radial piston hydraulic pump factory

The Radial Piston Pump (RKP) with Digital Control is an electro-hydraulic version of the RKP with a fieldbus interface. It is the flexile and advanced solution for machine ...

The radial piston pump type R consists of valve-controlled pump elements arranged in star form around an eccentric. For large flow rates, up to 42 pump ...

The radial piston pump type R consists of valve-controlled pump elements arranged in star form around an eccentric. For large flow rates, up to 42 pump ...

... damage from exceeding the maximum rated pressure. It"s an economical gerotor/radial piston pump designed for remote mounted valves only. Consult Hytec for information on pump ...

... transmission, the C Pump has a reputation for long, dependable service. The Oilgear C Type pump is a constant-delivery, one-way, radial rolling piston pump. ...

Manufacturer of engineered air equipment and products. Products include positive displacement blowers, pump packages, sound enclosures and heat exchangers. Also, a distributor of compressors, fans, butterfly and check valves, filter elements, v-belts, roller bearing units, blower overhaul kits and pumps. Types of pumps include liquid ring vacuum, pressure, radial piston, regenerative, rotary vane and screw. Blowers are also available on rental. Other services such as blowers, pumps and compressor repair are also offered. Suitable for aquaculture, dry bulk hauling, oil and gas, power generation, soil remediation, vacuum excavation and wastewater treatment applications.

The RKP-D family of products has an intelligent control mechanism that allows the user to optimize the usage of control entities within a hydraulic system, often making the need for central control hardware redundant

Moog is the leading supplier for Radial Piston Pumps (RKP) worldwide. This mature and robust product has been used for decades and runs today in over 100,000 machines in various applications around the globe. It is widely known for its robust and reliable design.

The Moog Radial Piston pump comes in 8 pump sizes between 19 cc and 140 cc per revolution (19, 32, 45, 63, 80,100, 140 and 250) and has a maximum speed range of 1,800 to 2,900 rpm

Large selection of controls, including standard pressure compensator (Type F), remote pressure compensator (Type H), pressure and flow control (Type J,R) and digital electro-hydraulic control (RKP-D)

The popularity of hydraulic piston pumps stems from their ability to maximize energy use and productivity. Even a hydraulic hand pump, which is powered by a foot or hand pedal, can convert as little as 4.5 pounds of force into 100 pounds of load-moving force. Electric hydraulic pumps can reach pressure ranges up to 4,000 PSI. As capacities show such variability, the intended use of a pump should be carefully considered. Several other variables should also be taken into account.

Task-specific power sources, operating speeds, maximum fluid flows and pump weights are widely available in standard and custom configurations. Measurements such as diameter, rod extension length, height and width should also be considered, especially when a hydraulic piston pump is to be fitted to a pre-existing hydraulic system.There are two basic variations of hydraulic piston pumps: axial and radial pistons. The essential difference between the two is the placement of the pistons within the hydraulic cylinder and the directionality of the movement. Axial pistons run parallel to the cylinder, while radial pistons are perpendicular to an inner column running through the cylinder. The latter provides a rotary movement. Axial pistons provide linear motion and are more popular in heavy machinery contexts.

Both can be single action or double action pumps. Despite the differing piston placements, both systems function in a similar fashion. Hydraulic fluids, usually oil or water composites, are housed in a reservoir connected to the main cylinder by tubes or hoses. The cylinder houses the pistons as well as one or more intake check valve and an equal number of discharge check valves. When the piston is withdrawn it creates a vacuum, and the liquid solution is pulled into the cylinder.

The piston is then returned to its original position and the intake valve is sealed. This creates pressure within the enclosed space and compresses the fluids. The plunger-like action is repeated until enough pressure is accumulated to force the hydraulic fluids out through the discharge valve. This creates the energy needed to work the attached machinery and move the intended load.

Check out our Hydraulic Oil Recommendations page to assist with oil selections and assistance in preventing future hydraulic failures.Hydraulic Cores and Surplus

Whether you have a single pump or crates of used hydraulic equipment, ProActive Fluid Power can provide an immediate appraisal, assist with freight, and provide a hassle-free selling experience.

Searching for a hydraulic supplier who can assist with factory new, reconditioned, obsolete and hard to find items? Do you have cores for sale? Do you have questions regarding shipping?

During this time, we have become the go-to source for end users, hydraulic repair shops as well as original equipment manufacturers that demand quality products delivered within a reasonable period of time.

Do you have a customer who is threatening to buy from your competitor because he needs an answer now? Are you losing thousands of dollars every hour because your machine is down? Do you have a stranded street sweeper or a tractor with hydraulics that failed out in the field?

Are you an OEM distributor or hydraulic equipment reseller who would like to have a product shipped directly to your customer without them knowing where it was purchased from?

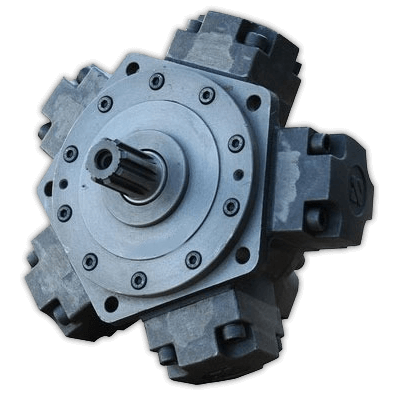

As professional China Radial Piston Motor manufacturers and Radial Piston Motor suppliers, Taizhou Eternal Hydraulic Machine Co.,Ltd can supply you with high-quality products and services.

Eternal Hydraulic commit ourselves to be Global One-Stop Mall for Hydraulic products in worldwide, with professional hydraulic solutions and nice Quality&Price products to satisfy with each customer. The company firmly believes that “ Only The Best Can Satisfied The Best”, become the First Purchase Choice of hydraulic components for all customers in the world.

Low Speed High Torque piston air motor Hydraulic Piston Motor is one kind of low speed high torque radial piston hydraulic motor. It can be widely applied in petroleum industry, chemical industry, mining, shipping, constructing machinery, especially for plastics injection molding machinery, hydraulic winch, transmission ect. Characteristics Characteristics: 1.Low noise 2.High staring torque ( mechanical efficiency improved to over 0.9 ), good stability when low speed.

HYDROWATT specializes in the development and manufacture of innovative, hermetically sealed radial piston pumps. The unique pump technology has set new standards in the field of water hydraulics.

For more than 30 years, HYDROWATT has been supplying the industry with these extremely reliable high-pressure piston pumps for applications up to 600 bar. HYDROWATT also develops and produces complete hydraulic systems for applications in the industrial and mining sectors.

In 1916, over 100 years ago, Kawasaki began manufacturing Hele-Shaw type radial piston pumps – only the second ever product in the world designed for use with hydraulic oil.

Now we lead the hydraulics industry in scale and production facilities, manufacturing a wide range of products, from hydraulic pumps, motors, valves, various hydraulic components and electric controllers, to hydraulic systems for mobile, industrial and marine machinery, and many other applications.

More than 60 years ago, in 1957, the first ever hydraulic radial piston motor was designed by George Hally junior, previously a Hercules radial aircraft engine designer, he named it the “Staffa” motor.

Hydraulic piston pumps move fluids throughout professional equipment and industrial machinery. They’re known for their high efficiency and are commonly used in high-pressure applications.

There are also two major types of hydraulic piston pumps: axial and radial; both can have fixed or variable displacement; fixed displacement means that the pump is delivering the same amount of liquid or gas each time, while variable means that the amount of gas or liquid delivered may be different each time. Although both are considered piston pumps, each one operates differently.

An axial piston pump features four major components: a shaft, swashplate or bent axis, cylinder block, and valve plate. The cylinder block houses the piston pumps, which are laid out cyclically around the drive shaft’s axis (thus why it is named anaxialpiston pump).

The pistons in the cylinder block pump up and down as the drive shaft rotates. The piston’s stroke will vary depending on how it is angled in the swashplate or bent axis. As the pistons move in one direction, they are connected to a suction line, and when they move in the opposite direction, they connect to a discharge channel, allowing a continuous flow of fluid.

The design of a radial piston pump is significantly different from an axial pump. The radial piston pump consists of a cylinder block, rotating camshaft, and pistons. The pistons are arranged around the cylinder block in a radial pattern and diverge from the camshaft like rays. The rotation of the cam causes the pistons to change from suction to discharge and vice versa.

In general, choosing a hydraulic pump requires an application evaluation. You’ll need to know pressure requirements, desired flow rate, speed, horsepower, and the type of fluid the pump will be dispersing.

Radial piston pumps can usually handle all fluids, including mineral oil and water-glycol hydraulic fluid, while axial piston pumps are preferred for extremely high-pressure applications.

Although piston pumps are highly efficient and reliable, contamination, over-pressurization, and inlet blockages can cause the pump to fail. If and when this happens, you’ll need to replace your pump as soon as possible.

When choosing a replacement pump, you’ll have to choose between a direct OEM replacement and a remanufactured pump. Unfortunately, direct OEM replacement pumps and services can be a significant investment. Additionally, if you have outdated equipment, you may not be able to find thepump partsneeded to restore your equipment.

If you’re looking for a quick and relatively inexpensive solution, a remanufactured pump is your best choice. However, if time and money aren’t an issue, a direct OEM replacement will most likely be the best option if the manufacturer hasn’t discontinued the pump.

Do you need help finding the right piston pump? Turn to Panagon Systems. Founded over 25 years ago, we’re an industry-leading remanufacturer of hydraulic piston pumps and motors. We specialize in remanufacturing pumps from brands like Vickers/Eaton, Rexroth, and Caterpillar, and we also carry. All pumps and motors are remanufactured in-house in the United States, guaranteed to meet OEM specifications, and are backed by a one-year warranty.

A radial piston pump is a form of hydraulic pump. The working pistons extend in a radial direction symmetrically around the drive shaft, in contrast to the axial piston pump.

When filling the workspace of the pumping pistons from "inside" (e.g., over a hollow shaft) it is called an inside impinged (but outside braced) radial piston pump (picture 1). If the workspace is filled from "outside" it"s called an outside impinged radial piston pump (but inside braced) (picture 2).

The outer ring for bracing of the pumping pistons is in eccentric position to the hollow shaft in the center. This eccentricity determines the stroke of the pumping piston.

The piston starts in the inner dead center (IDC) with suction process. After a rotation angle of 180° it is finished and the workspace of the piston is filled with the moved medium. The piston is now in the outer dead center (ODC). From this point on the piston displaces the previously sucked medium in the pressure channel of the pump.

A disadvantage is the bigger radial dimensions in comparison to the axial piston pump, but it could be compensated with the shorter construction in axial direction.

Due to the hydrostatically balanced parts it is possible to use the pump with various hydraulic fluids like mineral oil, biodegradable oil, HFA (oil in water), HFC (water-glycol), HFD (synthetic ester) or cutting emulsion. That implies the following main applications for a radial piston pump:

"Variable Stroke Radial Piston Pump", T.S. Patriot State Engineering Manual, Massachusetts Maritime Academy, 1996, pp. 234–241, retrieved 14 September 2022

Originated in 1982, now Polyhydron is a 100 cr turnover brand. Polyhydron manufactures high-quality components that are suitable for any hydraulic machine whether it is Industrial Application or Mobile Application. Like Hydraulic Presses, Hydraulic Lifts, Powerpacks, SPM’s Etc.

Our range comprises Handpump, Piston Pumps, Relief Valves, Handlever Valves, Prefill Valves, Pressure Switches, Pressure Relief Valves, Check Valves, and many more. We offer these products in several specifications to our customers all over India.

8613371530291

8613371530291