schematic lippert hydraulic pump diagram quotation

Chalk up one more leaky Lipper pump. I reported last week on another tread that my second pump failed the same as the first. I"ll contact Lipper tomorrow and plead my case again for a new pump. In the mean time I"m disassembling the replacement pump to find the leak. The motor was full of oil but the seal didn"t look bad to me. This time the seal had a "C" keeper holding the seal in place. I don"t think the first pump had this keeper. The replacement lasted about 18 months.

I did replace the seal in the first pump 18 months ago in hopes I"d have a spare. I tried it and it doesn"t work. I must have done something wrong when I reassembled it, or the motor may be bad. I"ll trouble shoot it later.

And so it is with slide room maintenance. Slide rooms were introduced in travel trailers and 5th Wheels as far back as the 1970s and the “Power Slide” was invented and introduced in 1990 by Newmar. Most other companies joined the slide-out craze a few years later with a variety of new mechanisms such as HWH, Power Gear, and others. Since then there have been both hydraulic and electric mechanisms from companies such as Kwikee, RBW Industries, and more recently, Lippert Components Inc (LCI) which has purchased Power Gear, Kwikee, BAL Accu-Slide, and others.

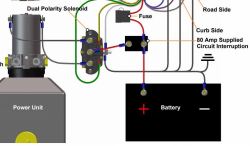

Typically a hydraulic slide-out mechanism uses a pump that that is often shared with the hydraulic leveling jacks if equipped. It has a fluid reservoir and pumps the fluid through the lines and cylinders to move the room in and out. There is little maintenance required of the pump other than making sure the fluid level is checked and topped off with the recommended hydraulic fluid.

Lippert Components Inc (LCI) uses an inner and outer assembly with a drive tube. They also recommend extending and retracting the room twice a month to keep the seals lubricated and to visually inspect all components for debris, dirt build up, and bent parts. If you experience a squeaking noise during operation apply a coat of lightweight oil and wipe off the excess and DO NOT USE GREASE!

Smaller, lightweight rooms use a more inexpensive electric motor, especially models that do not have hydraulic leveling jacks that could utilize the jack motor. Once again there are several options such as the cable slides (BAL Acu-slide), Schwintek with small motors in the sidewall and a gear driven track, or a standard mechanism with an electric motor.

8613371530291

8613371530291