vane type hydraulic pump supplier

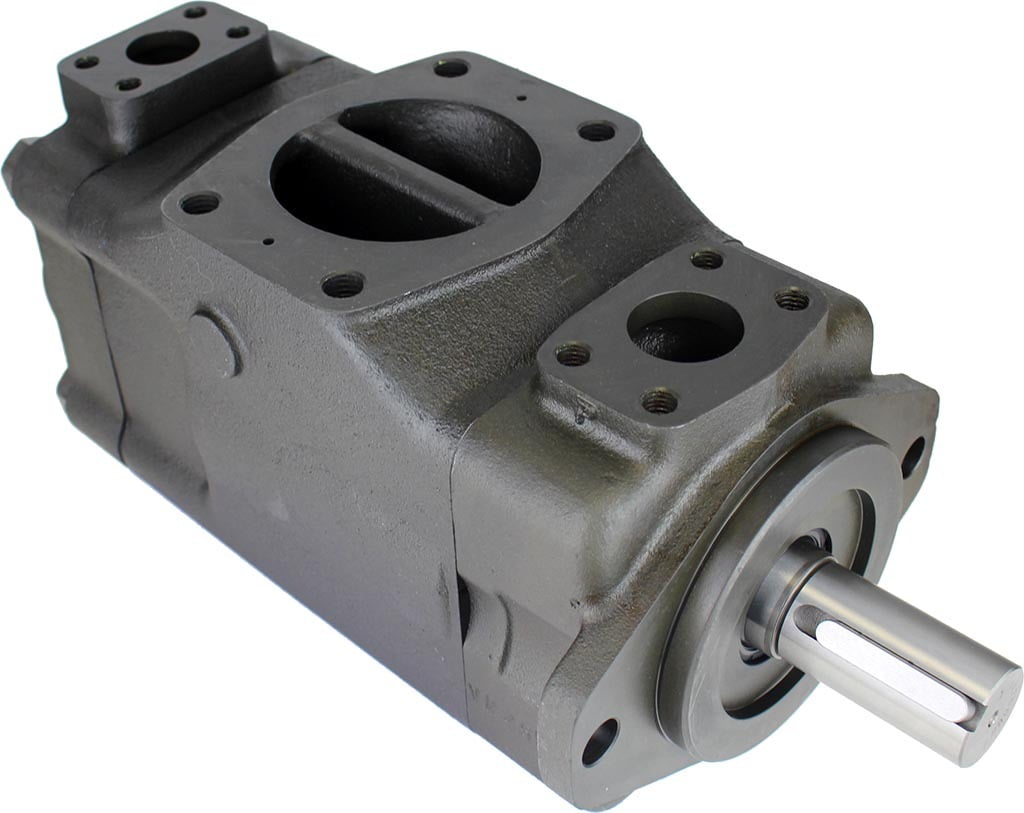

ISO 9001:94 certified manufacturer of pressure compensated, variable displacement & volume hydraulic vane pumps for transfer applications. Specifications of vane pumps include capacities ranging from 4 gpm to 70 gpm, operating pressures ranging from 100 psi to 3,000 psi, & pressure compensation ranging from 100 psi to 2,000 psi. Features include bolt & manifold mountings, variable volume & pressure compensated design, direct spring-operated compensator, hydrodynamic journal bearings, balanced vane tip loading, 1-piece forged rotor shaft, & pressure balanced thrust plates. Applications of vane pumps include food processing equipment, machine tools, marine, & oil field equipment.

In vane pumps, a number of vanes slide in slots in a rotor which rotates in a housing or ring. The housing may be eccentric with the center of the rotor, or its shape may be oval. In some designs, centrifugal force holds the vanes in contact with the housing, while the vanes are forced in and out of the slots by the eccentricity of the housing. In one vane pump, light springs hold the vanes against the housing; in another pump design, pressurized pins urge the vanes outward.

During rotation, as the space or chamber enclosed by vanes, rotor, and housing increases, a vacuum is created, and atmospheric pressure forces oil into this space, which is the inlet side of the pump. As the space or volume enclosed reduces, the liquid is forced out through the discharge ports.

There are three basic models of the Atos PFE vane pumps available. These fixed-displacement cartridge types offer a long service life and versatility. The cartridges are fully interchangeable, and 13 ...

The DFP pumps are fixed displacement vane pumps made in four different sizes, each size having five different nominal displacement. They are available with one pumping element (single ...

... HV2020 series of double pumps are utilized in both industrial and mobile application. Possessing a vane design that reduces wear and clearances, the volumetric ability of the pump is ...

... follows: up to 25MPa for gear pumps, 16MPa for vane pumps and 28MPa for piston pumps. The capacity for the gear pumps is up to 60cm3/rev and up to 100cm3/rev ...

Hydraulic industrial vane pumps reduce installation costs and drive extended life due to their high pressure capability, up to 320 bar in a small operating envelope.They ...

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump production service, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer"s demands are met.

CML, Camel Hydraulic, Camel Precision welcomes you to view our high-quality products Vane Pump, Gear Pump, Solenoid Valve, Modular Valve, Hydraulic Pump and feel free to Contact Us.

High-speed steel pump vanes are made from a highly durable material that is resistant to wear and tear. This makes them ideal for use in pumps that are required to operate at high speeds or under heavy loads. Steel pump vanes are durable and corrosion resistant, making them suitable for use in harsh environments where other materials might break down or become damaged and reducing maintenance requirements and downtime for the pump.

Each hydraulic pump vane is precision-machined to exacting tolerances and has high dimensional stability, balance, and excellent mechanical and sealing properties which can extend pump performance and life, and have given maximum power to pumps. you need further information about our hydraulic pump vanes, such as rotary compressor pump vane or,please feel free to contact us soon. To provide the best vanes for our customers is our main goal.

Vane pumps are hydraulic pumps that operate at very low noise levels. Hydraulic vane pumps operate with much lower flow pulsation, i.e. constant flow. As such, vane pumps produce less noise while maintaining a relatively high speed of up to 3,000 rpm. Small hydraulic vane pumps like the Parker Denison T7A or T7B, with higher displacement volume of 50 cc, have a maximum speed of 3,600 rpm at hydraulic system pressures of up to 300 bar intermittent.

The hydraulic vane pump finds its use in die casting and injection moulding machines in industry, as well as in land and road construction machinery. The operating pressure of vane pumps does normally not exceed 180-210 bar. However, in specially designed vane pumps the operating pressure may go well over 200 bar and up to 300 bar. Parker Hannifin has Denison Vane Technology to provide us with the best solution in the market of fixed displacement balanced vane pumps.

Hydraulic pumps are manufactured depending on different functional and hydraulic system requirements, such as operating medium, required range of pressure, type of drive, etc. Our sales engineers will assist you in selecting the most appropriate hydraulic pump for your application. Contact DTA for your hydraulic pump needs today!

Continental Hydraulics PowrFlow™ PVX Vane Pumps deliver the rugged, reliable performance and value you"ve come to expect in all our products. They outperform sensitive piston pumps in harsh enviroments. PVX Vane Pumps deliver faster response, and require less external compensation compared to fixed displacement designs. The pumps are designed to meet requirements of the machine tool, general machinery and other markets where low noise, high performance and competitive pricing are needed.

Continental Hydraulics PowrFlow™ PVX Vane Pumps deliver the rugged, reliable performance and value you"ve come to expect in all our products. They outperform sensitive piston pumps in harsh enviroments. PVX Vane Pumps deliver faster response, and require less external compensation compared to fixed displacement designs. The pumps are designed to meet requirements of the machine tool, general machinery and other markets where low noise, high performance and competitive pricing are needed.

WE CAN GIVE YOU DOUBLE VANE PUMPS IN SARVA HYDRAULIK SARVA HYDRAULIK S6CC Pump is rated for 300 bar pressure. which is maximum pressure a pump can take against same type of pumps in the whole Industry. S6CC pump is a very versatile pump and can give a flow from 30 liters to 280 liters. The Design of Sarva Hydraulik pump is as per Denison Design. So its spares are interchangeable with Denison design spares. SARVA HYDRAULIK S6CC PUMP can take more pressure then other competing brand

The tips of the vanes are the most vulnerable part of each pump. Because the vanes are held out under pressure and subject to centrifugal forces, the area where the tip moves across the outer ring is critical. Vibrations, dirt, pressure peaks or high local fluid temperatures can all result in a breakdown of the fluid film, resulting in metal to metal contact and reduced service life. With some fluids, the high fluid shear forces created at points like this can damage the fluid and again lead to reduced service life. Although this effect is not limited to vane pumps.

Suction head pressures are very important for vane pumps and must not exceed the manufacturers stated minimum. Always pre-fill the tank suction line and pump casing. It"s always better to make sure the installation has a positive suction head, e.g. the pump is below the fluid level, but never self-prime. Remember that as soon as you remove any valve or break the circuit in any way, it"s likely all of the fluid will drain out of the pipework and back into the reservoir. This will result in the need to re-prime any pumps that do not have positive pressure heads.

Case leakage lines allow all of the fluid that has leaked past the rotating faces to drain back to the reservoir. Without a case leakage line, the pumps would instantly fail. Because these case leakage lines take away the lost fluid, the volume and temperature of the fluid will be directly related to the operating efficiency of the pump. By monitoring the temperature of this fluid and preferably flow, and contamination level as well, you should get a good indication of the condition of the pump and an early warning of potential failures.

8613371530291

8613371530291