roper hydraulic pump quotation

We’ve spent more than a century and a half developing innovative pumping solutions for clients in a wide range of industries. Thousands of our pumps are currently in the field delivering superior performance every day.

Our product line boasts broad capabilities – from the workhorse 3600 and A series to a wide variety of Bulk Liquid Handling, High Pressure, and Severe Duty Pumps. Every Roper Pumps product is backed by expert technical support and customer service dedicated to getting the right pump at an economical price for every application.

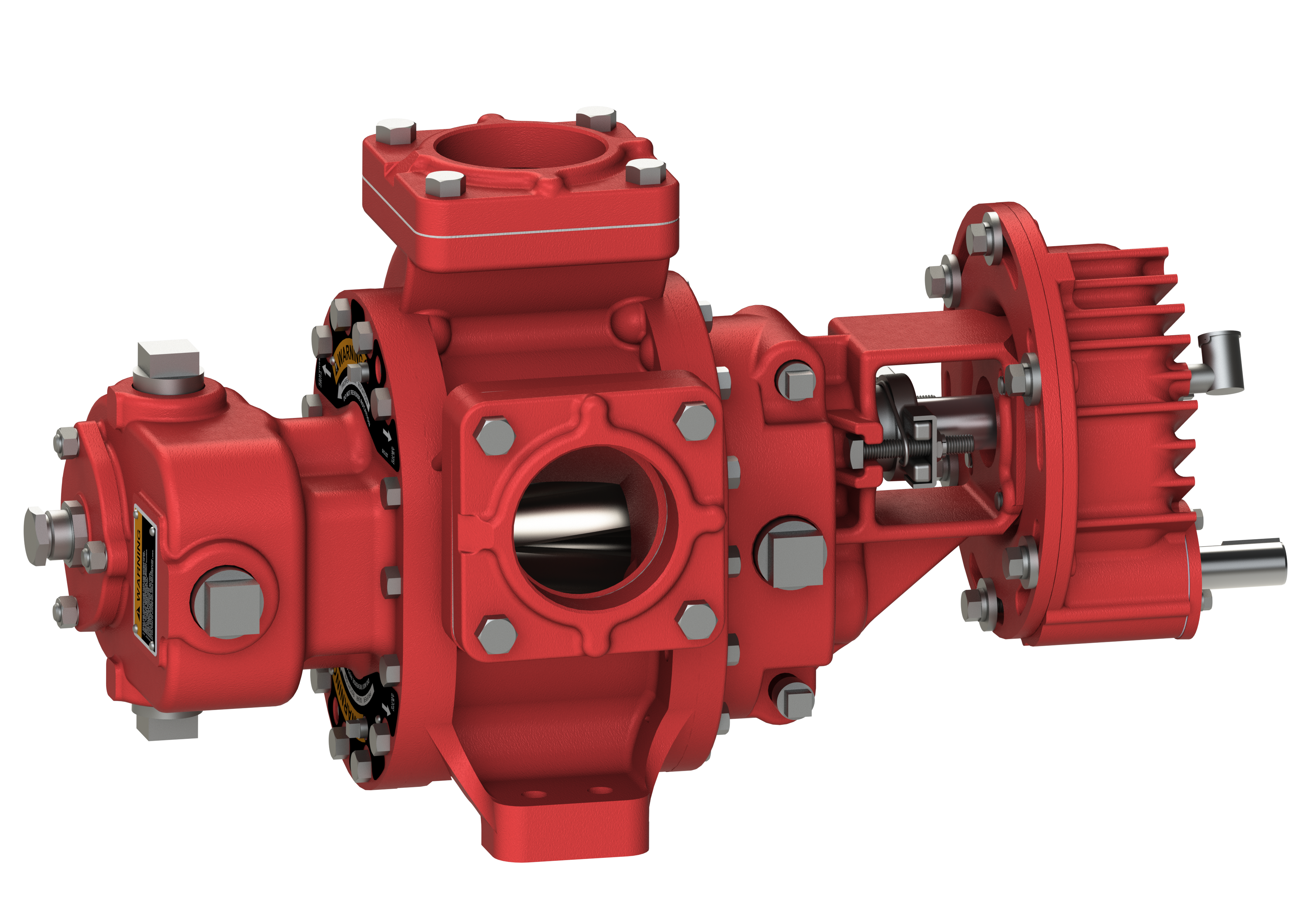

The Roper 3600 series pump has been the industry leader for decades. Rugged, versatile and dependable the 3600 is the gold standard of tank truck pumps. These pumps operate smoothly and with equal ef?ciency in either direction of rotation

The 3600 series is the industry standard for pumping fuel oils and gasoline. They also effectively handle heavy, viscous materials such as asphalt, molasses, roo?ng compounds, and printing inks.

All Pumps listed below come with a built in relief valve and an outboard drive shaft bearing to supports external radial loads and absorb thrust loads.

Roper Pumps are recognized worldwide as a leading provider of innovative fluid handling solutions including external gear pumps & flow dividers and progressing cavity power sections & pumps.

The Roper 2AP21 Series A pump is adaptable to a wide range of applications, pumping clean fluids such as pressure lubrication, hydraulic service, fuel supply or general liquid transfer. The precise manufacturing tolerances provide minimum clearances for maximum pumping efficiency. Typical applications for the 2AP21 include Pressure Lubrication, Hydraulic Service, Fuel Supply and General Transfer. This pump has an internal pressure relief valve with a factory setting that is not the same as the pressure setting required in your application. The relief valve must be positioned as shown in instructions for direction of rotation otherwise the valve will be inoperable, and the discharge pressure will not be working against the relief valve. If the builtin relief valve is used, it is mandatory that the relief valve be set BY THE USER, since maximum relief valve pressure depends upon the viscosity and specific gravity of the liquid, the flow rate pump RPM, and also the initial relief valve setting. A builtin relief valve should not be used on applications where the discharge must be closed for more than a few minutes. Prolonged operation with the relief valve fully bypassing will cause heating of the liquid circulating thru the valve, thus resulting in possible damage. This pump has a packing ring type shaft seal. Operate the pump under normal conditions and, after a short runin period, examine the packing for leakage. If leakage is excessive, stop the pump and follow the procedure described below. A slight leakage is a necessary and normal condition for packing and allows for expansion and proper seating.

Amin corporation is established in 1992 and are engaged in supply of all kinds of NEW and USED marine machinery, equipments and spares removed from largest ship recycling yard of the WORLD ALANG.We supply engine spares, hydraulic motors & pumps, auxiliary machinery & equipments, deck machinery and equipment, deck crane and winches, refrigeration machineries and equipments, steering gear equipments and all miscellaneous items available from the ALANG ship recycling yard.

Rubber gear pump specifically designed for handling liquids with high solid content and abrasives. Often used for oilfield service, hydro-seeding, waste oils, tallow and sludges.

8613371530291

8613371530291