vane type hydraulic pump brands

Norman Equipment has been a leading supplier of hydraulic equipment including hydraulic piston pumps and motors for over 70 years. Full-line authorized stocking distributor of quality hydraulic components and systems from top manufacturers renowned for performance and reliability.

We recommend using the piston pumps in high-pressure applications. In some cases, it is more economical to run a piston pump compensated that puts out a very low output flow until needed. This lowers electric cost and pump wear that may reduce system down time.

Norman currently stocks the Parker Denison PV (PVP) units and is part of the Parker Denison Distribution Network if another unit is needed that is not in stock at Norman Equipment. Denison is one of the most recognized names in hydraulic units in the world. For many years, their products were recognized by their distinctive blue color. Today, the Denison brand is part of the Parker-Hannifin family and all pumps are painted black.

Products: Sliding Vane Pumps for Aviation fuels, Biofuels, Diesel, Ethanols, Fuel oils, Gasolines, Lube oils, Solvents, Agricultural ammonia, Butane, CO2, Hydrocarbons, Propane, Refrigerants and many more liqueifed gases

There are three basic models of the Atos PFE vane pumps available. These fixed-displacement cartridge types offer a long service life and versatility. The cartridges are fully interchangeable, and 13 ...

The DFP pumps are fixed displacement vane pumps made in four different sizes, each size having five different nominal displacement. They are available with one pumping element (single ...

... HV2020 series of double pumps are utilized in both industrial and mobile application. Possessing a vane design that reduces wear and clearances, the volumetric ability of the pump is ...

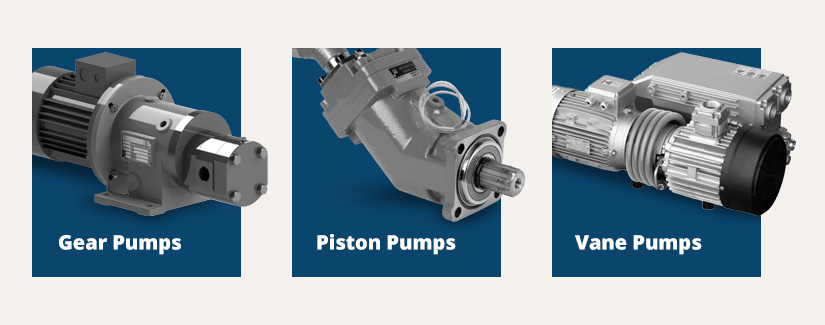

... follows: up to 25MPa for gear pumps, 16MPa for vane pumps and 28MPa for piston pumps. The capacity for the gear pumps is up to 60cm3/rev and up to 100cm3/rev ...

Hydraulic industrial vane pumps reduce installation costs and drive extended life due to their high pressure capability, up to 320 bar in a small operating envelope.They ...

ISO 9001:94 certified manufacturer of pressure compensated, variable displacement & volume hydraulic vane pumps for transfer applications. Specifications of vane pumps include capacities ranging from 4 gpm to 70 gpm, operating pressures ranging from 100 psi to 3,000 psi, & pressure compensation ranging from 100 psi to 2,000 psi. Features include bolt & manifold mountings, variable volume & pressure compensated design, direct spring-operated compensator, hydrodynamic journal bearings, balanced vane tip loading, 1-piece forged rotor shaft, & pressure balanced thrust plates. Applications of vane pumps include food processing equipment, machine tools, marine, & oil field equipment.

In vane pumps, a number of vanes slide in slots in a rotor which rotates in a housing or ring. The housing may be eccentric with the center of the rotor, or its shape may be oval. In some designs, centrifugal force holds the vanes in contact with the housing, while the vanes are forced in and out of the slots by the eccentricity of the housing. In one vane pump, light springs hold the vanes against the housing; in another pump design, pressurized pins urge the vanes outward.

During rotation, as the space or chamber enclosed by vanes, rotor, and housing increases, a vacuum is created, and atmospheric pressure forces oil into this space, which is the inlet side of the pump. As the space or volume enclosed reduces, the liquid is forced out through the discharge ports.

AFP carries a vast line of hydraulic pumps, including vane, gear and piston types with an excellent line of manufacturers to choose from. This page is just a snapshot of the pumps we carry and that are on the market. Leads times and pricing may vary between manufacturers. At AFP we understand this, which is why we give our customers so many different pricing and brand options. We feel confident AFP can deliver to you the pump you want, at a competitive price point, with excellent customer service. Give our team of specialist a call today to discuss your many options.

Can’t find information on the manufacturer? A few of the manufacturers listed below are either no longer in business or have merged with another company. Our team at AFP can translate the model number from your pump and cross it over to a variety of current manufactured pumps on the market. Give AFP a call or request a quote today to discuss your many options.

The combinations of available pumps are too numerous to list. To list every type of pump, with every detailed variation and option, from every manufacturer would be an endless task. We would prefer to speak to you in person so we can get you back up and running as soon as possible. Give our team of specialists a call or request a quote today.

Norman Equipment has been a leading supplier of hydraulic equipment including hydraulic piston pumps and motors for over 70 years. Full-line authorized stocking distributor of quality hydraulic components and systems from top manufacturers renowned for performance and reliability.

We recommend using the piston pumps in high-pressure applications. In some cases, it is more economical to run a piston pump compensated that puts out a very low output flow until needed. This lowers electric cost and pump wear that may reduce system down time.

Norman currently stocks the Parker Denison PV (PVP) units and is part of the Parker Denison Distribution Network if another unit is needed that is not in stock at Norman Equipment. Denison is one of the most recognized names in hydraulic units in the world. For many years, their products were recognized by their distinctive blue color. Today, the Denison brand is part of the Parker-Hannifin family and all pumps are painted black.

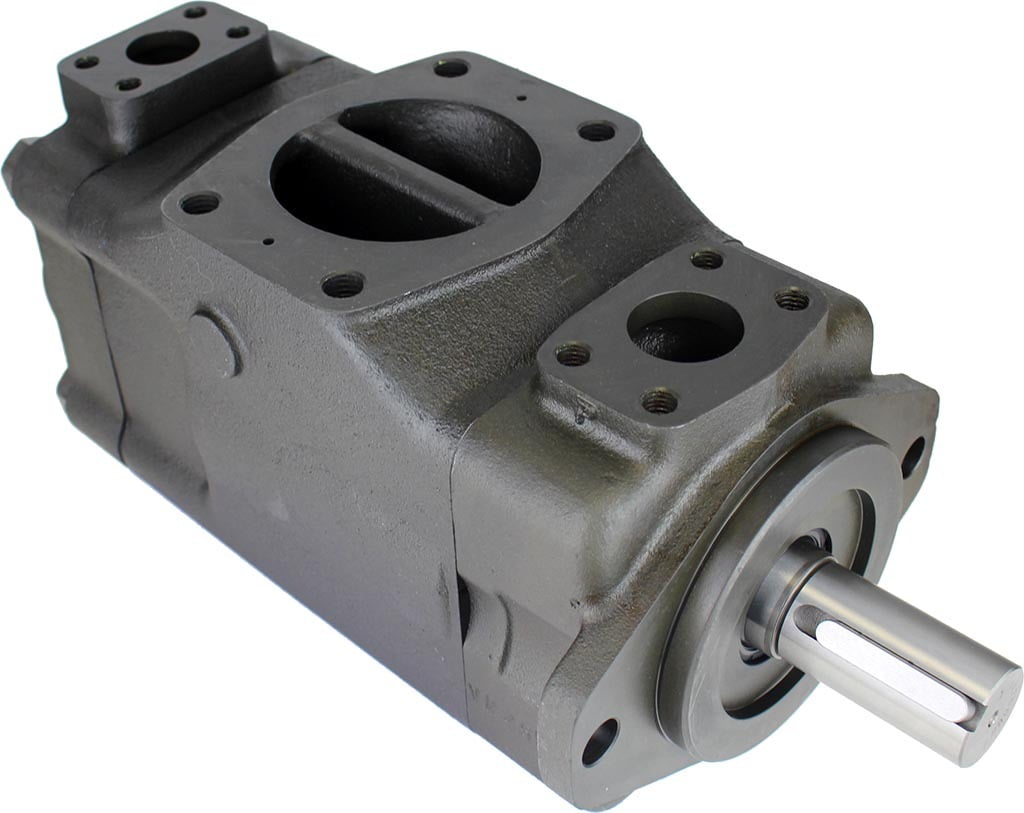

Vane pumps are hydraulic pumps that operate at very low noise levels. Hydraulic vane pumps operate with much lower flow pulsation, i.e. constant flow. As such, vane pumps produce less noise while maintaining a relatively high speed of up to 3,000 rpm. Small hydraulic vane pumps like the Parker Denison T7A or T7B, with higher displacement volume of 50 cc, have a maximum speed of 3,600 rpm at hydraulic system pressures of up to 300 bar intermittent.

The hydraulic vane pump finds its use in die casting and injection moulding machines in industry, as well as in land and road construction machinery. The operating pressure of vane pumps does normally not exceed 180-210 bar. However, in specially designed vane pumps the operating pressure may go well over 200 bar and up to 300 bar. Parker Hannifin has Denison Vane Technology to provide us with the best solution in the market of fixed displacement balanced vane pumps.

Hydraulic pumps are manufactured depending on different functional and hydraulic system requirements, such as operating medium, required range of pressure, type of drive, etc. Our sales engineers will assist you in selecting the most appropriate hydraulic pump for your application. Contact DTA for your hydraulic pump needs today!

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump production service, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer"s demands are met.

CML, Camel Hydraulic, Camel Precision welcomes you to view our high-quality products Vane Pump, Gear Pump, Solenoid Valve, Modular Valve, Hydraulic Pump and feel free to Contact Us.

High-speed steel pump vanes are made from a highly durable material that is resistant to wear and tear. This makes them ideal for use in pumps that are required to operate at high speeds or under heavy loads. Steel pump vanes are durable and corrosion resistant, making them suitable for use in harsh environments where other materials might break down or become damaged and reducing maintenance requirements and downtime for the pump.

Each hydraulic pump vane is precision-machined to exacting tolerances and has high dimensional stability, balance, and excellent mechanical and sealing properties which can extend pump performance and life, and have given maximum power to pumps. you need further information about our hydraulic pump vanes, such as rotary compressor pump vane or,please feel free to contact us soon. To provide the best vanes for our customers is our main goal.

Many industries utilize hydraulic vane pumps, from the automotive and aerospace industries to the food processing industry. These pumps consist of a sealed cavity with a rotor to which vanes attach. They especially excel at processing low viscosity fluids. For example, when you fill your soda at a fast-food restaurant, a hydraulic vane pump powers the beverage carbonator.

But hydraulic vane pumps are not only valuable for manufacturing and delivery processes. You can also find them in end-user products, such as automobiles, where they’re used for things like power steering and air conditioning.

A true testament to any technology is its long usage history. Patented in 1874, hydraulic vane pumps have been around for roughly a century and a half. Their use across industries has only grown in that time. MAC Hydraulics has been an authority on these pumps for quite a long time as well, and we can answer any questions you may have.

Hydraulic vane pumps create pressure by forcing hydraulic fluid into an ever-smaller area before releasing it back into the system. This is achieved through a combination of sliding vanes, inlet and discharge holes, and a drive shaft that’s off-center compared to the chamber.

Fluid is pushed through inlet holes and into the chamber of the pump by the atmospheric pressure acting on the fluid in the reservoir. Once in the chamber, the fluid is collected in the space between two vanes that are connected to the driveshaft and pressed against the external wall of the chamber to form a seal.

Because the drive shaft is off-center in relation to the pump chamber, as it rotates, the vanes are pressed in by the external wall and the space between them becomes smaller. This change in volume increases the pressure of the fluid, which is then forced out of the pump on the other side of the chamber when the pressure is at its greatest.

One advantage of using a vane pump is how it can handle a wide range of low to medium viscosity fluids. This means they can be used by a wide variety of industries to move fluids including, but not limited to:

The internal system of a vane pump is highly lubricated with fluid and minimal metal-to-metal contact. This makes these devices relatively easy to maintain, with the vanes being the parts that are the most prone to wear and tear. Luckily, vanes are cheap and easy to replace.

One potential safety issue in many industries is the noise level in the workplace. Thankfully, a pump that is running with no issues is quiet. So making use of them in a manufacturing facility helps keep the noise down, or at least does not add to it.

When properly constructed and maintained, a hydraulic vane pump is a highly reliable piece of equipment. It has the potential to last a very long time. In fact, it could last you a lifetime. That is why it is important to take care of it and know what to look for as far as signs of problems.

Like everything else, these systems have their limits. No instrument, substance, or part will suit the needs of every job. A hydraulic vane pump typically does not do well with the processing of very high viscosity fluids. It also will not handle excessively high pressures or abrasive fluid contaminants.

Industry insiders have calculated that dirty fluid is either directly responsible or at least a contributing factor to over 80 percent of all hydraulic vane pump system failures. It does not matter how well-constructed your hydraulic vane pumps are or how tight the seals are if you are running fluid with abrasive contaminants through them. Running these abrasive fluids through a pump at high speeds will wear down the vanes and affect other parts such as the rotor and cam.

Sometimes the contamination of the fluid may not come from the fluid distributor or manufacturer but from the machine itself. Just as we explained about fluid, the fact that your machine is new does not guarantee its cleanliness. So, when you purchase new equipment, you should clean it before beginning operations to avoid contamination to your pump and adjoining parts or systems.

The cost of filtration systems, quality control checks, and basic cleanliness in fluid and machines will more than pay for themselves over the years. Over time, the increased production resulting from not having to shut your line down due to a pump failure and needing less frequent repairs will result in higher profit.

Cavitation is when small air bubbles manifest in your pump’s fluid and then implode. It seems like a relatively benign issue at first glance, but it can cause extensive damage to your hydraulic vane pump after some time.

The implosion of air bubbles in the hydraulic fluid can generate a massive amount of heat. This is a problem for two reasons. First, if the temperature gets too high, it can cause the hydraulic fluid itself to break down and be less effective. Second, the temperature and pressure differences caused by the implosions can wear down the metal components within the pump.

Both the wearing of internal metal components and the loss of the hydraulic fluid’s ability to properly lubricate parts of the pump can lead to metal chips and other contaminants entering the fluid. Once this happens, a snowball effect begins and the damage will exponentially get worse over time.

As we mentioned above, one of the hallmarks of well-running hydraulic vane pumps is quietness. If you hear knocking or banging from the inside, you’re either dealing with the presence of air or extremely low pressure in your pump. Therefore, unusual noise (that isn’t a simple hum or regular “operating” noise) is almost always a sure sign that something is wrong. Loud whirring sounds are also often present when there has been extensive damage.

If you notice external leakage around the pump, that points to a failure of one or more seals. Sometimes, this can also mean a bent rod. If the damage is not too extensive, you can have this problem fixed.

Maybe you’re noticing your hydraulic vane pumps have been less efficient, combined with sudden and frequent pressure drops in the pump. There may also be excessive heat. When you notice any of these symptoms, it is time to have your systems checked out by a professional technician.

Problems with hydraulic vane pumps tend to worsen very quickly due to the nature of their high-speed operation. A few metal shavings can quickly damage the vanes, rotors, and walls and create a ripple effect of problems. Calling attention to it right away may enable you to have it repaired rather than having to buy a replacement.

At MAC Hydraulics, our expert hydraulic technicians have experience maintaining and repairing hydraulic pumps of all kinds, including vane pumps. We’ll even come out to your place of business to make the whole process as simple and efficient as possible. Contact us today to request repairs or to set up a preventative maintenance plan.

8613371530291

8613371530291