rexroth hydraulic pump service center factory

The availability of spare parts, repairs and technical support is guaranteed as standard, not only for all products in the current portfolio, but also for a period of at least 10 years beyond the active sales phase. After that, Bosch Rexroth experts supports with services in an extended service phase.

In many cases, this enables machine running times of more than 25 years to be achieved and secured with service agreements. The extensive service network in 80 countries with over 200 locations ensures short distances.

Our specialist for spare parts and our online shop helps to identify fast and reliable the right spare part. We deliver them all over the world. That makes maintenance and repairs fast and easy to plan. Rexroth original parts are always made to the latest design version in hard and software to let you get the most recent technology.

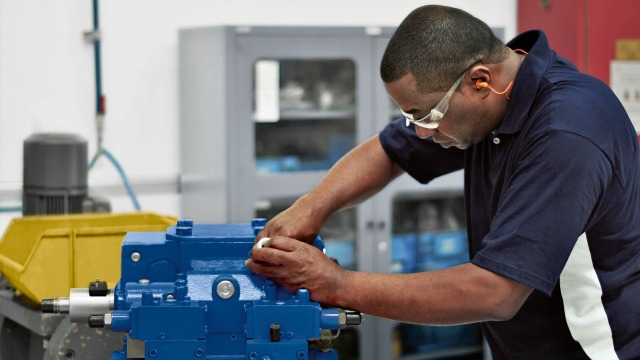

Fast and reliable repair instead of expensive replacement – Thanks to a fast repair the machine and production can continue to run. Broken drives and controls or wear parts do not always need to be replaced: using Rexroth technology allows us often to refurbish your components fast and cost effective to be as new. The parts are repaired and tested in modern Rexroth service centers using original manufacturer specifications using exclusively original parts.

All centers are ISO9001 certified. They offer unified quality standards and full warranty for repaired parts. For urgent repairs our specially trained technicians bring the components fast and cost effective back to function. We repair, inspect and refurbish nearly every Rexroth component of your drive system.

Get like-new performance from your hydraulic equipment when you count on our expert Houston Technology Center. Created to serve industrial and mobile hydraulics users across the West and Southwest, it is the region"s premier resource for the swift repair and service of Rexroth axial piston pumps & motors, Rineer motors, large hydraulic cylinders and Hägglunds radial piston motors.

All Bosch Rexroth Service Facilities are fully certified from our lead plants to carry out repairs and warranty service on Rexroth hydraulic equipment. No other service or repair shop can deliver the expert analysis, preventive maintenance and repair services available only from Bosch Rexroth Certified Service Centers.

Only trained experts using the right equipment can bring back "like new" performance. Contact us so together we can address your unique needs with our expert service and applications engineering personnel. Get started today:

Are you looking for a replacement or rebuild of your Bosch Rexroth hydraulic pump? Get in touch with us today. We are an independent Bosch Rexroth repair center and we specialize in Bosch Rexroth pump repair and rebuilds.

We provide fast, reliable hydraulic pump repair service on all Bosch Rexroth models. We only use genuine OEM parts for our repair work, so you know that you won’t get gray-market or counterfeit parts.

Our team of skilled technicians will give your pump the attention it needs, and put it through our detailed inspection and repair process. Once the pump has been reassembled, we’ll test it thoroughly with our state-of-the-art test equipment. When you get it back, it will meet or exceed factory specs.

When you work with us, we think that you will keep coming back to us for all of your Bosch Rexroth hydraulic repair needs, including Bosch Rexroth hydraulic motors and genuine replacement parts for Caterpillar, John Deere, Case New Holland, and Volvo.

The list below includes numbers that we have worked on in the past. If you don’t see your model number listed, just let us know. We service every hydraulic pump available from Bosch Rexroth.

We can send our field technicians to your location for on-site Bosch Rexroth hydraulic pump repair. We can help get your pump back up and running as soon as possible. Our reliable, experienced team can perform diagnostic services and minor repairs for equipment and machinery used in many industries. Our team can travel throughout the United States and many international locations, including North America and South America.

The commitment to the quality of products and services has a long tradition within Bosch, and the company has implemented a process-oriented quality management system that helps the entire organization to continuously improve. Bosch Rexroth makes hydraulic pumps for a wide variety of mechanical industries. Bosch Rexroth makes pumps for everything from automotive applications to power generation and more. Their pumps produce force with uniformity at a low cost. The concept of “Quality first – first in mind, first in action” drives Rexroth to keep itself at the head of the competition. This strengthens Rexroth in the growing machine and plant construction environment.

Don’t see your Bosch Rexroth hydraulic pump model number? Not a problem. Call 800-800-6971 or send us an email. Chances are we’ve worked on it before and have parts for it, even if it’s not listed on our website.

If you"re in need of Bosch Rexroth repair and hydraulic service, look no further than Dover Hydraulics. We offer pump repair, parts and new units to keep your equipment humming. We can meet all of your needs for Rexroth repair. That includes reconditioning, parts and service, and warranty work on all hydraulics.

Your Rexroth pumps and motors are in expert hands with Dover Hydraulics. The skillful technicians at Dover Hydraulics are seasoned professionals when it comes to servicing the complete Rexroth product portfolio. Your hard-working hydraulic equipment will be returned to you performing like new and ready to provide hours and hours of reliable service.

Our experienced team of hydraulic repair specialists is second to none in the market. No matter the application or industry, they are masters when it comes to Rexroth repair and equipment service. The technicians at Dover Hydraulics will keep your pumps, motors, servo and proportional valves in top working condition.

TESTING - Dover Hydraulics excels at testing even the largest pumps in service. We"ll take on full-flow pumps and units with up to 730 horsepower. We have the industry"s most comprehensive testing and calibration equipment as well as control testing capabilities.

DIAGNOSTICS - Hydraulic pump and motor breakdowns will be thoroughly examined and diagnosed by the professionals at Dover Hydraulics. We then provide hydraulic engineering solutions that address the root cause of the breakdown.

JOB TRACKING - We know the status of your job at all times with our industry-leading Automated Tracking System. Each job at Dover Hydraulics is tracked so we know where your Rexroth unit is in our facility and who is performing the work. A meticulous service history is also maintained that tells us the work that"s been performed previously in our shops.

Reach one of our authorized Rexroth repair specialists or parts representatives by calling us toll free at 800-394-1617. Or click here to reach us through the web.

Your Rexroth hydraulic pumps or other electronic equipment is great when it’s functioning at its best, and you’ve probably come to rely on it. That’s why if any of it breaks down, it could be disastrous.

You’ll have to make a decision about whether to try to replace your equipment or repair it. Knowing about Global Electronic Services and our Rexroth hydraulic repair services should make the decision a little easier.

You can save a significant amount of money by letting Global Electronic Services handle your Rexroth pump repair services or other electronics repair needs rather than buying new equipment.

Our factory-trained professional repair technicians understand Rexroth hydraulic pumps, so you can send us your repair job without concern. And because we know how important your peace of mind is on these matters, you’ll also appreciate our 18-Month In-Service Warranty on your repair.

We know that when your Rexroth hydraulic pumps or other electronics are out of commission, there’s no time to lose. That’s why you should know that our work is not only high-quality, but it’s also fast. We do most jobs within five days. If it’s a rush job, we can get that down to one to two, so you’ll be back up and running as soon as possible.

Quality, price and service are how Global Electronic Services provides the best value to you for your Rexroth electronics repair. If you want to talk about it more, call us anytime. We have a 24/7 customer support line, so we’re always in communication about your repair.

Womack is pleased to announce the expansion of our repair and service capabilities, building on over twenty years of service and repair experience out of our Mountain Region. Our new facility, located in Dallas, Texas, will also become the first ever Rexroth Industrial Hydraulic Authorized Repair and Service Center (ARSC).

For Bosch Rexroth units, we compare performance data of the repaired unit with the original data from the unit when it was manufactured to ensure the pumps and motors we service are as good as new. All other manufacturers are repaired to new condition based on catalog performance data.

Possessing extensive expertise in manufacturing and repairing hydraulic components, Panagon Systems is your best source for Rexroth pump repair and replacement services.

Rexroth A10V series pumps offer a wide range of uses and applications. The A10 comes in several sizes and with its load-sensing hydraulic circuits, it delivers better fuel economy and operational efficiency. Rexroth’s A10V series pumps have a maximum operating pressure of 4,000 PSI with displacement at 1,800 RPM. Their flexible and compact designs also made them cost-effective and easy to integrate into many kinds of systems: tractors, forklifts, mobile machines, commercial vehicles and more.

Naturally, continued regular use of a hydraulic pump creates wear and tear. Though they’re high-quality and reliable, Rexroth pumps can also develop faults or completely fail for several reasons. Hydraulic fluid contamination is usually at the top of the list, and it can occur when unwanted debris ends up in the fluid. Another typical cause is over-pressurization, which happens when the pump undergoes more pressure than recommended by its specs. Over-pressurization wears out the pump more rapidly and leads to failure sooner than expected. Depending on your production or operation environment, other types of faults are possible:Excess heat from the operational environment

As you may already know, many manufacturers such as Rexroth, Vickers, Caterpillar and Denison often phase out their hydraulic pumps and associated components. When you’ve come to depend on a particular pump model in your operations, this obsoletion can cause some major problems.

Bosch Rexroth typically promises that spare parts for specific pump models will be available for 10 years. Even so, obsolete Rexroth hydraulic pump parts can be difficult to track down. Depending on the model of pump that you use, they can also cost quite a bit to acquire. Rebuilds can also be expensive and take a lot of time to complete.

Panagon Systems can also supply minor components such as seals and bolts, delivering durability and dependability like the OEM editions. You enjoy the power and efficiency you rely on to fuel your operations and deliver the value, convenience and service that your customers expect.

We cover our pumps with a competitive limited warranty, ensuring that they contain no defects in materials and workmanship. Our limited warranty spans 18 months from your original invoice date for new items, and 12 months for repaired or remanufactured items.

Damage sustained by Rexroth Pumps can result in decreased efficiency, which may jeopardize your business’s reputation. While repairs may be possible using Rexroth hydraulic pump parts, we believe replacement is the best option in many cases, especially for older, obsolete items. In terms of specs, our replacement pumps have a maximum operating pressure of 4,000 psi. Product models include A10V10, A10V28, A10V45, A10V71, A10V100, A10V140, and A10VSO.

A replacement has much to offer, as illustrated here:Multiple Applications –Our A10 piston pumps are designed to suit multiple applications to suit the varied needs of our customers. They can be used in a variety of equipment, such as forklifts, tractors, commercial vehicles, and mobile machinery like cranes, riding mowers, snowplows, etc. The Rexroth A10VSO can also be used within industrial environments thanks to its rugged durability.

Reduced Fuel Consumption –Keeping fuel costs manageable is an essential aspect of business success. With our pumps, you can look forward to decreased fuel use due to enhanced fuel-efficiency. In fact, we’ve designed these pumps to operate at peak efficiency at all times, regardless of the application it’s being used for.

Improved Productivity –Lengthy downtime is a disaster for any business, especially when you’re trying to meet a tight deadline. Our pumps ensure extended operation. And thanks to our manufacturing process, our pumps can be used to replace all types of models, including those considered obsolete in design.

We want our customers to rest assured of their purchase long after it’s taken place. That’s why we offer a limited warranty on our equipment so our customers have access to quality equipment that best suits their needs. If you purchase a new item, your warranty will be good for 18 months from the date the invoice is created. When it comes to remanufactured or repair pumps, the warranty is good for one full year.

For almost 25 years, businesses in many industries have depended on Panagon Systems for hydraulic parts supply and repair. We specialize in producing current components, but we also manufacture OEM-grade replacement pumps, motors and transmissions for obsolete models by Vickers, Denison, Rexroth, Caterpillar and other makers. No matter what you need, count on Panagon to keep your operations up and running. Tell us about your company’s needs by completing our online contact form or calling us at (586) 786-3920.

CJ Plant are one of the UK’s leading hydraulic repair specialists who specialise in the repair of all major brands of machinery/ OEMs. We are a well-established company with years of experience in all aspects of hydraulic repairs to hydraulic pumps, motors, final drives, swing reduction units, control valve blocks etc. We believe we offer one of the most complete and cost-effective services in the country to deal with all your maintenance and repair needs in one place and place us far ahead of our competitors. Savings of up to 50% compared to main dealer prices are not uncommon for our customers. We deal daily with customers not only from the UK but from all over the world and offer a quick and professional solution which can be broken down into nine key points:

To ensure our customers receive the optimum performance from their equipment on its return we have invested in custom built hydraulic testing equipment unique to our facility to be certain we deliver the best results. This means our hydraulic testing can be performed at various speeds and pressures to simulate the actual working conditions the part will be subjected to when working in line with OEM standards. All fluids used are filtered to ensure purity and prevent any contamination at the last stage.

Our large network of parts suppliers means that not only can we provide repairs in the shortest time possible but the range of spares we carry means we can also supply these when needed for jobs the customer can complete on their own. When repair is not possible, we can also supply a range of reconditioned and new unit. We can also offer a service exchange programme when necessary and all the products we supply are fully OEM tested.

At CJ Plant we pride ourselves not just on the speed and quality of our work but on the standard of service we provide to all customers, regardless of location, size of order or complexity of their request. Our friendly, professional staff make it their business to help satisfy all our customers’ needs and requirements and would be happy to answer any enquiries. Please call and speak to one of our Hydraulic Repair Services today.

Every hydraulic pump you send in for repair goes through our rigorous inspection process. We perform a detailed cleaning and inspection before rebuilding your unit with precision machined parts. Upon completion of the rebuild, we dynamically test your unit thoroughly to ensure its level of OEM efficiency has been met or exceeded. All rebuilt hydraulic pumps pass tough quality checks before leaving our ISO 9001:2015 Quality Management compliant repair facility.

Years of wear and tear can render your Rexroth pneumatic and hydraulic cylinders, pumps, or motors useless. This not only hampers your normal course of operations, but also results in costly downtime. When you need performance stability even in the most demanding applications, Motor & Gear Engineering, Inc. is your partner of choice.

Our hydraulic cylinder specialists have more than 40 years of combined experience in repairing and remanufacturing Rexroth cylinders. The management team and crew are dedicated to giving our customers the best service available. We can repair your obsolete cylinders or design and build you a custom cylinder.

Rexroth’s complete line of hydraulic pumps serve virtually every industry in manufacturing and technology applications such as railway engineering, chemical process plants, power and environmental engineering, automotive engineering, plastics processing machinery, paper industry, presses, test rigs and simulation systems, marine/offshore engineering, special projects, and civil/water engineering, transportation technology, and machine tools.

Keeping a market expectations mindset and being one of the leading Rexroth hydraulic pump distributors, we carry a wide range of Rexroth Hydraulic pump, motors and spare parts that enable us to supply and repair throughout their entire range.

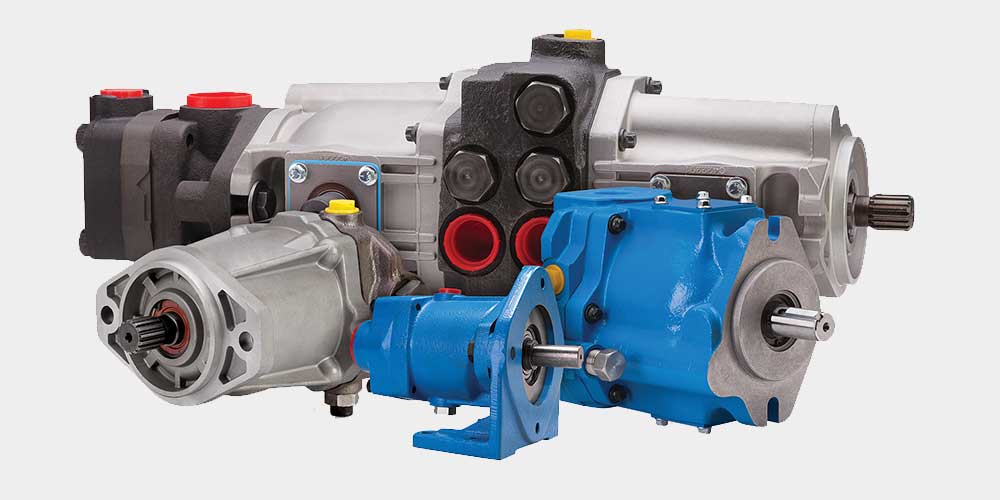

External gear pumps are cost-effective displacement pumps, available in many different versions. Rexroth external gear pumps are built in four frame sizes: Platform B, F, N and G.

Internal gear pumps can be used up to a continuous pressure of 315 bar (depending on the frame size). This pump principle features a compact design with particularly high energy density.

Gerotor pumps are used in the low-pressure range up to 15 bar. They are often used in connection with other Rexroth pumps in cooling, filter or lubrication circuits.

Radial piston pumps are characterized by very high operating pressures of up to 700 bar. The volume flows of the individual pistons can be used for various tasks.

EHP series drive unit for vehicles and material handling systems. Electric motor and pump can be combined according to the required performance, guaranteeing.

8613371530291

8613371530291