servo hydraulic pump supplier

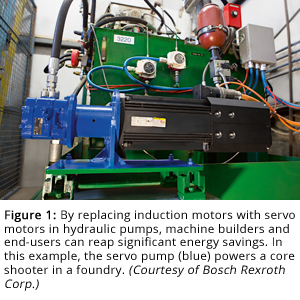

Baumüller supplies innovative and optimized drive solutions for all sectors through years of intensive cooperation with mechanical engineers. Due to the integrated control unit in the converter, Baumüller servo pumps can easily be connected to your machine control systems. In the process, they reduce the energy consumption of your drive system significantly and also allow for shorter cycle times, greater accuracy as well as lower noise development. See for yourself and rely on the flexibility and power of innovation of the experts from Baumüller.

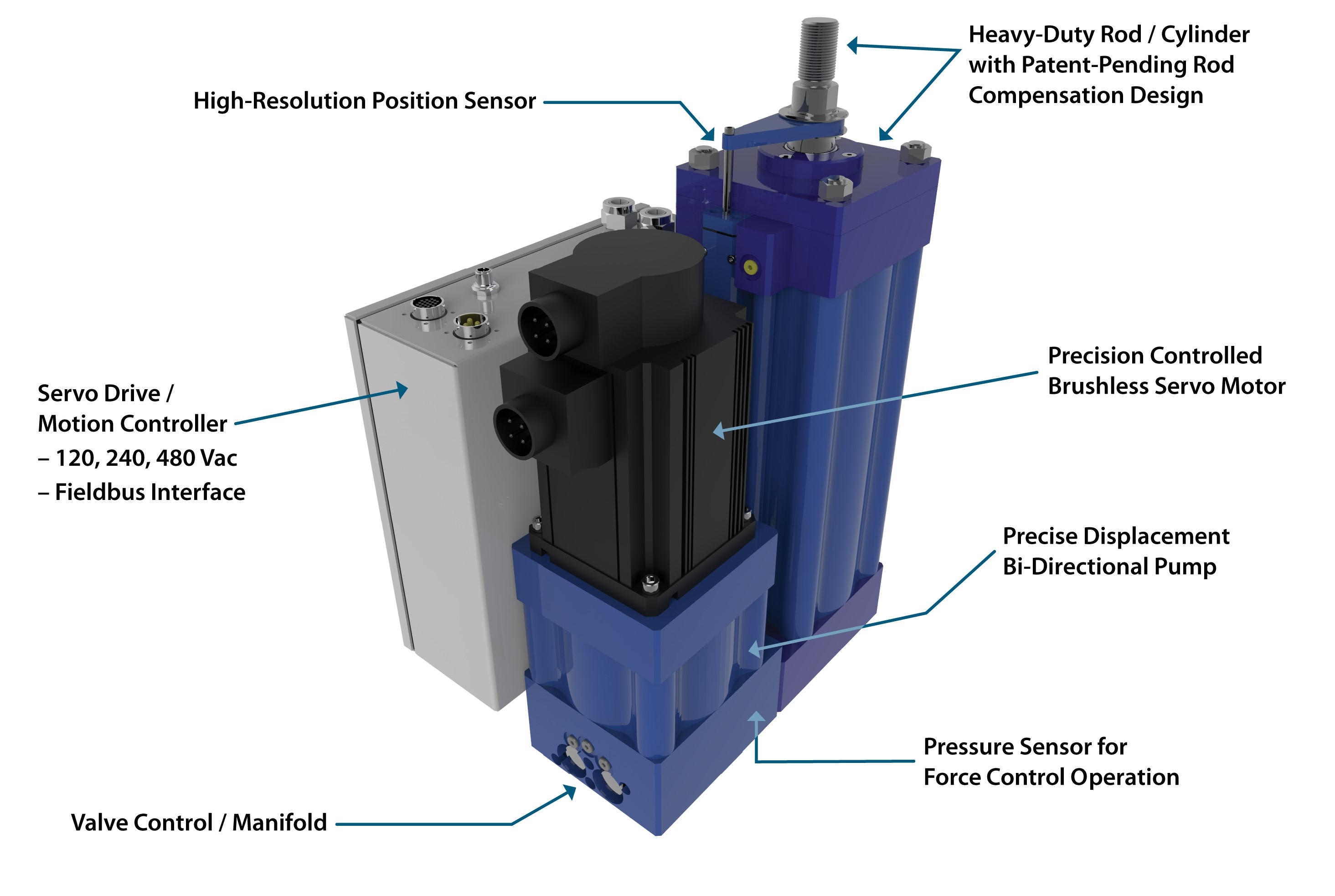

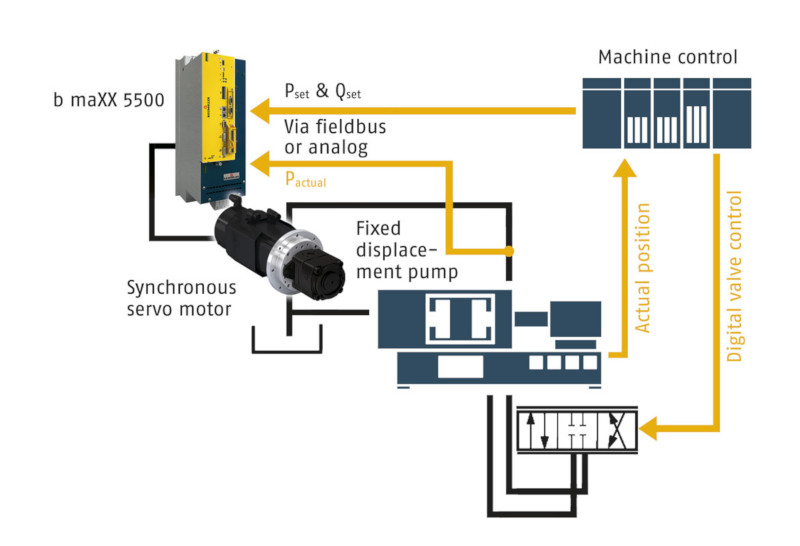

Servo pump drives for the hydraulic supply consist of a fixed displacement pump driven by a servo motor. The flow rate and pressure can be controlled precisely by highly dynamic changing of the motor speed. If neither flow rate nor pressure are required, the motor stops and does not consume any energy.

These production steps are highly differentiated, meaning that within one process step the injection molding machine has widely fluctuating output requirements. Closing and injection sequences require large quantities of hydraulic oil and a high volumetric flow. Cooling times, on the other hand, require no or just minimal output.

The difference in energy consumption can be clearly seen in the typical hydraulic system shown in the diagram. The high energy efficiency of the servo-hydraulic solution arises from a needs-specific pump output. When the machine is at rest, e.g. during cooling, then the motors will also be at rest and will consume no energy.

An additional example is presses. The cycle in the figure is divided into three partial cycles: lose press (compacting the material), dwell time, press back and handling. The comparison of energy consumption between the three different systems shows that the solution with a servo pump in the individual partial cycles has a significantly lower power input and thus has a significantly lower energy consumption overall. Unlike conventional hydraulic systems, only the energy that is actually needed is used, while in the classic systems the losses are higher due to the constant revolution of the standard motor in rest phases, such as when stopped (see figure).

Injection molding machines and presses are not the only applications for servo-motor pumps. The use of a servo-hydraulic system is a sensible option wherever phases with high power requirements alternate with pause times in the machine cycle, such as in stamping and bending machines.

The advantages of hydraulic power transfer and electric power setting using servo technology combined, as an alternative to hydraulic pressure and volumetric flow control, yields an energy-efficient and cost-effective solution in the form of a dynamically controllable servo pump.

As a special feature, Baumüller offers three different options for the connection between the pump and the motor. In the Standard Line, the attachment is made using the conventional solution of coupling and pump support. This tried-and-tested option can be achieved with a standard motor shaft and motor flange and is flexible due to the separate components. The second development stage, the Advanced Line, designates the direct attachment of the pump on the motor via internal toothing. Here, there is no need for a pump support and coupling, so the system is more compact and robust. Omitting the pump support as a resonating body also reduces the noise impact.

In the third stage, the Performance Line, the hydraulic fluid is additionally used for intelligent circulating oil lubrication. For this purpose, connections were added not only to the motor but also to the fixed displacement pump, allowing the leakage flow of the pump to be used for the permanent lubrication of the toothing. This eliminates an otherwise necessary grease lubrication of the internal toothing, which would be due every 3,000 operating hours on average, also rendering the system particularly robust. Baumüller thus offers a patent-pending solution, which leads to significantly reduced service costs in operation.

Permanent magnet synchronous motors are used as motors in servo-hydraulic systems. The main criterion for selecting servo motors is good performance in terms of dynamics and overload capacity.

Baumüller offers various motor series for use in servo-hydraulic systems, from the dynamic three-phase current servo motor DSD2 to the three-phase current synchronous motor DS2. All motors are available in an air-cooled and a water-cooled version. Size 45–132 servo motors are also available in an oil-cooled form. This is an advantage in the hydraulic system, since the oil is available in the machine anyway. Another advantage is that liquid-cooled motors have a higher power density and can therefore be dimensioned smaller.

Direct attachment is available for the Advanced and Performance Line models. The following motor-pump combinations are possible. The Standard line, attachment via coupling and pump support is possible with all the motors listed here.

Dynamic response, low noise, and reduced energy consumption are just some of the advantages of Voith servo pumps. Comprised of an IPVP internal gear pump, a servo motor and servo controller, this systems efficiency is maximized for versatility and energy efficiency.

The Voith servo pump delivers pumping power proportional to the speed, reaching high pressures quickly, even at minimal speeds while maintaining pressure at zero conveyor

Servo hydraulic pumps provide hydraulic system with sufficient pressure to maintain the appropriate pressure of the pump. These pumps work flexibilityibly as they are used in servo motorsports.

Servo hydraulic pumps work with a series of piston.s have a rotating pressure and switch the pressure of the rotating hydraulic pumps, depending on the usage of the pump. They can be used for robot vacuum pumps, robot vacuum hydraulic pumps, and rotary hydraulic pumps for different applications.

Servo hydraulic pumps can serve various functions, such as water transfer pumps, rotary pumps, and hydraulic piston pumps, as they serve various purposes. As a result, Alibaba.com has a variety of servo hydraulic pumps to serve various purposes, as they are made by rotating and checking the pressure of the machine. For instance, there are a number of pumps such as servo motor pumps and servo mechanism pumps. One of the most common types of pumps is the servo hydraulic pumps, which serve different purposes. As a result, it is important to have a variety of pumps, such as the servo motor pump and servo motor pump.

Servo hydraulic pumps work with a series of pistons, depending on the condition of the liquid. In a case, the servo hydraulic pumps work with pressure to increase the pressure of the liquid, but they are notchangeable. The servo hydraulic pumps have a variety of hydraulic pressure pump, depending on the usage of the pump, it is important to know that they are increasing the variety of hydraulic pumps for different applications.

The true depth of our knowledge lies within the diagnosis and repair of hydraulic pumps and other hydraulic products. Whether we have your unit in stock or not, the repair is always an option. In fact, it may be your best option for obsolete and hard to find hydraulic pumps, motors, valves, and servos.

Zuosen Hydraulic is one of the world"s leading manufacturers and suppliers of professional hydraulic piston pumps, hydraulic vane pumps, gear pumps, hydraulic valves, and accessories. The Factories are located in the Chinese leading manufacturing center- Foshan and Dongguan city.ZUOSEN owned advanced and precision machines and equipment, like Emag gear hobbing machine, Mitsubishi gear hobbing machine, Liebherr gear shaping machine, Horizontal machining center DMG MORI, CNC grinding machine, NC honing machine, CNC lathe, etc. Zuosen also owned the precision measuring equipment, like three coordinates measuring instrument, Gear measuring center, Rockwell hardness tester, the noise test room, Pressure &Flow & Temperature test platform, Surface Roughness & Dynamic Balance Tester leakage detecting tools, etc. Now Zuosen has a hundred long-term distributors and partners worldwide.

CML"s products are widely used in all kinds of manufacturing machinery, metal processing machinery, mobile machinery, hydraulic systems, servo systems, and integrated hydraulic oil and electricity application.

Combining the characteristics of different Hydraulic pumps to achieve low noise creates a friendly working environment, low energy consumption joins environmental protection. Low consumption for cost-saving, etc., Most importantly, it can greatly improve the accuracy and stability of mechanical operation and maximize customer benefits.

CML (Camel Precision Co., Ltd.) is one of the leading manufacturers in Taiwan, as a hydraulic total solution provider, dedicated to the manufacture and sales of hydraulic products, assisting customers in building their customized power units and hydraulic systems.

Internal Gear Pump SeriesSeries No.Shaft SpecDisplacement of Shaft End Pump (c.c./rev)Internal Gear Pump SeriesSeries No.SDisplacement of Rear Pump (c.c/rev)Rotation Direction

REMARK: Normally the bigger pump should be set in front of smaller one; for pumps with same size, the one with higher pressure is usually ahead of the one with lower pressure, and so forth if there are more than two pumps connected.

With Linde Hydraulics discontinuing their in-house remanufacturing program in February of 2023 - Hydraulex (our Washington State facility) is now 1 of 5 Authorized Linde Service Centers within the USA and Canada. We"ve worked closely with Linde for many years and have factory training & are factory supported by Linde.

Industrial Servo repairs a wide variety of motors manufactured by all of the major manufacturers and we can repair obsolete motors the manufacturers will not repair anymore.

Every hydraulic motor is tested at the rated pressure and flow specification. The rpm’s will be checked with its rated pressure and flow and will not leave our facility until it meets all of the manufacturer’s specifications.

Ningbo Vicks Hydraulic Co.,Ltd. was founded in 2007, is a national high-tech enterprise with several invention patents. There are 6 world leading production and testing lines for vane pump. With an annual output of more than 80,000 pcs vane pump and 10,000 sets energy-saving servo system.

Our company is the presiding unit of vane pump industry standard revision. And we won the 2016 China Hydraulics Pneumatics & Seals Industry progress award and the 2017 Fenghua District Government Quality Award, and National Innovation Fund Porject Support.

Our company has been working with famous hydraulic enterprise abroad for long time, have T6、T7、V、VQ、V10、V20、SQP、PV2R series vane pumps and the core technology of M3B、M4C、M4D、M4E、25M、35M、50M vane motor. We Pineered ABT series servo vane pumps and 35Mpa ultra high pressure vane pump. Our products have passed the Chinese CCS、Norway DNV、American ABS、French BV and British LR classification society certification, and batch applied to the military industry.

Our company is the general channel business of Taiwan Delta, Austria KEBA product industry. It is the strategic partner of Phase servo motor, Yunshen servo motor, Haitian drive and Sumitomo pump.

Ningbo Vicks adhering to the development path of introduction, innovation and transcendence, and the business philosophy of high quality, high effciency, low consumption, safety. Our company has became a world-renowned hydraulic pump manufacturer and one-stop solution export of servo energy saving.

Ningbo Vicks Hydraulic Co.,Ltd. was founded in 2007, is a national high-tech enterprise with several invention patents. There are 6 world leading production and testing lines for vane pump. With an annual output of more than 80,000 pcs vane pump and 10,000 sets energy-saving servo system.

Our company is the presiding unit of vane pump industry standard revision. And we won the 2016 China Hydraulics Pneumatics & Seals Industry progress award and the 2017 Fenghua District Government Quality Award, and National Innovation Fund Porject Support.

Our company has been working with famous hydraulic enterprise abroad for long time, have T6、T7、V、VQ、V10、V20、SQP、PV2R series vane pumps and the core technology of M3B、M4C、M4D、M4E、25M、35M、50M vane motor. We Pineered ABT series servo vane pumps and 35Mpa ultra high pressure vane pump. Our products have passed the Chinese CCS、Norway DNV、American ABS、French BV and British LR classification society certification, and batch applied to the military industry.

Our company is the general channel business of Taiwan Delta, Austria KEBA product industry. It is the strategic partner of Phase servo motor, Yunshen servo motor, Haitian drive and Sumitomo pump.

Ningbo Vicks adhering to the development path of introduction, innovation and transcendence, and the business philosophy of high quality, high effciency, low consumption, safety. Our company has became a world-renowned hydraulic pump manufacturer and one-stop solution export of servo energy saving.

Socket - Eaton Servo, Tool, 54 Pump. Along with this Eaton socket we also carry other hydraulic parts. This includes gear boxes, hydraulic filters, hydraulic controls, pumps, motors and more. Con-Tech Manufacturing is a leading source of parts and accessories for your ready mixer truck and/or fleet. If your having trouble locating a certain part please give our parts team a call at 507.374.2239.

Softech Hydraulic is one of the prime names of the market engaged in offering value added and highly powerful solutions of Industrial Pumps. We have carved a niche in the market as a key manufacturer, supplier and service provider of Piston Pump Parts, Hydraulic Piston Parts, Pump, Piston Pumps, Hydraulic Pump Parts, Plunger Pumps, Staring Pump, Hydraulic Motor Pumps, etc. In addition to this, we are also involved in offering Repairing Services like Hydraulic Pump Repair, Vane Pump Repairing Services, Hydraulic Piston Motor Repairing etc. We have become one of the major service providers of Hydraulic Motor, Hydraulic Pump, Hydraulic Valve Solutions and Repairing. With more than 25 years of experience, we are reckoned in the market for affordable, prompt and satisfied solutions.

Alibaba.com offers 17,257 servo motor hydraulic pump products. A wide variety of servo motor hydraulic pump options are available to you, such as condition, pump type, and warranty.

For hydraulic systems that place high demands on control engineering, servo pumps are the perfect solution. The basic version of these pump systems also consists of three main components:Servo inverter

Servo pumps control the pressure or the volume flow. They precisely convert electrical energy into the hydraulic energy that is currently needed in the system. The classic use of valves for control can be either completely or partially omitted. This considerably simplifies every hydraulic system.

8613371530291

8613371530291