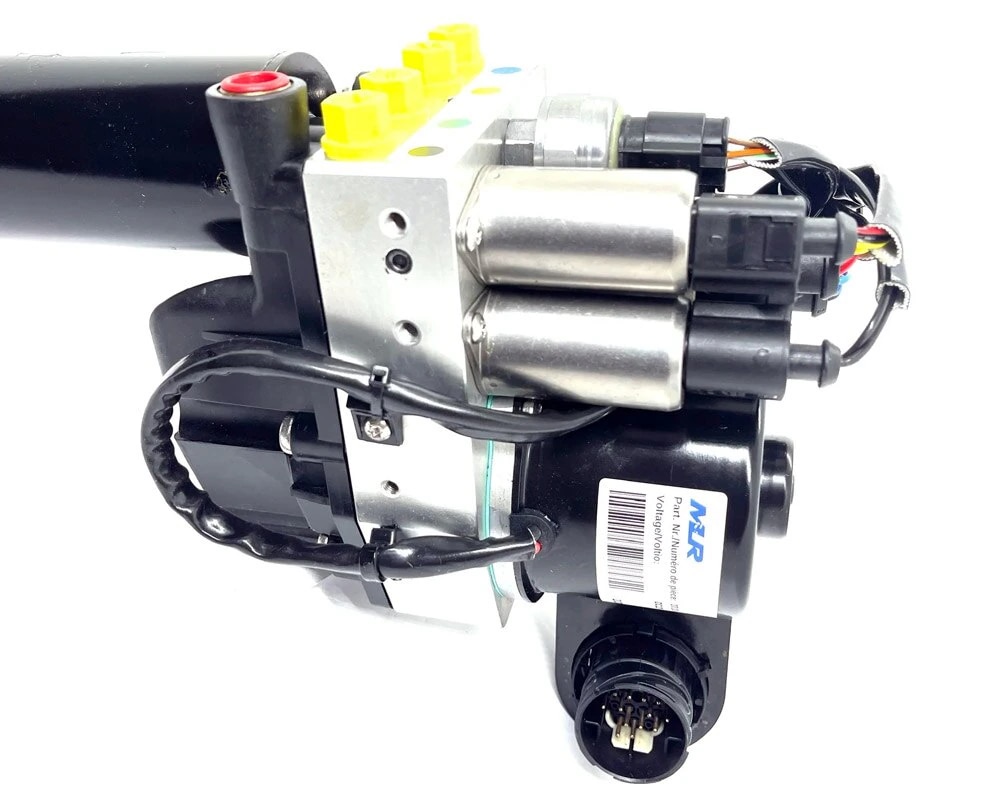

smg hydraulic pump e46 m3 made in china

Renew your worn or burn"t out SMG pump with our remanufactured units! Our remanufactured pumps are disassembled, thoroughly cleaned and reassembled with all new components.

This part is listed by BMW as BMW part number 21532229715 (21-53-2-229-715) and is described as SMG Hydraulic Pump with Pressure Accumulator - E46 M3.

The SMG pump on the SMG (sequential manual gearbox) equipped E46 M3 is a very well known failure point. It"s really not a question of IF your SMG pump will suffer a failure, but when. Typically, the SMG pump lasts somewhere in the neighborhood of 100k miles, but they have been known to fail with much less miles.

If your E46 M3 has suffered the dreaded SMG pump failure, you need a new SMG pump. And BimmerWorld has the best price available to assist in getting your E46 M3 back on the road.

Pentosin CHF 11S is a synthetic high performance hydraulic fluid for life-time application in modern vehicle aggregates. Pentosin CHF 11S is especially designed for hydraulics in the automotive industry with the highest technical requirements such as in: power steering, level control, shock absorber, hydro-pneumatic suspension, stability and traction control, hydraulics for convertible tops, central lock systems, etc.

Pentosin CHF 11S is a synthetic high performance hydraulic fluid for life-time application in modern vehicle aggregates. Pentosin CHF 11S is especially designed for hydraulics in the automotive industry with the highest technical requirements such as in: power steering, level control, shock absorber, hydro-pneumatic suspension, stability and traction control, hydraulics for convertible tops, central lock systems, etc.

In most cases the reason for this is because of worn electric motor, which drives the hydraulic pump in the hydraulic unit. In addition, the gap losses in the hydraulic system increase enormously at high temperatures. If many hydraulic consumers are now active (clutch slave cylinder and transmission actuator), the hydraulic unit can no longer keep up with the pressure build-up. We have ours for that Burkhart Engineering High performance hydraulic oil developed. The required system pressure we up to 25% faster built up than is the case with the normal pentosine CHF 11s.

The worn original engine can "Plug & Play" exchanged for our repair engine. The replacement engine is equipped with the required pins and seals and can be pinned directly into the original BMW wiring harness. It is a replacement part OEM quality. The alternative to avoid having to buy a new hydraulic unit.

Here"s my long winded response to the Magneti SSG system offered in the Z4 & e46 325/330, not to be confused with the Siemens system SMG II on e46 M3"s. . I had SMG special ordered in a 2004 330I that I drove the hell out of, including 4 all out track days and never had a problem. BTW - the actual transmission and clutch is the same as the base e46 330 and can handle SC kits, as a matter of fact, most of the firms offering the kits have software to take SMG into account.

On 03"s and early 04"s SMG (SSG) had problems with the hydraulic pump failing (hence the slipping people have talked about). Other than that issue, the system is rock solid. On any used car, I would check the service records to ensure the pump has been replaced and, or the clutch/pressure plate due to the wear caused by the pump. The driving experience: In general I loved it - would have ordered a similar system for the Z4MC had it been available. Its great on the race track. In traffic it can be cumbersome due to the computer getting a little out of sync with the inputs you"re giving it via the throttle and brake. You need to be conscious that you are driving a standard - how you manage the throttle in relation to how the computer is managing the clutch creates smoothness...

Many early versions of these transmissions that are semi-automatic in operation, such as clutch — often using various forms of clutch actuation, such as electro-mechanical, hydraulic, pneumatic, or vacuum actuationclutchless manual systems.fully automatic in operation, such as ECU, therefore requiring no manual intervention or driver input for gear changes.

The usage of modern computer-controlled AMTs in passenger cars increased during the mid-1990s, as a more sporting alternative to the traditional hydraulic automatic transmission. During the 2010s, AMTs were largely replaced by the increasingly widespread dual-clutch transmission, but remained popular for smaller cars in Europe and some developing markets, particularly India where it is notably favored over conventional automatic and CVT transmissions.

Gear shifting, clutch actuation, shift-timing, and rev-matching are all under automated control via the electronic sensors, computers, and actuators.transmission shift lever, while electronic sensors and actuators connected to a TCU (transmission computer) or microprocessor will automatically operate the clutch and throttle to match revs and to re-engage the clutch in milliseconds. Torque and power transfer to the drive wheels will also be electronically controlled. Most modern implementations of this transmission function in a sequential mode, where the driver can upshift or downshift by only one gear at a time. However, this is not the case for all modern transmissions. For example, BMW"s "SMG" and Ferrari"s "F1" transmission can skip gears on both downshifts and upshifts, when selecting gears manually via the steering wheel-mounted paddle-shifters, as seen on most modern transmissions. Older clutchless manual transmissions (mostly prior to the 1990s) will retain H-pattern shifters, plus the shift gate, and will require the driver to select the required gear ratios manually. The clutch, however, will be a servo-controlled unit, connected to various actuators, a solenoid and sensors which control the clutch automatically.

Another alternate means of clutch automation is the "clutch-by-wire" system. The system generally uses an electric actuator and electronic sensors, which replace the mechanical clutch linkage or hydraulic clutch connection, to monitor and control clutch positioning, completely replacing the hydraulic linkage between the mechanical clutch and pedal itself with a single electro-mechanical actuator.

Add-on AMTs can also function as a regular manual gearbox (with a manual shift lever), whereas integrated AMTs do not need a "normal" shift layout, so they can be designed with an optimized AMT shifting layout (which would have an unusual pattern to manually shift). Integrated AMTs either have gear-selector drums (which allows only serial shifting and no gear-skipping, but this system is fairly inexpensive, because it needs only one actuator), or single actuators. Single-actuator systems require one actuator for each shifting sleeve (which is why this type of system is more expensive, but it also shifts faster). The actuators can either be electro-hydraulic (more expensive, but faster, well-suited for single-actuator systems, and allow for higher torque), or electro-mechanical (less expensive, but usually limited to 250 N·m (184.5 lb-ft) of gearbox input torque). This limit is because the clutch actuation force increases with higher torque, and short shifting times; electro-mechanical actuators are just electric motors – using larger motors reduces the motor dynamics due to the motors" higher mass moment of inertia (which is not good for fast shifting), and bigger motors also put more stress on the car"s 12-volt electrical system. As a result, one can have either slow shifting and a very large lead-acid battery (not suitable for cars), or fast shifting and a smaller battery (works up to 250 N·m of torque).

Another early example is the 1955 Citroën DS, which used a 4-speed "BVH" transmission. This semi-automatic transmission used an automated clutch, which was actuated using hydraulics. Gear selection also used hydraulics, however, the gear ratio needs to be manually selected by the driver. The 1956 Renault Dauphine 3-speed manual transmission was available with an optional Ferlec automated clutch, which used an electromagnetically-operated clutch system.NSU Ro 80 (3-speed Fichtel & Sachs)Porsche 911 (4-speed Sportomatic), both of which used vacuum-actuated clutches and hydraulic torque converters. The 1968 Volkswagen Beetle and Volkswagen Karmann Ghia offered a 3-speed Autostick transmission, which used an electric switch on the gear shifter connected to a solenoid, to operate the electro-pneumatic vacuum clutch servo.

The Isuzu Isuzu Aska mid-size sedan (sold in the Japanese domestic market only). This transmission, originally designed for trucks, was based on a manual transmission with the addition of hydraulic actuators for the gear shifter and the clutch. Initial versions did not allow direct selection of gear ratios, instead allowing drivers only to lock out higher gears (as per many traditional automatic transmissions). Later versions added a manual mode, allowing the driver to control the gear selection.

BMW"s involvement with automated manual transmissions began in 1993, when the "Shift-tronic" 6-speed semi-automatic was offered on the Alpina B12 coupe (based on the E31 850CSi).BMW E36 M3 coupe.sequential manual transmission. The SMG was replaced by the SMG-II when the E46 M3 was introduced in 2000.BMW E60 M5 and related BMW E63 M6. The SMG-III could achieve a shift time of 65 milliseconds in its most aggressive mode

From 2002 to 2007, the Toyota MR2 (3rd generation) was available with an "SMT" 6-speed automated manual transmission. The SMT system utilized an electro-hydraulic activation system for both the clutch and shifting, but no H-pattern shifter like with the standard transmission. Instead, there was a shift lever that could be pulled and pushed forward or backward to upshift and downshift, as well as the addition of electronic steering-wheel-mounted shift buttons.

BMW E46 M3 SMG Pump Repair kit + SMG Temperature Sensor. E46 M3 SMG Pump Motor Repair kit including SMG Fluid Temperature sensor Only fits e46 M3 - if you have another model with SSG / SMG then please check our other items. Kit Includes: -Brand New SMG Pump Motor. -Brand new Genuine BMW SMG Fluid Temperature Sensor. This is the only such kit on the market and has been tested extensively to make sure it works. The E46 M3 SMG pump is a common failure item beyond 80,000 Miles, Most E46 M3 SMG will need a replacement pump around that time and certainly during their life time. The common faults to indicate the Pump is failing are: (INPA Diagnostic Software) 56 Switching on time of Hydraulic unit: Means hydraulic unit has been on for too long to build up pressure, this can be seen due to pump motor issue or on track and hard use. 53 Lower level of pressure reached HE: Means that the pump has failed to build up pressure and the pressure dropped to below the minimum limit, this is a straight indication that the pump is failing, relay might be the issue as well. A lot of owners with SMG issues attempt to change the Salmon relay which could be the issue in a small number of cases, or apply a temperature sensor fix in which they bypass the sensor al together which is not good or put in a resistor to fool the ECU into thinking the temperature is fine, both are not good and BMW has already updated this sensor and we supply the latest updated sensor as part of this repair package. As mentioned above the SMG relay gets blamed for a lot of pump failures which is not totally true but we recommend changing it anyways when repairing the pump. The main fault with the pump is the electric motor which you cannot buy from BMW, you can only buy a complete pump unit for about 1700 GBP!!! We can supply these motors out of our UK stock, they are German manufactured by one of the most reputable companies that build OEM motors for large manufacturers including BMW. We have tested them extensively to make sure they are reliable and work well and have them installed in our cars. There are a few companies out there that attempt to refurbish the SMG pump, these companies only rewind the motor and sometime replace the temp sensor which works for some time but not reliable as having a new sealed motor. We have extensive experience in SMG gearboxes and have identified 2 items to be the source of most SMG pump faults which are the motors and the temperature sensor and both are supplied in this kit. We stand behind our product and provide a guarantee the motors for 12 months. (an ECU error print out is needed before issuing a return authorisation - INPA Preferred) That’s what you need to fix your SMG Pump Motor and sensor without any waiting or reliability issues. We always recommend diagnostics and fitting by qualified BMW mechanics with the correct equipment. Make sure you read and understand the description well before buying. The SMG system is complex with many possible issues so m ake sure your M3 is diagnosed properly by a competent mechanic so you don"t end up buying a apart that does not fix your problem. We can help and support troubleshooting but final diagnosis cannot be done remotely so bear that in mind. We don"t offer returns if it turns out the problem is something else, We know the kit works as per our testing in our own cars and the feedback from customers so far ( 300+ sold, fitted and working Fixing your SMG is not about luck but about proper diagnosis. We stand by our product and offer 12 months warranty for defective parts / kits. Please make sure the above is clear and contact us first in case you have issues. A capable DIYer can also do the job with loads of instructions on the web about how to replace the SMG pump on the e46 M3. Feel free to contact us with any questions. Beware of knock offs who attempt to sell you used or refurbished motors as new, Also beware of Chinese motors on ebay there are a couple of them on ebay Check our Feedback. Always in Stock - Ready to Dispatch for next day delivery 1000+ units sold and supported with positive feedback. Top BMW specialists across the the UK are our loyal customers Buy with confidence FAST DISPATCH Free Insured UK and international shipping - Insured Dispatch from UK stock. International shipping available at checkout (Except Cyprus). We only use reputable insured couriers for our deliveries.

Burkhart Engineering, based in southern Germany, is a BMW specialist renowned worldwide for its expertise with the E46 M3 SMG2 transmission system. Through countless repairs and a refreshing approach to the problems the SMG system can present, Burkhart has since developed a range of rebuild kits and upgrades to make SMG ownership a worry-free experience.

The Burkhart Engineering SMG Hydraulic Pump Repair Kit can not only repair your pump, but also improves it to be ready for high temperature track use, traffic jams and hot summer weather.

In most cases this is caused by a worn electric motor, which drives the hydraulic pump in the SMG unit. Further the gap leakage in the hydraulic system increase massively during high temperatures. If additionally many hydraulic consumers are working (clutch slave cylinder and gearbox actuator), the hydraulic unit no longer produces enough pressure – for this issue Burkhart Engineering High Performance Hydraulic Fluid offers a huge improvement. The pump runs on pressure up to 25% fasterthan using the conventional Pentosin CHF 11s.

The old motor can be replaced by the new one as a plug and play swap. The replacement motor is equipped with the required pins and seals and can be directly installed with the original wiring loom. These are brand new spare parts in OEM quality – the alternative to save you from buying a complete new SMG hydraulic unit.

This Repair Kit only works if the rest of the hydraulic unit is functional. The accumulator for example needs a defined preload pressure. Should this not be the case, the accumulator has to be replaced, too. In Burkhart Engineering’s SMG-Wiki you can find instructions about how to check the preload pressure in the accumulator.

8613371530291

8613371530291