reciprocating hydraulic pump quotation

Explore a wide variety of hydraulic reciprocating pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These hydraulic reciprocating pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these hydraulic reciprocating pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right hydraulic reciprocating pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of hydraulic reciprocating pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

Explore a wide variety of reciprocating pump cost on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These reciprocating pump cost are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these reciprocating pump cost is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right reciprocating pump cost for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of reciprocating pump cost to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

A plunger pump operates using the reciprocating motion of plungers or pistons. Depending on the design of the pump, the use of a single or multiple plungers may be used.

Action 3: After reaching it’s maximum position, it is then pushed back into the cavity. During this process, the piston applies enough pressure to the fluid to overcome the pressure in the outlet of the pump. This pressure differential pushes the fluid from inside the cavity through the outlet of the pump.

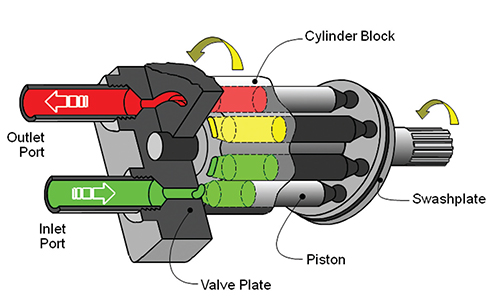

All these parts have the basic functionality of moving the liquid inside the cylinder. The piston is a lubricated sliding shaft that moves inside the cylinder and pushes the liquid in a forward and backward motion, creating a cavity and a high volume pressure at the outlet. In a diaphragm pump, the diaphragm is used to avoid leaking of the liquid since it completely seals the liquid to penetrate outside, and hence they are especially useful when the liquids are dangerous or toxic. In a plunger pump, there is a high-pressure seal that is stationary and a smooth cylindrical plunger slides through the seal.

Crank and Connecting rod: Crank is a circular disk attached to the motor and used to transfer the rotary motion of the motor to the piston. Piston, in turn, moves in a reciprocating motion with help of a connecting rod.

Reciprocating pumps are different from Centrifugal pumps on basis of its working, features, applications etc. The main difference is that Impellers are used in Centrifugal pumps whereas in reciprocating pumps piston is used to move the liquid. Centrifugal pumps continuously discharge the liquid, unlike reciprocating pumps. They are used for high viscous fluid and are lighter in weight, less expensive as compared to reciprocating pumps.

The basic Quality standards of reciprocating pumps include ISO13710, API (American Petroleum Institute) standard 674, API standard 675 “Positive Displacement Pumps- Reciprocating” and Reciprocating Pump Standards, Hydraulic Institute.

High Pressure, Low Flow Applications: Reciprocating pumps are generally designed to pump in low flow, high head applications. One of the most extreme of these applications is water jet cutting, where only a few gallons pass through the pump per minute but exceed pressures of 10,000 PSI.

Proven, Common Technology: Reciprocating pumps are one of the oldest, most proven pump types. Today, a wide variety of reciprocating pumps can be found in many different materials, types, and sizes. Reciprocating pumps range from less than 1 horsepower to over 3,000 horsepower.

Durability: Reciprocating pumps are used in some of the most abrasive and corrosive applications. Fluid ends and fluid end parts can be made of many different materials such as stainless steel, aluminum bronze, tungsten carbide, ceramic, and more. A wide selection of valve types is used in abrasive applications such as pumping cement, sand slurry, mud, etc.

Efficiency: Reciprocating pumps operate at high a higher efficiency compared to other pump designs. In most cases, at any setpoint, reciprocating pumps operate around 90%.

There are several performance indicators of a reciprocating pump which determine how effectively it works. Following are some of the key performance indicators:

High Maintenance / Short Life:The main disadvantage of a reciprocating pump is high maintenance and short life. There are many parts in the pump works, all constantly changing directions. Unless careful maintenance takes place, the lifespan of the pump is greatly reduced. While pumps such as centrifugal pumps can last 15 to 20 years with little maintenance, a reciprocating pump requires higher levels of attention and rebuilding several times within the same time frame. The cost of a reciprocating pump rebuild is usually inexpensive which still makes them cost-competitive compared to longer-lasting, higher-priced pump designs.

Pulsations:A characteristic of reciprocating pumps is the production of pressure pulsations through the pump inlet and outlets. The reciprocating motion of the pump produces these pulsations. Increasing the number of pump chambers can greatly reduce the pulsations produced, but it does not remove them completely. To negate damage to piping and surrounding systems or the pump itself, pulsation dampeners must be installed. Further system design can further decrease pulsations to nearly zero. In all cases, overall system design is important when using reciprocating pumps.

Plunger pumps come in a variety of styles, shapes, and sizes. The specific type of pump chosen for an application takes into account the pressures encountered, the flow rates needed, measurement and control systems, fluid viscosity and corrosivity, pipe material, etc. Careful attention should be given to the application before selecting a pump. Selecting the wrong pump for a job can result in damage to equipment, piping, systems, and possibly endanger personnel.

Simplex, Duplex, Triplex, Quintuplex Pumps: Many reciprocating type pumps are simplex(one), duplex (two), or triplex (three) cylinder. Duplex pumps are usually used where the two pumps can be used alternatively. Such pumps are commonly used in oil-line pumping, mine de-watering, and chemical and petroleum products transfer, but has many more applications. A triplex pump consists of three plungers, with the aim of reducing the pulsation of a single reciprocating pump. Quintuplex pumps are designed with a gear case that assists in a high-pressure task. Common applications of which are in cement slurries, sand-laden fluids, crude oil, acids, mud, and other oil well-servicing fluids. Well known manufacturers for these types of pumps are National, Gardner Denver, FMC, SPM, Oilwell, Kerr, Union, Gaso, Emsco, Aplex, and Wheatley.

Metering Pumps: A metering pump is usually used where the rate of flow of the liquid needs to be adjusted in a specific time period. Most of the metering pumps are piston-driven and are called Piston pumps. Piston pumps can pump at a constant flow rate against any kind of discharge pressure. Both Piston pumps and Plunger pumps are reciprocating positive displacement pumps that use a plunger or piston to move fluid/substance through a cylindrical chamber. Manufacturers such as

Reciprocating Pumps can also be classified according to the number of cylinders: Single cylinder and double cylinder pump. They are also sometimes classified according to their operation, known as simple hand-operated reciprocating pump & power-operated deep well reciprocating pump.

Reciprocating positive displacement pumps are highly effective, where a high degree of accuracy and reliability under different ranges of conditions that are required. Reciprocating pumps with very high efficiency are often available in a wide range of hydraulic, mechanical, and material options. They are widely used across industries such as chemical, petrochemical, refinery, pharmaceutical, cosmetic and water treatment. Typically, these types of pumps are used for applications such as Salt Water Disposal, Well Services, Descaling, Hydraulic Fracturing, and Oil & Gas Pipelines. All types of reciprocating pumps are easily available in the market to meet the diverse demands, as per different processes and applications. Piston pumps are widely used in applications such as Energy Recovery, Steam Recovery and hazardous area pumping and are available with manufacturers such as

Diaphragm Pumps are commonly used for Sludge Transfer, Acid Pumping, and Chemical Fluid Transfer and are easily available with manufacturers such as Wilden, Sandpiper, ARO, Roughneck, and Graco.

All the mentioned manufacturers in this article, offering various kinds of pumps hold a good reputation with respect to quality, price, revenue (value), and market share and are preferred by many consumers. However, a thorough check of all its features, specific to your process application, should be ideally done to buy the most suitable reciprocating pump, which can be used for a longer period of time requiring low maintenance, ease of operation, and easy availability of its spare parts.

Reciprocating pump terms are based on how the fluid is pumped (action) and the number of plungers or pistons (arrangement). For example, a Union TX-200 is a “single-acting triplex plunger pump”, a Gaso 1849 is a “double-acting duplex plunger pump”, and an Oilwell B-558 is a “single-acting quintuplex plunger pump”.

Incepted in the year1990, Hydro Power Hydraulic Systemcommenced its operation as a reliable and competent Wholesale Trader of Hydraulic Vane Pump, Hydraulic Piston Pumps, Hydraulic Accumulator, etc. Along with this we are also Service Providerof AMC Service and Pump Repairing Services. Offered range of products is widely used and demanded across many industries. We provide these products to make our clients competent in the market place. Our culture is derived by growth of our products and customer base while making client satisfied with the quality and solutions we offer. Based on our focused endeavors and product innovation, we have been admired by our clients. Today, our organization is providing one stop shop for all relevant needs.

Reciprocating pumps provide a steady and constant flow rate under any level of delivery pressure. They are best suited for high-pressure, low-flow applications and industries that require precise mechanical operations. Industries that use reciprocating pumps include oil and gas, food processing, chemical processing, mining, and wastewater treatment.

While centrifugal pumps are more effective for higher discharge volumes, they may have a fluctuating flow rate during operation. Reciprocating pumps rarely require priming (unlike centrifugal pumps) and generally operate at 90% or higher efficiency. However, the efficiency and durability of a reciprocating pump depend heavily on the quality of the suction and delivery valves used.

In order to transform hydraulic energy into pressure energy, reciprocating pump types such as water pumps are employed. The reciprocating pump has a lot of parts with a wide range of cost. It uses a cylindrical piston arrangement, and this pump is devoid of rotating components. Forced pumps is another term for reciprocating pumps. In fact, reciprocating pumps are employed in high pressure and low vacuum applications. The reciprocating pump"s discharge oscillates and pulses. Positive displacement pumps are used in reciprocating pumps. For the designated application, the volume of fluid is gathered in an airtight seal and discharged under pressure.

How much does a water pump replacement cost? In the US in 2020, the cost to replace a water pump ranges from $461 to $638 on average. However, it typically depends on the kind and model of the vehicle you drive as well as the mechanic you use. While materials cost between $205 and $314, labor costs range from $256 to $324. Estimates exclude taxes and duties. Low - $461 Small - $550 $638 for height Replacement of the water pump is typically coupled with repairs: Cost of a new time belt $554 - $689 Time and expense of replacing a gear set $805 - $963 Describe a water pump. To help keep the engine from overheating, the water pump distributes coolant throughout the engine cooling system. How does it function?

The reciprocating pump is made up of the following parts: Suction pipe, delivery valve, cylinder, piston, piston rod, and connecting rod for the reservoir strainer Description of the components of a reciprocating pump The reciprocating pump"s component elements are described as follows: A reservoir is a source of water. Water must be moved with a piston from the sump to the delivery pipe. Strainer: Functions as a net that may clear the tank of all dirt, dust, and other particles. If there isn"t a strainer, dirt and dust will get inside the cylinder, blocking it and reducing the pump"s efficiency? Suction pipe: The suction pipe"s primary job is to draw water from the sump and convey it, via the suction valve, to the cylinder. The water tank is connected to the cylinder via a suction pipe. Check valve, or suction valve. This implies that while liquid can be drawn through the suction pipe and delivered to the cylinder, water cannot be pumped back into it. The flow is unidirectional in this regard. A valve that only opens during fluid suction and closes during fluid discharge. Cylinder: A hollow steel or cast iron cylinder with a piston and piston rod inside. Piston and piston rod: The piston slides back into the cylinder for intake and moves forward for discharge. A piston rod aids in the pistons forward or backward linear movement. Crank and connecting rod: The connecting rod serves as an intermediate between the crankshaft and the piston, transforming rotary action into linear motion, and the crankshaft is connected to a power source for rotation such as a motor, motor, etc.

The following are the principal parts of a reciprocating water pump: All of these components—whether a piston, piston, or diaphragm—have the primary purpose of moving fluids inside a cylinder. A lubricated sliding shaft called a piston slides back and forth inside a cylinder to push fluid, generating a hollow at the exit and a high volume pressure. Since the diaphragm entirely seals the fluid and permits it to exit, it is employed in diaphragm pumps to avoid fluid leakage. Consequently, it is particularly helpful when the liquid is hazardous or poisonous. A smooth cylindrical piston that moves over a fixed high pressure seal is the feature of a plunger pump. Connecting rod and crankshaft: The crankshaft, a round disk attached to the engine, transmits the rotation of the engine to the piston. With the assistance of the connecting rod, the piston oscillates back and forth. Suction pipe: This pipe allows liquid to enter the cylinder. The tube is attached to the cylinder at one end and has one side submerged in the liquid. Delivery Pipe: Consider this to be an output pipe. The cylinder is attached to one end, while the exhaust/outlet side is connected to the other end. Adjust the liquid flow rate at the aspiration and distribution locations using the aspiration and distribution valves. Centrifugal pumps and reciprocating pumps have different behaviors, characteristics, uses, etc. The primary distinction is that while reciprocating pumps utilize pistons to move the liquid, centrifugal pumps employ impellers. Contrary to reciprocating pumps, centrifugal pumps continually pump liquid. High viscosity fluids are pumped using lighter, less expensive reciprocating pumps.

DAE Pumps’ Reciprocating power pumps are designed with exceptional versatility for more accessible product selection and faster turnaround. These units are driven via electric motors or diesel engines through a V-belt or gear. The electric motor is more popular because it is more efficient and has a lower environmental impact. The diesel engine is more powerful and is often used in industrial applications.

8613371530291

8613371530291