rexroth hydraulic pump adjustment for sale

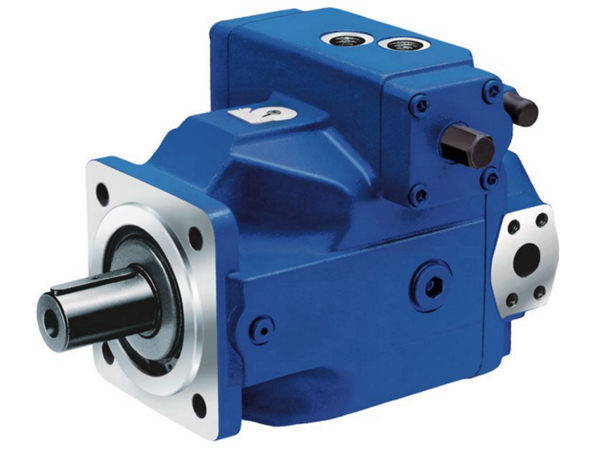

Rexroth’s complete line of hydraulic pumps serve virtually every industry in manufacturing and technology applications such as railway engineering, chemical process plants, power and environmental engineering, automotive engineering, plastics processing machinery, paper industry, presses, test rigs and simulation systems, marine/offshore engineering, special projects, and civil/water engineering, transportation technology, and machine tools.

Pursuing a comprehensive understanding of these application areas and working closely with customers, our engineers have developed unique electrohydraulic innovations in control technology. The result is hydraulic pumps with greater precision, dependability, and reliability.

Keeping a market expectations mindset, Bosch Rexroth is setting a new standard for hydraulic pumps with continuous development at the highest standards and quality. Rexroth pumps are designed for high reliability and efficiency.

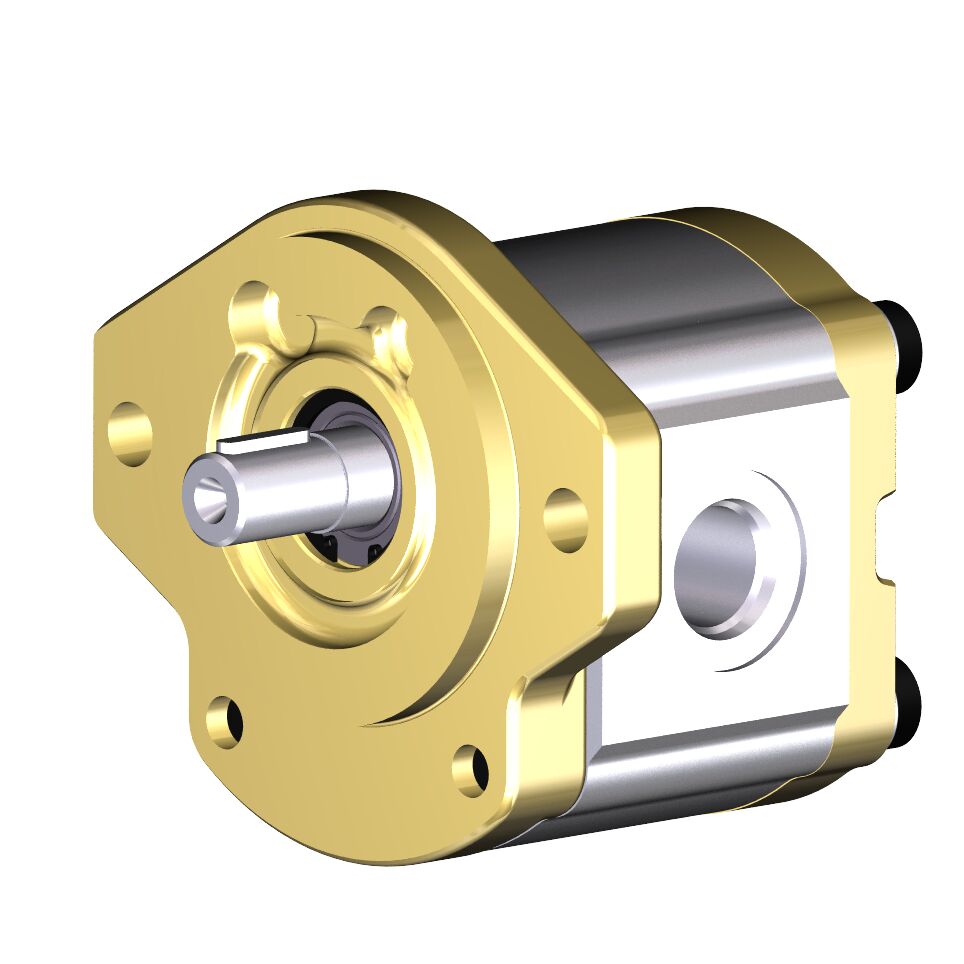

The lineup of pumps includes: Axial Piston Pumps, External Gear Pumps, Internal Gear Pumps, Gerotor Pumps, Vane Pumps, Radial Piston Pumps and Electro-hydraulic Pumps.

Rexroth pumps are designed as a solution point of view where the products are compatible with each other in order to provide a whole portfolio for our customers.

To help keep your systems operating safely and at maximum efficiency, Rexroth offers a wide range of pump accessories. Replacement seals, safety valve, mounting flanges, brackets, and adapters make installation easier and faster.

Continuous development within hydraulic pumps industry and latest technologies at the highest level of development Bosch Rexroth will always provide the best matched reliable products for your business.

We carry a large selection of Bosch Rexroth hydraulics pumps, motors & more. If you can’t find the Rexroth Pump you’re looking for or you need a Bosch Rexroth hydraulics pump repair, contact us today!

We can supply what you need or repair what you have. Before purchasing, there may be a good chance that your current Bosch Rexroth hydraulic pump or motor can be repaired. Bosch Rexroth hydraulics repairs and motor repairs come with our two year warranty.

When purchasing, consider remanufactured Bosch Rexroth hydraulics or after-market hydraulic units. They can get you back up and running for less than the cost of a new Bosch Rexroth hydraulic unit. We will give you a free quote so you can compare costs for a new, repaired or re-manufactured Bosch Rexroth unit, saving you money without compromising the results of your Bosch Rexroth hydraulic unit.

In 1795, the Rexroth family established an iron forge in Spessart, Germany. However, it wasn’t until 1952 that they began producing standardized hydraulic components and hydraulics. In 1953 they invented the first industrialized gear pump for mobile machines. Later, in 1972, Rexroth launched the first hydraulic servo valve onto the market and became a wholly-owned subsidiary of Mannesmann AG in 1975. They developed the world’s first maintenance-free AC servomotor in 1979, revolutionizing the mechanical engineering industry. Throughout the 90s Rexroth continued to grow and revolutionize the industry, launching inventions used in a variety of industries. Mannesmann Rexroth AG and Bosch Automation Technology merged to form Bosch Rexroth in 2001 and today, Bosch Rexroth is one of the leading specialists in drive and control technologies.

Axial piston pumps: intended for the medium and high-pressure range and come in a variety of designs, performance ranges, and adjustment options for mobile, stationary and industrial applications.

Bosch Rexroth units we commonly stock in new, remanufactured or aftermarket are: A10V, V3, V4, V5, V6, V7, RPV, PVQ, VPV, PSV, PVF, PVK, PVQ, PVS, PVT, 20L, 20H, E055, 80L, 80M, 80H.

Bosch Rexroth hydraulic motors are known for their reliability, long life cycles, low noise emissions, as well as high efficiency, and cost-effectiveness. The range is available in swashplate or bent axis designs which are used in medium and high-pressure applications. They have several models including:

Bosch Rexroth hydraulics offers a range of hydraulic “on/off” valves including isolator valves, directional valves, pressure valves, flow control, and throttle valves, and directional cartridge valves.

Directional valves:control the flow and direction of movement or rotation of hydraulic actuators which include directional seat or spool valves, direct operated or pilot operated valves.

Hubs for the combination of single pumps or the combination of SYDFE with other pumps. Observe that the attachment pump has a splined shaft SAE J744 with the specified diameter.

The following conditions apply to the attachment pumps listed in the table:SYDFE and A10VSO with shaft S or R Internal gear pump PGH with shaft R, flange U2, see data sheet 10223 Internal gear pump PGF3 with shaft J, flange U2, see data sheet 10213 External gear pump AZPF with shaft R, front cover R, see data sheet 10089

Observe that the through-drive of the main pump and the flange of the attachment pump (see type key pump) are identical. Check in the current data sheet of the gear pump whether the shaft ends have the specified dimensions.

Mounting flange, drive shaft and functions identical to A2VK, thus easy to replace Reduced dimensions and mass in comparison to A2VK Improved volumetric efficiency through robust unit in well-tried axial tapered piston technology Manual adjustment with precision gauge and clamping device to prevent unintended adjustment Double shaft sealing of special compound and flushing chamber In closed design (A7VKG) or open design (A7VKO) available Increased corrosion protection through special surface treatment Optional with mounted high-pressure relief valve Low operating noise Bent-axis design

SAAR specialized in pumps, motors, valves, bearings, couplings, gearbox, engine spare parts, filter elements, fittings, connectors, electronic components and accessories, mobile equiupment spare parts.

The Overview And Working Principle Of Rexroth a4vso Series Variable Piston Pump: The pressure oil of the German REXROTH A4VSO series variable displacement piston pump enters the lower chamber of the variable housing through the check valve through the oil hole in the pump body and casing variable casing. The REXROTH hydraulic pump pushes the servo piston when the pull rod moves downwards. Move down and the upper valve opening of the servo valve opens. The pressure oil in the lower chamber of the variable housing enters the upper chamber of the variable housing through the oil hole in the variable piston. Because the upper chamber area is larger than the lower chamber, the hydraulic pressure pushes the piston downward. , Drive the pin to rotate the variable head around the center of the ball, change the tilt angle (increase) of the variable head, and the flow of the A4VSO pump increases. If the rod moves upwards, the tilt angle of the variable head changes in the opposite direction, and the flow of the pump also changes. When the angle of inclination changes to zero, the head of the variable changes in the direction of the negative declination angle, the flow changes, and the pump inlet and outlet ports change.

Although A4VSO is robust pump with very long service life, but on the running of the A4VSO pumps, especially it has been a long running, there will meet several breakdown as following:

(a) Inadequate inhalation: The reason is that the resistance in the suction pipe is too large or the amount of oil is insufficient. If the speed of the pump is too high, the liquid level in the tank is too low, the intake pipe leaks, and the oil filter is blocked. (b) Excessive leakage: The cause is excessive clearance of the pump and poor sealing. If the oil pan is scratched by metal fragments, iron scraps, etc., the end surface leaks oil; the one-way valve sealing surface in the variable mechanism is not well-matched, and the bearing surface of the pump body and the oil pan is blistering or grinding marks. It is possible to discriminate where the pump is damaged by checking for foreign matter in the hydraulic fluid in the pump body. (c) The inclination of the swash plate is too small and the displacement of the pump is small. This requires adjusting the piston of the variable and increasing the swash plate inclination.

Rexroth A4VSO piston pump oil leakage mainly has the following reasons: (a) The spindle oil seal is damaged or the shaft has defects or scratches; (b) The internal leakage is too large, causing the pressure at the oil seal to increase, and the oil seal is damaged or washed out; (c) ) If the drain pipe is too long, oil leaks from the seal; (d) The external oil pipe of the pump is loose, the pipe joint is damaged, and the gasket is aged or cracked; (e) The loose bolt of the adjusting mechanism and the seal is damaged; (f) Cast iron pump The shell has trachoma or poor welding.

Output flow fluctuations are related to many factors. Variable pumps can be considered to be caused by poor control of the variable mechanism. For example, when foreign objects enter the variable mechanism, step marks, wear marks, and scars are marked on the control piston, resulting in unstable control piston movement. Due to the lack of energy in the amplifier or the damage to the parts, the damper of the control piston with springs is poor in performance, which can cause unstable control piston movement. Unsteady flow is often accompanied by pressure fluctuations. This kind of fault generally needs to disassemble the hydraulic pump, replace the damaged parts, increase the damping, increase the spring stiffness and control the pressure.

There are two reasons why the A4VSO hydraulic pump overheats. One is that mechanical friction generates heat. Because the moving surface is in a state of dry friction or semi-dry friction, moving parts rub against each other to generate heat. The second is liquid friction heat. High-pressure oil leaks into the low-pressure chamber through various gaps, and a large amount of hydraulic energy is lost to heat energy. Therefore, the correct selection of the gap between the moving parts, the volume of the fuel tank and the cooler can prevent excessive heating of the pump and high oil temperature. In addition, blockage of the return filter causes high back pressure on the return oil, which can also result in high oil temperatures and overheating of the pump body.

(a)Mechanical vibration and noise: If the pump shaft and the motor shaft are not concentric or top dead, the bearings and joints of the rotating shaft may be damaged, and damage to the elastic mat and loosening of the mounting bolts may generate noise. For pumps that operate at high speeds or that transmit large amounts of energy, they must be periodically checked to record the amplitude, frequency, and noise of each component. If the rotational frequency of the pump is the same as the natural frequency of the pressure valve, resonance will occur and the pump speed can be changed to eliminate resonance. (b) The noise generated by the flow in the pipeline: The inlet pipeline is too thin, the inlet flow capacity of the inlet filter is too small or blocked, the intake pipe intakes air, the oil level is too high, the oil level is too low, and the oil pressure is insufficient and high pressure If liquid strikes in the pipeline, noise will be generated. Therefore, the fuel tank must be properly designed to properly select the oil filter, tubing, and directional valve.

The output pressure of the A4VSO pump is determined by the load and is approximately proportional to the input torque. There are two kinds of faults in the output pressure abnormality.

(a) The output pressure is too low: When the pump is in the self-priming state, if the inlet pipe leaks or the hydraulic cylinder, one-way valve, and reversing valve in the system have large leakage, the pressure will not rise. This requires finding leaks, tightening, and replacing seals to increase pressure. If the relief valve is faulty or the adjustment pressure is low and the system pressure does not rise, the pressure should be readjusted or the relief valve checked. If the deviation between the cylinder and the valve plate of the hydraulic pump results in a large amount of leakage, and if the cylinder block may be broken when it is serious, the mating surface or the hydraulic pump should be replaced. (b) Output pressure is too high: If the loop load continues to rise, the pump pressure continues to rise, which is normal. If the load is constant and the pressure of the pump exceeds the pressure required by the load, hydraulic components other than the pump, such as directional valves, pressure valves, transmissions and return lines, should be checked. If the maximum pressure is too high, adjust the relief valve.

When the swash plate inclination angle of the variable displacement axial piston pump is zero, it is referred to as the neutral position, and the output flow rate of the pump at this time should be zero. However, sometimes there is a phenomenon that the median deviation deviates from the midpoint of the adjustment mechanism, and there is still a flow output at the midpoint. The reason for this is that the position of the controller is deviated, loosened or damaged and needs to be re-zeroed, tightened or replaced. This phenomenon can also be caused by the insufficient maintenance of the angle of the pump and the wear of the tilted trunnion.

With Linde Hydraulics discontinuing their in-house remanufacturing program in February of 2023 - Hydraulex (our Washington State facility) is now 1 of 5 Authorized Linde Service Centers within the USA and Canada. We"ve worked closely with Linde for many years and have factory training & are factory supported by Linde.

Notes on the engineering of multiple pumpsPV7 pumps can be combined as a standard. Each pump is fitted with a splined, second shaft end. When the PV7 is operated as fixed displacement pump, the fixed displacement pump must be used as rear pump. The general technical data are the same as that of the single pump. The pump that is subjected to higher loads (pressure x flow) should be the first pump stage. When several pumps are combined, the torques that occur can reach impermissibly high values. The sum of torques must not exceed the permissible values (see table) Combination parts must be listed as separate items on the order. The combination parts include the required seals and screws

This means that only the sound emission of the pump is shown. Ambient influences (such as place of installation, piping, etc.) were eliminated. The values are valid for only one pump.

If, for example, two pumps of the same frame size are operated under the same load conditions, the noise level increases according to the following formula

The power unit design and influences at the final place of installation of the pump result in the fact that the sound pressure level is usually 5 to 10 dB(A) higher than the value of the pump alone.

The external leakage fluid of the pump dissipates a part of the frictional heat. The leakage fluid should be directed with low line resistance directly into the tank. The distance between the leakage line and the suction line must be sufficiently large so that the returning leakage fluid cannot be directly re-aspired. The flow of average, external leakage is shown on Product description. These values must not be used for dimensioning the tanks. The relevant variable for the selection of the tank size is the zero stroke power (see Diagrams/characteristic curves).

The values for external leakage fluid given on Technical data are average values that are valid for continuous operation. When the pump goes off stroke, the leakage fluid volume briefly increases due to the pilot fluid of the controller. Reductions in cross-sections, long leakage lines, or also leakage fluid coolers can lead to impermissibly high pressure peaks. Suitable measures, e.g. a check valve in the by-pass must prevent the leakage fluid pressure (pmax = 2 bar) from exceeding the permissible values. Otherwise, the shaft seal ring could be damaged.

How? Well, they perform a mechanical action that creates a vacuum at the pump inlet. This vacuum allows pressure to force liquid from the reservoir into the inlet of the pump. This mechanical action delivers the liquid to the pump outlet and forces it into the hydraulic system.

The liquid runs throughout the hydraulic system and runs back to the reservoir. By repeating this process, a steady flow of hydraulic fluid running through the system is created.

To reduce heat loss, Rexrothexternal gear pumps are designed to be extremely efficient. This efficiency is achieved through pressure-dependent gap sealing and high-precision manufacturing technology.

Rexrothinternal gear pumps provide needs-based volume flows in a broad speed range with a high degree of efficiency, thus making an important contribution to saving energy.

Its low moment of inertia allows dynamic drives to be created. Variable-speed drives with internal gear pumps are the low-noise alternatives to conventional variable displacement pump systems.

In axial piston variable pumps, the flow is proportional to the drive speed and the displacement. The flow can be steplessly changed by adjusting the swivel angle. Axial piston variable pumps are available for hydrostatic drives in open and closed circuits.

Bosch Hydraulic Pump catalog Bosch Hydraulic Pump manual Bosch Hydraulic Pump manufacturer Bosch Hydraulic Pump repair Bosch Hydraulic Pump seal kit Bosch Hydraulic Pump s uk Bosch Rexroth electro Hydraulic Pump Bosch Rexroth Hydraulic gear Pump Bosch Rexroth Hydraulic piston Pump Bosch Rexroth Hydraulic Pump Bosch Rexroth Hydraulic Pump efficiency Bosch Rexroth Hydraulic Pump repair Bosch Rexroth Hydraulic vane Pump s Bosch Rexroth variable displacement Hydraulic Pump eckerle Rexroth Hydraulic Pump high pressure Hydraulic Pump Rexroth Hydraulic Pump not Pump ing oil Hydraulic Pump Rexroth pricemannesmann Rexroth Hydraulic Pump Rexroth 7930 Hydraulic Pump pdf Rexroth a10 Hydraulic Pump Rexroth closed loop Hydraulic Pump Rexroth electro Hydraulic Pump Rexroth gear Pump catalogue pdf Rexroth gear Pump f002 Rexroth gear Pump india Rexroth gear Pump manufacturer india Rexroth gear Pump mnr Rexroth gear Pump mnr 0510 Rexroth germany Hydraulic Pump Rexroth Hydraulic axial piston Pump Rexroth Hydraulic gear Pump Rexroth Hydraulic gear Pump pdf Rexroth Hydraulic hand Pump Rexroth Hydraulic motor catalogue pdf Rexroth Hydraulic motor with brake Rexroth Hydraulic piston Pump Rexroth Hydraulic Pump Rexroth Hydraulic Pump 7878 specs Rexroth Hydraulic Pump a10v Rexroth Hydraulic Pump a10vo series user manual Rexroth Hydraulic Pump a10vso Rexroth Hydraulic Pump a10vso series user manual Rexroth Hydraulic Pump a10vso140 Rexroth Hydraulic Pump a11vo Rexroth Hydraulic Pump a4vg125 Rexroth Hydraulic Pump a4vg71 Rexroth Hydraulic Pump aa10vso Rexroth Hydraulic Pump adjustment Rexroth Hydraulic Pump assembly Rexroth Hydraulic Pump authorised dealer in india Rexroth Hydraulic Pump catalog Rexroth Hydraulic Pump china Rexroth Hydraulic Pump compensator Rexroth Hydraulic Pump control Rexroth Hydraulic Pump cost Rexroth Hydraulic Pump coupling Rexroth Hydraulic Pump d-72160 horb Rexroth Hydraulic Pump d-89275 Rexroth Hydraulic Pump dealer Rexroth Hydraulic Pump dealers in ahmedabad Rexroth Hydraulic Pump dealers in bangalore Rexroth Hydraulic Pump dealers in chennai Rexroth Hydraulic Pump dealers in delhi Rexroth Hydraulic Pump dealers in hyderabad Rexroth Hydraulic Pump dealers in india Rexroth Hydraulic Pump dealers in mumbai Rexroth Hydraulic Pump dealers in pune Rexroth Hydraulic Pump dealers kolkata Rexroth Hydraulic Pump distributors Rexroth Hydraulic Pump Rexroth Hydraulic Pump in uae Rexroth Hydraulic Pump india Rexroth Hydraulic Pump installation Rexroth Hydraulic Pump ireland Rexroth Hydraulic Pump Malaysia Rexroth Hydraulic Pump manual Rexroth Hydraulic Pump manufacturers Rexroth Hydraulic Pump near me Rexroth Hydraulic Pump parts Rexroth Hydraulic Pump pdf Rexroth Hydraulic Pump ppt Rexroth Hydraulic Pump pressure adjustment Rexroth Hydraulic Pump price Rexroth Hydraulic Pump price list Rexroth Hydraulic Pump problems Rexroth Hydraulic Pump pv7 Rexroth Hydraulic Pump Qatar Rexroth Hydraulic Pump rebuild Rexroth Hydraulic Pump rebuild kit Rexroth Hydraulic Pump relief valve Rexroth Hydraulic Pump repair Rexroth Hydraulic Pump repair manual Rexroth Hydraulic Pump rotation direction Rexroth Hydraulic Pump schematic Rexroth Hydraulic Pump seal kit Rexroth Hydraulic Pump service center Rexroth Hydraulic Pump service manual Rexroth Hydraulic Pump Singapore Rexroth Hydraulic Pump spare parts Rexroth Hydraulic Pump spares Rexroth Hydraulic Pump specifications Rexroth Hydraulic Pump suppliers Rexroth Hydraulic Pump swash plate Rexroth Hydraulic Pump turkey Rexroth Hydraulic Pump working principle Rexroth Hydraulic Pump s Edmonton Rexroth Hydraulic tandem Pump Rexroth Hydraulic valve parts Rexroth Hydraulic valve price Rexroth Hydraulic vane Pump Rexroth Hydraulic wheel motor Rexroth sigma Hydraulic gear Pump Rexroth variable displacement Hydraulic Pump types of Rexroth Hydraulic Pump uchida Rexroth Hydraulic Pump used Rexroth Hydraulic Pump for sale.

Do you need to fix your Bosch Rexroth A2FO Series 6x hydraulic pump? Or buy a new one? We are an independent Bosch Rexroth service center, and we specialize in repairing and remanufacturing A2FO Series 6x pumps.

Things like restrictions and blockages can impede the flow of fluid to your pump. which could contribute to poor fluid flow. Air leak in suction line. Air present in the pump at startup. Insufficient supply of oil in pump. Clogged or dirty fluid filters. Clogged inlet lines or hoses. Blocked reservoir breather vent. Low oil in the reservoir

Now that we’ve ensured that the directional control is not reversed, it’s time to check that the drive motor itself is turning in the right direction. Sometimes incorrect installation leads to mismatched pipe routings between control valves and motors, which can reverse the direction of flow. Check to see that the motor is turning the pump in the right direction and if not - look at your piping.

Check to ensure that your pump drive motor is turning over and is developing the required speed and torque. In some cases, misalignment can cause binding of the drive shaft, which can prevent the motor from turning. If this is the case, correct the misalignment and inspect the motor for damage. If required, overhaul or replace motor.

Check to ensure the pump to motor coupling is undamaged. A sheared pump coupling is an obvious cause of failure, however the location of some pumps within hydraulic systems makes this difficult to check so it may go overlooked

It is possible that the entire flow could be passing over the relief valve, preventing the pressure from developing. Check that the relief valve is adjusted properly for the pump specifications and the application.

Seized bearings, or pump shafts and other internal damage may prevent the pump from operating all together. If everything else checks out, uncouple the pump and motor and check to see that the pump shaft is able to turn. If not, overhaul or replace the pump.

If your pump is having problems developing sufficient power, following this checklist will help you to pinpoint the problem. In some cases you may find a simple solution is the answer. If your pump is exhibiting any other issues such as noise problems, heat problems or flow problems, you may need to do some more investigation to address the root cause of your pump problem. To help, we’ve created a downloadable troubleshooting guide containing more information about each of these issues. So that you can keep your system up and running and avoid unplanned downtime. Download it here.

8613371530291

8613371530291