pto hydraulic pump meaning in stock

The transmissions commonly found in Class 4 and larger vehicles will have provisions for the mounting of a PTO. Generally there are two apertures, one on each side of the transmission. When discussing aperture location one refers to the passenger side of the truck as the right and the driver’s side as the left.

The power take-off may be engaged by means of a cable, air pressure or hydraulic pressure. Various output shaft configurations are available to allow for a driveshaft connection or the attachment of hydraulic pumps directly to the PTO without an intermediate shaft. The Society of Automotive Engineers (S.A.E.) has established standard mounting face dimensions for hydraulic pumps, which PTOs are made to accept. The S.A.E. type B mounting is the most common.

The transmission’s PTO aperture may be of the six-bolt, eight-bolt or ten-bolt type, referring to the number of fasteners used to attach the PTO to the transmission. Six- and eight-bolt openings are S.A.E. standard sizes as found on manual and automated manual transmissions. The ten-bolt opening is exclusive to Allison automatic transmissions.

Power take-off input gears mesh with the transmission’s PTO drive gear and transmit power to the PTO output shaft. Muncie Power Products works closely with truck transmission manufacturers to ensure that the PTO gear matches the mounting depth, pitch and helix angle of the transmission gear.

Power take-off output shaft speed is dependent upon truck engine speed, transmission gearing and the internal gear ratio of the PTO. To simplify selection, Muncie Power calculates the transmission data and catalogs PTOs according to their output shaft speed in relation to the truck engine. In the Muncie Power Products PTO Quick Reference Catalog and online application aids, one will see PTO speed expressed as a percentage of engine speed. One can therefore determine the PTO speed in revolutions per minute (RPM) by multiplying the engine speed by the PTO percentage.ENGINE SPEED × PTO % = PTO SHAFT SPEED

All PTO driven components have an operating speed range, and the power take-off is selected that will properly match the desired engine operating speed to the required component input speed. This can be determined by referring to the written specifications of the driven component or consulting with one’s PTO supplier.

A hydraulic power take-off, or hydraulic PTO, is a system that transforms your vehicle’s or machine’s engine power into hydraulic power. Hydraulic power is the power that the hydraulic oil flow and pressure creates. The hydraulic oil flow and pressure are lead through piping to external equipment, like a hydraulic compressor or generator. These pieces of equipment use the hydraulic power for operating. The power transfer is made through many hydraulic components, which form a hydraulic system.

Hydraulic systems have five main components: hydraulic pump, piping, hydraulic oil reservoir, hydraulic oil cooler, and the hydraulic equipment. In addition to these, the system has a bunch of valves and other smaller parts to control the oil flow, system, and pieces of hydraulic equipment that are connected to the system. Actually, the hydraulic pump is the component that transforms engine power into hydraulic power. A hydraulic system is possible to install basically on any vehicle varying from cars to ATV’s. As a sum up, the hydraulic system opens up the possibility to benefit from hydraulic equipment.

Hydraulic generators, compressors, and power washers are great examples of hydraulic equipment. The benefit of the hydraulics is the compact size of the equipment. This makes it possible to install multiple pieces of hydraulic equipment into one vehicle. Service trucks and vans have often at least two or three pieces of hydraulic equipment onboard.

Further, hydraulic tools are tools that use the power of the hydraulic system also. For example, fire departments often use hydraulic powered spreaders and such in their rescue operations. A service van can also have hydraulic quick couplers so the user can attach hydraulic tools to it fast. So, the quick couplers give you the possibility to use reliable hydraulic tools on the road.

Moreover, this versatility makes it possible to do more on the road. In addition, you can get more value out of your vehicle or machine with hydraulic equipment. All you need is the hydraulic PTO to your vehicle and the new advantages are at your reach. At the end of the day, hydraulic equipment can offer new opportunities to you. Further, these can mean ways to earn more or save money. As you know, almost any vehicle can have hydraulic PTO. We are specialized in hydraulics and with over 30 years of experience, we can provide the best solution for you. Download the guide about the advanced knowledge of hydraulic PTO’s and hydraulic systems to get started!

We will give an insight into how you will benefit from equipping a service vehicle with hydraulic equipment. Watch the video and leave questions to the comment section of the YouTube video.

Road planers, dredges, and other equipment require power from some type of engine to perform their designed function. Without a power take-off, it would be necessary to add a second engine to provide the power required to run hydraulic pumps and other driveline attached equipment.

Adding an additional engine is simply not practical, which makes power take-off (PTO) a valuable element in providing power to secondary functions. To recognize their value requires a better understanding of these systems, their various types, and their diverse applications.

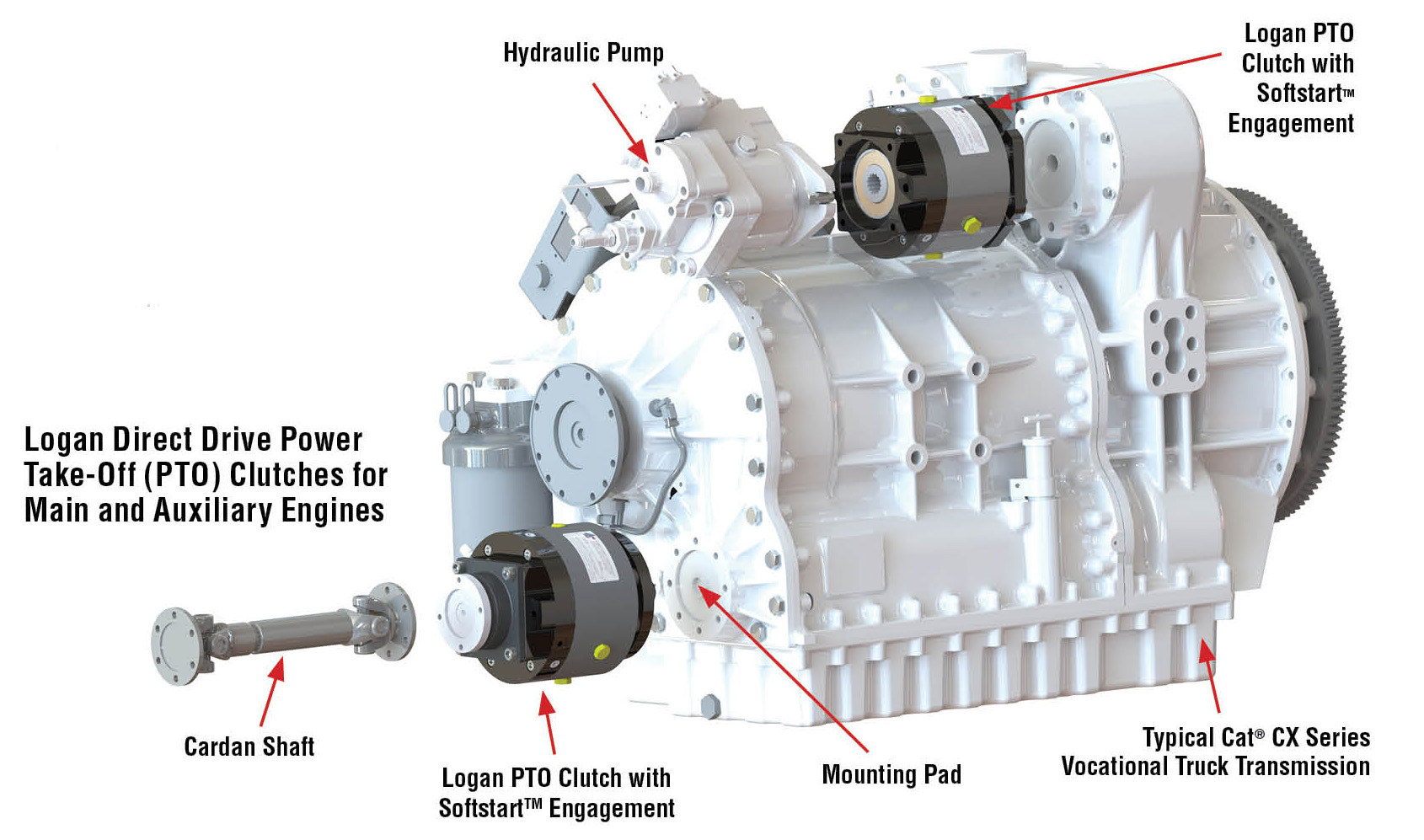

Power take-offs allow mobile crushing plants, road milling machines, and other vehicles to perform auxiliary functions without needing an additional engine to power them. A PTO is a device (a mechanism) usually seated on the flywheel housing, which transfers power from the driveline (engine) to a secondary application. In most cases, this power transfer applies to a secondary shaft that drives a hydraulic pump, generator, air compressor, pneumatic blower, or vacuum pump.

PTO choice is critical to provide sufficient power to the auxiliary equipment without severely limiting the main function of the prime mover. Selection of a power take-off requires specific information relating to the application and the power needs of the secondary or driven component.

Speed and rotation requirements of a PTO are among the most critical specifications in the list above, with speed being necessary for calculating torque. The torque and horsepower requirements of the driven component are essential for optimal performance.

Keep in mind that these calculations only apply to PTOs that drives a hydraulic pump. In cases where power take-off is providing power to a different type of drive component, it will require the manufacturer’s specifications of the driven element.

Though they perform the same general function—transferring power from the primary drive shaft to a secondary drive shaft for a driven component—there are various PTO types available that serve specific industrial applications. These diversifications are why WPT Power supplies OEM’s units in agricultural, energy, forestry, and road building sectors, among others.

The distinguishing characteristic of this type of PTO is the intentional removal of the pilot bearing. Benefits of this design feature come with an increased side load capacity, reduced inventory, increased uptime and engine life, and a quicker and easier installation. Industrial applications of the Pilotless Mechanical PTO include:

This type of flywheel PTO applies to either inline or sideload uses. It includes a sealed-for-life pilot bearing, utilizing a lever-actuated manual clutch. The benefit of this type of PTO is a straightforward installation which minimizes downtime and maintenance requirements. This type most commonly applies to:

This is a rugged, high-capacity power take off used in a broad range of industrial functions. Characteristic of this type of PTO are the sheaves between heavy-duty spherical roller bearings designed to utilize their full load potential. This bearing arrangement reduces the damage produced by crankshaft loading. Among the most common applications for the Type 1 PTO are:

The design of the Type 2 PTO features a heavy-duty side loading capacity using sizeable spherical roller bearings. Actuation of this PTO can be either hydraulic or pneumatic. It is self-adjusting and removes the need for the pilot bearing inside the engine flywheel. Features include reduced maintenance, less chance of premature failures, and improved engine and bearing life since there is no direct loading to the crankshaft. Common applications for Type 2 PTOs include:

This PTO design eliminates the need for the pilot bearing while providing increased side loading or inline potential. Its engineering accommodates the most demanding requirements of high-loading diesel engines. Features include simple installation, reduced downtime, and improved engine service life. This style of PTO is used on inline applications with its hydraulic and air fittings. They are mounted near the bell housing instead of at the rear of the shaft like type 1 and type 2.

The GM Style PTO reduces maintenance time and cost by using sealed main bearings and eliminating the need for the pilot bearing. Designed to mount directly to GM® style engines, these operate without the need for any particular PTO or engine adaptations. Notable features include clutch adjustments using an external ball stud and jam nut adjustment points.

Also known as “flat-faced” style PTOs, they incorporate similar design characteristics, features, and benefits of the GM style PTO. It is a spring-loaded clutch making it easier to engage and disengage than over the center power take-offs. Typical uses include irrigation units, brush chippers, or other gas or diesel engine applications.

PTOs are relatively simple mechanical units with minimal operational problems, but a few common issues are associated with them, and each has a straightforward solution. Here are some of the most frequently encountered issues:

PTO is hot. A newly installed PTO will run hot for the first 10-20 hours of operation after installation. Several issues contribute to overheating (220º F measured by infrared thermometer at the bearing carrier), including too much or too little grease, excessive sideload, or a new installation. Follow proper lubrication specifications and reduce the sideload to remedy the first two problems.

Getting the appropriate PTO to meet your operational needs is a priority at WPT Power. Manufacturing our PTOs takes place in our ISO 9001:2015 facilities, where all our products are engineered to meet the highest standards of quality demanded by our customers. ABS type approvals and ATEX certifications minimize risks, time, and costs. Type approval certification available: DNV & ABS (Others available on request)

Our broad range of products is developed to meet most requirements on standard industrial applications. Custom or modified PTOs are available for original equipment manufacturers (OEM) requiring specialized design and where volume is needed.

Power take-offs play an essential role in allowing for the transfer of power from a primary mover to a secondary or driven component without needing an additional separate engine. Various PTO types serve many applications, from smaller-scale operations to major industrial and construction projects. Choosing the correct PTO for a specific application is critical to the proper performance of the driven component.

Contact us for more information about the range of solutions offered by WPT Power Corporation, for assistance in selecting the right PTO to fit your specific application, or request a quote from one of our experts.

A power take-off is a gearbox that directs power from the engine and transfers that power to auxiliary equipment through the rotation of the PTO gears and the vehicle transmission gears meshing. The power is generated from the truck’s engine power and is used to power the piece of equipment on the vehicle application.

PTOs are generally categorized by their mounting type. The three most common PTOs are side mount, rear mount, and top mount. Refer to previous blog post Understanding Why There are So Many Options for Mounting a PTO to read about the main mounting types available for a PTO.

The speed of the PTO output is dependent on internal gearing of the PTO as well as the internal ratio of the transmission in relation to the PTO driver gear. For an automatic transmission, the minimum input speed higher than torque converter lock-up must be maintained for PTO operation (unless the transmission offers “live drive”, meaning the PTO is powered through the impeller). Depending on the internal gearing, PTO output speeds can be less than, greater, or equal to that of the transmission.

When specifying a PTO, we need to find the input horsepower required of the driven equipment. Horsepower is the measure of capacity for doing work per unit of time. Torque is the effort required to perform a twisting or turning motion. The horsepower is figured into the equation to find the torque requirements for the proper PTO to be used. Parker Chelsea categorizes product series using torque values.

Parker Chelsea classifies PTO series as either intermittent or continuous. It is important to note that for an application that is “continuous” duty, (i.e. the PTO is in operation more than five minutes in any given 15-minute period), intermittent torque values must be de-rated by 30% unless the PTO is already classified as continuous duty.

Power take-off provisions include special wiring and programming along with apertures on the vehicle’s transmission that allow for the mounting of the PTO. The “PTO ready” option needs to be ordered and configured at the chassis manufacturer when building out a work truck.

There are two major types of independent PTOs; mechanical (i.e. 489 series) and hydraulic (i.e.new 210 series). A hydraulic shift PTO uses a clutch mechanism for engagement. Hydraulic shift PTOs apply to traditional (torque converter) automatic transmissions. A mechanical shift PTO physically engages by shifting one gear into another. This is done typically through a lever, cable or air pressure. Mechanical shift PTOs apply to manual and automated manual transmissions.

Pitch (Gear): The measure of the size of the gear teeth determined by the number of teeth in a given area measured at the pitch line. PTO gear pitch is normally classified as 5, 6, or 7-pitch.

It is very important to have periodic PTO maintenance for proper, safe, and trouble-free operation of the PTO. It is recommended to follow below the maintenance schedule.

Monthly: Inspect for possible leaks and tighten all air, hydraulic and mounting hardware, if necessary. Torque all bolts, nuts, etc. to Chelsea specifications. Ensure that splines are properly lubricated, if applicable. Perform maintenance as required.

A potential issue with a PTO can be premature spline fretting or wear caused by torsional vibrations. Traditionally, regular grease application between the PTO output and the PTO shafts is incorporated into the preventive maintenance schedule of the truck. This entails every two to three months having the pump removed from the PTO and having the mating shafts cleaned and regreased. Parker Chelsea provides spline lubrication grease with every PTO that has a pump mount option. They have also developed Wet Spline technology that helps provide a constant flow of fresh oil to the PTO and pump shafts to mitigate the issue of spline fretting and the wear which leads to not needing the maintenance inspections. Check out what Parker Chelsea offers forWet Spline Technology and the additional benefits it provides.

It is recommended to begin analyzing a PTO application using pre-determined necessary technical information about the work output and installation requirements. Go through the following steps to specify a PTO.

Establish the approximate engine speed desired during operation or PTO ratio (if known). PTO speed is stated as a percentage of engine speed. An example being the required pump speed of 1000 RPM and having an engine operating speed of 1500 RPM. The percentage of PTO to engine speed would be calculated to approximately two-thirds, or approximately 67 percent (e.g. 1000/1500 = 66.67, or 67%).

Define the direction of the Driven Equipment Shaft Rotation with there being two choices, engine and opposite-engine. The PTO requirements will be determined by the driven equipment. It is important to note the PTO output shaft rotation listed on the application page is in relation to the vehicle crankshaft rotation as viewed from the rear of the vehicle.(See Figure 1).

Define the duty cycle as intermittent or continuous. Intermittent duty cycles are defined as PTO operations that last for less than five minutes in any fifteen-minute period. Conversely, continuous duty cycles are defined as PTO operations for more than five minutes out of every 15. If an intermittent PTO is used for continuous operation, the required torque must be divided by .70 to get the torque requirement for the driven equipment. The PTO will need to de-rated if it was not designed for continuous duty.

Determine the type and size of the PTO output required (i.e. driveshaft – the size of output required, direct mount pump – mounting flange and shaft type/size).

While not all information is always available, here is an informal guideline that can get you started with the right information to help you select the right PTO for your application.

It is important to remember when the appropriate PTO has been selected through the concluded gathered information, review the application guide, and make sure that all the necessary information has been included. When searching for a PTO in a catalog, please remember to read the footnotes as there may be additional information to consider for specifying a PTO. This can include transmissions not being able to withstand torque capacity of the PTO and the application or some other unique feature of the unit may be mentioned through the footnotes.

To further investigate what different PTOs are being offered, including the new 210 series PTO for the 2020 Ford Super Duty 10R140 Transmission, be sure to check out www.parker.com/chelsea to learn more.

PTO is one of the most critical components in the truck hydraulic system. It is accountable for transferring mechanical energy from the hydraulic pump to auxiliary parts for executing given applications. However, a slight issue with the truck PTO hydraulic pump can cause system failure resulting in loss of revenue.

If you"re noticing whining or high-pitched sound – it could be because PTO"s gears are not appropriately merged or being too tight, issues with bearings or hydraulics. However, the clattering sound indicates that gears are too loose or have torsional vibrations.

In general, PTO hydraulic pump"s engagement issues could cause due to blocked hoses or bad fittings, connections, or the solenoid. In addition, mechanical engagement could generate from low air pressure, backlash too tight or improper cable deployment.

Once identifying the symptoms, it needs to operate rightly to enhance the vehicle"s life. Routine and scheduled maintenance is essential to ensure the PTO tool functions trouble-free. In this blog, we"ve outlined the maintenance steps for helping the end-users.

The PTO maintenance is divided primarily into three stages. The initial stage, short-term and system stages. The maintenance process needs adequate planning, operational expertise and thorough system knowledge. So, keep that in mind before the initiation of the process of vehicle maintenance.

The first step should be carried out within 24 to 48 hours of use or after experiencing symptoms of PTO hydraulic system damage. It would be best to analyse drive train sound if it seems louder than usual – it means further investigation may be required.

Further in the process, after cooling down the engine, look for potential damage such as leaks. These leaks could impact the transmission fluid level and affect the system performance over time. The PTOs must be checked within a week of installation for making sure that its mounting bolts have been torqued appropriately.

After the initial check-up, the truck operator needs to think about the next maintenance schedule based on the duty cycle. Usually, the duty cycles are divided into normal or severe duties. When the PTO operates five minutes extra out of every 15 minutes, it is defined as a severe duty. Lower than that compared as a normal duty. You can choose which duty cycle is ideal for long-term maintenance based on PTO performance.

The more complex a truck PTO hydraulic pump works, the more it needs to be inspected. Based on previous maintenance, the normal duty cycle inspects which items need replacement, checks the fluid level, or verifies that the equipment is tight and secure.

Long-term PTO maintenance is essential, suggested by vehicle manufacturers. It can help improve the performance of the hydraulic pump. Check fasteners are torqued rightly, and no fluid is leaking around the seal. If you find any leak source, seals need replacement.

Keeping the vehicle in optimal condition and PTO functioning requires periodic maintenance. When regular maintenance is carried out on the vehicle chassis (frame), it will be good to inspect the PTO of the hydraulic system.

During a weekly or monthly maintenance schedule, along with other components, PTO is checked for cleaned shaft proper lubrication. The application of lube simplifies parts engagement and disengagement issues. Applying an anti-seize grease helps smoothen parts movement in high-temperature cases. Also, make sure to clean off the grease fitting once the lube is applied.

Visual Inspection – To make the equipment run smoothly, the PTO inspection needs to be performed weekly or monthly. The inspections include checking for leaks, wear or tear, making sure the hose and wire are not rubbing against the transmission. Through visual inspections, you can prevent many issues immediately.

Physical Inspection –When it comes to checking the condition of PTO – physical inspection is equally important. It is suggested to perform after 100 hours of use. If you have removed the PTO from the hydraulic system for inspection, check the wear patterns and bearings. The periodic physical inspection could reduce the amount of downtime and expenses.

Surya Truck Parts – Your Trusted Online Supplier for Heavy Truck PartsWe are one of the best market leaders in Power Take-Off (PTO) products for the truck and mobile vocational markets. We are an establishedsupplier,having years of experience serving customers with the best and most affordable products.

We offer a complete range of PTO hydraulic system parts to match your needs. At Surya Trucks, you can enjoy cost benefits and get crucial components like PTO wet kit for sale.

Hydraulic pumps convert mechanical energy into fluid power energy. All hydraulic pumps are positive displacement which means the outlet flow is sealed from the inlet flow. A small amount of fluid is designed to leak internally to lubricate and cool the internal components of the pump. The only function of the pump is to produce flow in a system. Bailey International, LLC provides a wide range of pumps and accessories including clutch pumps, dump, gear, jaw couplers, mounting brackets, pistons, PTO, vane and two stage pumps.

PTO stands for Power Take-Off, which is a common form of mechanical power delivery in the mobile machine market. Here at Flowfit, we are proud to offer industry-leading PTO gearboxes and pump assemblies to transfer high volumes of power and torque from the hydraulic or mechanical systems engine. Typically, these models can be found in high-powered industrial or agricultural machines, including trucks and tractors.

Our PTO gearbox and pump assemblies are available in a wide range of designs and specifications to meet the exact requirements of your system. Typically cast in mechanically-resistant iron or housed in shell-cast aluminium, our models are designed for connecting gear pumps to power take off systems.

For more information on any one of our pump and gearbox assemblies, get in touch with our friendly team of hydraulic and mechanical specialists today on 01584 876 033.

Brand new cast iron made P.T.O gearbox is ideal for adding hydraulic power to tractors and landscape equipment not already equipped with hydraulic circuits, or in need of auxiliary hydraulics. Used to power hydraulic Auger, front-end loaders, mowers, rotary sweepers, etc. These gearboxes are used mainly for connecting hydraulic pumps to the power take-offs of agricultural tractors. It is powerful enough to transfer the load of 100 LPM @ 2850 psi. Please note the last photo is of the gearbox fitted with a Vivoil Group 3 pump. This pump is not included in this sale, it is purely to show how this looks once you mount a pump.

These PTO speed increases can be used with either a Group 2 DIN mount pump, or a Group 3 DIN mount pump. See other listings for a PTO Speed increaser complete with a pump. This listing is just the speed increase box with a pump shaft spline adapter. If you supply your own pump, it needs to be CW, clockwise rotation.

If running your PTO at ; 540 RPM x 3 = 1620 RPM . Then multiply the pump CCs. ie. 39cc x 1620 = 63180ccm / 1000 = 63LPM Please allow for approx 20% pump inefficiency, so if after 60LPM, go up to 43cc pump, 1620 x 43 =69LPM less 20% = 56 PM

The standardized PTO output of 540 Rpm is, in this way, increased x 3:1 to optimum operating speeds for the hydraulic pumps. This gearbox and pump offer either direct or remote mounting options to the tractor P.T.O to provide independent hydraulic service. This gearbox itself is rated to provide up to 37 KW or 50 HP to the hydraulic gear pump. This figure is nothing to do with your engine horsepower, only the power the gearbox is able to transfer to the hydraulic pump(see chart below) Female or Male shafts are the same prices.

This comes with standard Female 1-3/8" 6 splined shafts generic to most PTO output shafts. This step-up gearbox has a ratio of 3:1 which means, if your PTO is spinning at 540 RPM, it will step up the speed to 1620 RPM.

The main considerations in choosing the correct size pump for your application; are the amount of Flow required & the pressure required. As the need for higher pressure (PSI) is increased, the power required to produce this pressure rises. It is easy to pump fluid at a high flow rate if low psi is required, but it takes a lot of HP to pump high flow rates at a high PSI.

A: PTO stands for power take-off, which is an auxiliary clutch on the bottom of an industrial truck. These are used in construction applications. You see these big trucks with the water tanks on them going up and down and spraying water out the back. They’re using that for dust control.

While water covers over 70% of the earth not all of it is readily accessible to all locations. Water trucks often bring water where it’s needed the most. They carry thousands of gallons of water and disperse them using a PTO water truck pump.

Before we get into what a PTO water truck pump is and PTO for that matter, let’s talk about PTO water trucks. A water truck is essentially a water reservoir on wheels that can disperse water at a regulated volume. It is mainly used for irrigation or other watering applications where a fixed water source is not readily accessible.

PTO water trucks are also used for compaction on construction sites. When dirt is dug up and displaced it is often very uneven. That can be dangerous for heavy equipment, plus it makes it hard to create flat road surfaces. The trucks can add just the right amount of water distributed evenly so that a plate compacter can smooth the ground. If there’s too much water it will turn to sludge, if not enough water the soil particles will not stick to each other. With the controls on water trucks, the water flow can be precisely controlled.

Using PTO water trucks for irrigation became very popular between 2011 and 2017 due to a series of droughts along the west coast and in the Midwest. California, one of the hardest states hit, was struggling to keep crops in the central valley from drying up.

PTO water trucks are used both in a precautionary role and a reactive role in firefighting applications. Especially in the country and rural areas that lack organized water sources such as hydrants. They’re not only used for putting out fires but also as a precaution against wildfires. Water trucks during the summer will frequently dampen areas prone to burn.

Bulk water delivery providers rely heavily on water trucks to deliver bulk water to their residential customers. Often used to fill swimming pools, and landscape water features, for example. This application is especially popular for residential properties under drought control or surviving on untreated water from a well. Rather than wait for days for a hose to fill a pool wasting well water, trucks bring in the water and get it done quickly. This also prevents damage or excess stress on the well pump.

Water trucks use a special type of pump that runs off the powerful engine these trucks have. The process is referred to as “power take-off or PTO for short. A power take-off (PTO) pump is used to convert the rotary power from the engine to hydraulic power to run the water pump. A PTO doesn’t just run pumps, on tractors they can also run cotton balers, power mowers, and more. In the city, you see PTO’s in use on street sweepers and fire truck pumps.

PTO pumps, also called trunk pumps connect directly to the truck’s driveshaft. It uses that rotary power and converts it with the PTO, into hydraulic power. The hydraulic power is used to power the PTO water pump which is typically connected on-frame and to the tank.

PTO pumps deliver water at a high-output, and their most unique benefit is the ability to capture the massive engine output of these trucks. This output is the source behind the pumps ability to move large amounts of water very quickly. There are other great benefits PTO pumps bring to the table:

If you’ve ever tried repairing a broken water pump you know it’s almost easier to just buy a new one. That’s why you have to take such great care in maintaining most water pumps—except PTO pumps. These pumps, since they use the power of the truck engine to drive them—are practically maintenance-free.

There’s no worries about gasoline breaking down the pump. No spark plugs to worry about changing, and PTO pumps are built from powder-coated steel to take a beating.

Because they are quite large and have extreme performance capabilities, some assume these pumps are hard to set up. However, you’d be surprised just how simple it is.

Simply follow the instructions to mount the pump, connect it to the driveshaft and be about your business. They don’t even require many tools for setup and teardown.

These pumps simply do not cut corners on power. In fact, the most powerful PTO pump in existence moves 30,000 gallons of water an hour (GPH). GPH capability is typically the most important factor when choosing the right PTO pump for your application. However, keep in mind most PTO pumps measure capacity in gallons per minute (GPM).

Whether you have a single water truck or a fleet of 20 trucks for your contracting company, we’ve got you covered. Gulf Coast only carries the best pumps from legendary manufacturers such as Goulds. Contact us today and let us show you our selection and help you get the pump you need.

8613371530291

8613371530291