replacing hydraulic pump on log splitter brands

Are you trying to buy a new hydraulic pump for your log splitter or do you need a perfect replacement pump kit for your wood splitter? Then, you should start your buying journey by reading this post. In this article, we’ll review the six best log splitter hydraulic pumps in 2022.

We compiled our list of the best gear pumps available after considering thoroughly their construction, splitting power, the flow rate for cycle time, operating speed, safety features, and overall benefits. We also included a buyer’s guide, FAQs, and summary to help you make a well-informed choice that suits your log splitter’s requirements and needs.

Log splitters are powerful machines designed to split logs efficiently. The machines offer effective splitting power to logs of various sizes. Almost all log splitters (including electric and gas types) use a hydraulic pump which is the integral component of a hydraulic machine that helps achieve the basic splitting of logs. The major components of a log splitter include an engine, hydraulic oil pump, valve, and hydraulic oil tank.

A typical hydraulic pump used for a log splitter is designed to feature a 5 hp gasoline engine, two-stage pumping sections, a hydraulic cylinder (4” diameter, 24” long), a 20 tons rated splitting force, and a 3-5-gallon hydraulic oil reservoir. Log splitters often use a two-stage pump to generate the right amount of pressure and flow rate required for splitting logs.

It’s tough to pick one product when you have many products from different brands making similar claims. So, we’ve done the hard work for you. Here are the best six pumps for a log splitter on the market. After reading this review, making a decision will become easier for you.

The RuggedMade 11 GPM 2-Stage Hydraulic Log Splitter Pump is perfect for log splitters with a rated force not up to 35 tons. It’s built with aluminum material for a longer service lifespan.

This hydraulic pump boasts up to 3000 PSI capable of powering log splitters and outdoor power requirements that range from 5 to 37 tons, depending on the hydraulic cylinder diameter (inner).

The two-stage pump operates at a maximum speed of 3600 rpm for faster cycle times during unloading. It’s preset to gear down mode at 500 PSI to help relieve the pump’s pressure; thus, ensuring the proper functioning of your splitter hydraulic system.

The Yaegoo 11GPM 2-Stage Hydraulic Log Splitter Pump is suitable for any log splitters application. It features a flow rate of 11 GPM capable of creating a stream of high-pressure oil required for generating maximum splitting force.

This two-stage hydraulic pump works at 3000 PSI to ensure effective splitting power without a loss of pressure. It’s built to automatically switch from high-pressure to low-pressure at 500 PSI for quick drawing back of the piston after splitting the log.

This log splitter hydraulic pump is ideal for log splitters with a rated splitting force of about 35 tons. It supports both vertical and horizontal applications.

The Bestauto Log Splitter Pump Kit is a suitable replacement pump kit for log splitters. It’s built with extrusion aluminum material that can resist wear and tears for an extended service life cycle.

This kit comes with a two-stage hydraulic pump, pump bracket, and jaw coupler. The 2-stage hydraulic pump works at 3600RPM maximum to ensure the fastest possible cycle times. The pump offers 13 GPM flow at 3000PSI maximum operation pressure to provide quick oil output.

The pump bracket and jaw coupler make lifting, pressure type, elbow, bending row, straightening, cutting, assembly, and more possible for a hydraulic log splitter. It’s compatible with a wide range of engine sizes.

The RuggedMade 16 GPM 2 Stage Hydraulic Log Splitter Pump features a body built with aluminum material for longevity. It’s designed to contain two pumping stages and a bypass valve to allow for efficient log splitting.

The first stage of the pump generates 16 GPM at 650 PSI required to reset the entire splitting system back after splitting. The second stage of the pump delivers 3.5 GPM at 2500 PSI to generate the maximum splitting force required to push the piston into a log for effective splitting performance.

The TooTuff Log Splitter Build Kit is a perfect kit for a DIY splitter project. It provides two-stage pump action to allow for maximum log splitting efficiency. The 1st pumping stage operates with a maximum flow rate (13 GPM) at a lower pressure of 650 PSI to help ensure a quicker cylinder return position.

In the second stage, the pump switches to a lower flow rate (3 GPM) and higher pressure (2500 PSI) to generate the maximum effective splitting power to split the log.

This hydraulic pump provides faster cycle times (16 GPM at 3600RPM) and higher possible pressure (up to 4000 PSI) with a small engine or most 8-14HP gas engines.

The Bestauto Log Splitter Pump Kit consists of a powerful hydraulic pump and hydraulic tools such as a jaw coupler and pump bracket. This hydraulic pump is built with sturdy and durable materials that can withstand even harsh environments.

The pump offers two-stage hydraulic actions to keep your log splitter running correctly. The 1st stage of the pump is preset to operate with a maximum flow rate of 16 GPM at 650 PSI for quicker withdrawing of the piston after the log has been split.

While the 2nd stage of the pump operates with the lower flow (3.5 GPM maximum) at higher pressure (2500 PSI maximum) to ensure excellent splitting efficiency.

The materials used in the construction of a hydraulic pump for log splitters would determine the longevity and performance of such a pump. Log splitter pumps built with high-quality materials such as aluminum have a longer service lifespan.

It’s important to ensure that all the components of the pump you intend to buy are built with materials of high strength and hardness that can resist wear and tear over multiple uses. It’s also important to check if the pump’s quality is well-assured by the manufacturer so that you can have a great user experience.

The splitting power of a hydraulic pump for log splitters is largely dependent on the maximum pressure that such a pump can generate. The amount of pressure that a pump generate vary from brand to brand.

However, the higher the pump’s maximum pressure, the more effective its splitting power. We don’t recommend more than 3000 PSI, which is the practical maximum pressure that most 2-stage gear pumps required for excellent log splitting.

The flow rate of the hydraulic pump determines the periods of time the pump would take to work through a pile of logs. The pump’s flow rate is largely dependent on the size of the engine powering the system.

A two-stage hydraulic pump for log splitters often requires minimum horsepower such as 5-7 hp engines with 11 GPM pump, 6hp engine with 13 GPM pump, 8 hp with 16 GPM pump, and 11 hp with 22 GPM pump.

You don’t have to worry too much when choosing a hydraulic pump based on the flow rate as virtually all log splitter pumps out there are rated for the same pressure.

It’s important to know that the operating speed of the hydraulic pump is hugely dependent on the hydraulic flow rate (GPM). Generally, larger pumps produce more flow which means more operating speed. However, bigger gear pumps require larger engines or powerful engines to drive them. Small pumps produce less flow but don’t require more horsepower to function properly.

The safety valve ensures smooth operation and performance of the hydraulic pumps. It helps to control the maximum pressure created by the hydraulic pump. Without a safety valve, most hydraulic pumps will build pressure up to a point that something break. Uncontrolled maximum pressure is likely to break your hydraulic hoses, garden hoses, hydraulic pressure hoses, the cylinder, or the pump itself.

To ensure the entire safety of your hydraulic system, you should go for 2-stage pumps with features such as a hydraulic relief valve, check valve, directional control valve, unloader valve, or hydraulic valve. Any of these safety features would help keep your pump’s pressure in check.

Besides, you should check if the pump you want to buy comes with a return filter, filter element, or filter head. Any of this would function to keep dirt out of its hydraulic reservoir (fluid reservoir).

Most simple wood splitters use a 2-stage gear pump for efficient log splitting. The two-stage pumps give log splitters effective splitting power using small engines. They can help generate the highest possible pressure required to keep most log splitters working smoothly and efficiently.

The approved fluid types for the hydraulic system of most wood splitters are AW-32 10-Weight (ISO 32) and AW-46 20-Weight (ISO 46). These hydraulic fluid types help lubricate your gear pumps and other hydraulic parts for protection against corrosion and weariness during extreme cold and heat.

We recommend changing the hydraulic oil in your log splitter every 100 hours of work. Regular changing of the hydraulic oil in your log splitter would help improve the performance of your log splitter hydraulic system. In addition to replacing your log splitter hydraulic oil as recommended, you also need to change your filter to keep dirt away.

A single-stage hydraulic pump features only a single pumping section or setting. It’s designed to generate just one flow rate (maximum GPM) at one maximum pressure to create the maximum splitting force. While a two-stage hydraulic pump features two pumping sections or settings. It’s designed to generate two flow rates at two different pressure levels.

A two-stage pump automatically switches to its ‘high-pressure/low-flow stage to split the blog (something that can’t be achieved with a single-stage pump). Two-stage pumps generally save splitting time than its counterpart (that’s one-stage pumps).

Look no further than this review if you would like to try out the best hydraulic pumps for log splitters out there. Any of the review gear pumps are capable of giving your splitters the power required to split log efficiently. We’re certain that you won’t go wrong with choosing to buy any of the above products. They are the best anyone can find on the internet at the moment.

Keep your hydraulics in motion with a wood splitter hydraulic pump from RuggedMade. Designed to meet the needs of high-force log splitting, our precision 2-stage hydraulic pumps ensure cylinders perform smoothly and rapidly, helping to shave down cycle times.

Our expanded line of one and two-stage log splitter pumps are constructed to produce up to 3,000 PSI and can also be used at the heart of a variety of hydraulic applications to keep fluid flowing freely and steadily, throughout the life of your machine.

This 2-Stage pump fits a wide variety of log splitters and outdoor power equipment and works in both horizontal and vertical orientations. The included inlet nipple requires a 1" inner diameter suction hose.

Rated for up to 3,000 PSI at 3,600 RPM, this pump can power log splitters from 5 to 35 tons, depending on the inner diameter of the hydraulic cylinder. It features a fast cycle time by moving quickly when unloaded. It automatically shifts to low-flow/high-pressure mode at 500 PSI.

Be sure to use AW-32 10-Weight (ISO 32) or AW-46 20-Weight (ISO 46) light hydraulic fluid or Dexron III automatic transmission fluid. This pump is not designed for use with “universal” or "tractor" transmission oil, such as "303". The use of incorrect fluid may damage the pump and void the warranty.

Make sure the hydraulic fluid reservoir is not below the pump to ensure a sufficient flow of fluid to the pump. Suction-side filtration should be no finer than 150 microns. The use of a 10-25 micron filter on the suction side of the pump is too restrictive and will cause failure.

We recommend using an L-style jaw coupling to connect the pump to an engine. Couplings and mounting brackets are available. You should use at least a 5hp 163cc engine to maintain 3,600 RPM under load.

Brand new 19GPM, 2 stage hydraulic replacement pump for log splitters. Fits many different applications, including newest models sold at Tractor Supply Co.

- The 2-stage pump can give you faster cycle times and higher possible pressure with a small engine. Excellent for use on log splitters. 85% efficient.

- This 2 stage pump can give you much faster cycle times and higher possible pressures with a small engine. Excellent for use on log splitters. 85% efficient.

Aftermarket replacement for MTD 718-04127 log splitter pump Hi/Lo 2 stage hydraulic gear pump. 11 GPM @ 3600 RPM, 3 GPM @ 400 PSI and 8 GPM @ 3000 PSI. 3600 RPM rated speed, SAE 4 bolt flange mount. 1" metal tube inlet port with 1/2" NPT outlet port. 1/2" keyed shaft. Right hand rotation (clockwise). Cast iron housing. The pump will automatically switch from low pressure (400 PSI) to high pressure when it reaches 900 PSI and then advance to 3000 PSI.

We ordered this for our troy bilt wood splitter. Everything fit well and we have used it twice since putting on. We had to use coupler that was sent to get it to work with ours. The price was very reasonable and shipping was very fast sent through the usps. We use wood to heat our home so that was a tremendous plus.

I called several other companies that said that it was in stock only to find out that it wasn"t. I called Fremont expecting the same. They had it and shipped the same day. These guys do what they say they will do. Kudos to Fremont Industrial Supply

Bolted right up on my Troy Built 27 ton log splitter. Fired right up and did the job with no leaks. Happy to find this company thanks to Google search!

Hey, it happens. We break stuff. Wait… are your log splitter parts breaking or getting damaged by your usage or your wrong equipment? Answer these questions first:

“A log splitter is a piece of machinery or equipment used for splitting firewood from softwood or hardwood logs that have been pre-cut into sections (rounds), usually by chainsaw or on a saw bench. Most log splitter parts consist of a hydraulic or electrical rod and piston assembly and rated by the tons of force they can generate. The higher the pressure rating, the greater the thickness or length of the rounds are split.”

For most commercial or home-based splitters, it doesn’t matter much if you power the log splitter by an electric motor, a gas engine, or even a diesel engine. They all drive a hydraulic pump. And regardless of the power source and pump combination, a log splitter typically uses a hydraulic piston to drive the log through a fixed wedge or blade.

Let’s start with the heart of the log splitter – the hydraulic pump. Did you notice I didn’t mention the engine or motor? Don’t get hung up on how big the engine or motor is. It is the primary mover, but it’s only good as the hydraulic pump it will operate.

Hydraulic pumps for log splitters usually are either a single-stage or a two-stage pump. Cheaper, often off-brand log splitters, and even some larger well-known commercial log splitters may come with a single-stage pump. A single stage pump will do the task, but it moves the hydraulic cylinder slower. Splitting time is increased. If you’re not concerned about time, then there’s no real concern about using this type of hydraulic pump.

Hydraulic two stage pumps are ideal for log splitters. A two-stage pump will first produce high volumes of low-pressure fluid (first stage). This stage moves the hydraulic cylinder in and out quickly. The two-stage model is great for moving the splitter ram up against the wood fast, and for retracting it fast.

When the pump encounters resistance (splitting wood), the second stage of operation engages. A calibrated valve will sense the pressure change and divert service to the pump’s high-pressure fluid stage for splitting. The volume of fluid (speed of the ram) will drop considerably during the second stage, but the force increases significantly. For example, a typical first-stage log splitter pump may unload fully around 450 psi while the second stage operates up to 3000 psi.

The effectiveness of a log splitter ram determined by the bore size, the stroke length, and rod diameter. Bigger isn’t always better in this case. You have to have the correct amount of fluid volume and pressure matched to the cylinder for it to provide the proper force. For example: let’s say you placed a much more significant, higher volume ram in place of a smaller one. You may experience inadequate performance simply because your splitter isn’t able to handle the increased demand for fluid pressure and return.

Your return lines and fluid reservoir may be too small placing back pressure on the cylinder. The control valve porting may be too little doing the same. Your pump may not be able to deliver enough pressure due to a lack of fluid volume.

Since pressure creates heat, it’s recommended to use a reservoir that can hold a 3/1 ratio of fluid. Meaning, if your system uses one gallon of fluid each cycle, then your reservoir should hold three gallons. This gives the fluid time to cool down.

It’s best to be sure you have matched components on your log splitter. Often a larger tonnage no-brand splitter may look very attractive at first, but the parts may be miss-matched, or of poor quality.

Determine your replacement log splitter parts needs by using calculators. Give Don’s Hydraulic Cheat Sheet a try. Just change the fields marked “Bore, Rod, Stroke, Pressure and GMP” to calculate your force and speed. To find a bore size, input the desired force you need and applied pressure to the ram. This will output the required bore size.

Whether you need a hydraulic filter or just cylinder repairs, Cylinder Services carries a quality range of log splitter parts including control valves, Prince Hydraulic Cylinders, NBC hydraulic log splitter pumps, and accessories. Be sure to check out our store.

Northern Hydraulics offers a full line of 2-stage hydraulic pumps for your log splitters, compactors, and press-type applications. Haldex/Concentric pumps have a cast iron gear housing and are available in flows ranging from 9 GPM to 28 GPM. These 2-stage hydraulic pumps are designed for heavy-duty use and long cycle times. The Haldex brand assures you are getting top-quality, high-performing products. Northern Hydraulics replacement pumps also have a cast iron gear housing and are available in flows ranging from 5 GPM to 28 GPM. These log splitter hydraulic pumps are ideal for the recreational wood splitter user, as they are still a quality product, but offered at a much lower price point.

This product is a Hi-Lo cast iron hydraulic gear pump with max pressures of 900 PSI for the low pressure and 3000 PSI for the high pressure pump. Typical applications are log splitters and presses, where alternating low and high pressures are required to move a cylinder.

This pump is the same as our standard pumps with clockwise rotation but is designed for opposite rotation. Some splitters that use a belt drive like Swisher would use this pump.

We are not responsible and will not warranty customer cross threading hydraulic fittings or stripping out threads into this pump, if you are not familiar with tightening or installing pipe threads into aluminum then you will need to have someone familiar with doing so.

A broken flexible pump coupler, clogged hydraulic fluid filter, failed hydraulic control valve, broken hydraulic pump or faulty hydraulic cylinder can prevent the hydraulic cylinder from extending the wedge on a log splitter.

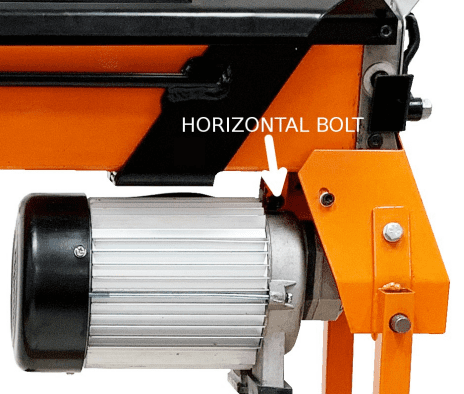

Accessing the flexible pump coupler is fairly easy, so check that part first. The flexible pump coupler connects the engine drive shaft to the hydraulic pump. The coupler is designed to break if the hydraulic pump seizes up, protecting the engine from damage. Because the flexible coupler is plastic, the coupler can deteriorate over time and crack or break. Replace the flexible coupler if it"s broken or damaged.

If the flexible coupler broke, try to rotate the hydraulic pump drive shaft with the drive shaft disconnected from the engine drive shaft to check for a locked-up hydraulic pump. If you can"t rotate the hydraulic pump shaft, you"ll likely need to replace the hydraulic pump. You"ll also need to replace the hydraulic pump if it"s leaking hydraulic fluid because the pump can"t build up hydraulic fluid pressure to extend the wedge to split a piece of wood if its seals leak.

Hydraulic fluid leaking from the hydraulic control valve or hydraulic cylinder often indicates that the leaking part has failed. You"ll likely need to replace the control valve and/or cylinder if they leak hydraulic fluid.

Although it doesn"t happen often, a clogged hydraulic fluid filter can impede hydraulic fluid flow and prevent the cylinder from extending the wedge. Check the hydraulic fluid filter and replace the filter if it"s clogged.

· 16GPM Powerful Pump: This hydraulic pump comes with a 25 GPM auto control detent valve. It features a 3600 RPM max rotating speed, 2250PSI valve setting along with a 16GPM high flow rate. It will bring powerful performance to your log splitter. Get ready to start cutting logs in half, in half the time.

· 1" Inlet & 1/2" NPT Outlet: Our log splitter pump is equipped with a standard 1/2" NPT outlet port ( for Minimum 8 HP engine) and 1" barb on the inlet port. It also has a 1/2" diameter shaft with a 3/8" key, allowing it to rotate clockwise. Quality you can trust, for unmatched results you can see.

· Sturdy & Durable: The high-strength extrusion aluminum casing enables the pump to resist impact, rust, and high pressure. This sturdy structure can prevent leaks and ensure a prolonged service life.

· Simple Installation: This pump stands out with a 4-hole bolt-on design, and it allows for a direct and quick installation. Install the pump effortlessly, making your log splitting more effective and robust.

· Doesn"t Just Split Logs: The 2-stage hydraulic pump is excellent for log splitters, press, machine tools, and power units for snowplows. It has outstanding compatibility with many OEMs like Speeco, Huskee, Champion, and many more.

Replacement Log Splitter Pump Kit: This replacement log splitter hydraulic pump kit consists of high-quality parts with high strength and hardness, which is capable of good wear resistance, durable in use and is replaceable and compatible with OEMs like Speeco, Huskee, and Champion, etc.

Powerful Hydraulic Pump: This powerful pump is a 2-stage 16GPM hydraulic pump offer you the fastest possible cycle times, which ensures a fast start and long using period for each time. It dramatically reduces the labor intensity, improves work efficiency.

Excellent Performance: Equipped with other hydraulic tools like jaw coupler and pump bracket, it can carry out lifting, pressure type, elbow, bending row, straightening, cutting, assembly, demolition and many other works with a hydraulic log splitter.

Multiple Model Combinations: As this log splitter pump kit is designed for meeting the replacement of a variety brand, the parts of this kit have a standard specification that is suited for your multiple combinations for your demands.

Wide Application: Used in applications where extending a hydraulic cylinder is needed, truck tailgate lift, scissor lift, dump trailer, lift truck, snowplow, aerial platform, road signs, material handling, wheelchair lifts, etc.

A log splitter is an efficient, time-saving machine that can help you prepare firewood for your fireplace or a wood-burning stove. A log splitter comes in many designs from simple manual splitters to large industrial-type machines. For home use, you need a machine that can produce enough power and driving force for your needs.

Replacing an old engine is always the best idea especially when it’s already showing signs of failure. And to further diagnose your wood splitter engine, take it to a repair specialist.

The XtremeowerUS 62029 gas log splitter engine is an electric start, 7HP gasoline motor that"s great for different applications including log splitting equipment, water or trash transfer pumps, pressure washers, mobile carwashes, rototillers, go-karts, and much more. This engine has an industrial design; it"s very durable and capable of working in demanding environments.

This gas-electric start engine starts easily and works smoothly and quietly. It runs on an 87 octane fuel or higher fuel rating. It also comes with safety and maintenance features with a low oil shut-off feature to avoid damage or engine failure.

The BILT HARD log splitter gas engine is easy to use, compact, and fuel-efficient. It"s a 7 HP 4-stroke gas motor ideal for a log splitter, go-karts, lawnmowers, mini bikes, etc. It is also an industrial motor that works with cement mixers, pressure washers, tillers, chippers, blowers, and compressors. It can replace old and worn-out motors for different applications.

This is a durable gas engine with a cast-iron cylinder, fuel shut-off features for easy and safe transport, and fuel-saving features. All parts are guaranteed to last longer. It is one of the best replacement motors compatible with Honda engine, Briggs and Stratton engines, Yamaha, and Kawasaki.

The Lifan LF168F-2BQ is a 6.5-HP 4-stroke gas engine capable of providing pure power to your log wood splitters, lawnmowers, and go-karts. It"s a general-purpose motor with a convenient universal mounting plate ideal for construction, recreational vehicles, ranch or farm use, and so much more.

It has an industrial-grade design with a .75-inch keyway shaft and compression release for easy, seamless starting. This replacement engine comes with protection features such as low oil shutdown to keep the engine safe and avoid costly repairs.

You can count on this replacement engine to take the place of broken or low-performing engines such as Honda engine, Kohler, harbor Freight, Briggs and Stratton, Kawasaki, and more. It’s available in different variants: 3 HP, 4 HP, 6.5 HP, 9 HP, 13 HP, and 15 HP. You can get this LiFan motor in recoil start with 2:1 centrifugal wet-clutch reduction, recoil starts with 6:1 gear reduction, electric start with a 15-amp external charging system, recoil start, and electric start varieties.

Special Features: universal mounting plate, .75-inch keyway shaft, low-oil shutdown protection feature, EPA certified, available in different start switches, thread starter, and horsepower

The XtremepowerUS 62027-2 is a 4-stroke gas-powered log splitter replacement engine with a horizontal shaft. This small engine is perfect for small and compact equipment and machines including log wood splitters and other similar machines.

It comes with an OHV design so it’s more efficient to use and provides optimum force transfer no matter where you use it. This engine also has a high-precision camshaft feature to improve valve timing and overlap. These contribute to enhanced fuel economy in all applications.

This engine comes with damage protection features like a low oil shutoff. This shuts the engine down to avoid serious failure or costly damage. It has a recoil start system and operates on standard 87 octanes or higher fuel.

Special Features: smallest replacement engine, optimal force transfer, high-precision camshaft, valve timing and overlap, horizontal shaft, low oil shut down feature, recoil start

The AlphaWorks gas log splitter engine offers 7HP, high torque, and speeds enough to cut logs with ease. This engine was built for industrial use and reliable performance. It"s equipped with a TCI ignition system and a forced air-cooled feature to keep the motor cool when in use.

This gas engine has a maximum fuel capacity of 0.7 gallons and runs on 87+ unleaded fuel. It comes with a simple spark plug system and is compatible with Torch spark plug brands. Because of its streamlined design, you can use this engine on almost any machine including wood splitters, lawnmowers, mini bikes, go-karts, and more.

If you want to build your wood splitter for home or farm use, there are many DIY options for you. A lot of online wood splitting machine plans with combination parts are available online. These DIY plans vary in engine power, design, features, and pump combinations. Here are some of these DIY kits

This log splitting machine DIY plan makes use of a powerful Honda engine GX 160 or a similar replacement motor to produce the best power. The GX is available in 120, 160, and 200 variants with low noise levels, reduced vibration, and very low engine emissions. This engine offers a very precise camshaft design for accurate valve timing and overlap for enhanced fuel efficiency.

Also part of this kit is an 11-GPM pump such as a Barnes Haldex pump, a heavy-duty, high-performance pump. The kit won’t be complete without a 4 x 24-inch shafts such as the Clevis welded cylinder/rod ends and a wood splitting machine D-tent valve.

A wood splitting machine with a 13.6-GPM hydraulic pump is more efficient, easier to use, and best for commercial, residential, and recreational uses. This pump produces faster cycle times and improved pressure even when used with small engines. It’s a great choice for log splitters, go-karts, lawnmowers, tillers, and more.

Combine this efficient hydraulic pump with a powerful GX 200 engine and you’ll create a versatile splitter made for home or commercial use. You also need a 4 x 24 – inch 3000 PSI welded cylinder shaft/rod and a log splitter D-Tent valve to complete your kit.

Partner a GX 270 engine with a 16-GPM hydraulic pump and you’ll get a durable and powerful log splitter. This engine offers a higher force output, reduced fuel consumption, and reduced exhaust. You’ll be using a quiet log splitting machine with reduced vibrations at home, on-site, and anywhere you need to cut logs. The 16-GPM hydraulic pump is efficient and ideal for log splitters, lawnmowers, and general uses.

A larger 22-gallon hydraulic pump is very efficient, offers high speed-low pressure and low-speed-high pressure applications. This combination is best for DIY log splitters, lawnmowers, and pressure washer machines.

Make your log splitters safer and more efficient with an electrical start engine such as a Honda V Twin 639 electrical start or other similar models. This comes with an adapter engine to pump with an electrical start.

This is a heavy-duty engine that costs more than a regular gas engine but is durable and will provide more force for a residential or commercial splitter.

If you want a splitting machine that will last longer or a machine that will carry you every winter then you may need to spend more than your average budget.

Another consideration is to get a pre-owned machine but repairs may still cost you an arm and leg. It’s still better and safer to buy a reliable replacement motor than to try to repair one.

Whether you’re overhauling your log splitting machine setup or building your log splitter machine, it’s best to use the right replacement engine and splitter components.

Take time to check engine specs as well as all the component specs and features. When all these are considered, you’ll be splitting wood with your newly overhauled or repurposed log splitter in no time.

8613371530291

8613371530291