scotch yoke hydraulic pump pricelist

In real life scenarios with critical service valves, there are situations such as the loss of air or loss of power where a valve must be forced into a position other than its current position. In those critical times, the right accessories on an actuator will allow an operator to move a valve from closed to open or open to closed, regardless of the position it was designed to “fail” to. Max Air’s HD line of scotch yoke actuators offers this capability. Shown here is our hydraulic manual override system. A self-contained hydraulic reservoir and hand pump are utilized to power an auxiliary hydraulic cylinder and drive the actuator to the required position. The Double Acting actuator will stroke the valve, manually, either clockwise or counter clockwise as required. The Spring Return unit compresses the spring and drives the actuator to the opposite of it’s fail position. i.e. Opens a valve with a fail closed actuator or closes a valve with a fail open configuration.

Ideally, when pumping from any significant depth, you should not operate the Motorized System (Scotch Yoke Option) configured to pump into a pressurized system. The most difficult part of delivering water to a pressurized system is moving it out of the well. Once at ground level, the water can be delivered by a booster pump available at a fraction of the cost of the Motorized System (SYD Option). The only other additional cost is the tank for ambient storage, i.e., not under pressure.

The water lifted out of the well is pumped into the ambient storage tank by the Motorized System. Booster pumps designed specifically to pump into a pressure tank are available from a number of vendors, many for under $150 (US). The vendors who supply these include Dankoff, Surflo and Jabsco.

Configuring like this also raises the overall reliability of the system. Most notably, booster pumps include an integrated pressure sensor. It signals the booster pump to turns the pump on and off, according to a target pressure, when water is demanded from the pressure tank.

By contrast, any Simple Pump provides water in pulsed delivery, and therefore varying pressure, making the task of regulating flow to the pressure tank more difficult.

The task of supplying power above the 11.5V and 23.5V (for 12VDC and 24VDC systems) thresholds is more complex than many anticipate, particularly with solar-powered systems. Because most configurations using the Simple Pump Motorized System are powered using solar panels, only solar is discussed in this section.

Contact Simple Pump if you want help finding a solar professional to assess your needs in the U.S. We do not have the expertise, but we can help you find it.

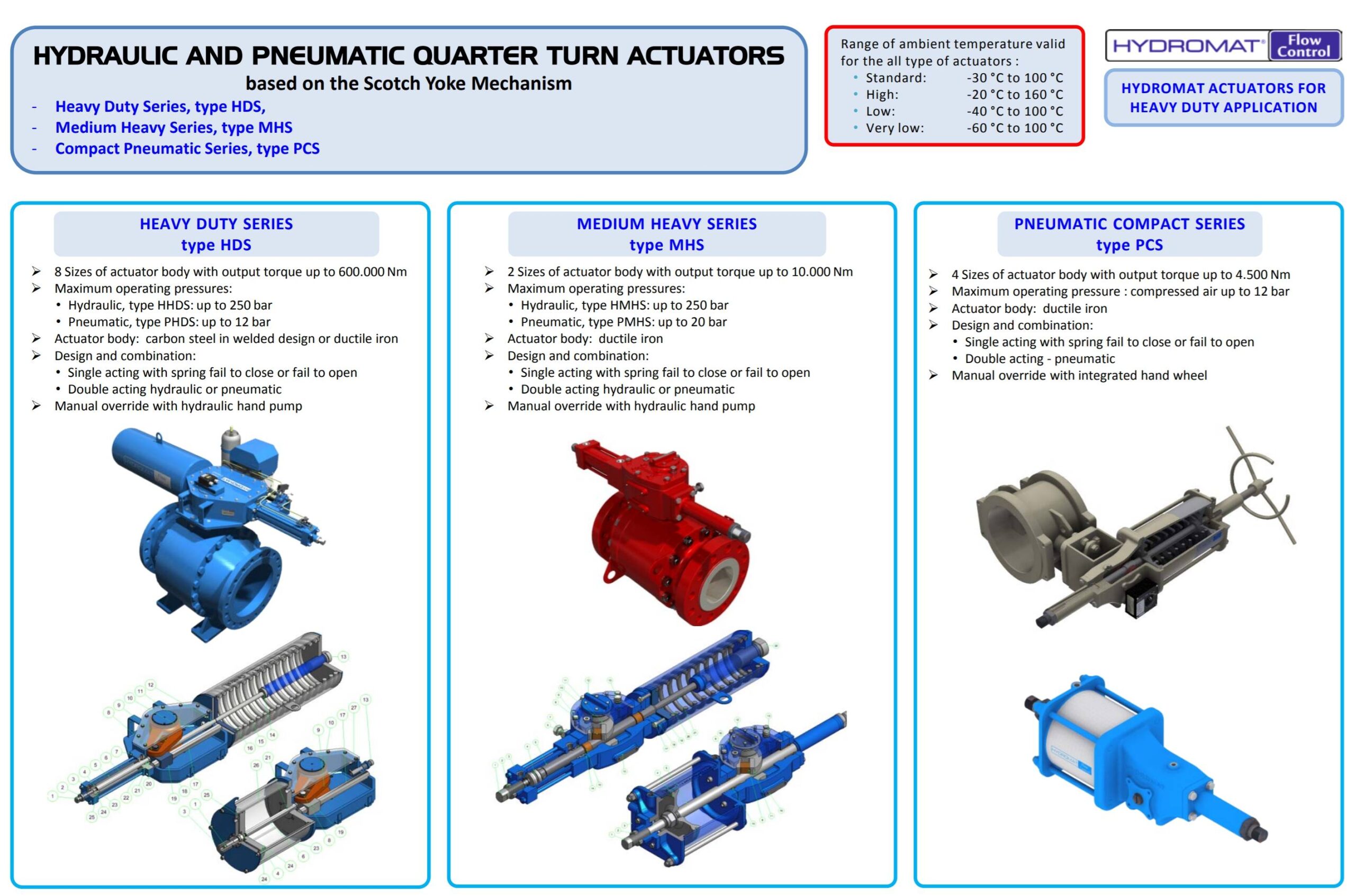

What is a scotch yoke valve actuator? Scotch yoke valve actuators are 90˚ driving mechanisms that can be powered by compressed air or hydraulic oil from an external source.

Deciding which actuator is best for a certain application depends on several factors like environment, required accuracy, and close/open speed. A scotch yoke valve actuator is engineered to automate all types of quarter-turn valves (butterfly, ball, plug, and damper) with various torque profiles to provide a “best fit” for every application. When choosing between a 90˚ actuator such as a Rack & Pinion or Scotch Yoke, the main difference between these actuators are the torques they can generate. The following table shows the difference between the two main types of 90˚ actuators:

A scotch yoke actuator typically consists of a crank and piston system in a hollow cylinder. Pressure is applied to a side of the piston inside the cylinder. As a result, force is generated which moves the piston along the axis of the cylinder to rotate the actuator stem 90° with pilot air application. When the pressure is relieved, the piston then returns to its original position by a spring.

The torque output of a scotch-yoke actuator changes as a function of stroke position, resulting in higher torque at the beginning and end of the stroke (fig 4).

For example, if we have a valve with 44,000 inch-Lbs of start-end torque and 25,000 inch-Lbs running torque, a typical scotch-yoke product selection manual would have a torque rating with required pressure tables as shown below.

EVERY Actreg Scotch Yoke series actuator is built to provide long and efficient service with minimum maintenance. The design, engineering and materials used in their construction ensure optimum performance even in the hardest environments.

Scotch Yoke actuators are for automation and operation of quarter-turn valves like Butterfly, Ball and Plug valves as used in various industries like refining, pipeline, offshore, chemical, pharmaceutical, water processing, etc.

Scotch Yoke actuators are available for a wide range of advanced applications. Most well know are the temperature related trim kits that allow High Temperature or Low Temperature operation. Other applications are related special operating media, or fast operating speeds. For many of these advanced applications, dedicated control accessories are available

Valve actuator is a mechanical component \ device used to operate the valve using power source. It can be Manual, Electric, Pneumatic, or Hydraulic . There are two main types of actuators Rotary and Linear.

Hydraulic Actuators: operate similarly to pneumatic actuators, but an in-compressible liquid (Hydraulic Fluid) from a pump rather than pressurized air moves the cylinder.

Pros of Hydraulic Actuators:They are suitable for high pressure applications where they can produce forces 25 times greater than pneumatic cylinders of equal size. They also operate in pressures of up to 4,000 psi.

Cons of Hydraulic Actuators:Leak of fluid ,loss of fluid leads to less efficiency, leads to cleanliness problems and potential damage to surrounding components and areas.

Hydraulic actuators require many companion parts, including a fluid reservoir, motors, pumps, release valves, and heat exchangers, along with noise reduction equipment.

8613371530291

8613371530291