scag turf tiger hydraulic pump rebuild kit quotation

Scag Seals offer high-quality seals for industrial, commercial, and residential applications. They provide superior sealing performance, superior quality and superior value for money. Their seals are designed for a wide range of applications, from heavy duty industrial equipment to light duty residential applications. They offer a wide range of materials, including rubber, metal, and plastic, to meet the needs of any application. Their seals are designed to provide superior sealing performance and long-lasting reliability. With Scag Seals, you can be sure that your sealing needs are met with the highest quality and reliability.

Genuine Scag Seals are essential for keeping your equipment running at its best. OEM parts ensure your Scag mower, tractor, or other equipment runs at peak performance and lasts for years to come. Genuine Scag Seals are designed to maintain the original performance of your equipment and keep it in top condition. OEM parts are the only way to guarantee your machine is running as intended and provides the necessary protection from wear and tear. Investing in genuine Scag Seals is a wise choice for keeping your equipment running like new.

www.scagpartsonline.com is the best place to purchase scag wheel motor seal kit, scag gearbox seal, and scag turf tiger gearbox seal kit. With one of the largest selections of OEM parts and accessories, you can always find the right parts for your desired scag model. The website also offers the best prices for the very highest quality parts, meaning you get the value for your money. Moreover, the customer service ensures that the process of buying and ordering is hassle-free and timely. The website also offers free technical support if you require any assistance with installation. With our commitment to your satisfaction, www.scagpartsonline.com is your ultimate source for all your scag parts needs.

The envy of the industry, Velocity Plus™ decks deliver an amazing quality-of-cut and a wide, even discharge. This deck is equipped with Scag’s ultra-tough cast-iron spindles featuring tapered roller bearings and a top-mounted grease fitting with a relief valve to prevent over-greasing.

The Turf Tiger™ is ultra-strong and built for long life. It has a wide mower stance and extra-low center of gravity for ultimate stability and a replaceable front caster-wheel weldment.

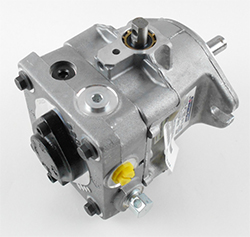

Dual Hydro-Gear pumps (16 cc) and Parker wheel motors (18 ci) deliver dependable power. Pump shock valves ensure reliability and long life. Cooling fans help maintain safe operating temperatures.

Standard-equipment oil cooler extends system life by keeping the hydraulic oil cooler. Cooler location utilizes the engine airflow to draw cool air through the cooling fins.

Depending on the mower model and engine selection, the Tiger Eye™ Advanced Monitoring System monitors a wide variety of systems in real-time, giving you valuable information in just a glance, right from the operator’s seat.

Heavy-duty hydraulic drive system includes dual 16cc Hydro-Gear pumps and Parker wheel motors for reliable, zero turn maneuverability. Hydro-Gear 16cc hydraulic pumps provide smooth, positive and reliable power to the drive wheels. Extra large input bearing, input shaft and internal components add to reliability and performance. Built-in pressure relief valves reduce internal pressure spikes and add to pump life.

Standard equipment auxiliary canister air filter system on all Turf Tiger II"s. This provides increased service intervals and longer engine life. Kohler engines feature removable access panels for easy cleaning of the cooling fins.

Engine radiator is mounted in front of the engine, as the engine manufacturer intended. Having the radiator positioned behind the seat offers extra protection against impacts and foreign material. Hydraulic oil cooler is also mounted in front of the radiator for maximum airflow and heat dissipation.

Extra large 26 x 12 x 12 inch drive tiresand 13 x 6.5 - 6 caster wheels ensure better traction, less turf tearing and easy curb climbing. 52" models feature 26 x 9.5 x 12 drive tires.

No plastic pulleys - Some [other brands] actually use plastic pulleys on their mowers. Not Scag. All Scag pulleys are made from metal. Plastic is for toys.

User-friendly mower design allows quick, clean access to the engine and filters, for easy maintenance. Rear access panel exposes self adjusting PTO, and hydraulic pump drive belts.

There are many, time saving, money making accessories for the Turf Tiger II like the Tiger Striper lawn striping kit, spindle driven grass catchers, halogen light kits and more.

Getting the right transmission or replacement pump can be tricky, so please call us or email us if you have any questions about ordering a large replacement component like this. We would be happy to look up your model and serial number to find the exact replacement part your mower needs. From the filter head to the complete pump assembly, we have every transmission or pump part you could need to fix your mower and keep cutting.

I have watched a couple videos and while it doesn"t look too difficult none of the videos are of my exact pump and don"t cover every aspect in detail.

he took apart the hydraulic pump on a big ass genie type lift or excavator or something, I think...then couldn"t put it back together. so here comes the whole crew of a few construction guys, the owner and mechanic with a pump in a bunch of pieces and a bunch of parts.

it was a big ass 6 piston hydraulic pump. I put the seals on it, and had to hang it from the lift arm while I lifted the housing onto the pistons to get them all in there.

A variable displacement piston pump is a little more challenging than a simple gearrotor pump, but if the exact parts are available it shouldn"t be too big of a deal.

It shouldn"t be to bad. Make sure you have plenty of clean rags available and plenty of bench space to spread your parts out on as you disassemble. If you have a schematic and the correct seal kit it should be a breeze.

There generally aren"t to many tricks or special tools needed. Can you get the specific number off of the pump and look it up on the net and get an assembly breakdown? I wouldn"t even start unless I had that in hand. I am sure many of the ZTR mowers use standard pumps, or worse yet one big drive unit. On one that I worked on, one side ran the hydraulics for the deck lift and the other didn"t so they were slightly different.

There generally aren"t to many tricks or special tools needed. Can you get the specific number off of the pump and look it up on the net and get an assembly breakdown? I wouldn"t even start unless I had that in hand. I am sure many of the ZTR mowers use standard pumps, or worse yet one big drive unit. On one that I worked on, one side ran the hydraulics for the deck lift and the other didn"t so they were slightly different.

My first step would torque the pump assembly bolts to spec. See if any move and if so does the leak stop. Clean the housing up real good and mow the yard to see if new oil shows up. I"d try it before I even unbolted the pump from the mower....if you can get to said bolts. Check the pump housing for cracks. If the pump was over torqued during assembly or took a hit one of the tapped assembly bolt holes could have cracked and fatigued so the bolt has insufficient threads to hold torque.

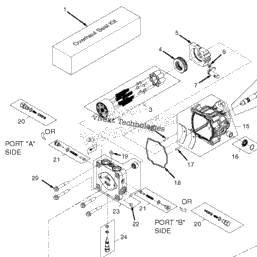

Most likely the failure point is #13 which looks to be a standard shaft oil seal. If you are careful you should be able to get the seal out without dissembling the pump. Often we will drill a small hole in the seal and use a screw in slide hammer to extract it. You can probably find the oil seal at your local Motion Industries for like 5 bucks

If you’re asking how hard it’ll be you probably aren’t experienced enough to do it. Not trying to be use but this is a piston pump and there are quite a few moving parts. Hell I could be wrong but as a dude that’s been repairing hydraulic shit for a long time I’d trust the pro or buy a new pump.

About half of the pumps and cylinders that we get into our shop (mostly high pressure, 10,000 psi) have been "worked on" by the customer before we get them

PLEASE make sure you run the proper hydraulic fluid for the cylinder. I have seen a lot of pumps messed up running "cheap" alternatives to factory oil, it eats seals and bushings in a lot of case.

About half of the pumps and cylinders that we get into our shop (mostly high pressure, 10,000 psi) have been "worked on" by the customer before we get them

PLEASE make sure you run the proper hydraulic fluid for the cylinder. I have seen a lot of pumps messed up running "cheap" alternatives to factory oil, it eats seals and bushings in a lot of case.

View QuoteThe shop I talked to said that 9 times out of 10 it was the O ring. He said that if it was a seal that the pump would likely need to be replaced.

Timely thread. I have a scag turf tiger that is about 12 years old with about 750 hours on it. I replaced the wheel motor on the left side last year because it was leaking. The hydraulics on that side are now weak...it struggles to get up hills, and the other side can easily overpower it if I push the levers all the way forward.

If #13 is the leak just replace it and roll on and see what happens. It could have a piece of trash wrapped around the shaft causing it to leak. No pump disassembly required. Remove the snap ring, drill hole in seal and pull It out, install new one.

#5 is the only one that you should have to disassemble the pump to replace. If any of the other screw in fittings and valves are leaking just remove, replace seal and reinstall.

If you"re asking how hard it"ll be you probably aren"t experienced enough to do it. Not trying to be use but this is a piston pump and there are quite a few moving parts. Hell I could be wrong but as a dude that"s been repairing hydraulic shit for a long time I"d trust the pro or buy a new pump.

View QuoteIf you do have to take the pump apart just make sure everything stays super super clean and protected from any dings or scratches. And don"t force anything, possibly marring it. This is way more important than on something like changing that impeller.

Most likely the failure point is #13 which looks to be a standard shaft oil seal. If you are careful you should be able to get the seal out without dissembling the pump. Often we will drill a small hole in the seal and use a screw in slide hammer to extract it. You can probably find the oil seal at your local Motion Industries for like 5 bucks

If you do have to take the pump apart just make sure everything stays super super cleanand protected from any dings or scratches. And don"t force anything, possibly marring it. This is way more important than on something like changing that impeller.

View QuoteIf it were a gear, vane or gerotor pump I"d tell you to give it hell but a variable piston pump is not where I"d suggest getting your feet wet in hydraulics. There are small parts, things that need to be perfectly lined up and add to that the back plate is under some spring pressure. It makes it hard to tell if you"ve got it going together right. If you screw up putting it back together it may still work just long enough to send shrapnel into every other part of the hydraulic system.

Seriously, after removing the pump, wash the pump exterior absolutely clean before disassembly. Have a clean area prepped to lay out the parts when they are cleaned. The blue shop towels in the box are fairly lint free. I"d also have some crocus cloth handy to polish the seal surfaces on the shaft. Take some hydraulic fluid and mix 1:1 with STP oil additive for build up lube.

Its not hard at all but i have rebuilt a few variable displacement piston pumps. The hardest part is getting the piston and slippers back in. I usually wrap some 550 cord around them to hold them as i install the rotating assembly.

If you have no mechanical experience then a simple error will cause major problems. If it was a gear or vane pump, those are very basic and easy to repair.

If it were a gear, vane or gerotor pump I"d tell you to give it hell but a variable piston pump is not where I"d suggest getting your feet wet in hydraulics. There are small parts, things that need to be perfectly lined up and add to that the back plate is under some spring pressure. It makes it hard to tell if you"ve got it going together right. If you screw up putting it back together it may still work just long enough to send shrapnel into every other part of the hydraulic system.

8613371530291

8613371530291