scag tiger cat hydraulic pump rebuild kit free sample

The main enemy of any hydraulic system is heat. By properly sizing the hydraulic oil reservoir, efficient hose routing, and the use of oil coolers and fans where needed, Scag drive systems have been designed to have normal operating temperatures well within the safe range of the hydraulic components using “standard” oil. Using larger oil tanks, oil coolers and fans (where needed) does add additional cost to the manufacturing process, however, we feel that this extra attention to performance, longevity and value is one of the many reasons people decide to “step up” to a Scag mower.

The “requirement” to use synthetic oil in a mower is generally the result of producing a machine with a hydro system that has an operating temperature that can exceed the temperature range of the hydraulic components. These systems usually have very small oil reservoirs located in an area without sufficient airflow (due to limited space on the mower) and do not use oil coolers or fans. This is a less expensive way to manufacture mowers, however, the extra cost of the synthetic oil (synthetic oil is normally four to five times the cost of standard oil) is a burden that you, the customer, will have to pay.

Occasionally customers inquire about switching the hydro oil in their new Scag to synthetic. While there is nothing in the drive system that could be damaged from its use, as outlined above, it is certainly not necessary. We do suggest that they wait until after the initial break-in period before making the switch, if desired.

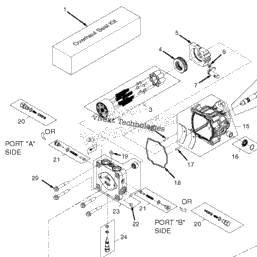

Heavy-duty hydraulic drive system includes dual 12cc Hydro-Gear hydraulic pumps and large capacity Parker wheel motors for reliable, zero turn maneuverability.

Compact mower size enables you to take the Tiger Cat II into tight places. The Tiger Cat II occupies less space on your trailer without sacrificing performance.

12cc hydraulic pumps equipped with cooling fans provide smooth and reliable power. Built in pressure relief valves reduce internal pressure spikes and add to hydraulic component life.

"Split-Steel" pulleys are used on load-carrying areas like the cutter deck spindles and pump drive systems. Split steel pulleys are stronger than cast-iron or stamped pulley designs. Our pulleys are strong for long life and lightweight for reduced inertia and decreased wear on the cutter deck drive system.

No plastic pulleys - Some [other brands] actually use plastic pulleys on their mowers. Not Scag. All Scag pulleys are made from metal. Plastic is for toys.

Multi-point steering dampers are designed and located for smooth operation and minimal fatigue. Mount the dampers in one of three mounting locations for a customized feel.

Operator friendly instrument panellocated just to the left of the operator. It includes Tiger Eye: Advanced On-Board Monitoring System, ignition switch, mower engagement switch, and separate choke and throttle controls.

High quality electrical components such as switches, wiring, sealed fuses and harness looms are used throughout the Scag mower line for dependable service.

There are many productive accessories for the Tiger Cat II like the Tiger Striping kit, the 16 bushel spindle driven grass catcher, the 12 bushel dump-from-the-seat catcher system, and many more.

8613371530291

8613371530291