tractor auxiliary hydraulic pump manufacturer

Our PTO Auxiliary Hydraulic System is used for any type of agricultural equipment when an application or piece of equipment requires more hydraulic oil flow than the tractor/equipment can provide. Out most typical application is for Air Seeders (planters) when Ag Tractor Hydraulic systems don"t meet the flow, pressure or cooling requirements for proper operation of equipment. DFP"s PTO Auxiliary Hydraulic Systems are completely customizable to fit your specific application.

Hydraulic reservoir is typically 25 gallons, but capacity is flexible to meet any application requirements as these systems are built to order. Also included is a Spin-on Return Filter and an Oil Cooler (12VDC) with Temp. Switch mounted and plumbed to Hydraulic Reservoir (tank). (end user to supply power to 12VDC Fan on cooler) Other options for the hydraulic reservoir, but are not limited to: Relief Valve Block, Pressure and Tank Manifolds, Hydraulic Directional Control Valves and Flow Controls. DFP"s PTO Auxiliary Hydraulic Systems are completely customizable to fit your specific application.

This industrial built and designed 3-point auxiliary hydraulic unit allows you to operate attachments on tractors that don’t generate enough hydraulic horsepower on their own. This self-contained unit produces enough gallons per minute allowing you to operate these hydraulically-driven attachments, thus expanding the versatility and value of your tractor loader. The hydraulic pump offers superior performance over any of our competitors because it generates higher gallons per minute and line pressure. This allows for a wider range of attachments to be used.

The Blue Diamond® Auxiliary PTO Pump offers constant hydraulic flow to give your tractor the ultimate performance for our Multi-Purpose Series Cutter. The weight of this unit can also be used as a counterbalance for front cutters.

High performance and dependability are the trademarks of all Kawak Auxiliary Hydraulic Systems. The Kawak Bell 47 auxiliary hydraulic pump is designed to provide an inexpensive, robust, and reliable replacement for pumps which have been previously installed. The Kawak auxiliary pump drive is also fully compatible with our Chemical Pumps and Boom Valve Assemblies.

These pumps are specially designed with drive shafts which have been engineered to shear when torque between 850-1000in/lbs is applied. This feature functions as an automatic system disconnect should the hydraulic system malfunction while the aircraft is operating. The adapter plate which attaches the pump to the engine pad also includes a drain port which allows for simple inspection of failing pump shaft seals to enable the operator to minimize revenue-generating aircraft downtime.

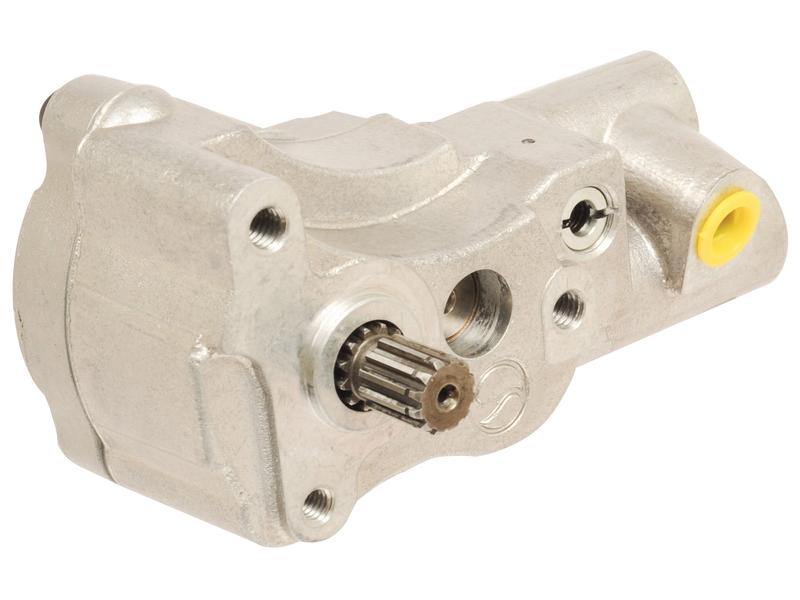

This Auxiliary Hydraulic Pump is for models: 135 UK, 165, 165 UK, 175, 178, 180, 1080, 1085, 235, 240, 245, 250, 253, 255, 265, 270, 275, 283, 285, 290, 298, 298, 670, 690, 698, 699. Replaces OEM Numbers 1663627M92, 1686765M1, 1686765M91, 1686766M91, 1869458M92, 526099M93, 531604M92, 5316073M92, 531607M92, 531607M93, 886367M95, 886367M96, 531607M91. Reference ID: 1663627M92Condition: New

New, aftermarket Massey Ferguson 165 Auxiliary Hydraulic Pump for sale with a solid manufacturer warranty. In addition, we have a generous 30-day return policy if this item needs to be returned for any reason. Please see our Parts Warranty and Return Policy links for complete details before returning.

Yesterday"s Tractor Co. has spent many years locating the correct parts for your Massey Ferguson 165 tractor. Our extensive research has helped us identify these parts and make them available through our online catalogs. If you can"t locate what you need or have questions feel free to call us.

ABOUT THIS PAGE: You are viewing the product page for our Massey Ferguson 165 auxiliary hydraulic pump. As one of the largest suppliers of new and rebuilt Massey Ferguson 165 tractor parts we most likely have the parts you need. Use the information above including the auxiliary hydraulic pump part number and picture (if available) to assist you in making your decision to purchase. If you are looking for a different auxiliary hydraulic pump, or have trouble locating the Massey Ferguson 165 parts you need, we have MANY parts that are not listed on our website so feel free to contact us.

This Auxiliary Hydraulic Pump is for models: 135 UK, 165, 165 UK, 175, 178, 180, 1080, 1085, 235, 240, 245, 250, 253, 255, 265, 270, 275, 283, 285, 290, 298, 298, 670, 690, 698, 699. Replaces OEM Numbers 1663627M92, 1686765M1, 1686765M91, 1686766M91, 1869458M92, 526099M93, 531604M92, 5316073M92, 531607M92, 531607M93, 886367M95, 886367M96, 531607M91. Reference ID: 1663627M92Condition: New

New, aftermarket Massey Ferguson 245 Auxiliary Hydraulic Pump for sale with a solid manufacturer warranty. In addition, we have a generous 30-day return policy if this item needs to be returned for any reason. Please see our Parts Warranty and Return Policy links for complete details before returning.

Yesterday"s Tractor Co. has spent many years locating the correct parts for your Massey Ferguson 245 tractor. Our extensive research has helped us identify these parts and make them available through our online catalogs. If you can"t locate what you need or have questions feel free to call us.

ABOUT THIS PAGE: You are viewing the product page for our Massey Ferguson 245 auxiliary hydraulic pump. As one of the largest suppliers of new and rebuilt Massey Ferguson 245 tractor parts we most likely have the parts you need. Use the information above including the auxiliary hydraulic pump part number and picture (if available) to assist you in making your decision to purchase. If you are looking for a different auxiliary hydraulic pump, or have trouble locating the Massey Ferguson 245 parts you need, we have MANY parts that are not listed on our website so feel free to contact us.

If field installing this option code, kit part numbers for power beyond, motor return, and flush-face sump connectors for wheel and track tractors are available.

Compatible with 8030 Series Wheel Tractors (serial number 040000) and above, 8030 Series Track Tractors (serial number 905000) and above, and 8R Series Wheel Tractors.

NOTE: To assist hooking up to large planters, seeders, and harvesting equipment where multiple connections are required, factory-installed auxiliary hydraulic couplers on wheel tractors are available.

There are many agricultural tools and machines that employ hydraulics for smooth working. And note that a tractor is among these powerful and sturdy machines that rely or depend on the sheer power of hydraulics.

Many people are familiar with hydraulics and hydraulic systems; however, how many among us really know and comprehend how hydraulics work and operate in the tractor loader? Keep in mind that the components and parts of a typical hydraulic system comprise a reservoir, many valves, and pump. And it’s worth noting that hydraulic control valves and other parts can operate in a system that accurately directs, or controls liquid flow.

Hydraulic control valves for tractor loaders are an irreplaceable part that’s used in various kinds of machines in several industries. For example, it is the basis of activity in agriculture and construction. It is hard to imagine modern excavators, tractors, and loaders without a hydraulic control valve.

We can say that a hydraulic valve is an effective mechanical device that regulates the fluid flow within a specific hydraulic system or circuit. Did you know that you can also use it to completely close a line, or redirect pressurized fluid or even control the degree of flow to specific areas?

Hydraulic valves are usually used in hydraulic power packs in order to direct the fluid either from or to a hydraulic cylinder. Hydraulic valves are important as they help control and regulate the amounts and direction of fluid power in a circuit by closely controlling and tracking the flow rate and pressure in various components of the circuit.

Keep in mind that hydraulic valves in a tractor must be capable of withstanding high degree of fluid pressure. And it’s because the nature of many contemporary hydraulic systems means high pressure values of 3,000 PSI or even more.

Remember that the hydraulic system in the machine has to lift the bale or the load of dirt and the bale fork. So, even a small tractor’s hydraulic system is usually under massive pressure.

As a result, they are usually constructed of iron, or steel. The material should have sufficient strength to withstand continuous and extreme operation under pressurized conditions. Also, the hydraulic reservoir is typically used for storing non-pressurized hydraulic fluid.

Before learning how to add a hydraulic valve to your tractor, you must know and appreciate how a hydraulic system typically works on any tractor. Note that the hydraulic system works with the help of pumps. These pumps are essential and transfer the fluid from the hydraulic system’s big reservoir to the tractor’s hydraulic system.

And this process raises the level of energy. This is done by gradually raising the pressure. And the motor inside your tractor is the primary power source for pumps. The fluid or liquid is under intense pressure and acts on both the piston and rod inside your cylinder.

On the other hand, when these parts gradually retract and move back, you will see that all the fluid will slowly get back to the reservoir. After that, you will notice the metallic walls of this reservoir start to trigger a drop in the fluid temperature by letting all the heat energy escape. This is crucial as it reduces the total pressure in the reservoir. The operation or mechanics of a tractor’s hydraulic system works mainly based on Pascal’s law.

If you attach a remote hydraulic system in order to make your tractor more efficient, it will give you the opportunity to add many hydraulic accessories. A few of them are a log splitter, hydraulic top link, blades, and hydraulic auger motor. Note that if you used an open centered valve, then the oil will be moving along the standard route to the 3 point until someone pulls the handle on the valve.

After that, the valve may divert the oil to increase or lower your hydraulic accessory. You can reverse the oil or fluid flow to your accessory by pushing the handle in the other direction.

There is no doubt that a hydraulic valve in your tractor loader is among the most integral components in this valuable hydraulic machinery. The valve is crucial. This is because it allows fluid to flow in different directions from either one or multiple sources. It’s worth noting that hydraulic valves in tractor loaders usually have a spool. We can say that the spool is encased in a cylinder that you can control either mechanically or even electrically.

The best thing is that it is simple to turn an old tractor, such as your garden tractor, into a capable earth moving machine or convert its conventional manual lift system to hydraulic. Did you know that adding hydraulics can multiply a tractor’s engine power manifold?

⦁ You should carefully and gradually depressurize the sensitive hydraulic system. It is essential that you consult and go through your specific system documentation to make this step simple.

⦁ Now remove any electrical power or energy source from your system if electric pumps are pressurizing it. You can do this by disconnecting your pump’s power connector or simply pulling its circuit breaker. However, keep in mind that some mechanically driven pumps, like engine-driven pumps, might not have electrical connectors.

⦁ You should remove your old or current valve by removing the current electrical connector. Now place a few buckets underneath the hydraulic valve in a careful manner and then unscrew the bolts and nuts that are leading to the valve.

⦁ Carefully position your valuable hydraulic valve where it will be installed. You should plug the fittings present on it and then cap all the ends of either the tubing system or pipes it will connect to. You should plug all hydraulic lines. These lines may lead to or/and from the valve. Plugging them will minimize the risk of fluid loss. It is best to use plastic plug or aluminum plug that easily screws into the fitting.

⦁ You should supply proper electrical energy if it’s required to provide pressure and force to the hydraulic system. Keep checking for leaks in the system while it is under pressure. You have to understand and appreciate that liquids are incompressible, and they transmit pressure with equal force in nearly all directions.

Did you know that engines in tractors, even garden tractors, have sufficient power to push hydraulic oil up to 2,000 PSI or even more? The hydraulic system you will find on all major N-Series tractors was carefully designed for plowing.

Conversely, electric hydraulic valves for tractor loaders use electromechanical solenoids for carefully sliding the spool. As the uncomplicated application of electric energy offers much-needed control, now these valves are popular.

Many N-Series tractors, such as 9N, and 2N from Ford-Ferguson now use a 2-stage clutch. Some even use an efficient hydraulic pump driven directly off an engine. Keep in mind that adding these clutches to these newer models may seem almost impossible; however, few can deny that engine-driven pumps are too complex.

It is worth noting the original and renowned belly pump comes with a test port. This port offers a convenient and feasible place for supplying pressure and force to any hydraulic system.

When working with a hydraulic system, including hydraulic valves, pumps, and hydraulic hoses and cylinders, it is vital to remember all the proper safety precautions in order to avoid accidents and injuries.

When you are transporting your tractor or other machine, it is imperative to lock the cylinder stops in order to hold or secure the working units firmly in place.

⦁ Many pumps and other hydraulic devices, such as control valves are bulky. So, before removing them, you need to find a reliable support structure like a chain hoist.

For the farming and agriculture industry, a tractor is important for performing various agriculture tasks safely and precisely. And like other heavy vehicles and machinery, tractors use hydraulics for their steering and braking systems. And the hydraulic systems for tractors can be used to lower or raise heavy agricultural implements attached.

Are you looking for the best option for a hydraulic control valve? If so, you must contact the leader in all hydraulic manufacturing: Magister Hydraulics.

All hydraulic control valves and hydraulic gear pumps for tractor loaders are made with high-quality materials designed to prevent corrosion and enhance the function of this key element in the most severe working conditions. In our store, you will find hydraulic control valves, hydraulic hoses, and hydraulic cylinders for tractor loaders only of the best quality. As a result, you can be certain that you are purchasing a proven product that will always work in your business.

8613371530291

8613371530291