serpentine belt driven hydraulic pump manufacturer

NOTES: Pump inlet never to exceed 8 inches/HG vacuum; inlet oil velocity not to exceed 8 ft./sec. Engine speed not to exceed 1500 RPM without special approval; pressure spikes to never exceed 10% beyond maximum rating. Pressure ranges based upon degrees of belt wrap, can vary by kit.

NOTES: Pump inlet never to exceed 8 inches/HG vacuum; inlet oil velocity not to exceed 8 ft./sec. Engine speed not to exceed 1500 RPM without special approval; pressure spikes to never exceed 10% beyond maximum rating. Pressure ranges based upon degrees of belt wrap, can vary by kit.

NOTES: Pump inlet never to exceed 8 inches/HG vacuum; inlet oil velocity not to exceed 8 ft./sec. Engine speed not to exceed 1500 RPM without special approval; pressure spikes to never exceed 10% beyond maximum rating. Pressure ranges based upon degrees of belt wrap, can vary by kit.

NOTES: Pump inlet never to exceed 8 inches/HG vacuum; inlet oil velocity not to exceed 8 ft./sec. Engine speed not to exceed 1500 RPM without special approval; pressure spikes to never exceed 4400 PSI; Pressure ranges based upon degrees of belt wrap, can vary by kit.

There is a lot to consider when planning the optimal way to power a vocational truck application, such as cost, available space, system power requirements, among many other variables. While it seems the vast majority of hydraulically powered work truck applications today utilize a power take-off as its primary power source, a common alternative is a hydraulic clutch pump.

A hydraulic clutch pump is a belt-driven pump that can be used instead of a power take-off for some applications, such as wreckers and bucket trucks, and is necessary on trucks without a power take-off aperture on the transmission.

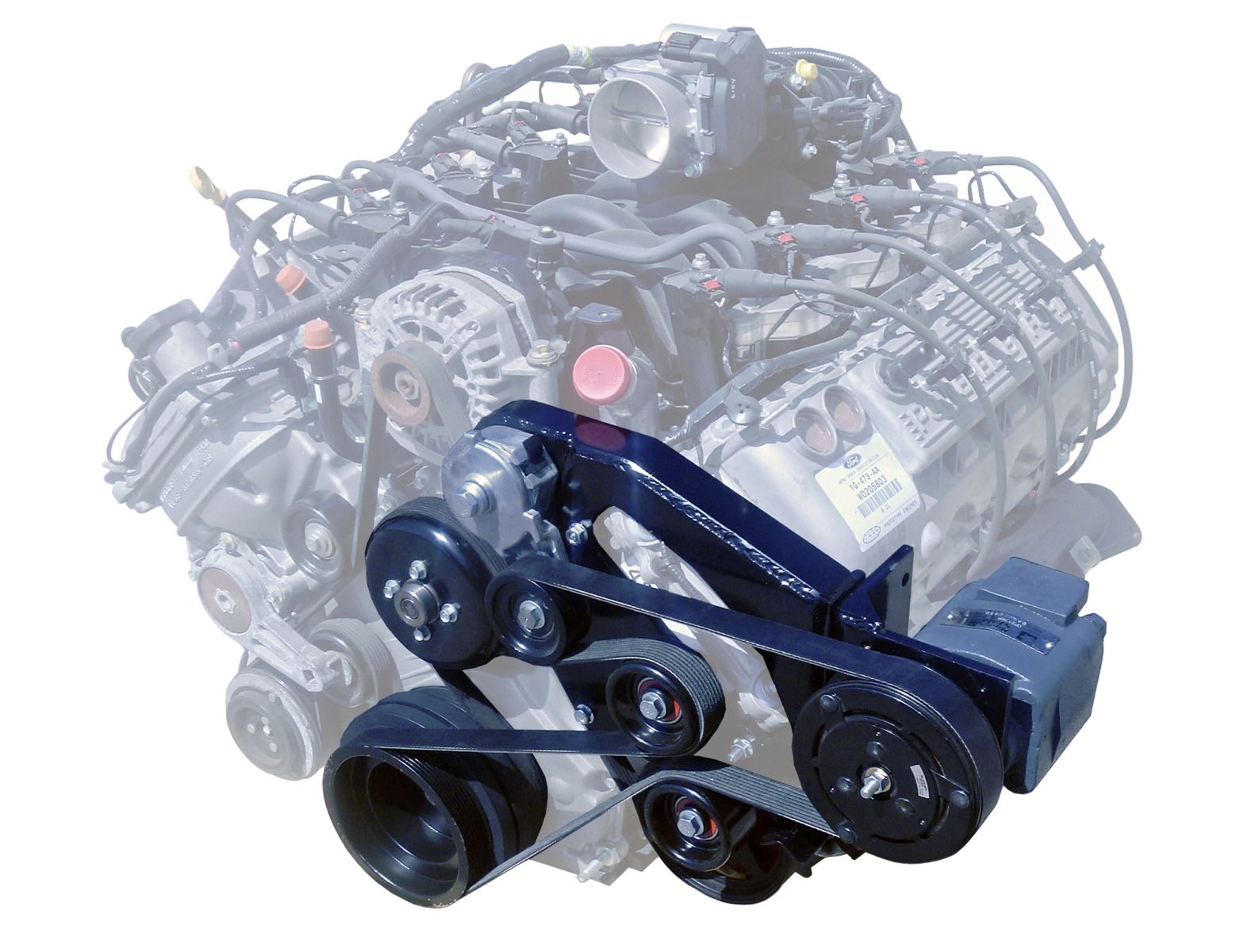

A clutch pump is mounted to the engine compartment of the truck utilizing a mounting kit to secure in place. It is important to make sure there is enough space under the hood to accommodate the appropriately sized pump. The pump is belt-driven from the crankshaft pulley through an electric clutch, similar to what may be found on an automobile air conditioner compressor. Most applications will use a poly-V serpentine belt or two V-belts to drive the pump.

When considering a clutch pump, one critical aspect is to understand the horsepower requirements of your application versus the limitations of the engine belts. Most engine type belts can only drive somewhere between 7–18 horsepower which prohibits the use of large displacement pumps and may not provide enough displacement to effectively power the application at hand. With that said, clutch pumps remain a popular option for hydraulic applications requiring flows up to 15 GPM.

Muncie Power currently has clutch pump options and mounting kits available for most popular truck chassis including current models of Chevy/GMC, Dodge/Ram, Ford, International, and Freightliner.

Reach out to our customer service team (800-367-7867) or utilize our clutch pump online builder module to review available options and determine the best product for your unique application.

Hydraulic clutch pumps are systems in which a clutch assembly is accompanied by a pump that allows the user to apply the required pressure to either engage or disengage the clutch system. Hydraulic clutches, like all clutches, are designed to either connect two shafts, lock them together to spin at the same speed, or decouple the shafts, allowing them to spin at different speeds, as is necessary to shift gears or decelerate.

Hydraulic clutch pumps are generally foot or hand-powered despite their close connection with engine components. The clutch pedal is used to engage a hydraulic piston pump in a basic vehicle design. The pump may be mounted directly to the clutch, or mounting brackets may be used. They were compressing the pedal forces a piston into a hydraulic cylinder, pressurizing the hydraulic fluids already in the enclosure. The mechanical energy created in this manner is transferred from the engine to related devices such as the transmission and drive wheels, allowing the driver to steer, shift, and decelerate. When the clutch is released, the piston is withdrawn. This action draws in hydraulic fluid from a reservoir, which will be compressed with the next engagement of the pedal. The engine environment and close proximity to possibly corrosive hydraulic fluids necessitate pump components to be made of materials that can handle high temperatures created by friction and stand up to corrosion. Die cast stainless steel and cast iron components are popular choices, though ceramics such as silicon carbide and alumina are also applicable in some instances. The fluid used must be compatible with the hydraulic clutch pump parts and the engine itself. Pumps may be mounted directly to the clutch, or mounting brackets may be used.

Hydraulic pumps, when used in clutch systems, use incompressible fluids, such as oil to transmit the force necessary to connect and disconnect an engine to the transmission’s input shaft. Clutch systems such as these are used in agriculture, automation, robotics, transit, automotive, transport, military, aerospace, and construction industries, among others. All kinds of engines and lift systems, ranging from conveyor belts to snow plows and tractors, utilize the power of hydraulic pumps to effectively move heavy loads with minimal effort.

Because these assemblies are used in vehicle power steering and braking systems, selecting the proper pump for a given application is essential. Considerations include torque rating, power, diameter, cross-sectional width, length, weight, rotational speed, and maximum pressure. Additionally, application-specific hydraulic clutch pumps may be either spring-actuated or spring-return. The former requires pressure to disengage the input shaft while the latter uses the hydraulic fluid to engage the power source.

Pitts Electric heavy-duty belt driven clutches come in 12 or 24 volts DC, 75 to 300 lb ft torque. These clutches are compact and can mount in limited space. Install a clutch and experience an increase in the live of your hydraulic pump and a decrease in fuel consumption. Not sure which clutch size is right for your application? We"re ready to help and only a phone call away.

Ace belt driven pumps are available in a variety of models which can be belt driven or direct coupled to a power source. The pumps are available in either clockwise or counterclockwise rotation. The standard bare shaft pumps are designed with a keyway for mounting a drive pulley or coupling.

The integral magnetic clutch driven centrifugal pump design was first offered by Ace in 1982. These models enabled the operator to free the PTO shaft and hydraulic system for other uses. The 12 volt DC magnetic clutch is driven by a v-belt from the engine drive shaft. The clutch is idle until engaged by an on-off toggle switch located at the driver’s seat.

Ace magnetic clutch driven frame mounted centrifugal pump models are available with counterclockwise (CCW) rotation and clockwise (CW) rotation. The direction of rotation is determined when facing the shaft. Sizes available are 1-1/4" x 1", 1-1/2" x 1-1/4", and 2" x 1-1/2".

Hydraulic pumps, when used in clutch systems, use incompressible fluids, such as oil, to transmit the force necessary to connect and disconnect an engine to the transmission"s input shaft. Clutch systems such as these are used in agriculture, automation and robotics, transit, automotive, transport, military, aerospace and construction industries among others. All kinds of engines and lift systems, ranging from conveyor belts to snow plows and tractors, utilize the power of hydraulic pumps to effectively move heavy loads with minimal effort.

Because these assemblies are used in vehicle power steering and breaking systems, it is essential to select the proper pump for a given application. Considerations include torque rating, power, diameter, cross-sectional width, length, weight, rotational speed and maximum pressure. Additionally, application-specific hydraulic clutch pumps may be either spring-actuated or spring-return. The former requires pressure to disengage the input shaft while the latter uses the hydraulic fluid to engage the power source.

Despite their close connection with engine components, hydraulic clutch pumps are generally foot or hand-powered pumps. In a basic vehicle design, the clutch pedal is used to engage a hydraulic piston pump. The pump may be mounted directly to the clutch, or mounting brackets may be used. Compressing the pedal forces a piston into a hydraulic cylinder, pressurizing the hydraulic fluids already in the enclosure.

The mechanical energy created in this manner is transferred from the engine to related devices such as the transmission and drive wheels, allowing the driver to steer, shift and decelerate as needed. When the clutch is released, the piston is withdrawn. This action draws in hydraulic fluid from a reservoir, which will be compressed with the next engagement of the pedal.

The engine environment and close proximity to possibly corrosive hydraulic fluids necessitates pump components be made of materials that can handle high temperatures created by friction as well as stand up to corrosion. Die cast stainless steel and cast iron components are popular choices, though ceramics such as silicon carbide and alumina are also applicable in some instances. The fluid used must be compatible not only with the hydraulic clutch pump parts but also with the engine itself. Pumps may be mounted directly to the clutch, or mounting brackets may be used.

Zip’s AW Direct has the electric clutch you need for an eight-groove belt pump system. Find this and other clutch pump kits and repair parts today to keep your rig running like it should. We also carry serpentine belts, tensioners and idler pulleys for most makes and models.

Although the V-belt is now regarded as the most common solution for power transmission, this was a monumental product in 1917 that solved the slippage and alignment problem.

The first team focuses mainly on the production of drive belts, while the second produces rubber auto hoses. The company currently supplies the markets of 30 countries across the globe.

Some of the most notable products developed and manufactured by the Gates Corporation include water pumps, power transmission kits, hoses, automotive accessories, wiper components, belts, and fluid power tools.

Muncie clutch pumps provide hydraulic power at the flip of a switch. Clutch pumps can be used in situations where a PTO aperture is unavailable or difficult to access. Although normally belt driven, clutch pumps may also be shaft driven from the engine crankshaft.

PF4 series pumps are more compact and are driven via a serpentine belt. (Some kits utilize the OEM pulley and belt, while others use an add-on crankshaft pulley.)

Belt driven hydraulic pumps vary in a number of forms, among them. There are various types of belt driven hydraulic pumps, such as electric belt driven hydraulic pumps, in addition to the number of piston pumps available in the market. Firstly, hydraulic pumps are popular because they are different from the above type and can be divided into three types.

The belt of hydraulic pumps usually has less energy than other types of pumping., ary hydraulic pumps usually use these or other types of pumps, energy-efficient, and less waste maintenance of any equipment.

A belt driven hydraulic pump has a piston pressure, which is smaller than a hydraulic pump type. It is also a primary hydraulic pump unit, which allows a pressure-sensitive process to increase the pressure- theplacement of a pump. It is a secondary hydraulic pump unit, a compressor pump, and a piston compressor pump can perform more at once compared to a hydraulic compressor.

Do you need more power? Rely on DewEze to drive your work truck fleet. Originally designed to power the agriculture industry nearly 50 years ago, DewEze Hydraulic systems are equipped to meet the needs of today’s work truck industry across the globe. Ranging from 5 to 17 GPM, our Clutch Pump Kits deliver the flow, pressure and power to take on any job. Machine cast for precision, each kit is mounted to the engine offering live hydraulics while in motion. DewEze kits are engineered to fit three-quarter, one-ton, super-duty, and an increasing number of medium-duty and HD trucks, regardless of air conditioning and pollution control devices. From wreckers and carriers to utility trucks and high-pressure kits, DewEze drives this.

Belt-Driven Clutch Pump Kits:DewEze Hydraulic Clutch Pump Kits run independent of your truck"s transmission, meaning you get instant, mobile hydraulic power with a flip of a switch.

Quick, Easy Installation:Engineered to save space and time, DewEze’ slick bracketry system minimizes installation labor. No more working to make the part fit, or fiddling with belt alignment.

8613371530291

8613371530291