quiet hydraulic pump manufacturer

In axial piston fixed pumps, the flow is proportional to the drive speed and the displacement. Axial piston fixed pumps are available for hydrostatic drives in open circuit.

... control options provide the flexibility to match the pump to a wide range of pressing, punching and other operations. Compare the ZE2 to the other pumps in the ZE-Series and determine the best pump ...

... piston pump type V30D is designed for open circuits in industrial hydraulics and operate according to the swash plate principle. They are available with the option of a thru-shaft for operating additional ...

... adopted for conventional pumps. Accordingly, multiple pumps can be assembled using silent stages together with conventional stages, and silent pumps can also be equipped with all the ...

Gear pump with reversible Rotation direction and internal drainage. Built in aluminium body, lighter than casting pumps, permits to work at high pressures with a low level of noise.

Compact, Portable, Cordless Hydraulic Pump for MRO Applications. Compact, Li-ion 18VDC, 9.0 Ah battery-powered pump provides extended run-time. Two-stage, high-pressure ...

... Team 400 series offers both single or multiple cylinder applications. Two-speed high output pump delivers up to 5 gpm (16 liter/min) of oil, with a low noise level of 73-80 dBA. Integral ...

The Power Team 120 series pump is exactingly designed for heavy duty, extended cycle operation up to 400 Ton. Built in grit, the series 120 pump can start and operate under full load, even with voltage ...

Like all the pumps of the HP Series, it is suitable for any hydraulic application which require very high hydraulic output pressures and a moderate and controllable oil flow, to ensure ...

... HP-LEVER pump of the HP Series is a single-acting air-hydraulic pump with manual operation with an ergonomic lever. It has an oil flow rate of 2.4 to 0.1 l / min and operating pressures ...

Air hydraulic pump, double pneumatic motor, double effect, foot operated with lock-up function, lever distributor valve (4/3), 10L tank, oil flow 8.5 / 0.26 l / min

Gear pumps GP1K Group 1 is an Ideal solution for hydraulic power packs. Modern technologies and many years of experience of the HYDROSILA company allow us to create pumps with high reliability ...

... variable displacement pump DPVD impresses with its innovative technology. Thanks to the inverse piston, the pump manages large swing angles and can be used with nominal pressures up to 400 bar. The model ...

The best match of low-noise and high-efficiency! The helical shape of the patented Elika® profile eliminates the phenomenon of air encapsulation typical of normal gear pumps, curing the ...

... DIN is a series of in-line dual flow pumps with extremely low noise levels for demanding mobile hydraulics. SLPD 20/20-64/32 DIN comes in eight different sizes, where ...

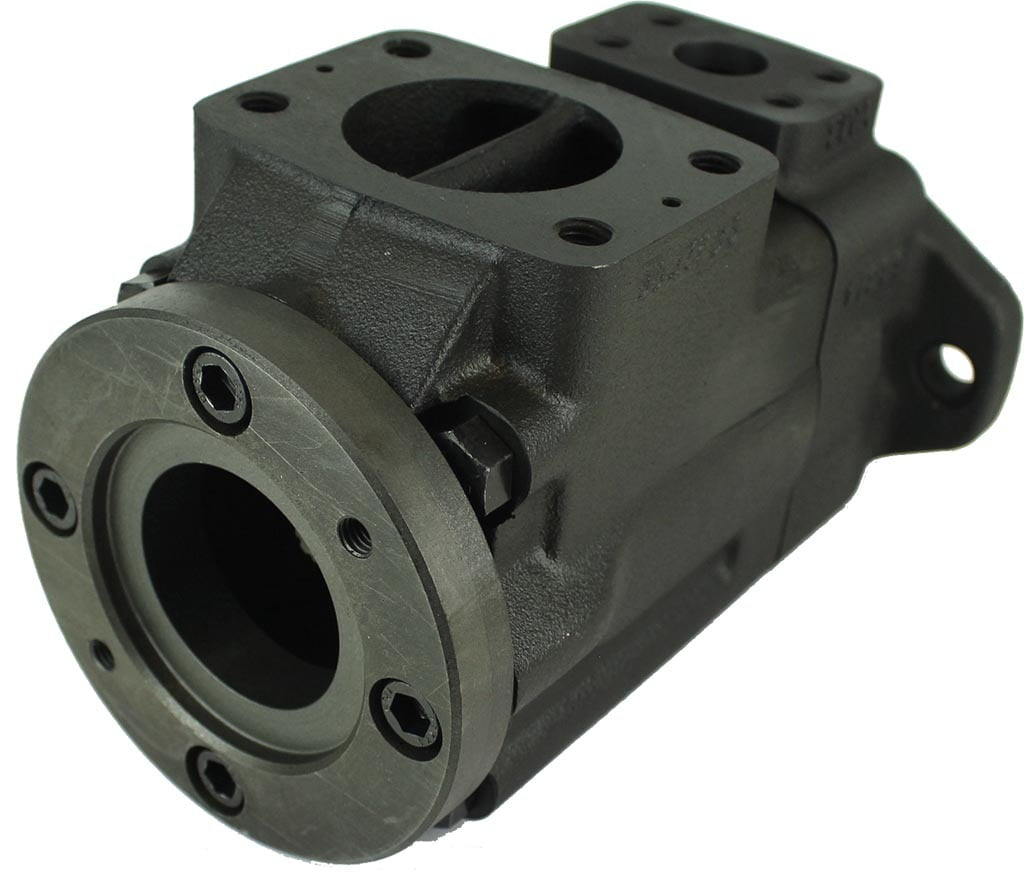

1. High pressure fixed vane pump with high working efficency and can be applied in hydraulic circuits. ...

PGP 500 pumps offer superior performance, high efficiency and low noise operation at high operating pressures. They are produced in four frame sizes (PGP 502, PGP 505,PGP 511, PGP 517) ...

Continuum pumps are used to pump fluids in a continuous flow. They are often used in industries such as the chemical, oil and gas industry, water treatment plants, and power stations as well as in forklifts, machine tools, and on boats.

These silent pumps’ helical rotors don’t trap any fluid volume. Continuum pumps run highly efficiently while still producing minimal sound, continuous flow can be maintained even at maximum operating speed. They produce exremely low vibrations and low pulsations, operating silently which helps to not disrupt operations and prevent noise pollution or complaints.

Pumps are a vital part of any water or wastewater project, and choosing the right one is an important decision. Continuum pumps are one of the most popular options because they offer a number of advantages over other types, such as centrifugal pumps. Here at Antech, we can help you choose the right pump for your project or application, we have a team of experts who have been supplying hydraulic equipment for many years and know all the ins and outs of it.

Here at Antech, we’re complete experts in everything to do with hydraulic engineering, as well as our team always being happy to help our existing customers, past customers, and potential future customers. We always provide fantastic customer service and our team is always here to provide advice and guidance when you need it. Simply use our contact form, email us, or call our number and you’ll be put through to a member of our fantastic sales team.

> quiet series pumps for heavy duty continuous operation. > oil dely (cu. in./min): 730 @ 100 psi, 60 (60 series) & 120 (120 series) @ 10,000 psi. > enclosed 2 hp 230v motor (60 series) & 3 hp 460v motor (120 series). > * - models with S suffix include solenoid valve with 25" remote control.

These gear pumps are specified with helical teeth and a special finishing process that significantly reduce hydraulic pulsation of the oil flow, resulting in lower noise levels and consequently recommending them as the best option for all mobile equipment and industrial applications where superior acoustic comfort is a requirement.

Quiet-running and modular. Aluminium and cast iron components of the silent series are designed applying the same modular logic as adopted for conventional pumps. Accordingly, multiple pumps can be assembled using silent stages together with conventional stages, and silent pumps can also be equipped with all the accessories available for other series. Silent pumps with cast iron body, besides being suitable for heavy duty applications, also offer better performance in terms of mechanical noise reduction.

Hydraulic systems are in general members of the fluid power branch of power transmission. Hydraulic pumps are also members of the hydraulic power pack/hydraulic power unit family. Hydraulic units are encased mechanical systems that use liquids for hydraulics.

The hydraulic systems that hydraulic pumps support exist in a range of industries, among them agriculture, automotive manufacturing, defense contracting, excavation, and industrial manufacturing. Within these industries, machines and applications that rely on hydraulic pumps include airplane flaps, elevators, cranes, automotive lifts, shock absorbers, automotive brakes, garage jacks, off-highway equipment, log splitters, offshore equipment, hydraulic motors/hydraulic pump motors, and a wide range of other hydraulic equipment.

When designing hydraulic pumps, manufacturers have many options from which to choose in terms of material composition. Most commonly, they make the body of the pump–the gears, pistons, and hydraulic cylinders–from a durable metal material. This metal is one that that can hold up against the erosive and potentially corrosive properties of hydraulic fluids, as well as the wear that comes along with continual pumping. Metals like this include, among others, steel, stainless steel, and aluminum.

First, what are operating specifications of their customer? They must make sure that the pump they design matches customer requirements in terms of capabilities. These capabilities include maximum fluid flow, minimum and maximum operating pressure, horsepower, and operating speeds. Also, based on application specifications, some suppliers may choose to include discharge sensors or another means of monitoring the wellbeing of their hydraulic system.

Next, what is the nature of the space in which the pump will work? Based on the answer to this question, manufacturers will design the pump with a specific weight, rod extension capability, diameter, length, and power source.

Manufacturers must also find out what type of substance does the customer plan on running through the pumps. If the application calls for it, manufacturers can recommend operators add other substances to them in order to decrease the corrosive nature of certain hydraulic fluids. Examples of such fluids include esters, butanol, pump oils, glycols, water, or corrosive inhibitors. These substances differ in operating temperature, flash point, and viscosity, so they must be chosen with care.

All hydraulic pumps are composed in the same basic way. First, they have a reservoir, which is the section of the pump that houses stationary fluid. Next, they use hydraulic hoses or tubes to transfer this fluid into the hydraulic cylinder, which is the main body of the hydraulic system. Inside the cylinder, or cylinders, are two hydraulic valves and one or more pistons or gear systems. One valve is located at each end; they are called the intake check/inlet valve and the discharge check/outlet valve, respectively.

Hydraulic pumps operate under the principle of Pascal’s Law, which states the increase in pressure at one point of an enclosed liquid in equilibrium is equally transferred to all other points of said liquid.

To start, the check valve is closed, making it a normally closed (NC) valve. When the check is closed, fluid pressure builds. The piston forces the valves open and closes repeatedly at variable speeds, increasing pressure in the cylinder until it builds up enough to force the fluid through the discharge valve. In this way, the pump delivers sufficient force and energy to the attached equipment or machinery to move the target load.

When the fluid becomes pressurized enough, the piston withdraws long enough to allow the open check valve to create a vacuum that pulls in hydraulic fluid from the reservoir. From the reservoir, the pressurized fluid moves into the cylinder through the inlet. Inside the cylinder, the fluid picks up more force, which it carries over into the hydraulic system, where it is released through the outlet.

Piston pumps create positive displacement and build pressure using pistons. Piston pumps may be further divided into radial piston pumps and axial piston pumps.

Radial pumps are mostly used to power relatively small flows and very high-pressure applications. They use pistons arranged around a floating center shaft or ring, which can be moved by a control lever, causing eccentricity and the potential for both inward and outward movement.

Axial pumps, on the other hand, only allow linear motion. Despite this, they are very popular, being easier and less expensive to produce, as well as more compact in design.

Gear pumps, or hydraulic gear pumps, create pressure not with pistons but with the interlocking of gear teeth. When teeth are meshed together, fluid has to travel around the outside of the gears, where pressure builds.

External gear pumps facilitate flow by enlisting two identical gears that rotate against each other. As liquid flows in, it is trapped by the teeth and forced around them. It sits, stuck in the cavities between the teeth and the casing, until it is so pressurized by the meshing of the gears that it is forced to the outlet port.

Internal gear pumps, on the other hand, use bi-rotational gears. To begin the pressurizing process, gear pumps first pull in liquid via a suction port between the teeth of the exterior gear, called the rotor, and the teeth of the interior gear, called the idler. From here, liquid travels between the teeth, where they are divided within them. The teeth continue to rotate and mesh, both creating locked pockets of liquid and forming a seal between the suction port and the discharge port. Liquid is discharged and power is transported once the pump head is flooded. Internal gears are quite versatile, usable with a wide variety of fluids, not only including fuel oils and solvents, but also thick liquids like chocolate, asphalt, and adhesives.

Various other types of hydraulic pumps include rotary vane pumps, centrifugal pumps, electric hydraulic pumps, hydraulic clutch pumps, hydraulic plunger pumps, hydraulic water pumps, hydraulic ram pumps, portable 12V hydraulic pumps, hydraulic hand pumps, and air hydraulic pumps.

Rotary vane pumps are fairly high efficiency pumps, though they are not considered high pressure pumps. Vane pumps, which are a type of positive-displacement pump, apply constant but adjustable pressure.

Centrifugal pumps use hydrodynamic energy to move fluids. They feature a rotating axis, an impeller, and a casing or diffuser. Most often, operators use them for applications such as petroleum pumping, sewage, petrochemical pumping, and water turbine functioning.

Electric hydraulic pumps are hydraulic pumps powered by an electric motor. Usually, the hydraulic pump and motor work by turning mechanisms like impellers in order to create pressure differentials, which in turn generate fluid movement. Nearly any type of hydraulic pump can be run with electricity. Most often, operators use them with industrial machinery.

Hydraulic clutch pumps help users engage and disengage vehicle clutch systems. They do so by applying the right pressure for coupling or decoupling shafts in the clutch system. Coupled shafts allow drivers to accelerate, while decoupled shafts allow drivers to decelerate or shift gears.

Hydraulic ram pumps are a type of hydraulic pump designed to harness hydropower, or the power of water, to elevate it. Featuring only two moving hydraulic parts, hydraulic ram pumps require only the momentum of water to work. Operators use hydraulic ram pumps to move water in industries like manufacturing, waste management and sewage, engineering, plumbing, and agriculture. While hydraulic ram pumps return only about 10% of the water they receive, they are widely used in developing countries because they do not require fuel or electricity.

Hydraulic water pumps are any hydraulic pumps used to transfer water. Usually, hydraulic water pumps only require a little bit of energy in the beginning, as the movement and weight of water generate a large amount of usable pressure.

Air hydraulic pumps are hydraulic pumps powered by air compressors. In essence, these energy efficient pumps work by converting air pressure into hydraulic pressure.

Hydraulic pumps are useful for many reasons. First, they are simple. Simple machines are always an advantage because they are less likely to break and easier to repair if they do. Second, because fluid is easy to compress and so quick to create pressure force, hydraulic pumps are very efficient. Next, hydraulic pumps are compact, which means they are easy to fit into small and oddly shaped spaces. This is especially true in comparison to mechanical pumps and electrical pumps, which manufacturers cannot design so compactly. Speaking of design, another asset of hydraulic pumps is their customizability. Manufacturers can modify them easily. Likewise, hydraulic pumps are very versatile, not only because they are customizable, but also because they can work in places where other types of pump systems can’t, such as in the ocean. Furthermore, hydraulic pumps can produce far more power than similarly sized electrical pumps. Finally, these very durable hydraulic components are much less likely to explode than some other types of components.

To make sure that your hydraulic pumps stay useful for a long time, you need to treat them with care. Care includes checking them on a regular basis for problems like insufficient fluid pressure, leaks, and wear and tear. You can use diagnostic technology like discharge sensors to help you with detect failures and measure discharge pressure. Checking vibration signals alone is often not enough.

To keep yourself and your workers safe, you need to always take the proper precautions when operating or performing maintenance and repairs on your hydraulic pumps. For example, you should never make direct contact with hydraulic fluid. For one, the fluid made be corrosive and dangerous to your skin. For two, even if the pump isn’t active at that moment, the fluid can still be pressurized and may potentially harm you if something goes wrong. For more tips on hydraulic pump care and operation, talk to both your supplier and OSHA (Occupational Safety and Health Administration).

Pumps that meet operating standards are the foundation of safe and effective operations, no matter the application. Find out what operating standards your hydraulic pumps should meet by talking to your industry leaders.

The highest quality hydraulic pumps come from the highest quality hydraulic pump manufacturers. Finding the highest quality hydraulic pump manufacturers can be hard, which is why we have we listed out some of our favorites on this page. All of those whom we have listed come highly recommended with years of experience. Find their information nestled in between these information paragraphs.

Once you have put together you list, get to browsing. Pick out three or four hydraulic pump supply companies to which you’d like to speak, then reach out to each of them. After you’ve spoken with representatives from each company, decide which one will best serve you, and get started on your project.

On electric vehicles, low noise is a key requirement, while low-speed operation enables improved control and positioning for various vehicle functions. This means that gear pumps which can operate efficiently and quietly at low speeds are among the most important priorities for electric vehicle designers. WISPY technology is also attractive in other market.

We developed a range of WISPY pumps in displacements from 4cc to 29cc. The company established itself as a leader in low-noise gear products a decade ago when it introduced the first WISPY series (quiet) gear pump product line. WQ introduced the concept of true dual flank engagement of the gear teeth (as opposed to “near dual flank engagement”), which is unique to VBC Hydraulics and which reduces the amplitude of the pressure pulsations introduced into the hydraulic system. WISPY is a significant step forward in low noise technology in that it reduces noise by up to 10 dB or 85% in low-speed applications. Low speeds at high pressure are the most severe condition for gear pump technology. The pump, features innovative tooth geometry, true dual-flank gear engagement, reduced trapped oil volume and advanced trapped oil management. The design reduces pressure pulsation by 70%, which is the key factor determining the pump"s noise levels, while also reducing energy consumption.

Both static and in-vehicle tests have demonstrated that WISPY series pumps offer significantly lower noise operation when compared with other external gear pumps. In many cases, they can also match or even out-perform more expensive internal gear pumps on efficiency and low-noise operation.

Our hydraulic motors can be used to power numerous applications for your manufacturing needs. All of our motors in stock are ISO-compliant and pass rigorous tests before they leave our facility. We can assure you that with us, you’ll receive the utmost quality and services from our standard motors to our heavy-duty hydraulic motors. We also have many flange mount and face mount hydraulic motors available. Hydraulic motors are currently available in maximum displacement sizes from 0.47 cubic inches to 0.93. We also have motors available in various torque ratings and power ratings from 4.5 to 12 hp.

As premiere hydraulic motor manufacturers We’re a trusted source of hydraulic motors and hydraulic motor parts for many repair shops, distributors and manufacturers in a variety of industries. Our entire line of hydraulic motors are backed by years of proven reliability and trusted performance, even under the toughest manufacturing conditions and the harshest working environments.

Repairing and supplying re-manufactured and new Racine hydraulics – Racine hydraulics pumps, Racine hydraulics valves, and Racine hydraulics motors. Search our online catalog or contact us and let us know how we can help you.

We can supply what you need or repair what you have. Before purchasing, there may be a good chance that your current hydraulic pump, motor, valve, or cylinder can be repaired. Contact us to see if we can repair your Racine hydraulic pump or send in your Racine pump for inspection and evaluation. Racine hydraulics pump repairs, including motors, valves & cylinders comes with our two year warranty.

When purchasing, consider Racine hydraulics re-manufactured or after market hydraulic units. Best of all they can get you back up and running for less than the cost of a new hydraulic unit. We will give you a free quote so you can compare costs for a new, repaired or re-man Racine unit.

Located in Detroit, Racine Hydraulics was founded in 1958. In 1997 the Racine was merged with Bosch Rexroth. Rexrothcontinues to support the PSV series vane pumps for new and replacement applications. As a carryover from the Racine Fluid Power legacy program, Rexrothcontinues to support the Racine PSV series vane pumps for both new and replacement applications. The PSV series, otherwise known as the SV or Silent Vane product line, has a very large installed base around the world. These variable displacement vane pumps have proven themselves in the most demanding applications and they have built an excellent reputation with the OEM and user markets.

The RKP-D family of products has an intelligent control mechanism that allows the user to optimize the usage of control entities within a hydraulic system, often making the need for central control hardware redundant

Moog is the leading supplier for Radial Piston Pumps (RKP) worldwide. This mature and robust product has been used for decades and runs today in over 100,000 machines in various applications around the globe. It is widely known for its robust and reliable design.

In the current generation, Moog made significant product improvements in the design to make it quieter and more compact, while offering rapid response times and high volumetric efficiencies.

The Moog Radial Piston pump comes in 8 pump sizes between 19 cc and 140 cc per revolution (19, 32, 45, 63, 80,100, 140 and 250) and has a maximum speed range of 1,800 to 2,900 rpm

Large selection of controls, including standard pressure compensator (Type F), remote pressure compensator (Type H), pressure and flow control (Type J,R) and digital electro-hydraulic control (RKP-D)

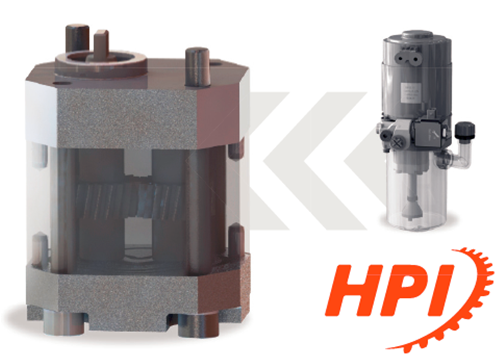

Noise reduction is indeed becoming the real challenge for today’s industrial market. Market competitiveness and new European regulations in the handling sector, particularly for pallet trucks, are such that the suppliers are impelled to develop new technologies meeting increasing requirements from their customers.Acoustic nuisances have several origins: the pump hydraulic pulsations, being propagated through hoses and pipes, and then affecting the truck structure via the frame (structure-borne sound) and the aerial noise (rotation frequency of an electric motor or a pump) which can be contained by an acoustic cover.

In order to lessen the hydraulic pulsations, we designed a specific helical tooth profile with a suitable propeller angle and increased the number of teeth of the pinions from 12 to 22.

The acoustic results show that the noise level has been reduced by an average of -10 dBA, when compared with a standard external gear pump. The new HPI Silent Pump is also characterized by a much more pleasant sound when in use. Indeed, the operating frequency ranges have been adapted for optimized working conditions for the user. The 22-tooth helical profile on series 0 pumps, unique for that size of pumps, reduces significantly the hydraulic pulsations. The capacities available are 1 – 1,25 – 1,5 – 1,7 – 2 cc/rev for operating pressures from 125 to 250 bar.

Since 1935, Muncie® Power Products has been a leading source of mobile power components to the truck equipment industry. In addition to Power Take-Offs and hydraulic motors, Muncie offers directional, pressure and flow control valves as well as system design capabilities. Call us today or visit our website for more information.

Hartmann Controls offers some of the most dependable hydraulic motors for industrial and mobile applications. Exceeding the capabilities of most other hydraulic motors, our products offer simplicity and precision for exact operations. Our superior motors can go for decades. Check out our catalog today! Our products are used by the world’s largest manufacturers and companies. Contact our company!

Planet Products Corp. is a contract manufacturer and manufacturer of various hydraulic products. Hydraulic products include motors, valves, and pumps. Planet serves mainly the defense, aerospace, machine tool, and industrial sectors and is ISO9001/AS9100 certified.

Precision Fluid Power sells new & rebuilt hydraulic motors. We also specialize in the repair of hydraulic components such as hydraulic motors, pumps, valves & cylinders. All units received for repair will be completely stripped down, cleaned and inspected, & any bad parts will be replaced. With over 150 years of experience we serve all industries, large or small. Please contact our company today!

For 40 years, Bucher Hydraulics, Inc. has specialized in hydraulic systems, including products such as hydraulic motors and hydraulic power units. Applications include concrete pumps, forage wagons, harvesters, lifting devices, recycling machines, door openers, log splitters and many others.

Danfoss has 45 years of experience offering hydraulic motor solutions. We supply hydraulic power systems for moderate to heavy load demands. Our orbital motors have speeds extending from 2,500 rpm to 600 rpm. We also have hydraulic motors that vary in size from mini to medium to large.

Established in 1966, Delta Power designs and manufactures industrial hydraulic cartridge valves and manifold systems using these valves. We also produce hydraulic motors and hydraulic power units. Contact us for cutting-edge hydraulic system designs and products.

For more than four decades, Dynex/Rivett has been manufacturing hydraulic power systems and components. Our products include hydraulic motors, hydraulic power units and variable speed motors. We serve the worldwide market with our top-quality motors and hydraulic systems.

Eaton Hydraulics designs, manufactures and markets a comprehensive line of reliable, efficient hydraulic systems and components including hydraulic motors, hydraulic power units and other hydraulic systems. We serve various markets and applications with our quality systems and accessories.

Flint Hydraulics, Inc. is dedicated to the worldwide distribution of original and replacement hydraulic pumps, hydraulic motors, and hydraulic pump replacement parts for heavy mobile and industrial equipment. We maintain a database of more than 30,000 hydraulic pumps, motors and parts by OEM part number for name brands of heavy mobile equipment such as Caterpillar, J.I. Case, John Deere, Clark-Michigan, Terex, Grove, Komatsu-Dresser, Bobcat and many more. Located in the heart of America’s distribution center, Flint Hydraulics, Inc. has grown into one of the largest suppliers of original and replacement hydraulic products in the world. Off-the-shelf availability, coupled with the distribution center advantages Memphis has to offer, give us the unique ability to provide hydraulic components across the globe, using the most efficient and economical means available. We stock substantial quantities of pumps, motors, parts and assemblies and can ship at a moment’s notice anywhere in the world. Most items are available for same or next day shipment.

Our production facility is uniquely designed for assembly and testing of various types and designs of hydraulic pumps & motors to meet the just-in-time inventory requirements of our clients. Our professionally trained staff is the most knowledgeable and schooled customer service team in the entire industry. Equipped with the latest distribution software and our own custom-tailored cross-referencing databases, our staff is able to provide instant information regarding the particular hydraulic component your client needs.

Fluidyne Fluid Power is a leading industrial power distributor and manufacturing facility specializing in hydraulic motors, components and custom-designed fluid power systems. We have an extensive product line able to provide exactly what you need. They combine fluid power expertise with a vast selection of world-class components to provide you with unsurpassed system efficiency.

Haldex is a global provider of vehicle solutions, including hydraulic pump motors, hydraulic power units, gear pumps and fan drive pumps as well as AC/DC motors. Reduce emissions and innovative diesel engines with Haldex excellent solutions and customer service. We base our decisions and actions on the customer’s best interests. Contact us today!

An employee-owned company, Hydraquip is a distributor of fluid power products, including hydraulic motors from Hydro-Gear, Hydrokraft, Rineer Hydraulics, Rotary Power, Sauer Danfoss, Ultra, Vickers and Von Ruden. Since 1951, we have been serving the fluid power industry.

Need an old cylinder swapped or remanufactured? Need telescopic cylinders, replacement cylinders or hydraulic cylinders for large industrial equipment? At Hydraulic Repair & Design, we can supply all industries with new, custom or repaired cylinders, experienced design & friendly customer service!

Hydreco® Inc. offers a wide range of hydraulic gear motors as well as hydraulic pumps and valves. We offer drive axles, gearboxes, hydraulic pumps, gear pumps and piston pumps. Contact us today for more information on our quality products.

Over 50 years, Hydro Leduc has developed more than 100 patents because of our passion for innovation in the hydraulics field. We find solutions to our customers’ most complex and demanding applications for piston pumps, hydraulic motors, hydro-pneumatic accumulators and custom hydraulic components. A complete list of available motors and features can be found on our website. Contact a representative today for any further inquiries!

Since1967, Hydrotech has provided industries with innovative solutions for their fluid power needs. Our listing of hydraulic motors are manufactured by Bosch Rexroth, Rineer Hydraulics and White Drive Hydraulics. For more information call our experienced team of technicians and sales support!

Founded 40 years ago, Innerspace designs, develops and manufactures top-quality, efficient propulsion systems for marine vehicles. Our product capabilities include hydraulic products such as hydraulic motors and customized hydraulic systems. Check out our website for more information.

For over 50 years, MacTaggert Scott has been in the hydraulic motor business. Our radial piston hydraulic motors are used in various markets such as marine, offshore and defense. If you are looking for a hydraulic motor that runs quietly and efficiently, MacTaggert Scott is your answer. Call us today!

Our DVT Series of hydraulic motors started our hydraulic drive efficiency in the 1970s. We’ve developed more products and grown since then. Now we invite you to explore our MHA Series of heavy-duty, high-torque, low-speed, rotating shaft or rotating case hydraulic wheel motors. Check our website.

Since 1921, the world’s most demanding hydraulic control applications have relied on Oilgear high-performance fluid power solutions. We’ve met the challenge. Every time.Founded in Milwaukee, Wisconsin, Oilgear was built to bring only the most advanced engineering to our customers. Decades later, Oilgear continues to set the standard in industries requiring precise, high-performance hydraulic systems. From the depths of the ocean to the surface of the moon, Oilgear products often operate in the harshest of environments. We’re known for our robust line of pumps, but we offer so much more. No matter what your operations need, we have cartridge valves, subsea pressure control solutions and electrical embedded controllers to tackle your issues head on.

It might not seem possible, but we’re more than those products too. Oilgear is a worldwide provider of complex fluid power control system. We have a strong presence in forging and extrusion press control systems. And high-specification HPUs and high-pressure hydraulic systems.

With products operating in the toughest environments on earth, quality is Oilgear’s top priority. You can see it in our full collection of hydraulic control products and systems. We know what it takes to perform to ISO and API standards. And with an extensive history of earning certifications from institutions like ABS, DNV and Lloyds.

Parker"s Hydraulic Pump and Power Systems Division provides a broad selection of piston pumps, hydraulic motors and power units that help our customers meet their industrial and mobile application needs.

The Parker Pump & Motor Division specializes in gear pumps and motors used in a myriad of industries. With decades of experience, PMD provides the best products in the market, supplemented by best-in-class customer service, and the deepest knowledge in the industry.

The Perfection Machining Company was founded in 1964 to design and manufacture replacement parts for the mining industry. Renamed Permco 4 years later, the family-owned business developed a wide array of replacement hydraulic parts and eventually expanded its manufacturing capabilities to include cast iron parts and the resulting complete units. Today, we maintain our focus on customer service and continue a decades-long tradition of developing fluid power systems that meet each of our customer’s specific needs. Permco’s product offering now includes gear and vane pumps/motors, flow dividers, intensifiers and a variety of accessories and components. Permco offers the highest quality product possible to our wide customer base of OEMs and distributors. Because we understand that our success depends on the success of our customers, we are committed to reducing customers’ costs and increasing the simplicity of doing business with us.

Poclain Hydraulics manufactures hydraulic motors, hydrostatic transmissions and high-torque cam-lobe motors, which are used in agriculture, construction equipment, industry, marine and material handling applications. Our innovative company culture motivates us to pursue progress and excellence in everything we do. Contact Poclain today to learn more!

Established in 1979, Southwest Seal and Supply has grown to become one of the most predominant distributors of sealing, hydraulic hoses, fittings, couplings/connectors, gasketing and fluid control products in the Southwest. We offer a wide range of products including the best in selection, quality, and value-added services.

Founded in 1945, Spencer Fluid Power remains a value added distributor of hydraulic components and systems. Spencer Fluid Power continues to sell and support hydraulic components to a wide array of customer types. Small to large OEM"s, timber, mining, construction and oil & gas are just a sample of the numerous industries Spencer supports today.

Sunfab was founded by Eric Sundin in the year of 1925. Sunfab develops, produces and sells components to operate hydraulic equipment within the area of mobile vehicles. After more than 90 years, the third generation of the Sundins are still running the company in the spirit of Eric Sundin, with a family atmosphere, flexibility and innovative solutions.

Wojanis Supply Company is a total fluid power facility encompassing sales, service, design and manufacturing capabilities for a full line of hydraulic motors, pumps, valves and integrated systems for a range of applications. Additionally, we are an authorized representative for many of the top component manufacturers allowing us to fulfill your every demand.

Marzocchi Pompe, a manufacturer of high-performance gear pumps and motors based in Bologna, Italy, just introduced its new ELIKA 1P pump at the Automotive CTI Symposium. The event, held in Berlin, focused on intelligent, hybrid and electric vehicle drivetrains.

The 1P is the latest addition to the ELIKA family, the low noise, high efficiency and low pulsation range of pumps developed by Marzocchi Pompe in close collaboration with the Faculty of Engineering at the University of Bologna.

ELIKA pumps are suited for applications requiring low noise and high efficiency, particularly at low speeds, according to the company. The products reportedly reduce noise emissions by as much as 15 dBA compared to traditional external gear pumps. Maximum working pressures of 300 bar are similar to those for the GHP series (cast iron/aluminum).

The unit’s proprietary tooth profile and housing geometry considerably reduce pressure oscillations and vibrations transmitted to other components connected to the pump — hoses, tank and valves — producing numerous advantages in the circuit and equipment. The helical gear effectively guarantees continuity of movement despite a low number of teeth. Having fewer teeth also significantly reduces the fundamental frequencies of noise output and results in a more pleasant sound, said the company.

ELIKA handles a wide range of rotation speeds, pressures and viscosities, and the pump’s structure minimizes leaks and maximizes volumetric efficiency under all operating conditions. The quiet-running ELIKA pump is often a better option for applications which currently use more-expensive screw, vane or internal-gear pumps. And it is particularly suited for equipment which uses inverters or variable-speed drives to regulate the speed of actuators.

8613371530291

8613371530291