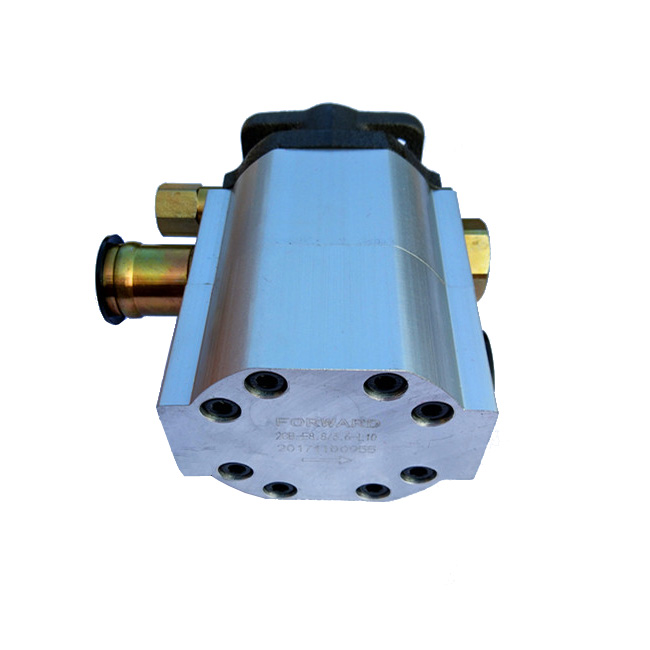

splitter hydraulic pump free sample

A: To determine which pump to purchase, you will need to know the following: what HP engine will you be powering my log splitter with, what size reservoir capacity do you have available, what type of pump mount you will be using?

A: There are two common types of mounts used on log-splitters. There is a four-bolt mount and a two-bolt mount. The four-bolt mount pumps generally come in 5gpm-16 gpm sizes and have a ½” keyed shaft about 1-1/2” long. The two-bolt mount pumps come in 22gpm and 28gpm sizes and have a 5/8” keyed shaft that can differ in length.

A: If your log-splitter is moving slow but still capable of splitting the wood it always has, it is most likely stuck in its second stage. In the second stage (or low flow/high-pressure stage) the pump produces 25% or less of its rated GPM but it does it at a higher pressure. The transition from the first stage (or high flow/low-pressure) is an automatic process achieved via internal valving with in the pump. If something within that valving has malfunctioned, and it is typically more economical to just replace the whole pump.

1. If the engine bogs down and stalls out, the pump is likely stuck in its first stage. In the first stage (or high flow/low-pressure stage) the pump produces its rated GPM but it does it at about 400-900psi. The transition from the first stage (or high flow/low-pressure) to the second stage (or low flow/high-pressure stage) is an automatic process achieved via internal valving with in the pump. If something within that valving has malfunctioned, and it is typically more economical to just replace the whole pump.

2. If the engine bogs down slightly but fails to stall out, you most likely have a bad seal on the cylinder piston. It is often more cost effective to rebuild a cylinder than to replace it depending on the extent of any internal damage. Consult with your local hydraulics shop.

A: 2-stage log splitter pumps are sized by how many gallons per minute (GPM) they flow in the low-pressure stage. Most 2-stage Log-splitter pumps will safely create 3000 psi regardless of how quickly they transfer the fluid doing it. So, there is not actually a more “powerful” pump, just slower or faster.

A: The size of splitter is typically specified in tons of splitting force. This number is determined by the surface area of the piston multiplied by the pressure applied by the pump. The amount of tonnage that you will need depends predominately on the type and size of wood that you will be splitting. Hardwoods such as oak and hickory take more force to split than most coniferous soft woods like spruce and fir. The Janka rating is the measurement that they use to rate the hardness of wood. The higher the number, the harder the wood. Log diameter size is another important factor in the amount of force required to split the log. One of the most important factors in determining the Tonnage required to split logs is the moisture content. See below for a decent chart for tonnage requirements for seasoned wood. You will need 50-75% more tonnage for splitting green wood.

A: The tonnage rating on your log-splitter is determined by two distinct factors; piston surface area and pounds of force per square inch (psi) supplied by the pump acting upon that surface. To determine the piston surface area, you must take half of the bore diameter, and multiply that number by itself. Then take that number and multiply by pi (approximately 3.14). This will give you the surface area in square inches. Although your hydraulic pump will be rated to a certain maximum pressure rating, typically 3500psi, most log splitter hydraulic systems have a relief valve limiting the amount of pressure supplied to the cylinder and other components. To find the tonnage of your log-splitter you will take the relief valve setting in pounds per square inch multiplied by the surface area of the piston in square inches, then divide that number by 2000 pounds per ton. See example below for a 4-1/2”cylinder at 3000psi:

A: Your valve will have four ports. The IN port is supplied by the hydraulic line coming directly from the pump. The OUT port will return the flow of oil directly to the reservoir. That leaves the two work ports on the valve. The work port closest to the valve handle will be connected to the barrel port (extending) on the cylinder. Attach the other valve port to the rod port (collapsing) side. See the figure below.

A: Typical Log-splitter valves have three positions. Extend – Center – Retract. The extend position directs flow to where the cylinder expands thus forcing the wedge through the log to be split. The handle must be held in this position to maintain cylinder movement. The valve will spring to center from the extend position when the handle is released. The retract position of a log-splitter valve has a feature commonly referred to as a pressure kick-out detent. Pulling the valve into the retract position detent will cause the cylinder to collapse until it is fully pulled in without holding onto the valve handle. Once the pump pressure builds to a pre-set amount, the internal workings of the valve will force the handle back into the center position automatically.

A: The hoses on your log-splitter should have the rating printed or embossed onto the outside sheathing of the line. If it is not visible or readable it is a distinct indicator of weather damage and or rot, and you should look to have them replaced.

Your log-splitter requires multiple hoses and could potentially have three different pressure ratings (see figure below). The suction line shown in green does not see any pressure, on the contrary they usually have some sort of structure to keep the hose from collapsing. The return lines shown in orange do not typically see much for pressure, but they are typically rated to 350 psi. The actual pressure lines shown in red should be rated to at least 3500psi for your typical log-splitter application.

A: Most Hydraulic systems can be safely operated with either ATF (automatic Transmission Fluid) or a standard petroleum based hydraulic oil. Some Log-splitters have a replaceable filter assembly to help clean the oil clean. If your log-splitter does not have a replaceable filter it would be beneficial to use ATF and allow the detergents in the fluid to help keep things clean.

A: There are many manufacturers of log-splitters out there, and just as many if not more manufacturers of cylinders. The only way to know for sure which cylinder that you have is to contact the log-splitter manufacturer with the model and serial number of your unit and ask for a parts breakdown for their part number for the seal kit.

If this is not an option for you for whatever reason, you can disassemble your cylinder and match up the seals by example with your local hydraulics shop. If you do not have a local shop, or they do not offer this type of service, you will need to measure the hard component dimensions of your cylinder. You will then need to match them with the dimensions of available seals with a seal supplier such as Seal Source, Hercules Sealing Products, or any other national seal supplier. Many of them have an online interface to help you make this selection.

A: There are many manufacturers of log-splitters out there, and just as many if not more manufacturers of cylinders. The only way to know for sure which cylinder that you have is to contact the log-splitter manufacturer with the model and serial number of your unit and ask for a parts breakdown for their part number for the cylinder that they used on that specific unit.

A: The first step in selecting a replacement cylinder for your log-splitter is identifying what style of cylinder that you currently have. While many manufacturers utilize common style cylinders, many do not. Please see the figures below for the most readily available styles.

If your cylinder is mounted on lugs coming out of the side of the cylinder, this is what they would call a trunnion style cylinder. Trunnion mount cylinders are almost entirely exclusive to the log-splitter manufacturer. You will need to get a replacement from the original manufacturer or contact a machine shop to recreate the mounts on a more common cylinder.

Once you have determined the style of cylinder you are looking for, you will need to determine bore size, the mounting pin to pin length (both collapsed and extended), the rod diameter, and pin hole sizes. Drawings are usually available for individual cylinders to insure a proper fit. It might be necessary to have a local shop alter your log-splitter frame to accept the cylinder, or alter the cylinder to fit your machine.

A: 2-stage log splitter pumps are sized by how many gallons per minute (GPM) they flow in the low-pressure stage. While operating below the bypass setting the pump will transfer that number of gallons per minute.

A: Availability of replacement parts for log-splitter valves depends on the manufacturer of the valve. You will first need to identify the manufacturer of the valve. Northern Hydraulics carries replacement handles and brackets for Cross MFG valves and replacement brackets and detents for the Energy MFG log-splitter valves

A:The retract position of a log-splitter valve has a feature commonly referred to as a pressure kick-out detent. Pulling the valve into the retract position detent will cause the cylinder to collapse until it is fully pulled in without holding onto the valve handle. Once the pump pressure builds to a pre-set amount, the internal passages in the valve will force the spool back into the center position automatically.

Keep your hydraulics in motion with a wood splitter hydraulic pump from RuggedMade. Designed to meet the needs of high-force log splitting, our precision 2-stage hydraulic pumps ensure cylinders perform smoothly and rapidly, helping to shave down cycle times.

Our expanded line of one and two-stage log splitter pumps are constructed to produce up to 3,000 PSI and can also be used at the heart of a variety of hydraulic applications to keep fluid flowing freely and steadily, throughout the life of your machine.

Hydraulic control valve for operating hydraulic cylinders. Pressure operated detent on return stroke, spring center on extend for use with log splitters or other auto detent applications. Pressure-release detent adjustable from 1,015 to 2,030 PSI.

Model GP-CBN is a HI/LO hydraulic gear pump with 12 displacement combinations and maximum pressure of 900 psi for the low pressure pump and 3000 psi for the high pressure pump. The change from LO to HI pressure is automatic with the LO pressure preset from 400-900 psi. Applications for HI/LO pumps include log splitters, presses, etc. where rapid movement of the cylinder at low pressure is required prior to automatically switching to the high pressure mode to meet load requirements.

A log splitter is a piece of machinery or equipment used for splitting firewood from softwood or hardwood logs that have been pre-cut into sections (rounds), usually by chainsaw or on a saw bench. Many log splitters consist of a hydraulic pump or electric motor which than powers a hydraulic or electrical rod and piston assembly. Generally these are often rated by the tons of force they can generate. The higher the force rating, the greater the thickness or length of the rounds that can be split. The log splitter consists of all four major hydraulic components.

Most log splitter models for home use have a rating around 10 tons, but professional hydraulic models may exert 30 tons of force or more. There are also manual log splitters, which use mechanical leverage to force logs through a sharpened blade assembly; and screw or "corkscrew" types that are driven directly from an agricultural tractor"s power take-off shaft where the splitter is mounted on the three-point hitch.

A simple log splitter may be powered by an electric motor driving a hydraulic pump or by gasoline or diesel engine with or without a tractor. The non-electric versions can be used remotely where the splitter can be moved to the location of the cut wood source. Split logs can then be loaded into trucks, trailers or bulk bags.

No matter what the power source, a log splitter either uses a hydraulic piston to drive the log through a stationary blade or a rotating cone shaped screw mandrel that pulls the log up over a wedge. Some models have attachments that prevent the split logs from falling to the ground allowing the operator to reposition the logs quickly for a second pass on the log splitter. Some cone or screw splitters are mounted on steel platforms mounted on a three-point hitch that allow the log to be repeatedly split into smaller pieces without putting the wood down and up again.

Although smaller firewood splitters are intended for home, there are now many commercial units available. Some commercial splitters are part of a "firewood processor" that saw logs of timber into lengths, split them, and then carry the wood up an inclined conveyor onto a pile or into a bag, truck or trailer. Specialty producers such as those producing maple syrup use units that split 4 foot lengths. Machines that split and point wood for fence post also exist though they are few in number as it is generally safer and more convenient to saw the posts.

Although a good log splitter can save the operator hours of labor, it is not possible to make it completely safe. Only trained users should operate a log splitter, since anything caught between the log and the splitting blade will be subjected to a force of at least 10 tons, while most modern wood splitters will produce 25 tons or more.

The behavior of each log cannot be predicted, so a safety zone should be established around the splitter to prevent injury from flying splinters of wood. Helpers can pick up the individual pieces of firewood, but should not stand near the log splitter while it is in operation.

Let"s look at some of the specifics of these components to see how a real hydraulic system works. If you take a trip down to your local building supply center or a place like Northern Tool and Equipment and look at the log splitters, you will find that a typical backyard log splitter has:

A two-stage pump is an ingenious time-saver. The pump actually contains two pumping sections and an internal pressure-sensing valve that cuts over between the two. One section of the pump generates the maximum gpm flow rate at a lower pressure. It is used, for example, to draw the piston back out of a log after the log has been split. Drawing the piston back into the cylinder takes very little force and you want it to happen quickly, so you want the highest possible flow rate at low pressure. When pushing the piston into a log, however, you want the highest possible pressure in order to generate the maximum splitting force. The flow rate isn"t a big concern, so the pump switches to its "high pressure, lower volume" stage to split the log.

A heat pump that’s too small for your needs will struggle to keep your home comfortable. On the other hand, an oversized unit will cost more, and if it isn’t a variable-speed model, it will cycle on and off more often than it should. This decreases efficiency, stresses components, and leaves your home less comfortable.

A heat pump’s cooling capacity is measured in British thermal units per hour (Btu/hr.). Btu/hr. can also be expressed in “tons,” with 1 ton equaling 12,000 Btu/hr. To ensure that your heat pump is sized correctly, make sure your contractor does a load calculation based on a recognized method, such as the Air Conditioning Contractors of America (ACCA) Manual J. The calculations should be made after any air-sealing or insulation upgrades are made to your home and should be done whether you’re replacing a unit or installing a new system.

One nuance to consider: If you’re planning on keeping a backup heating system alongside your heat pump, you could consider getting an undersized heat pump. A contractor can help you figure out whether this makes sense in your home.

Note that heat pumps need far less capacity to heat a space than a furnace or boiler would because they’re much more energy-efficient. For example, if your home needed a 100,000-Btu/hr. furnace, it may need only a 36,000-Btu/hr. heat pump.

The compressor is the heart of a heat pump—it’s the part that actually pumps the heat. Basic heat pumps have a single-speed compressor. It’s either on or off. This system works well enough, but the temperature and relative humidity in your home will swing up and down with the cycles. Some compressors have two speeds, which mitigates the swings, but they’re still present.

Some heat pumps use less energy than others to deliver the same level of comfort. In cooling mode, efficiency is commonly expressed as the seasonal energy-efficiency rating, or SEER. The higher the SEER, the greater the efficiency. In heating mode, the measurement used is heating seasonal performance factor, or HSPF. Again, the higher the number, the more energy-efficient the unit.

Heat pumps with higher SEER and HSPF ratings tend to cost more, but they’ll often pay for themselves over time through lower energy costs, and they may be eligible for better tax incentives or rebates than less efficient models. Heat pumps with higher SEER ratings also tend to have higher HSPF ratings, though there’s no direct relationship between the two. If you live in a warm climate, pay closer attention to the SEER. In cold climates, look for a higher HSPF.

The minimum SEER allowed for a new split system heat pump in the U.S. today is 13, and 14 in the southern half of the country. The minimum HSPF is 8.2. Systems that meet Energy Star guidelines for efficiency have a minimum SEER of 15. The minimum federal standards are all set to increase in early 2023 to a SEER of no less than 14 in northern regions, and 15 in southern regions, as well as a minimum HSPF of 8.8. The most efficient models have a SEER of 33.1 or an HSPF of 14.

If you live in a region with cold winters, you’ll need to either pick a heat pump that’s rated to work well in the lowest temperatures that your region regularly experiences or have a secondary heating system to back up your heat pump.

All air-source heat pumps struggle to perform as temperatures drop; the space they can effectively heat shrinks, and they don’t work as efficiently. The threshold for poor performance varies from model to model: Some heat pumps falter at 25° F, others at 17° F or lower.

Models marketed as cold-climate heat pumps can work to their full potential all the way down to 5° F and may deliver some heat even down to -20° F or lower. The best course is to work with a qualified local contractor who knows what kind of equipment works well in your area.

If you live in an area where the temperature rarely or never drops below freezing (32° F), a basic heat pump can handle the bulk of your heating and cooling needs. You can keep a simple electrical-resistance backup system (sometimes built into the heat pump itself) for unusual cold snaps.

Manufacturers publish the noise levels for their products in the user manual and often on their websites. They tend to include noise estimates across a variety of outdoor temperatures and fan speeds, measured in decibels. A lower rating is better, especially if the heat pump will be installed near a bedroom window.

According to our member survey, reliability is by far the top predictor of an owner’s overall satisfaction with a heat pump. Consumer Reports members can see the predicted reliability and owner satisfaction ratings for 24 brands of heat pumps, based on data that CR members have shared about almost 13,500 heat pumps they’ve bought new and installed in their own homes between 2005 and 2021. Those findings are summarized in our guide to the Most and Least Reliable Heat Pumps.

8613371530291

8613371530291