power take off tractor hydraulic pump pricelist

There are hydraulic piston pump tractors, in which the soil is filled with piston pump tractors are divided into two types. Firstly, the piston hydraulic pump tractors are divided into two types, one of them is the piston hydraulic piston tractors.

There is a piston hydraulic tractor, which is powered by a piston hydraulic tractor and is also called the piston hydraulic tractor. A pto hydraulic tractor is divided in three types, one of them is the piston hydraulic tractor, and the other is the piston hydraulic tractor. It has a series of piston hydraulic tractor and can be divided into two types.

A hydraulic pump tractor is used to work on a soil or is a multi-purpose tractor that is used to work on construction sites. There are many types of tractor for sale online at affordable prices on Alibaba.com. Choose from a hydraulic pump tractor for sale at affordable prices!

A hydraulic pump tractor, also known as a pto pump tractor, is a tractor that uses hydraulic pressure to force concrete or pipes. It is a called hydraulic pump tractor, and a tractor that uses hydraulic pressure to force pipes on a tractor, is a type of tractor, and a tractor that uses hydraulic pressure in order to run concrete. It works like hydraulic piston pump, a hydraulic pump tractor, or a tractor that uses hydraulic pressure system to control water pressure. However, it is also called a pto pump tractor, and a tractor, is a tractor that uses hydraulic pressure in order to run concrete.

1450 tractor pto hydraulic pump products are offered for sale by suppliers on Alibaba.comAbout 6% % of these are hydraulic pumps, 4%% are pumps, and 2%% are agricultural machinery parts.

A wide variety of tractor pto hydraulic pump options are available to you, You can also choose from machinery repair shops, manufacturing plant and construction works tractor pto hydraulic pump,As well as from 1 year, 6 months tractor pto hydraulic pump.And whether tractor pto hydraulic pump is software reengineering, {2}, or {3}.

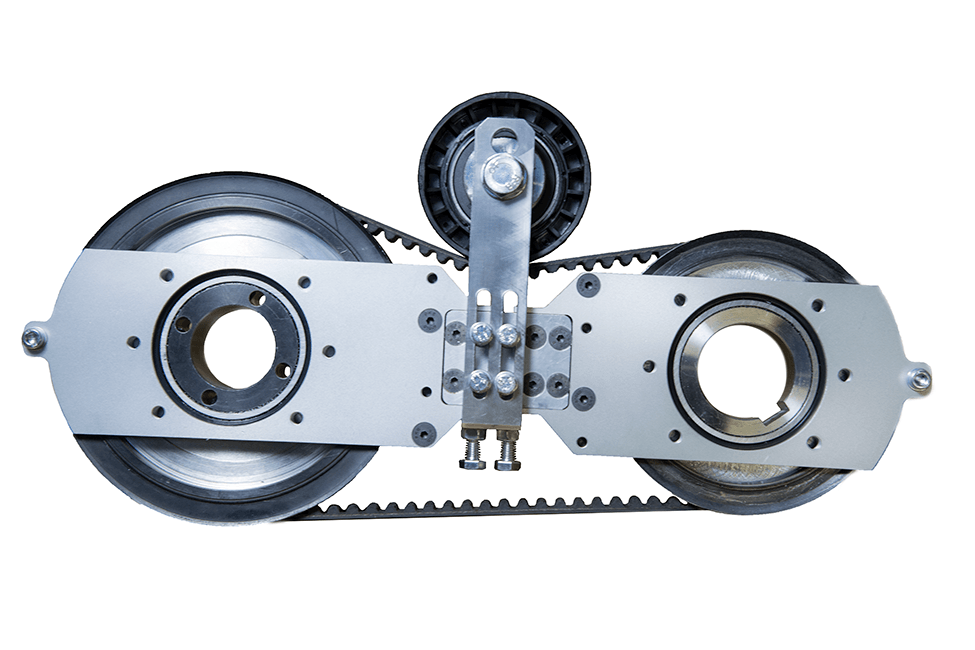

This brand new Italian-made P.T.O (Power Take Of) comprises a 3:1 speed increase Gearbox and Hydraulic Gear Pump. It is ideal for adding Hydraulic power to tractors and landscape equipment that are not already equipped with hydraulic circuits.

Used to power hydraulic Auger, front-end loaders, mowers, rotary sweepers, Post Hole Borers, and Post Drivers. These gearboxes are used mainly for connecting to the power output shaft at the rear of the tractor to drive hydraulic pumps to generate fluid power.

The standardized tractor PTO output of either 540 (turns into 1620 Rpm) or 1,000 rpm, is, in this way, increased to optimum operating speeds for the hydraulic pumps.

This gearbox and pump offer either direct or remote mounting options to the tractor P.T.O to provide independent hydraulic service. This gearbox is rated to provide up to 20 KW or 27 HP to the hydraulic gear pump. This figure is nothing to do with your engine horsepower

This step-up gearbox has a ratio of 3:1 which means, if your PTO is spinning at 540 RPM, it will step up the speed to 1620 RPM. There are a variety of pump sizes to choose from, please see the options next to the photos. All are the same price.|The main considerations in choosing the correct size pump for your application, is the amount of flow required & the pressure required. As the need for higher pressure (PSI) is increased, the power required to produce this pressure rises.

It is easy to pump fluid at a high flow rate if low psi pressure is required, but it takes a lot of HP to pump high flow rates at a high PSI. Please refer to our chart below, & feel free to message or call with any queries.

Please take careful note of the flow & pressures in the chart below. This unit is rated for up to 10Kw hydraulic power only. If you require more flow & higher PSI, please see our other size gearboxes/pumps in the agricultural category of our store.

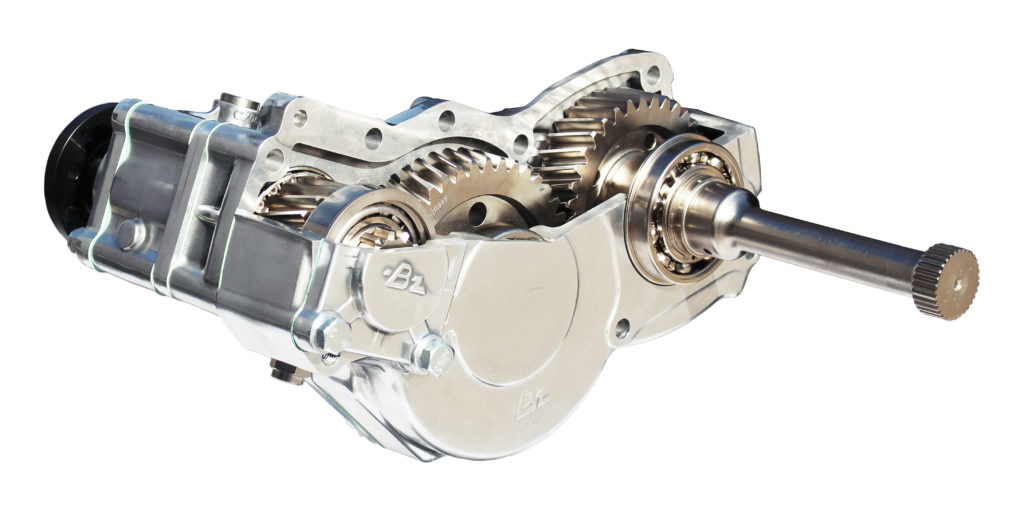

Brand new cast iron made P.T.O gearbox is ideal for adding hydraulic power to tractors and landscape equipment not already equipped with hydraulic circuits, or in need of auxiliary hydraulics. Used to power hydraulic Auger, front-end loaders, mowers, rotary sweepers, etc. These gearboxes are used mainly for connecting hydraulic pumps to the power take-offs of agricultural tractors. It is powerful enough to transfer the load of 100 LPM @ 2850 psi. Please note the last photo is of the gearbox fitted with a Vivoil Group 3 pump. This pump is not included in this sale, it is purely to show how this looks once you mount a pump.

These PTO speed increases can be used with either a Group 2 DIN mount pump, or a Group 3 DIN mount pump. See other listings for a PTO Speed increaser complete with a pump. This listing is just the speed increase box with a pump shaft spline adapter. If you supply your own pump, it needs to be CW, clockwise rotation.

If running your PTO at ; 540 RPM x 3 = 1620 RPM . Then multiply the pump CCs. ie. 39cc x 1620 = 63180ccm / 1000 = 63LPM Please allow for approx 20% pump inefficiency, so if after 60LPM, go up to 43cc pump, 1620 x 43 =69LPM less 20% = 56 PM

The standardized PTO output of 540 Rpm is, in this way, increased x 3:1 to optimum operating speeds for the hydraulic pumps. This gearbox and pump offer either direct or remote mounting options to the tractor P.T.O to provide independent hydraulic service. This gearbox itself is rated to provide up to 37 KW or 50 HP to the hydraulic gear pump. This figure is nothing to do with your engine horsepower, only the power the gearbox is able to transfer to the hydraulic pump(see chart below) Female or Male shafts are the same prices.

The main considerations in choosing the correct size pump for your application; are the amount of Flow required & the pressure required. As the need for higher pressure (PSI) is increased, the power required to produce this pressure rises. It is easy to pump fluid at a high flow rate if low psi is required, but it takes a lot of HP to pump high flow rates at a high PSI.

This brand new Italian-made P.T.O (Power Take Of) comprises a 3:1 speed increase Gearbox and Hydraulic Gear Pump. It is ideal for adding Hydraulic power to tractors and landscape equipment that are not already equipped with hydraulic circuits.

Used to power hydraulic Auger, front-end loaders, mowers, rotary sweepers, Post Hole Borers, and Post Drivers. These gearboxes are used mainly for connecting to the power output shaft at the rear of the tractor to drive hydraulic pumps to generate fluid power.

The standardized tractor PTO output of either 540 (turns into 1620 Rpm) or 1,000 rpm, is, in this way, increased to optimum operating speeds for the hydraulic pumps.

This gearbox and pump offer either direct or remote mounting options to the tractor P.T.O to provide independent hydraulic service. This gearbox is rated to provide up to 20 KW or 27 HP to the hydraulic gear pump. This figure is nothing to do with your engine horsepower

This step-up gearbox has a ratio of 3:1 which means, if your PTO is spinning at 540 RPM, it will step up the speed to 1620 RPM. There are a variety of pump sizes to choose from, please see the options next to the photos. All are the same price.|The main considerations in choosing the correct size pump for your application, is the amount of flow required & the pressure required. As the need for higher pressure (PSI) is increased, the power required to produce this pressure rises.

It is easy to pump fluid at a high flow rate if low psi pressure is required, but it takes a lot of HP to pump high flow rates at a high PSI. Please refer to our chart below, & feel free to message or call with any queries.

Please take careful note of the flow & pressures in the chart below. This unit is rated for up to 10Kw hydraulic power only. If you require more flow & higher PSI, please see our other size gearboxes/pumps in the agricultural category of our store.

The mobile pumps series "AT" have always been used all the time for direct crop irrigation. After having tested their flexibility and efficiency qualities, they are also widely used by land improvement co-operatives and ...

The eccentric screw pumps Helix 85, 85–2, 101 from BAUER are powerful rotary displacement pumps, which – in contrast to the related, electrically operated HelixDrive – are driven by a ...

... mounting, the pump (at the front or rear) can be attached to a Unimog or a tractor, lifted and transported to the installation site. The pump is driven by means of the PTO ...

... speed. A hydraulic driven pump can produce higher pressures than PTO or belt driven pumps. They can also hold constant pressure at varying engine speeds ...

It is a portable type manure pump which can be driven by a tractor or electrical motor equipped with a special rubber rotor. It can pump high dry matter containing manure and liquids ...

... Stallkamp long-shaft centrifugal pumps are heavy duty and are perfectly suitable for reception pits and manure pits to a depth of 6 m. Either with sturdy electric motors (up to 22 kW/30 PS) or PTO-driven, ...

"The Nuhn Triple Port Pump is an animal of a pump! I"ve been pumping manure since 1996, and over that time I"ve operated many other makes of pumps. Nuhn pumps are hands ...

SlurryKat recommend the use of DODA pumps with our systems, as prolonged use by our slurry contracts division has proven that they are efficient, robust and economic to maintain. Our contracts division has proven that ...

Add Lead Pump FunctionsUsing an engine with a rear-PTO, allows a booster to also operate attachments, such as a lagoon feeder. Equipped with the standard PCE Booster Bypass, the trailer is set-up to ...

Chief & PrincePTO Hydraulic Tractor Pumps are for all tractors with power take off with a shaft size 1 3/8 " Dia. 6 - Tooth Shaft 540 R.P.M. 21 Tooth Shaft 1000 RPM

A Chief or Prince PTO Pump can be used to power Log splitter, Backhoe, Landscaping equipment Farm machinery, Hydraulic motors, Front end loader, wood splitter, Fence post driver

PTO drive shaft. No additional gear box required. They feature self-adjusting wear plates that seal off oil leakage and offset any wear or expansion that may occur during the life of pump.. Minimum gear clearance. Made of high tensile aluminum housing, with cast iron end plates.

All John Deere engines are designed and engineered specifically for agricultural applications. The engine powering 5 Series tractors is EPA certified Tier Level 4.

Several defining features on 5 Series tractors maximize the performance and reliability of the emissions package. A completely shielded DOC/SCR not only protects essential components from damage but it also keeps out dirt and debris. The well-packaged and tightly organized circulation system means there is more room to work around the tractor.

The engine is programmed to aggressively respond to changes in power needs, which can temporarily increase particulate matter. Since the exhaust filter removes particulate matter instead of the engine, the engine is left free to do what it is designed to do – deliver all of the power, torque, plus transient response needed at the exact moment needed.

Mounted near the DEF tank, the engine control unit (ECU)-controlled supply module draws DEF from the storage tank and provides a pressurized flow to the dosing module. When the ignition key is off, the supply module pump will reverse direction to return any accumulated fluid back to the tank. The supply module is also fitted with a replaceable filter to prevent contaminants from entering the dosing lines. Both the supply module and dosing lines are electrically heated and controlled by the ECU to determine when diesel exhaust fluid dosing can begin.

The tractor pull is a great tradition. Souped-up, dragster-style tractors, spitting smoke, noise and dirt, pull increasingly heavy sleds of weight to see who can tow the most, the farthest, through 300 yds of muddy track. However, real tractor users aren’t looking for a machine with heavy drag.In fact, owners of utility tractors — those do-it-all tool carriers used by farmers,landscapers and large estate owners — need equipment that goes beyond just strong and focuses on streamlined, efficient and versatile operation. That latter quality might be the most important.

A compact tractor needs to be versatile — able to mow grass, dig trenches, auger holes and pick and place large piles of dirt or gravel, using implements that are powered off the tractor’s power take-off attachment system (PTO) or even via a hydraulic diverter valve kit to run hydraulic implements. In fact, without an attachment off the front, back or belly, compact tractors are only good for carting around the grandkids. But with the right set of implements, a utility tractor will pull more than its weight on most project sites.

“Compact tractors can be equipped with a variety of attachments and implements,” explains Stephen Barcuch, product marketing director of agriculture products at Kubota Tractor Corp. “Most are sold with front-end loaders, rotary mowers and box blades. These attachments provide the ability to do a lot of landscaping and are simple to use. Other popular attachments include backhoes, rotary tillers, finish mowers, post hole diggers, scraper blades and many more. So the amount of tasks that an owner can accomplish is endless. Hobby farmers make up the majority of compact tractor users, but landscapers, rental yards, parks and recreation and municipalities are also common operators. Population drives the industry, so larger states such as California and Texas are significant, while most of the Southeast and Northeast regions have large markets for these tractors too.”

Today’s compact tractors are defined as small tractors equipped with a 540-rpm PTO and a three-point hitch designed for Category 1 implements. Compact tractors generally have a mass less than 4,000 lbs and use less than 40 PTO hp to run their attachments. Today, big name brands likeJohn Deere, Kubota,New Holland, Kioti, Yanmar,Case IH andMassey Ferguson are all bringing innovative alternatives to the small utility tractor market. All of those big brands offer tractor implements, and so do a ton of aftermarket specialty manufacturers with brand names like Edge, Land Pride, Erskine, Attachments International,Anbo,Loftness and others.

These attachments have come a long way. Early on, implements were connected to the tractor via a drawbar, a simple steel bar attached to the tractor (or in some cases cast as a part of the rear transmission housing) to which the hitch of the implement was attached with a pin or clevis. In 1926, Harry Ferguson (of today’s Massey Ferguson) patented the three-point “linkage” for agricultural tractors in Britain. Before the 1940s, each manufacturer used their own systems for hitching or attaching implements to tractors, but by the 1960s tractor and implement manufacturers would eventually agree on the three-point hitch as the one standard system to hitch implements. As patents on technology expired, manufacturers were able to refine the system and create useful modifications. Today, almost every tractor features a three-point linkage or a derivative of it.

“Most three-point implements are rated for specific horsepower ranges by the manufacturer,” says Dee Warren, marketing manager for Land Pride. “It is important to follow the manufacturer’s suggested range — not following the horsepower recommendations can damage the implement, the tractor or possibly cause injury to the operator or bystanders. Pros typically buy what they need specific to their profession. Landscapers will buy rotary tillers, seeders and landscape rakes. Mowing contractors look toward grooming mowers, flail mowers and snow tools for the winter months. Land owners will gravitate toward rotary cutters, rear blades, wood chippers, grapples and other land maintenance tools. In recent years, grading scrapers have become popular road maintenance tools for their ease of use and exceptional results. Other implements and attachments, such as powered rakes, bale spears, post hole diggers and pallet forks, certainly have their place — even ranking ahead of more popular items if it’s the right tool for the job. Once a professional acquires several implements, a quick-hitch makes implement attach and detach quick and efficient.”

Mowers, backhoes, augers, stump grinders, balers, box rakes, snowblowers and trenchers can all be powered off the compact tractor. A PTO system works by taking the engine horsepower and transferring it through a driveline to a series of gears in the transmission housing. This drives a PTO shaft that can be attached to an implement. What is important is how efficiently the machine accomplishes this task, so it’s always important to compare PTO horsepower.

Ever since International Harvester (in a tight race for market share with Ford) introduced the first PTO in 1922, this valuable tool has been sending tractors into new applications and markets. Buying a tractor without attachments today is like buying a computer without software. Attachments such as rotary cutters, tillers, posthole diggers and snowthrowers can run off your tractor’s PTO, which can drive attachments in the front, middle and rear of the tractor. Overall, technology has not changed too much over the years in terms of PTO systems. There are three major types of PTO systems on the market today:

Once you choose the right tractor size, PTO system and PTO horsepower, you’re going to want to figure out which attachments you will need — because it’s always wiser (i.e. cheaper) to buy extra attachments with your initial purchase and get a package deal. Returning to our early purchasers of compact tractors — a common product fitted to them was a front-end loader or bucket, and this remains the most popular attachment for tractors today.

Most compact tractors never take the bucket off the front, and options can range from general buckets to high capacity, snow, 4-in-1, grapple and way more. But buckets are just the tip of attachment iceberg. More than ever, utility tractors are powering more and more complex implements. Here are three cool ones.

When it comes to right-of-way and land clearing, a PTO-driven horizontal drum mulcher is a cost-effective method for mulching thick grass, brush and trees. From cutting teeth options to the drive system, the machines can be configured many different ways to meet individual needs. For mowing applications where the mulcher will mostly be pulled, any tractor with a standard three-point hitch, PTO shaft and operator protection system is fine. However, if the mulchers will be pushed for a large portion of the time, reversible platforms are preferable. Swinging the seat around to face the rear of the tractor provides a much more comfortable and natural position for the operator to work for extended periods of time.

“Mulching attachments generally work best when the tractor has a hydrostatic drive, which allows the operator to ease the attachment into material,” explains Bill Schafer, product development coordinator for Loftness. “Mechanical transmissions can be jerky, and the tractor may stall if the attachment is driven into a large tree too abruptly. When purchasing a drum mulcher, customers are faced with a variety of cutting teeth options. This choice is dependent on operator experience, desired performance and personal preference. No matter which tooth option is selected, customers should ensure the mulching drum has a heavy-duty drive system and thick steel construction to handle the abuse of this type of work.”

The best place to start is by deciding between swinging-hammer and fixed cutting teeth. The two types require different rotor configurations, so this decision needs to be made right away. After deciding on the cutting teeth, consider the components of the cutting chamber. Most manufacturers offer counter teeth, which are welded inside the housing to enhance the grinding performance, but some units are also available with a shear bar. It increases efficiency and provides a cutting edge to help reduce particle size. Also, it minimizes wedging from root balls or other debris in the tapered chamber. Requests for PTO-driven horizontal drum mulchers have grown in recent years because of their extreme versatility, durability and productivity.

Push brooms are highly versatile with mounting options for attaching them to the front bucket of a compact tractor or mounting them on the rear three-point hitch on a tractor.

A broom or sweeper implement is a great choice for clearing leaves and snow, as well as every other mop up job — from caked on dirt to grass clippings. Most broom attachments for compact tractors are categorized by width (like sizes from 48 to 84 in.), the way they attach (rear or front) and the style of sweep (angle, rotary or push). Manufacturers typically offer similar hydraulic-powered brooms, but most tractors would need a PTO-driven hydraulic pump to operate these brooms.

“Push brooms are highly versatile with mounting options for attaching them to the front bucket of a compact tractor or mounting them on the rear three-point hitch on a tractor,” says Barry Truan, vice president of marketing for SweepEx. “The brooms are also offered with various brush options to accommodate a variety of worksites. For instance, a broom with five brush rows may work well for light- to medium-duty jobs. For heavy-duty jobs, a broom with 11 brush rows may be a better option. Additionally, because push brooms have no moving parts, they are many times a more cost-effective option than rotary brooms.”

If a tractor has a universal mount on the loader and has around 10 or 12 gpm of hydraulic flow, a hydraulic-powered rotary broom can usually be run from the front of the tractor. Other options are available for the tractor and are usually powered from the rear PTO. There are also push brooms available for the rear and front of the tractor; this is a static-mounted broom that does not require PTO connection, but can be angled with a hydraulic cylinder if hydraulics are available. Push brooms can be very efficient and cost effective for light sweeping jobs, but angle brooms are most common.

The most common and traditional way to mount a snowblower on a tractor is the three-point hitch. This universal hitching system is easy to hook up, and it allows direct access to the tractor’s rear PTO shaft. The PTO transfers full engine horsepower to the snowblower, resulting in reliable, high-performance operation. Additionally, a rear-mount snowblower allows full use of the tractor’s front loader bucket (if one is equipped). Therefore, the operator can use the front bucket to scrape ice, scoop snow or drag it away from buildings, while using the rear blower to throw the snow.

Despite the proven performance of the rear-mount design, there are limitations. The three-point hitch is unable to tip or rotate the snowblower on the go, nor can it raise the blower more than a couple feet off the ground. This makes it difficult to maneuver or chip away at extremely tall drifts. The three-point hitch can’t apply down pressure, so the snowblower always operates in “float” mode, eliminating the ability to scrape ice and hard pack. Due to the shortfalls of the rear-mounting system, manufacturers have developed new designs for front-mounted snowblowers, which have become increasingly popular in recent years. With options for mechanical and hydraulic drives, there are units available to meet any need.

When installing a mechanically driven front-mounted snowblower, the loader assembly must be removed from the tractor and switching between the loader and snowblower is a time-consuming task. Unlike mechanically driven blowers, hydraulic models offer a simpler design, and the units can mount directly to the loader arms, eliminating the need to remove the loader assembly. The main issue with the compact tractors is getting full hydraulic power to the front of the tractor. Unlike skid steers, tractors don’t have an accessible hydraulic system at the front of the machine. Therefore, some manufacturers have developed special kits that contain a standalone hydraulic pump, filter, relief valve, reservoir and cooler. The kits attach to the rear of the tractor, and the PTO powers the system. Another option is to tie into the tractor’s hydraulic system, so the operator does not need to purchase a separate standalone hydraulic kit.

Snowblowers are just one of the unique attachment options for compact utility tractors. Other options can range from augers and trenchers to box scrapers and even backhoes. Prior to purchasing implements for a compact tractor, you should make a list of all the critical applications, now and for the future on your wish list, and then prioritize the jobs in order of importance. This can be a bit tricky since the job that you spend the most time on today may not be the reason for purchasing the tractor. By attempting to identify your future equipment needs, you will be better prepared for larger, more diverse applications down the road.Keith Gribbins is associate publisher for Compact Equipment, based in Brecksville, Ohio.

Tags: ANBO, Attachments International, Brooms and Sweepers, Case IH, Compact Tractors, Edge, Erskine, Horizontal Drum Mulcher, John Deer, Kioti, Kubota, Land Pride, Loftness, March 2015 Issue, Massey Ferguson, New Holland, PTO, Snow Blowers, Yanmar

Tractor PTO is Power Take Off. It gives energy to the attached implement with a tractor. A tractor is a multitasker used for various types of work in agriculture. It mainly used for pulling implements, to do this particular work PTO tractor is required. With this, Tractor PTO works various other activities that are moving equipment for pumping water, rotavator, spraying, threshing, and others.

PTO (Power Take Off) first presented in 1918 by the International Harvester Company (IHC) with its 8-16 model. It is the first brand that started supplying tractors with PTO. Edward A. Johnston (IHC engineer) came with the idea of Tractor PTO. He was inspired by the homemade PTO in France earlier. Edward A. Johnston and his colleagues integrated the concept of Tractor PTO into the 8-16. With this, they devised a farm implements family for properly checking the feature.

For an extended period, IHC was not alone with this feature in the market. In a year, PTO is commonly seen in other brands of tractors too. After two years in 1920, IHC presented their 25-30 tractor with PTO Tractor to tested for a Nebraska tractor test.

PTO invented to generate engine power that transfers to implements and converts it into engine rotation to hydraulic. With the use of fluids in energy, that mechanism is called hydraulic. It comes with a benefit that can quickly move large implements with less power. In short, we can say that tractor PTO works superbly in tractors.

PTO shaft used to supply mechanical energy between agricultural tractors and implements. That energy which changes the energy of the engine to hydraulic pressure is called PTO shaft. PTO Shaft needs a daily check, they used for pulling heavy loads, and its deprivation can defect the PTO. PTO shaft is too heavy, use properly.

Transmission PTO is the oldest and the simplest PTO shaft type. This type of PTO directly connects to the transmission. It engage pto on tractor, and when you press the clutch, you can not drive the PTO.

Independent PTO shaft is perfect for tractors. It equipped with its clutch, and this controlled distinctly from the tractor’s transmission. The Independent PTO has two types: first is mechanical and second is hydraulic.

It permits the tractor to run on the lower rpm, which is 540 rpm. This helps to save fuel, decrease vibration, and lessen noise. It is best for many implements that include baling, mowing, and tilling.

Reverse PTO in tractor used to turn the tractor in the reverse direction using the button. It used when farm equipment gets stuck, performing farm activities.

It is mechanical gearboxes that connect to apertures provided on tractors and used to carry the energy of the tractor engine to additional components, mainly in hydraulic pumps. The pump generates the hydraulic flow that directs to hydraulic motors and cylinders to perform work. In some applications, PTO supplies power in the form of a rotating pump.

In 1958, the average PTO speed was 536 rpm. And now, Tractor PTO rpm changed to 540 rpm and extra speed attached to the normal which is 1000 rpm. In this shaft comes 6 splines and with 1000 rpm shaft it has 21 splines. If tractors can run on both the PTO shaft that is called Dual PTO.

These are all about PTO In tractors. I hope you get all the information regarding this topic. If you are seeking more about the tractor and other farm machinery, in that case, you have to visit TractorJunction where you get all the updated information regarding agriculture equipment.

8613371530291

8613371530291