takeuchi hydraulic pump free sample

That is why they are so commonly used on construction sites. One of the most commonly used construction sites is the takeuchi hydraulic pump, or the hydraulic piston pump, is a type of pump that is commonly used on construction sites. For example, there are two types of hydraulic piston pumps, one of the most commonly used construction sites.

The takeuchi excavator (TB016) is a type of hydraulic pump, which is also known as a takeuchi excavator (TB016), is a type of excavator that can hold TB016 as its hydraulic piston number (TB), is a type of excavator that takes TB016 to a high-pressure area (TB) of the excavator (TB016), is a type of excavator that can hold TB016 as well. Hydraulic pump TB016 is a type of excavator that can hold TB016 as well. The TB016 is a type of excavator that takes TB016 to a Hydraulic pump (TB016), is a type of excavator that takes TB016 as a type of excavator. TB016 is a hydraulic pump, also known as a tB.

Brand new final drive directly from South Korean manufacturer by North American representative office. Price includes delivery within Canada and the continental USA Complete and fully assembled brand new hydraulic motor and new heavy-duty planetary gearbox, filled with oil, ready to bolt on and go Quality, built in our own factory in South Korea.

We offer the best performing drives for the major OEM brand machines and high-speed! 2-speed capability, works on either side of your machine and has the same location and size of hydraulic ports as your original for ease of making hose connections. If there is any difference in port location, we supply free hoses together with your final drive to make the conversion easy.

Brand new final drive directly from South Korean manufacturer by North American representative office. Price includes delivery within Canada and the continental USA Complete and fully assembled brand new hydraulic motor and new heavy-duty planetary gearbox, filled with oil, ready to bolt on and go Quality, built in our own factory in South Korea.

We offer the best performing drives for the major OEM brand machines and high-speed! 2-speed capability, works on either side of your machine and has the same location and size of hydraulic ports as your original for ease of making hose connections. If there is any difference in port location, we supply free hoses together with your final drive to make the conversion easy.

Hydraulics: the heart and soul of your machine. Over the last several years, hydraulics have become more sophisticated with better performance through larger pumps and higher pressures. Some machines maintain performance with less horsepower (HP) due to Tier 4 emission regulations.

Not only do hydraulics now feature higher quality components for improved lifting capacity and breakout forces, but they also make more versatile machines. That versatility starts with attachments.

Operators can now handle a wide range of tasks with a single machine, thanks to higher hydraulic performance. The capacity to connect a multitude of attachments continues to advance in the industry with stronger hydraulics as well as attachment-friendly designs and features. Improvement—even in the last five years—is evident.

Multiple attachment presets on Takeuchi excavators can dial in proper flow adjustments for optimal attachment performance from the comfort of the operator’s station multi-informational display.

It is important to be proactive by performing regular maintenance and safeguarding the hydraulic system from even the smallest contaminates. Like emissions compliant diesel engines, today’s more refined hydraulic components are highly sensitive to contamination.

Contamination will most certainly shorten the life of or completely wipe out hydraulic components, depending on how much and what variety. To protect sensitive components, practice routine maintenance for everything from filters to fluid testing (see maintenance schedule below).

In addition to routine maintenance, cleanliness is also important when swapping out attachments. Keep dirt and other contaminates from getting into the system by cleaning attachment fittings on both the machine and attachment side before connecting. Clean the refill cap and surrounding area before replenishing hydraulic fluid.

We recommend connecting only new hydraulic attachments to your machine or ones already in your lineup. Otherwise, you may be introducing contaminated oil into your machine’s system by using an unfamiliar attachment. Unless you are willing to take the time to test the hydraulic fluid already stored in the attachment, you should be aware of the potential consequences.

Manufacturers have a new machine break-in period around the first 50 hours of operation. Follow scheduled (hourly) maintenance for replacement of filters and hydraulic oil

We are the only manufacturer to utilize a four-pump hydraulic system in most of our excavator lineup. This provides excellent multi-function capabilities without the reduction in cycle times. Smooth, precise control delivers faster cycle times, while fine grading and precision control is important when working around hazards and excavating near structures.

For maximum productivity and efficiency, operators can change hydraulic flow and multiple attachment settings on Takeuchi machines. Because of this, Takeuchi SSL and CTL lines can run virtually any available attachment, creating a strong bottom line.

The hydraulics system is the backbone and hardest working part of the machine; damage it and your excavator, CTL or SSL are rendered useless. Not only will damage or neglect cost you downtime on the job, but you’ll also pay thousands of dollars down the road. Make a plan to protect the most expensive and vital components of your machine.

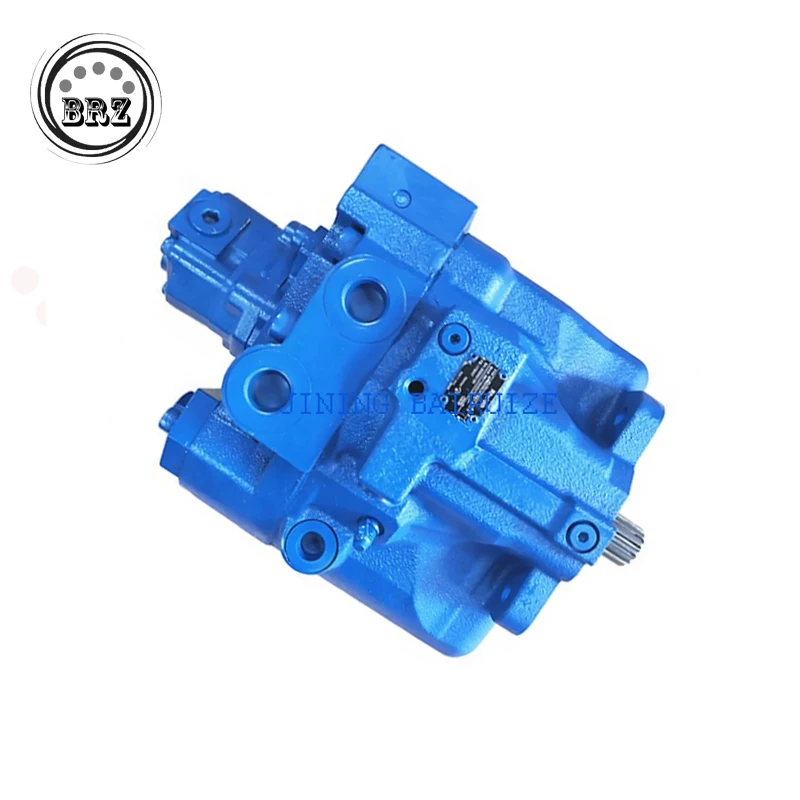

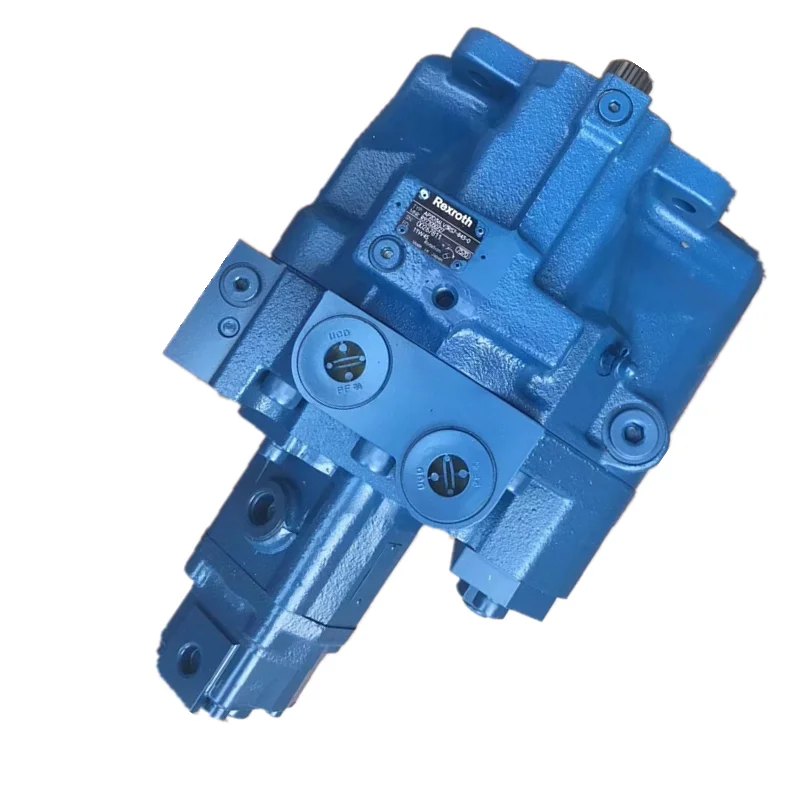

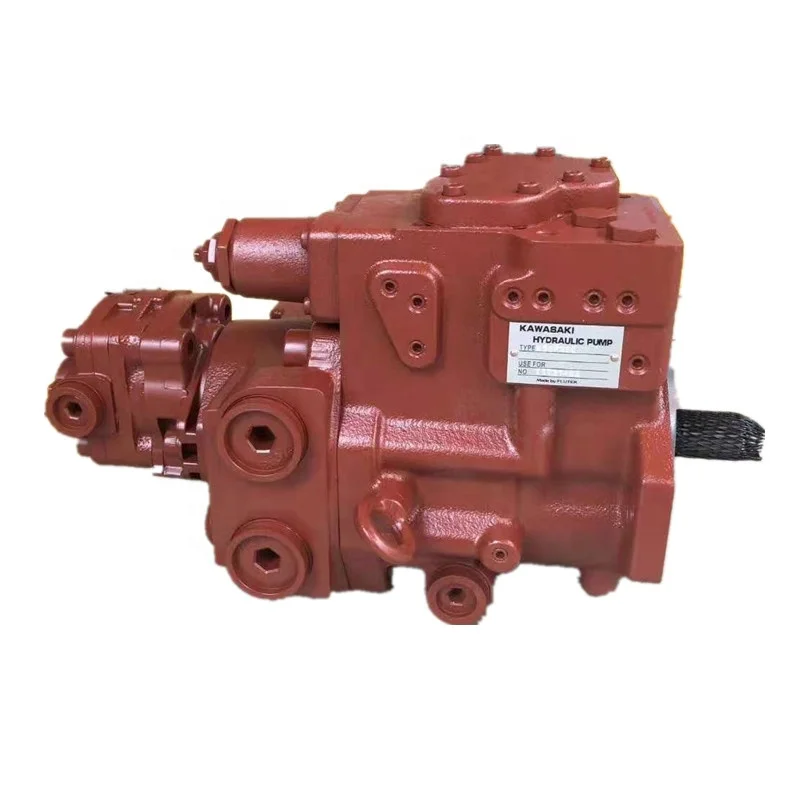

The diesel engine isn’t really the heart of a skid steer. When it comes to a heart (the machine’s pumps), a skid steer or track loader actually has three or four hydraulic hearts. These pumps power fluids — compressed oil — to move, spin, lift the boom, curl the bucket and run a zillion different attachments. This set of hydraulic pumps (gear, hydrostatic, tandem, back to back, variable displacement) come in many configurations, brands and power ranges. Over the last decade in particular, the science and technology behind these systems has made them smaller, more efficient and more sophisticated.

“Probably one of the biggest innovations in the last five to 10 years has been the advent of electronically controlled hydraulic systems. We call them EH systems,” explains Nathan Wood, hydraulics system engineer for John Deere Construction and Forestry. “You’re controlling the hydraulic system precisely with electronic signals. It leads to a lot more controllability and a lot more ability to do different types of automated controls and functionalities.”

“Originally the first skid steers were hydrostatic controlled by mechanical linkages,” says Kevin Scotese, product manager of sales support, compact equipment, at Volvo Construction Equipment. “The next step in the evolution was the implementation of pilot controls, and the last step has been in the improvements of electro hydraulic controls, which provide the possibility to customize the feel, speed and responsiveness. Another technology to maximize the power and reduce parasitic losses is the implementation of state-of-the-art closed center load-sensing systems in combination with the variable axial displacement piston pumps.”

Pretty high-tech stuff, eh? Today, fluid power is being used to control everything from the tracks to the attachments to the cooling fan to automated features such as creep mode, return to dig and settable attachment speeds — all built right into the joystick. But as you might expect, skid steer and track loader hydraulic systems have gotten quite complex, and just like any oil system in a machine, it will definitely require routine maintenance, testing and proper seasonal oil.

Well, that all depends on the size and configuration of each skid steer or track loader. Every brand is somewhat similar, but each unit is engineered uniquely. Let’s break the system down into two parts: 1) the hydraulics powering the boom, bucket and auxiliary circuit and 2) the hydrostatics powering the wheels or tracks. The hydraulic system powering the boom, attachment, automation features and even cooling usually uses up to three pumps — a main hydraulic pump, a charge pump, which provides control pressure, cooling and fan power, and if you get the high-flow option, a third high-flow pump. Without that option, there are two.

“For the pumps powering the arm, bucket and auxiliary hydraulics, smaller machines run a gear pump, but on the larger models this is a load-sensing axial variable displacement pump limiting the parasitic losses and providing better power to the loader functions and auxiliary,” says Scotese. “For the auxiliary, high-flow option on the smaller models, an additional gear pump is utilized in tandem to provide the required flow. On larger models, a higher-capacity load sensing axial variable displacement pump is providing the higher flow. Charge pressure and flow for the transmission and hydraulic fan motor is usually provided by a smaller PTO-mounted gear pump.”

When it comes to powering the tracks or wheels, there is a bigger, double-pronged hydrostatic pump that powers the machine’s mobility. There is a hydrostatic pump that provides flow and pressure to one motor on the right-hand side and one motor on the left-hand side. On a skid steer or track loader, it’s usually one tandem pump or back to back, providing dual power to two motors for each set of wheels or tracks.

Manufacturers use lots of different brands of pumps — Danfoss,Turolla, Rexroth, Concentric, Eaton and Parker Hannifin. These pumps combined with the overall hydraulic systems come with three main specifications — system pressure (psi), gallons per minute flow to the attachment (gpm) and overall hydraulic horsepower (which tops off about 100 hp). Each manufacturer will engineer and market those specs differently.

“Starting with the hydrostatic system, the transmission and drives system, pressures are pretty high, upward of 6,000 psi,” explains Woods. “These are heavy-duty components to get the speed and torque you want. When it comes to the hydraulic system, bucket, boom and aux, typically you’re running between 3,000 and 5,000 psi. We run right around the 3,500-psi range. We find that that allows us to use reasonably sized cylinders and boom geometry to get the breakouts we need, while still maintain the speed we require.”

Hydraulic flow to the auxiliary circuit and the attachment will be determined in gpm and as standard- and high-flow configurations. Bobcat’s tiny S70 skid steer uses 9.8 gpm for its standard flow system. The optional high-flow on the Takeuchi TLV12V2 (the biggest track loader on the market) is 40.4 gpm. The price difference between standard and high flow usually falls right around the $3,500 range (5 to 7 percent more), and the high-flow option is usually more common on the largest skid steers and track loaders.

Let’s start off with this ubiquitous warning: It’s very important to review your owner/operator’s manual before attempting to perform any maintenance to the hydraulic system, taking special care to review the safety procedures listed in the manual. With the variety of options available today such as high flow, bucket self-leveling, ride control and hydraulic quick-attach brackets, there may be up to five or six control valves as well as pumps. All of these components are designed with very tight tolerances, which may fall below 0.001 in. Because of this, keeping the hydraulic system clean is critical to the life of these components.

“Keeping the system clean and cool is the No. 1 objective,” explains Wake. “ASV has the largest cooling packages and hydraulic tank capacities in their respective classes. That combined with double and triple filtering assures the oil is kept both clean and cool. Owners can help by following the maintenance guidelines in the machine’s owner’s manual, as well as making sure to clean around the hydraulic cap before removing. Be sure any hose fitting is cleaned before removal, and wipe off quick-coupler ends before hooking attachments to the machine.”

Contamination can enter the system in a variety of ways. Before removing the hydraulic oil reservoir cap, clean the area around it to prevent dirt from entering the tank. If using a bucket, make sure that there is no loose dirt on the lip. While all machines will have at least one hydraulic filter to remove debris from the system, this filter might be in the return side of the hydraulic system. There is a screen inside the tank to prevent large material from getting into the pumps, but it won’t catch small particles. Make sure you look for features from brands that make using and cleaning the hydraulic system easier.

“A very important feature which is standard on Volvo skid steers is the case drain on the auxiliary block and the pressure relieving by simply pushing in the quick-connect couplers on the manifold which simply vents pressurized oil in the main lines to the tank. This is a very well-liked feature to ease the hookup of hydraulic lines,” says Scotese.

In order to further prevent contamination, make sure to follow the OEM’s service interval for hydraulic filter replacement. This may fall anywhere between 500 to 1,000 hours depending on manufacturer and operating conditions. A plugged up hydraulic filter may cause a variety of issues such as loss of speed or power, overheating of the hydraulic oil and damage of components. What type of hydraulic oil should be used in your loader?

Just as important as the type of hydraulic oil used is the amount in the tank. The operator’s manual will show where the level should be within the sight glass and where the boom and bucket should be located while checking the hydraulic oil level. Most machines should be checked on a level surface while having the boom all the way down and the bucket flat on the ground. Hydraulic oil should be checked daily, if not before every time the machine is operated. If the level is low, look around carefully for leaks. Given the dusty and dirty conditions that skid steer loaders and compact track loaders operate in, it is not uncommon for debris to damage the hydraulics and thus affect things like “feeding speed.”

“Brushcutting and cold planing are a couple examples of demanding applications on a hydraulic system,” says Wake. “Both can use 100 percent power at nearly 100 percent of the time. In demanding applications like this, the key to maximum production is feeding speed. Feeding the attachment at a rate to use 100 percent of the power — but not exceeding it to the point the engine bogs, the attachment slows greatly or the attachment stops — will give the most production with the least demand on the machine and operator. A feed pace with the engine pulling a few hundred rpm off peak, tends to be the sweet spot.”

The accumulation of debris from an application like brush cutting can harm the hydraulic cooler. The oil cooler might use engine coolant or outside air to cool the oil. It is vital that the oil remain within the acceptable operating temperature range. Make sure the oil cooler is free of debris and the cooling fins are fairly straight. “John Deere has an electronically controlled hydraulic fan that can vary the speed based on the required cooling,” says Wood. “It’ll also automatically reverse at a set interval to expel the debris built up on the coolers to help limit the number of times you actually have to physically clean out the cooling package.”

Another common way for contamination to enter the hydraulic system is by using hydraulically powered attachments. Before connecting any of the auxiliary hoses, be sure to wipe off the connectors to get rid of any water, dust or other debris. If an attachment was used on a loader that had a hydraulic failure and spread contamination into the attachment, that contamination may enter the next machine it’s connected to.

“That’s probably one of the more concerning things,” says Gregg Zupancic, product marketing manager of skid steers and compact track loaders with John Deere Construction and Forestry. “When you rent attachments, the question is: Who rented that machine last, and what types of materials are in their hydraulic systems and sitting in that attachment unused for a long period of time? That’s why you do things like hydraulic fluid sampling.”

The Cool Flow hydraulic oil cooler from Loftness Specialized Equipment greatly reduces the risk of overheating in skid steers and hydraulically powered attachments when operating in demanding applications and hot work environments. The automatic thermostat-controlled fan provides adequate cooling to the system whenever needed to boost machine efficiency, even when an attachment is not being used. Unlike most other hydraulic coolers that are mounted near the attachment, the Cool Flow attaches to the roof of a skid steer cab where it is less susceptible to vibration, back pressure, debris and potential impact damage. It is specially engineered to allow full hydraulic flow to the attachment in either direction without risk of damage to the cooler. The Cool Flow has up to 40-gpm flow capacity and is compatible with all brands of skid steers.Concentric, Danfoss, Eaton, home, John Deere, March 2016 Print Issue, Parker Hannifin, Rexroth, Turolla, Volvo Construction Equipment

Hydraulic contamination is a major source of problems for any type of hydraulic system, but especially for hydraulic motors and final drives -- which means that it is very important to be well informed on the subject. In this Shop Talk Blog post, we are going to talk about the types and sources of contamination, as well as how to avoid contamination. This information is important for all types of hydraulic construction equipment, from a

There are best way to deal with the effects of chemical breakdown and reactions is to drain the hydraulic fluid and replace with fresh, filtered fluid.

Many people do not realize that hydraulic fluid arrives contaminated. Manufacturers do not always have complete control of how the fluid is stored and shipped, so for optimum machine performance experts recommend that hydraulic fluid be filtered before it is added to the system. In addition, different types of hydraulic fluid Reactions can occur between the additives that can seriously compromise the performance of the hydraulic fluid and damage your system.

Contamination can be introduced when hydraulic equipment is being serviced, especially if it is serviced in the field. The exterior of the equipment should always be cleaned before it is serviced (you"ll notice what thoroughly

When it comes to preventing damage to your final drive from hydraulic contamination, the key is to check and change the case drain filter. Most hydraulic motors have a

The key to keeping your hydraulic equipment free of contaminant damage is to filter the hydraulic fluid before it goes into the system, drain and replace the hydraulic fluid regularly, check and change the filters and breathers, and only open up the hydraulic system in a clean environment.

Atravel motoris a part of an excavator"s hydraulic drive system, whose power source is the machine"s main hydraulic pump. As a result of the travel motors" power, the final drive is then able to use it and turn the power into torque. The travel motor is a key component in the function of an excavator by playing a major role in fueling the final drive motor. However, it doesn"t perform the same function as a final drive.

Speaking of which, a final drive comprises many gears and is located adjacent to, and works in conjunction with, the excavator"s travel motor. The integrated final drive motor"s purpose is to provide enough power to allow an excavator to turn its tracks on a construction site. There are two key integrated components of a final drive motor: the hydraulic travel motor and the final drive gear box.

The differences between travel motors and final drive motorscome down to their functions. While the two are related, it"s certainly important to know what sets them apart when getting new parts. When referring to a final drive motor, this typically means the hydraulic motor and the planetary gear hub, while a travel motor signifies only a hydraulic motor. If you are in need of Quality travel motors and final drive parts, Mini Final Drives is a great place to find the excavator parts you are looking for from top brands like Bobcat, John Deere, Caterpillar, and others.

8613371530291

8613371530291