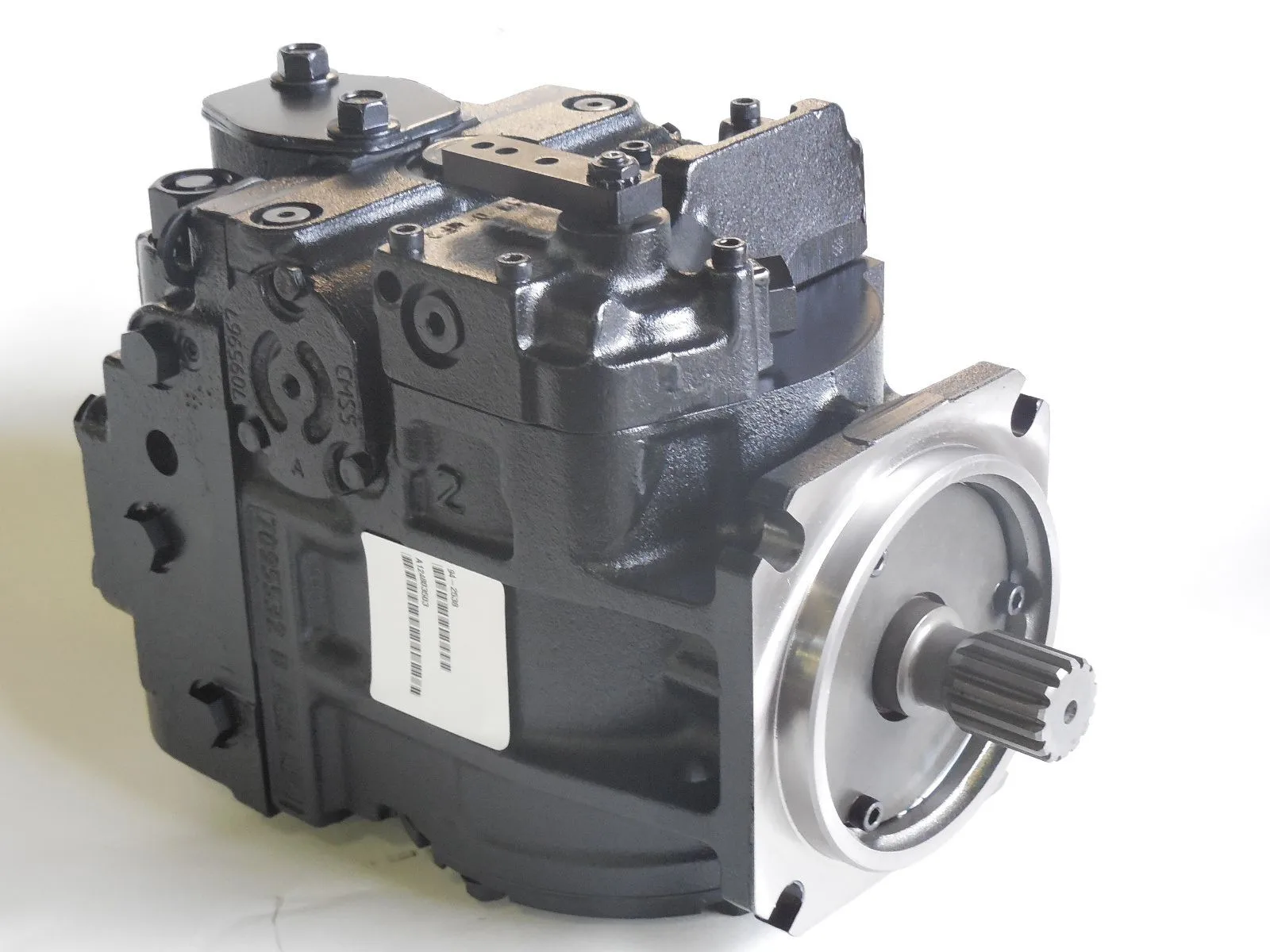

sauer danfoss hydraulic pump series 90 free sample

The Danfoss MP1 is the next evolution in closed circuit axial piston pumps. No matter what industry you serve, MP1 pumps offer the performance needed for today"s small- to medium-sized equipment. Another example of our commitment to the mobile hydraulic industry. You can count on us to do business at your speed. Delivering what you need, when you need it—to propel you forward.

Charge pump .................................................................................................................................................12

Charge pump .................................................................................................................................................56

Sauer Danfoss Hydraulics is one of the largest companies in the mobile hydraulics industry. Danfoss designs, manufactures and sells a range of hydraulic and electronic components and this includes orbital motors, piston pumps and motors, steering components and proportional valves.

Precision Fluid Power repairs and supplies re0manufactured and new Danfoss hydraulics – hydraulics pumps, hydraulics valves, and hydraulics motors. Search our online catalog or contact us and let us know how we can help you.

We can supply what you need or repair what you have. Before purchasing, there may be a good chance that your current hydraulic pump, motor, valve can be repaired. Sauer Danfoss hydraulics pump repairs, including motors, valves comes with our two year warranty.

When purchasing, consider Sauer-Danfoss® (Sauer-Sundstrand) hydraulics remanufactured or after market hydraulic units. Best of all they can get you back up and running for less than the cost of a new hydraulic unit. Get a free quote so you can compare costs for a new, repaired or reman unit.

Our team of trained engineers and technicians have been repairing and remanufacturing Sauer-Danfoss® (Sauer-Sundstrand) pumps and motors for over 40 years. Our technical knowledge, experience and technically advanced manufacturing equipment We specialize in the remanufacturing of nearly every Series in the Sauer-Danfoss/Sundstrand family. All units are fully tested and set to OEM specifications before leaving any of our facilities, and are backed by an industry leading 2 year warranty.

Units we commonly stock in reman or aftermarket are: Series 15, Series 18, Series 20-27, Series 30, Series 40, Series 44 (M46), Series 45, Series 51V, Series 90.

Since the beginning, Danfoss has always been looking for innovative ways to engineer solutions to some of the most complex problems. Danfoss strives to “achieve more with less” in feeding a growing population and allowing everyone to enjoy a better quality of life.

Danfoss is continuously engineering solutions to global challenges such as urbanization and the demand for productive, sustainable growth. Their solutions helped efficiently build, operate and maintain infrastructure. This includes HVACR systems in residential and commercial buildings, shipping, transportation, road construction, and mining, just to name a few. Their technologies help ensure that food is moving through every aspect of the food chain, while being safe, efficient and environmentally-friendly. They are responsible for agricultural equipment, food and beverage manufacturing cool storage and supermarkets.

Danfoss globalization efforts reduce greenhouse gases along with reducing energy consumption of buildings and homes, as well as other applications that use large amounts of energy. Through lower energy use, they are helping reduce emissions and move towards a more environmentally friendly approach.

Mads Clausen founded Danfoss on September 1, 1933 in Denmark then changed the name from the Danish Refrigeration Controls and Apparatus Manufacturer to Danfoss in 1946. They developed their first hydraulic product in 1964. They continued to expand until their merger with Sauer-Sundstrand Hydraulic Pumps, which formed Sauer-Danfoss. Later, in April 2013, the company officially became Danfoss when they brought the remaining shares from Sauer-Sundstrand. Now Danfoss is one of the largest companies in the hydraulics industry.

Danfoss Piston Pumps and Motors come in a wide range of displacements, pressures, shaft and flange combinations and control options and they have the ability to combine multiple units, allowing for comfortable operation and efficient fuel consumption.

H1 Series Pumps and Motors: specially designed for medium and high power needs, the H1 Series feature a functional design that provides more freedom and flexibility. The H1 Series offers higher output speeds and lower input speeds while reducing overall costs. It is available in a variety of displacements and sizes.

Low Power Pumps and Motors: offer reliability, flexibility and easy installation. Their feature high efficiency, low noise levels and the ability to customize interfaces meet any needs!

Medium Power Pumps and Motors: are available in a variety of configurations, displacements and control options. High quality performance, power density, and functionality are guaranteed features of these medium power pumps.

Power Pumps and Motors: offers high power density in a simple, compact design. Their high power series is proven to perform in the toughest situations and they are proven to increase productivity.

Open Circuit Axial Piston Pumps: are available in a wide range of configurations, displacements and control options. They are compatible with many fluid types and a wide range of mounting flanges for easy installation.

Danfoss designed their proportional Valves for the most demanding tasks. They have a range of functions in a compact design so that they, provide smooth, strong and dependable performance. Configure proportional valves in an infinite number of ways so that they fit any need.

Every once in a while I have to confront an opinion that Multi-Function valves from Danfoss series 90 closed-loop pumps are "all the same". There is a big chance that this myth is a local Portuguese phenomenon that emerged due to the lack of technical curiosity on the part of certain dealers, who traditionally give more attention to the commercial side than to the technical details of the product they sell and promote. In this article, I will explain, yet again, the function and principle of operation of these valves, as well as the difference in the dynamic behavior between their types.

The pressure limiter function reduces the pump"s displacement when the high-pressure setting is reached. The function is performed by the tiny poppet, pre-loaded by the adjustable spring (cutaway view). When the system pressure lifts it from its seat, the oil flows directly into the servo-cylinder opposite to the one that is tilting the swashplate, which reduces the effective delta-P of the servo cylinder and de-strokes the pump.

The reason I am putting only the types 1, 2, and 5 here is simple - these three are the only ones I"ve seen pass through our shop. According to the Danfoss parts list for series 90 there are more.

The multi-function valves for series 90 have a simple and compact design, and as a rule last as long as the pump itself. I have seen them shatter and cause a catastrophic pump failure, but it"s not an everyday malfunction. If I could change one thing about these valves - it would definitely be the hexagonal adjusters! I would make them taller and therefore easier to clamp a standard wrench on.

We can supply what you need or repair what you have. Before purchasing, there may be a good chance that your current hydraulic pump, motor, valve or cylinder can be repaired. Danfoss hydraulics pump repairs, including motors, valves & cylinders come with our two-year warranty.

When purchasing, consider Danfoss hydraulics remanufactured or aftermarket hydraulic units. Best of all they can get you back up and running for less than the cost of a new hydraulic unit. We will give you a free quote so you can compare costs for a new, repaired or reman Danfoss unit.

Mads Clausen founded Danfoss on September 1, 1933, in Denmark. The name changed from the Danish Refrigeration Controls and Apparatus Manufacturer to Danfoss in 1946. They developed their first hydraulic product in 1964. Danfoss continued to expand until their merger with Sauer-Sundstrand, which formed Sauer-Danfoss. Later, in April 2013, the company officially became Danfoss, as they brought the remaining shares from Sauer-Sundstrand. Now, Danfoss is one of the largest companies in the hydraulics industry.

Since the beginning, Danfoss has always been looking for innovative ways to engineer solutions to some of the most complex problems. Danfoss Power Solutions strives to “achieve more with less” in feeding a growing population and allowing everyone to enjoy a better quality of life.

Danfoss is continuously engineering solutions to global challenges such as urbanization and the demand for productive, sustainable growth. Their solutions helped efficiently build, operate and maintain the infrastructure which includes HVACR systems in residential and commercial buildings, shipping and transportation, road construction, and mining. Just to name a few. Danfoss technologies help ensure that food is moving through every aspect of the food chain while being safe, efficient and environmentally-friendly. They are responsible for agricultural equipment, food, and beverage manufacturing cool storage and supermarkets.

Danfoss globalization efforts reduce greenhouse gases along with reducing the energy consumption of buildings and homes, as well as other applications that use large amounts of energy. Through lower energy use, they are helping reduce emissions and move towards a more environmentally friendly approach.

Danfoss Piston Pumps and Motors come in a wide range of displacements, pressures, shaft and flange combinations and control options. They have the ability to combine multiple units, allowing for comfortable operation and efficient fuel consumption.

H1 Series Pumps and Motors: specially designed for medium and high power needs, the H1 Series feature a functional design that provides more freedom and flexibility. The H1 Series offers higher output speeds and lower input speeds while reducing overall costs. It is available in a variety of displacements and sizes.

Closed Circuit Low Power Pumps and Motors: offer reliability, flexibility and easy installation and their featured high efficiency, low noise levels and the ability to customize interfaces meet any needs!

The Closed Circuit Medium Power Pumps and Motors are available in a variety of configurations, displacements and control options and high-quality performance, power density, and functionality are guaranteed features of these medium power pumps.

Closed Circuit High Power Pumps and Motors offers high power density in a simple, compact design. The Danfoss high power series is proven to perform in the toughest situations and increase productivity.

Open Circuit Axial Piston Pumps: are available in a wide range of configurations, displacements and control options. They are compatible with many fluid types and a wide range of mounting flanges for easy installation.

The Danfoss Proportional Valves are designed for the most demanding tasks. Danfoss designed their proportional valves with a range of functions in a compact design, providing smooth, strong and dependable performance. Configure proportional valves in an infinite number of ways so that they fit any need.

259 sauer danfoss hydraulic pump 90 series products are offered for sale by suppliers on Alibaba.comAbout 80% % of these are hydraulic pumps, 5%% are construction machinery parts, and 1%% are other hydraulic parts.

A wide variety of sauer danfoss hydraulic pump 90 series options are available to you, You can also choose from piston pump, gear pump sauer danfoss hydraulic pump 90 series,as well as from 1 year, 6 months, and 1.5 years sauer danfoss hydraulic pump 90 series,And whether sauer danfoss hydraulic pump 90 series is fittings, {2}, or {3}.

Series 90 Axial Piston Pumps, Technical Information, Revisions, History of Revisions, Table of Revisions, Changed, Correct Shaft Torque Rating Information, Corrections to Nut Torque for Tapered Shaft, Edits to the Specifications, And Model Code, Other Edits, Minor Edits and Dimension Changes, Series 90 Family of Pumps and Motors, Series 90 – Advanced Technology, Seven Sizes of Variable Displacement Pumps, Proven Reliability and Performance, Compact, Lightweight, Worldwide Sales and Service, Series 90 Variable Displacement Pumps, Series 90 Motors, PLUS+1 Compliant Controls and Sensors, Design, Series 90 Pump Cross-Section, Slider Block, Servo Piston, Piston, Servo Arm, Slipper, Displacement Control, Bushing, Cylinder Block, Cradle Bearing, Valve Plate, Roller Bearing, Rear Bushing, Input Shaft, Charge Pump, SwashPlate, Cradle Guide, Typical Name Plate, Model Code, Serial Number, Place of Manufacture, Control Handle, Displacement Control Valve, Reservoir, Vacuum Gauge, Purge Relief Valve, Fixed Displacement Motor, Pump SwashPlate, Servo Control Cylinder, Loop Flushing Valve, Motor SwashPlate, System Schematic, General Specifications, Direction of Rotation, Pipe Connections, Recommended Installation Position, Features and Options, Feature, Flow at Rated Speed, Torque at Maximum, Mass Moment of Inertia of Rotating Components, Weight, Rotation, Main Ports, Main Port Configuration, Case Drain Ports, Other Ports, Shafts, Operating Parameters, Parameter, Input Speed, Minimum, Rated Speed, Operating Parameters, Fluid Specifications, Feature, Viscosity, Temperature Range, Filtration (Recommended Minimum), Overview, Input Speed, Minimum Speed, Rated Speed, Maximum Speed, Independent Braking System, System Pressure, System Pressure, Application Pressure, Maximum Working Pressure, System Pressure (Continued), Minimum Low Loop Pressure, Servo Pressure, Charge Pressure, Minimum Charge Pressure, Maximum Charge Pressure, Minimum Charge Inlet Pressure, Maximum Charge Pump Inlet Pressure, Case Pressure, Rated Case Pressure, Auxiliary Pad Mounted Pumps, External Shaft Seal Pressure, Temperature and Viscosity, Temperature, Maximum Intermittent Temperature, Minimum Temperature, Viscosity, Recommended Range, Filtration System, System Design Parameters, Filtration Options, Charge Pressure Filtration (Partial Charge Pump Flow), Technical Data According to ISO 16889, Remote Charge Pressure Filtration, Charge Pressure Filtration, Screen, Hydraulic Fluid Reservoir, Charge Pump, To Pump Case, Fluid Selection, Reservoir, Case Drain, Pump Life, Charge Pump, Charge Pump Sizing, Selection, Continuous Operation at Low Input Speeds, High Shock Loading, High Flushing Flow Requirements, Multiple Low Speed High Torque Motors, High Input Shaft Speeds, Bearing Loads and Life, Applications with External Shaft Loads, Understanding and Minimizing System Noise, Fluid-Borne Noise, Structure Born Noise, Sizing Equations, Mounting Flange Loads, Overhung Load Example, Series 90 Master Model Code, Type and Rotation, Controls, High Pressure Regulation, Auxiliary Mounting Pad, End Cap Ports, Filtration, Displacement Limitation, Shaft Options, Charging System, Series 90 Master Model Code, High Pressure Setting A, High Pressure Setting B, Charge Pressure Setting, Solenoid Connector, Pump Displacement VS. Electrical Signal, Solenoid Data, Response Time, Control Options, Electric Displacement Control (EDC), Options KA, KP, KT, Features and Benefits, Electric Displacement Control Schematic, Cross-Section, Control Options, Electric Displacement Control (EDC) (Continued), Electrical Characteristics, Control Signal Requirements, MS Connector, Deutsch DT Series Connector, Control Options, Response Time, Pump Output Flow Direction VS. Control Current, EDC Using a Dual Coil in Series, Manual Over Ride (MOR), EDC Pilot Stage (PCP), EDC Second Stage, Unintended MOR Operation Will Cause the Pump to Go Into Stroke, Control Options, Hydraulic Displacement Control (HDC), Option HF, Features and Benefits of the Hydraulic Displacement Control, Pump Returns to Neutral, Hydraulic Displacement Control Schematic, Cross-Section, Manual Displacement Control (MDC), Options Ma, MB, Features and Benefits of the Manual Displacement Control, Manual Displacement Control Schematic, Cross-Section, External Control Handle Requirements, MDC Handle Rotation Parameters, MDC with Neutral Start Switch (NSS), Non Feedback Proportional Electric Control (NFPE), Input Signal Requirements, Multi-Function Valves, Overpressure Protection, Pressure Limiting Function, To Control, Servo Piston, Bypass Hex Adjustment, Servo Piston, Multifunction Valve, Bypass Function, Auxiliary Mounting Pads, Mating Pump Requirements, Auxiliary Pump Mounting Flange and Shaft, Auxiliary Pump Dimensions, Displacement Limiter, Displacement Limiter Location, Shaft Torque, Shaft Torque and Spline Lubrication, Shaft Torque for Tapered Shafts, Shaft Availability and Torque Ratings, Charge Pump, Charge Pump Output Flow, Charge Pump Power Requirements, Features and Options, Speed Sensor, Electrical and Environmental Data, Electrical, Supply Voltage, Maximum Operating Current, Required Current, Output Voltage in Low State, Maximum Frequency, Peak Reverse Voltage, Operating and Storage Temperature, Features and Options, Connector Pin Assignments, Ground, Installation Drawings, Manual Displacement Control (MDC), Frame Size 055, Auxiliary Mounting Pad – Options AB, BC, CD, BB, Shaft Dimensions, Frame Size 075, Manual Displacement Control Handle Dimensions, Frame Size 075 NFPE Options FK, FL, FM, FN, Multifunction Valve, System Pressure, Coupling Must not Protrude Beyond this Surface, Shaft Dimensions, Control MDC, Option Ma, Manual Displacement Control Handle Dimensions, Frame Size 100, Undercut Diameter, Full Spline, Major Diameter, Pitch Diameter, Length, Pressure Angle, Frame Size 130, Frame Size 180, Frame Size 250, Cover Plate, 3-POSITION (F-N-R) Electric Control, Dimensions, Electric Displacement Control (EDC) with MS-Connector or Packard Connector, Hydraulic Displacement Control (HDC), Manual Displacement Control (MDC) with Neutral Start Switch, Electro hydraulic Displacement Control (NFPE) (Except 075 NFPE), Integral Pressure Filter, Remote Pressure – Without Filter…Pages: 88

Contenido:Manual for Sauer Danfoss Series 90 Axial Piston Pumps – Technical Information, Description, Specifications, Operating Parameters, System Design Parameters, Master Model Code, Control Options, Features, Options & Installation Drawings – Information

MANUAL – SAUER DANFOSS SERIES – AXIAL PISTON PUMPS – TECHNICAL INFORMATION – DESCRIPTION – SPECIFICATIONS – OPERATING PARAMETERS – SYSTEM DESIGN PARAMETERS – MASTER MODEL CODE – CONTROL OPTIONS – FEATURES – OPTIONS – INSTALLATION DRAWINGS Tags: manual, manuals, learning, books, instructions, file, book, document, free, instructionals, downloading, data, instructors, infos, learn, free, information, download, sauers, danfosses, series, axials, pistons, pumps, technicals, informations, descriptions, specifications, operating, parameters, systems, designs, parameters, masters, models, codes, controls, options, features, options, installations, drawings, learning, downloads

Danfoss pumps for intelligent vehicle management systems – delivering reduced fuel consumption and emissions while providing power and high operator comfort…

As one of the largest companies in the mobile hydraulics industry, Danfoss Power Solutions (re-branded from Sauer Danfoss in 2013) designs and manufactures a comprehensive range of engineered hydraulic and electronic components including: hydrostatic transmissions, mobile electronics, orbital motors, piston pumps and motors, steering components and PVG proportional valves:

With capacities up to 250cc/rev and pressures up to 480 bar, the range of Danfoss pumps offers: open and closed loop piston pumps, a choice of variable and fixed displacement, various control options including pressure compensated and load sensed, numerous shaft and flange combinations and the ability to combine multiple units… and not forgetting the reduced fuel consumption and high operator comfort.

Intended for high and medium power applications, H1 Danfoss pumps provide: greater output and decreased input speeds, lower complete installation costs across the pump lifecycle and common design technologies and assembly techniques. They provide straightforward, high performance designs with less components than former hydrostatic products. Being compact, these Danfoss pumps also give engineers more freedom and flexibility in hydraulic system design.

Today’s vehicles need more effective systems that maximize the use of available engine power. To improve overall efficiency, H1 Danfoss pumps are designed to reduce rotating group, control and charge pump losses, which helps save fuel, frees power for other vehicle functions and enhances operating performance and productivity. Danfoss H1 axial piston pumps are available in the following sizes: 045 / 053 (single), 045 / 053 (tandem), 060 / 068 (single), 069 / 078 (single), 089 / 100 (single), 115 / 130 (single), 147 / 165 (single), 210 / 250 (single).

Danfoss Series 45 Open Circuit Axial Piston Pumps: The Danfoss Series 45 is a complete family of high performance, variable displacement, axial piston pumps. Each frame (L, K, J, F and E) is made to surpass the tough work function demands of the mobile equipment marketplace and optimise performance. The Series 45 family of open circuit, variable piston pumps, offers a range of displacements from 25 to 147 cm³/rev [1.53 to 8.97 in3/rev]. With maximum speeds up to 3600 rpm and continuous operating pressures up to 310 bar [4495 psi], product selection is tailored to the flow and pressure requirements of individual applications and a variety of load sensing and pressure compensated control system options.

8613371530291

8613371530291