180,000m³/hr Centrifugal Pumps. The material of construction of PD pumps are more limited in range of available materials than that of Centrifugal Pumps and finally PD pumps have limited solids handling ability in terms of size and/or content.

A Positive Displacement Pump will usually self-prime due to the very small clearances which exist within the pump. This will help it pull a vacuum and thus expel the air through the pump until the liquid reaches the pump. Care should be taken on the suction line i.e installation of a “goose neck” which will ensure there is some liquid in the pump during the priming cycle which will prevent dry running & consequently failure.

An Air Operated Diaphragm pump (AODD pump) is able to self-prime without any liquid being present but this capability to lift is limited if the line is empty of fluid.

Certain Positive Displacement Pumps can run dry i.e Air Operated Diaphragm pumps have no parts requiring lubrication or no close clearances between parts. Peristaltic pumps can run dry as the hose is lubricated in a bath of its own fluid. Other types of PD pumps should not be run dry.

Every pump has a NPSH (Net pressure suction head) required to ensure reliable and trouble-free operation without damage caused by cavitation therefore therefore the system should be designed to ensure there is a sufficient margin between NPSHA (Net pressure suction head available) and NPSHR (Net pressure suction head required).

Unlike a centrifugal pump which produces pressure, a positive displacement pump does not produce pressure – it is the system itself that develops pressure from the pressure drop which then creates a back pressure which largely depends on the flow rate through the system i.e higher flow rates will result in higher losses and as a result a higher back pressure. The back pressure is also dependent on the pressure in the vessel at the point of discharge i.e a hydrogen blanket present or steam. The pressure is controlled largely by the pumping rate, therefore, pressure is controlled by varying the speed of the pump. In cases where the variable speed drive is not deployed the system pressure will be controlled to a degree by the setting of the pressure relief valve.

Positive Displacement Metering pumps are usually used where a high degree of accuracy is required e.g in dosing applications where pH control is required e.g Waste Water Treatment Plants or where filling lines require accuracy of volumes of fluid dispersed into containers.

Flexachem are the leading distributors for Netzsch Positive Displacements Pumps in Ireland – Progressive Cavity Pump, Rotary Lobe Pump (Industrial applications) & Screw Pump. We also supply Inoxpa Sanitary Rotary Lobe Pump and Flotronic Air Operated Diaphragm Pumps for the Food & Beverage & Pharma sectors.

We provide localised technical support & on-site service engineering to support the operational needs of our clients. We also hold a heavily stocked inventory to help take the pressure off you in the event of unexpected emergencies. Why not contact one of our Pump Specialists if you have a particular application in mind.

Gear pumps are a type of positive displacement pump that utilize interlocking cogs and gears to mechanically moves fluids in smooth, repeatable volumes. Pumping Solutions carries the internal and external gear pumps you need for your operations that involve viscous materials. These pumps come in various sizes, materials and flow rates to meet multiple fluid transfer applications. As a trusted distributor of pumps from industry-leading brands, we are confident that we can deliver quality pumps and pump parts faster than our competitors. We offer pumps for lubrication/circulation and magnetically couple gear pumps.

Gear pumps offer a versatile solution for pumping oils and high-viscosity fluids. The exact benefits of gear pumps vary depending on the model and composition, but general advantages include:

Gear pumps can efficiently pump high viscosity fluids and oils, as the rotating gears generate high enough pressure and suction to consistently transfer liquids at steady flow rates. Gear pumps can even transfer fluids ranging in temperature depending on the application and environment. Gear pumps can pump paint, ink, resins, adhesives, chemicals, solvents, food products and more at high pressures while still maintaining precise output. Because gear pumps have very few moving components, they are ideal for applications requiring high-volume pumping with little maintenance requirements.

Gear pumps are positive displacement pumps, meaning they use expanding and contracting chambers to move fluids at a fixed rate. Specifically, they are rotary positive displacement pumps, which utilize a rotating mechanism or assembly to cause this contraction and expansion. They function by using two or more internal gears that create vacuum pressure, propelling the fluid media.

Gear pumps are the most common type of positive displacement pump used. Typically, a rotating assembly of two gears (a drive gear and an idler) moves to create suction at the pump inlet and draw in fluid. The liquid is then directed between the teeth of the gears and the walls of the casing to the discharge point. Volume decreases as the liquid travels from inlet to outlet, causing a buildup of pressure. Pressure relief valves are typically built-in to the pump to protect the pumping system from a closed valve in the discharge piping. Flow in gear pumps is determined by the size of the cavity (volume) between the gear teeth, the speed of rotation (rpm) of the gears, and the amount of slippage (reverse flow). Slip increases as the pump wears.

Gear pumps are typically compact and economical, and provide accurate dosing that is suitable for a variety of industries. Gear pumps are useful for industrial applications such as:

Gear pumps, diaphragm pumps and peristaltic pumps are micro-liquid pumps that are widely used in chemical processing, wastewater treatment, medical applications and more. These pumps each have a unique design and structure that impacts performance, pressure, flow rate and cost performance, all of which should be considered prior to selecting your pump design. Gear pumps provide a steady and pulseless fluid flow and low noise comparable to double diaphragm pumps and peristaltic pumps. Gear pumps are typically more compact, reliable and simple in design for lower maintenance costs than peristaltic and diaphragm pumps. However, gear pumps do not offer the sanitary qualities of a peristaltic pump or the high flow and corrosion-resistant qualities of a diaphragm pump.

External gear pumps utilize two interlocking gears of the same size supported by separate shafts. External gear pumps are capable of sustaining higher pressures and flow rates, and can be used in hydraulic power applications.

Internal gear pumps are designed similar to external gear pumps, but internal gear pumps utilize gears of different sizes, with one rotating inside the other. Internal gear pumps have better suction and are suited for high-viscosity fluids in metering and blending applications.

As a premier supplier of positive displacement pumps including gear pumps, peristaltic pumps and double diaphragm pumps and pump parts, we are able to deliver a wide range of pump models and pump accessories from leading manufacturers. We offer gear pumps from brands trusted across the world, including:

We’re a leading supplier of gear pumps on the west coast. With locations in Arizona, California, Idaho, Montana, Washington and Northern Mexico, we can get you the gear pump you need – fast. Contact us for more gear pump options or request a quote online.

Positive Displacement pumps by John Brooks Company are commonly used for pumping high-viscosity fluids such as oil, paints, resins or foodstuffs. They are preferred in applications where accurate dosing or high-pressure output is required. The production of a pump is not affected by pressure and is selected where the supply is irregular. These pumps function to move fluid by repeatedly enclosing a fixed volume, with the aid of seals or valves and moving it mechanically through the system. The pumping action is cyclic and is driven by pistons, screws, gears, lobes, diaphragms or vanes. There are two main types: Reciprocating and Rotary.

At Coker Pump & Equipment Company, we are proud of our history of providing high quality pumping products since 1956. Our customers in Nevada and Central Valley / East Bay California have access to a wide selection of pumps, including positive displacement pumps. We offer gear, rotary lobe, air operated, and high pressure positive displacement pumps from many top manufacturers. Coker stocks gear pumps from Liquiflo and Viking Internal/External that can handle tough materials, including asphalt, chemical, corn syrup, fuel oil, resins, and many more. They can accommodate flows up to 1500 GPM and temperatures up to 800°F. We also carry rotary lobe pumps that serve industries from cosmetics and beverages to meat packing, chemical, and industrial. And our selection of air operated and high pressure pumps come from well-known brands like Graco, Lutz, and Versa-Matic.

Since 1929, Northern Pump has manufactured HIGH PRESSURE heavy duty positive displacement rotary gear pumps. With Northern’s inception as Northern Fire Apparatus Company through modern day, as part of McNally Industries, the intention is to manufacture a gear pump that can outperform others in high pressure and severe applications.

Northern® Heavy Duty gear pumps are available in all shapes and sizes. Our modular design allows us to customize a gear pump for your specific application.

Skilled mechanics at the Northern factory are standing by to recondition your pump back to it’s original condition. After a careful disassembly process, the entire pump is inspected to determine parts that need replacement or reconditioning.

Northern Pump has manufactured precision gear pumps for over ninety years. Yet, we still encounter new applications daily. Chances are, we already have experience with your application.

Midstream Company Utilizes the Northern® 4800Crude Oil Pipeline Injection Pump Grantsburg, WI – Northern Pump, entered into a purchase agreement with a […]

Northern Melts Away Sulfur Pump Delivery Concerns Grantsburg, WI – Northern Pump, successfully delivered two custom pumps for an international customer in […]

Northern 4800 Crude Oil Injection Pump Offshore Application Northern Pump, successfully completed a field overhaul project for a key crude oil pipeline […]

8613371530291

8613371530291