two speed hydraulic pump manufacturer

High pressure two stage hydraulic hand pumps, easy to handle and use, with very high oil flow rates to operate a wide range of hydraulic cylinders or ...

Rotary-Style Air Motor. Use where air is the preferred source of energy. Two-speed operation for high speed cylinder advance. Durable two gallon thermoplastic reservoir. ...

The 10 series Power Team hydraulic pumps are designed to have a maximum of 690 bar (10,000 psi) at a flow rate of 164 cc/min (10 cu. in/min). All Power Team pumps come ...

The Power Team HB series is purposefully constructed to convert low-pressure portable hydraulic pumps or on-board hydraulic systems, into high pressure power sources. HB series applications ...

Air hydraulic pump, double pneumatic motor, double effect, foot operated with lock-up function, lever distributor valve (4/3), 10L tank, oil flow 8.5 / 0.26 l / min

... operated pump range offers a choice of single or two speed operation and all models are supplied complete with a pre-filled oil reservoir, ready for immediate use. All models have a maximum ...

The HP245 range of high flow, two speed, manually operated pumps is ideally suited for applications where high tonnage cylinders are to be used on sites, without any available electric ...

... pressure hydraulic pumps is specifically designed for high pressure applications such as oil injection for bushing removal, valve testing, calibration of high pressure equipment and instruments, laboratory ...

... socket and etc. hydraulic lifting tools include: double acting jacks, single acting jacks, hollow jacks, big tonnage jacks.hydraulic pulling tools include: hydraulic pullers.Power pack ...

The Enerpac P202 is a two speed, lightweight, portable hand pump designed with durability and ease of use in mind. These pumps are constructed with large oil capacities to power a wide range of cylinders and tools.

The Enerpac P142 is a two speed, lightweight, portable hand pump designed with durability and ease of use in mind. These pumps are constructed with large oil capacities to power a wide range of cylinders and tools.

Compact Design, Economical Conception, High Rotating Speeds, High Output Pressure, Reduced Noise Level, Smaller Installation Dimensions, One Piece Pistons with Piston Rings, Special Suction Fittings & Accesories, Simple Change of Direction of Rotation..

A hydraulic valve is a mechanical device that regulates the flow of the hydraulic fluid in a hydraulic system. Hydraulic systems are typically high pressure systems, ranging from 200 Bar averaging 700 Bar upwards...

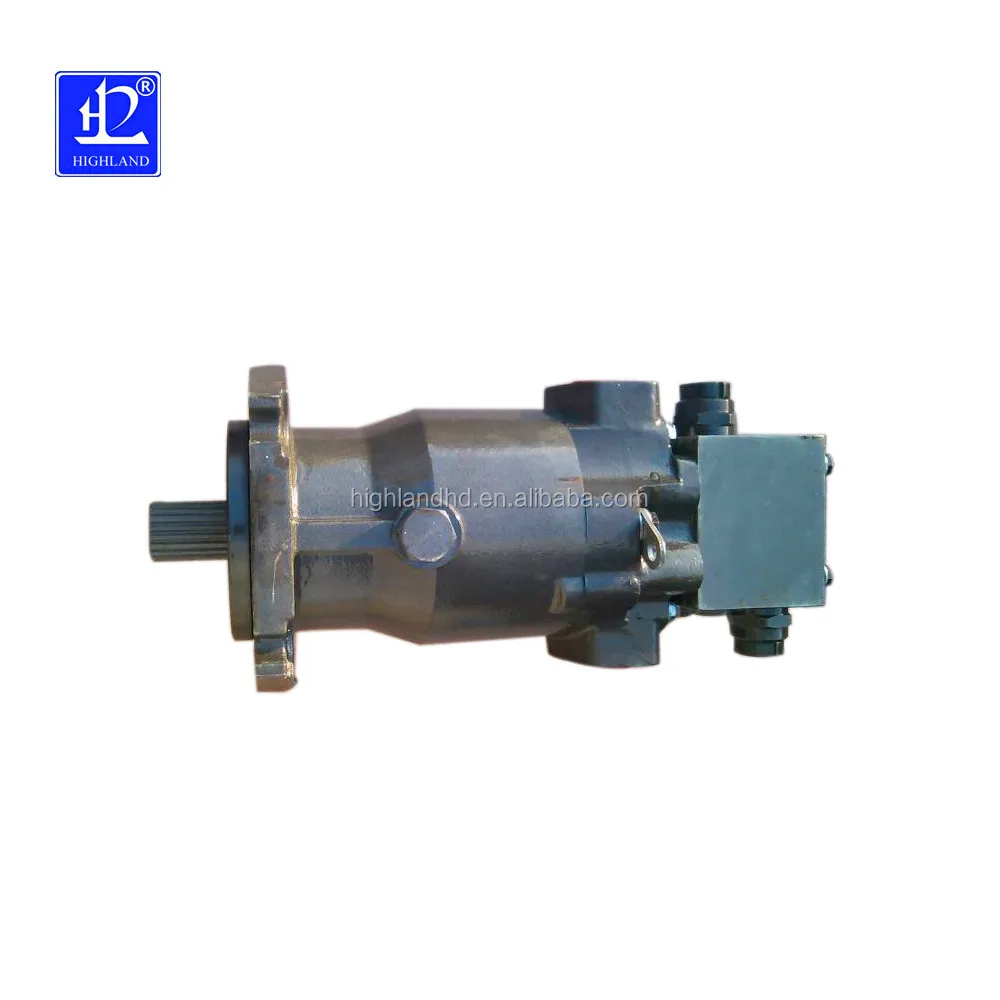

The main enclosure and interior components are made from metal such as steel or iron so they can withstand high pressures and operating speeds. High speed hydraulic motors are widely used in aircraft, vehicles, industrial lifting and in machinery that requires strong pressurized actions. High speed hydraulic motors, when used in a suitable system, are able to accomplish large amounts of work in short periods of time.

Additionally, hydraulic motors are frequently used in automated manufacturing systems, trenchers, automobiles, construction equipment, drives for marine winches, waste management and recycling processes, wheel motors for military vehicles, self-driven cranes, excavators, forestry, agriculture, conveyor and auger systems, dredging and industrial processing.

High speed hydraulic motors are simple machines that are composed of a reservoir, a pump and rotating machinery. The pump is connected by a line to a motor that draws the fluid, which is usually oil, from a reservoir and into the motor. The fluid forces motion by the moveable parts of the motor as it rotates. The rotation of the motor turns a coupled shaft which provides mechanical motion; the motor serves as the actuator that converts the pressure of the fluid into torque and rotational energy.

The fluid is discharged, filtered and reused. There are three main kinds of hydraulic motors: gear, vane and piston type. The differences among them are related to how the hydraulic fluid causes motion. Gear motors have interlocking gears that are rotated by streams of oil or water, the two most common fluids, being pumped down onto the teeth.

Vane motors have flat blades that move in and out of slots in a rotating wheel and piston type hydraulic motors have at least two pistons that transfer pressure back and forth to generate power. Radial piston motors are very efficient but have limited high speed capabilities. High speed hydraulic motors are able to provide energy for many different functions simultaneously because of the amount of power they can generate and their efficiency; one pump in a system can power several motors.

Technically, hydraulic motors are mechanical actuators; they convert pressure into rotational hydraulic energy and torque. They are also the rotary counterpart of hydraulic cylinders. Because hydraulic motors are driven by engines, they may also be called hydraulic drive motors.

Broadly, hydraulic motors serve the construction, automotive, agriculture, forestry, manufacturing, military, waste management and recycling, aerospace, marine, and oil and energy industries.

Hydraulic motors, for example, help raise the wing flaps of airplanes and power the lifting of industrial cranes. Some other of the many machines with which customers use hydraulic motors include agitator and mixer drives, crane drives and self-driven cranes, conveyor and feeder drives, drilling rigs, cars and trucks, drum drives for digesters, high-powered lawn trimmers, the wheel motors of military vehicles, shredders, trench cutters, trommels, kilns, excavators, marine winch drives, and plastic injection machines.

The first hydraulic motors were born during the Industrial Revolution, when industrialist William Armstrong started working on ways to make hydraulic power more efficient. One of the first results of his efforts was his invention of the water powered rotary engine. While his contemporaries did not make much use out his engine, it did serve as an example of a working hydraulic powered rotary actuator upon which later inventors could build. Later, Armstrong designed the hydraulic motor used to the power the Swing Bridge positioned over the River Tyne. His oscillating, single action engine featured three cylinders. Over the years, Armstrong designed many different hydraulic motors, used to power machines like hydraulic cranes and applications related mainly to bridges and docks.

Many of Armstrong’s designed wasted water because they used the same amount of water no matter the load size. This is because they featured fixed strokes and valves with cut-offs operators could not control. To remedy this, engineers such as Arthur Rigg began designing variable stroke hydraulic motors. Generally, operators were able to control water consumption and engine power by adjusting stroke. Arthur Rigg patented his engine design in 1886. It featured a three-cylinder radial engine, the stroke length of which operators could control using a double eccentric mechanism.

Since the Industrial Revolution, engineers have learned ways to use hydraulic power more efficiently and to achieve greater feats. Modern hydraulic systems power hydraulic equipment and products like bulldozers, cranes, kilns, hydraulic lifts, metalworking machines, and much more.

For the best results, manufacturers build the interior hydraulic motor components and main hydraulic motor enclosure from a durable metal, like steel or iron, that can weather both high operating speeds and pressure.

In order to build the best hydraulic motor possible, manufacturers must take a number of factors into consideration, including the state of the relief valves, fluid reservoir, and hydraulic pump. All of these components must all be endowed with levels of strength, capacity, and power that matches the needs of the fluid that will go through them. This fluid, in turn, must be chemically stable and compatible with the metals with which the motor is made, and it must be a good lubricant.

Hydraulic motors are constructed with a fair amount of simplicity. Its three main parts are the hydraulic pumps, reservoir, and cylinder. Of course, a hydraulic motor, or hydraulic pump motor, would be nothing without the addition of pressurized fluid, usually a type of oil. This hydraulic component creates motion by pushing against it so that the motor’s rotating components spin all the more quickly and generate mechanical energy. Hydraulic motors often also feature input shafts and output shafts. Shafts assist in operation by applying fluid energy to the load.

To work, a small pneumatic engine pumps oil from the reservoir, where it goes from an inlet valve to an outlet valve and through a series of gears and cylinders or turning vanes, depending on the motor’s design.

There are a few different types of hydraulic motors. The main ones, which are each named for the rotating component they use, are vane, gear, and piston hydraulic motors.

Gear motors, or hydraulic gear motors, consist of a driver gear and an idler gear. To generate power in a gear motor, high pressure fluid is forced into one side of the gears, where it flows around outskirts of the gears to the outlet port, where the gears then interlock and disallow the oil from flowing back out. Here, the gears rotate, generating energy.

Piston motors may use an axial piston pump or a radial piston pump. An axial piston motor pump consists of an odd number of pistons, arranged in a circle around a cylinder block, to regulate fluid pressure and flow. A radial piston motor pump, on the other hand, use pistons mounted around an eccentrically-balanced center shaft, which either radiate inward or outward.

In addition to the basic motor types, there are a few different types of specialized motors, modified for semi-specific applications. These include hydraulic wheel motors, high speed hydraulic motors, high torque hydraulic motors, and gerotor motors.

Hydraulic wheel motors are built directly into wheel hubs, where they contribute the power the wheels require to rotate. Depending on the size of the machine and the power of the motor, a hydraulic wheel motor can control just one or multiple wheels.

High speed hydraulic motors provide higher than normal amounts of power by converting hydraulic pressure fluid into force with an elevated number of rotations per minute.

High torque hydraulic motors, on the other hand, achieve increased torque by running at low speeds, which is why they are often called low speed-high torque (LSHT) motors.

Gerotor motors, or generated rotor motors, are motors that consist of an inner and outer rotor. These hydraulic motors can also work as pistonless rotary engines.

Hydraulic motors offer their users a wide a range of benefits. These benefits include improved power transmission, efficiency, improved power transmission safety, and increased ease and simplicity of power transmission.

In addition, hydraulic motors are much more powerful than electric motors of comparable size. They can also achieve high quality results even in a tight space; manufacturers are able to design compact hydraulic motors that use stroke lengths of less than an inch. A byproduct of this is the fact that they are very versatile.

Examples of hydraulic motor accessories you may require include motor seal kits, pump seal kits, check valves, tubing, pumps, and hydraulic fluid. To find out what accessories are best for your application, talk to your hydraulic motor supplier.

First, check your hydraulic motor regularly for issues like motor input shaft or output shaft misalignment, motor displacement, dirty hydraulic fluid and internal leaks (check motor feed lines and the like).

Second, treat your motor well by never operating it outside of its designed limitations. For example, do not push it beyond its designated load, speed, torque, temperature, and pressure. Exceeding your motor’s designed limits puts it at risks for issues like diminished internal lubrication (associated with excessive heat), single displacement reactions, and general malfunctions.

Finally, for your own safety, always handle your hydraulic motor components with proper care. For example, never make direct physical contact with active hydraulic fluid. Not only could it burn you, but if it is under pressure, it could release with a damaging amount of force. Look to organizations like OSHA to guide you when it comes to handling of hydraulic motors.

As we mentioned in the section above, you should always use hydraulic motors according to the guidelines of OSHA, or the Occupational Safety and Health Administration. OSHA puts out standard guidelines designed to keep you and your workers safe when operating machinery. You should also make sure your manufacturer builds your hydraulic motors in a way that supports OSHA requirements.

In addition to OSHA guidelines, your hydraulic motors likely need to meet the standards of a variety of other organizations. The answer to the question of which organizations and guidelines depends on your industry, application, and location. For example, in the United States, some of the standards organizations most influential in the hydraulics motor industry include the NFPA (National Fluid Power Association), SAE (Society of Automotive Engineers), and ANSI (American National Standards Institute). The premiere organization used internationally is the aptly named ISO, or International Standards Organization. All industries and applications either have their own standards or, most commonly, adapt standards from organizations like these. To find out which standards you should make sure your hydraulic motors meet, talk to your industry leaders.

If you are in the market for a hydraulic motor, you need to partner with a supplier that will drive you to success. Such a supplier will not only be experienced with a proven track record but will also offer you tangible advantages such as the ability to deliver high quality products within your budget, the assurance that they will work within your timeframe, the assurance that they will produce a product that meets your standard requirements, the ability to deliver to you, and the agreement to meet any post-delivery services you require (parts replacement, hydraulic repair, etc.).

Find a supplier like this by checking out the hydraulic motor manufacturers we have listed on this page. All of those we have listed are highly capable hydraulic service providers that have proven themselves many times over. Their information is dispersed evenly throughout the page, wedged in between our industry info paragraphs. For the best results, we recommend you pick three or four you believe have the potential to best meet your specifications, and then reach out to each of them individually to discuss said specifications. Once you have done that, compare and contrast those conversations, and pick the right one for you.

Durable and compact Two Speed Hydraulic Hand Pumps in 316 stainless steel for both everyday use and in harsh environments where corrosion is a challenge. These pumps offer high displacement at the low pressure stage then an easy switch to small displacement, high pressure operation via our no-nonsense manual changeover. Typical applications include actuation, pressure testing, charging and filling. Displacements up to 45 cc per stroke on the low pressure stage and pressures up to 1000 bar on the high pressure stage are available. Retrofit in place of some other industry standard 89mm units. True multi fluid capability. Easy and cost effective fitting of alternative seals for a very wide range of fluids. The standard unit has wide compatibility including oil, water and glycols.

Learn more about two speed hand pumps in general and operating basics in our Application Note “how do I select the right two speed hydraulic hand pump”.

A range of rugged Micropac Two Speed Hydraulic Hand Pumps for universal hydraulic, hydrostatic and pressure test applications. The Micropac MD series Two Speed Hydraulic Hand Pump offers a wide range of options to meet your specific requirement. High quality British engineering provides long service life and easy overhaul with service kits being readily available from us, the manufacturer. Manual hydraulic power up to 450, 700 or 1000 bar on three models with true multi-fluid capability. Three different displacements/pressure ranges are provided on the three models.

PM2V 5-80 Lm-byB-pm-s With exclusion lever for the first speed, with release hand knob, with pressure relief valve, presetting for pressure-gauge, withrubber protection.

PM2V 5-80 Lm-byB-M-s With exclusion lever for the first speed, with release hand knob, with pressure relief valve, with pressure-gauge, with rubber protection.

PM2V 5-80 a-byB-pm-s With automatic control for the first speed, with release hand knob, with pressure relief valve, presetting for pressure-gauge, with rubber protection.

PM2V 5-80 a-byB-M-s With automatic control for the first speed, with release hand knob, with pressure relief valve, with pressure-gauge, with rubber protection.

Piston-type hand pumps offer completely self-contained units for instant operation. Each pump consists of a pre-filled oil reservoir, pump head with external load release valve, and an operating lever. The two-speed model HP227 (807-895) enables rapid cylinder rod advancement until load contact, and then slows as the lift begins. Each pump is compatible with our range of high-pressure cylinders, and can operate one or more cylinders dependant on pump usable oil capacity and cylinder oil capacity. Each pump is tested to 125% of its working pressure and is issued with a manufacturers test certificate and instruction leaflet. The outlet connection is 3/8in. NPTF.

Use with single-acting hydraulic rams. Rugged all-metal construction. Maximum handle effort is 90 lbs. Two-speed action provides rapid approach of ram piston to the work. An appropriate and economical power source for applications in which 20 cu. in. of usable oil is adequate.

8613371530291

8613371530291