variable displacement hydraulic pump animation quotation

Hi Guys, Hydraulic pumps are of various types, axial flow variable displacement piston pump are used in heavy hydraulic construction equipments. Tracked exca...

The displacement of a pump is defined by the volume of fluid that the gears, vanes or pistons will pump in one rotation. If a pump has a capacity of 30 cm3, it should treat 30 ml of fluid in one rotation.

In axial piston variable pumps, the flow is proportional to the drive speed and the displacement. The flow can be steplessly changed by adjusting the swivel angle. Axial piston variable ...

... axial piston pump type V60N is designed for open circuits in mobile hydraulics and operate according to the swash plate principle. They are available with the option of a thru-shaft for operating additional ...

Variable displacement axial piston pumps operate according to the bent axis principle. They adjust the geometric output volume from maximum to zero. As a result they vary the flow rate ...

... piston pump type V30D is designed for open circuits in industrial hydraulics and operate according to the swash plate principle. They are available with the option of a thru-shaft for operating additional ...

... circuit axial piston pumps are used as hydrostatic transmission components in self-propelled machines and for rotary drives in both fixed and mobile equipment of all kinds.

Axial piston twin flow pump. With a very high performance in all job conditions. Due to its twin flow configuration this pump allows a great variety of solutions in different job applications.

Air hydraulic pump, double pneumatic motor, double effect, foot operated with lock-up function, lever distributor valve (4/3), 10L tank, oil flow 8.5 / 0.26 l / min

... customer system options for mechanical, hydraulic and electric input solutions are available. Further special regulating features like torque control and pressure cut-off are also available. The reliable ...

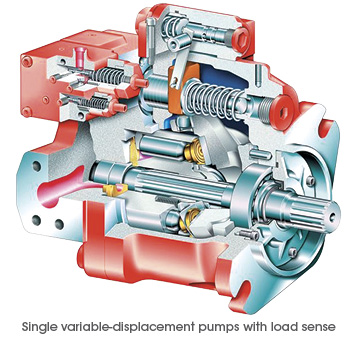

... needs of truck hydraulics, the TXV variable displacement pumps with LS (Load Sensing) control allow flow regulation to suit the application requirements. The pump ...

... rev. displacements, these pumps are designed to operate in both directions of rotation (clockwise or counter-clockwise). Only one reference regardless of direction of rotation. The TXV indexable pumps ...

... PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design ...

Variable displacement pumps in closed loop; 3 basic design units and 8 max. displacement sizes of 14, 18, 21, 28, 35, 46, 56, 64 cc/rev; various control options; max. ...

Parker P2/P3 High Pressure Axial Piston Pumps are variable displacement, swashplate piston pumps designed for operation in open circuit, mobile hydraulic ...

... Series pump offers variable displacement axial piston pumps for open-circuit applications. Featuring a compact footprint and continuous operating pressure ...

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

Quiet operation, high efficiency and compact design — all available at a competitive price. That’s what Oilgear PVWC closed-loop, hydrostatic axial-piston hydraulic pumps bring to the table. All designed around our proven rotating group.

Quiet operation, high efficiency and compact design — all available at a competitive price. That’s what Oilgear PVWC closed-loop, hydrostatic axial-piston hydraulic pumps bring to the table. All designed around our proven rotating group.

Quiet operation, high efficiency and compact design — all available at a competitive price. That’s what Oilgear PVWC closed-loop, hydrostatic axial-piston hydraulic pumps bring to the table. All designed around our proven rotating group.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids—and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Extremely effective across numerous industrial applications that require quick response in extreme environments, the XD5 series of pumps offer lightning-fast control response on both low-viscosity fluids and standard hydraulic oil. Engineered to handle the most challenging environments, they have been designed to be a high-performance solution for demanding mobile applications.

Designed for closed-circuit applications, C Series Variable Displacement Axial Piston Pumps boost reliability and uptime. They feature a rugged design, wide range of controls and proven protection from pressure overloads for increased performance, all while maintaining a small footprint for added flexibility. The C Series adds further versatility with multiple displacement options and the ability to perform with a variety of control options.

Not every closed circuit application needs a heavy duty C series or a severe duty Gold Cup Pump. The PC³ Series Pumps are a medium duty series that are designed to meet the needs of your application in a package that is compact in size, but big on performance. Learn more about how the PC³ line of medium duty hydrostatic pumps are the perfect fit for your application.

Hydraulic piston pumps move fluids throughout professional equipment and industrial machinery. They’re known for their high efficiency and are commonly used in high-pressure applications.

There are also two major types of hydraulic piston pumps: axial and radial; both can have fixed or variable displacement; fixed displacement means that the pump is delivering the same amount of liquid or gas each time, while variable means that the amount of gas or liquid delivered may be different each time. Although both are considered piston pumps, each one operates differently.

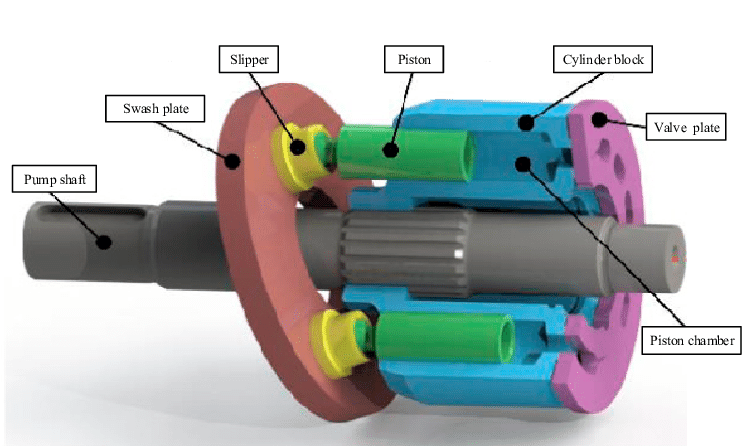

An axial piston pump features four major components: a shaft, swashplate or bent axis, cylinder block, and valve plate. The cylinder block houses the piston pumps, which are laid out cyclically around the drive shaft’s axis (thus why it is named anaxialpiston pump).

The pistons in the cylinder block pump up and down as the drive shaft rotates. The piston’s stroke will vary depending on how it is angled in the swashplate or bent axis. As the pistons move in one direction, they are connected to a suction line, and when they move in the opposite direction, they connect to a discharge channel, allowing a continuous flow of fluid.

The design of a radial piston pump is significantly different from an axial pump. The radial piston pump consists of a cylinder block, rotating camshaft, and pistons. The pistons are arranged around the cylinder block in a radial pattern and diverge from the camshaft like rays. The rotation of the cam causes the pistons to change from suction to discharge and vice versa.

In general, choosing a hydraulic pump requires an application evaluation. You’ll need to know pressure requirements, desired flow rate, speed, horsepower, and the type of fluid the pump will be dispersing.

Radial piston pumps can usually handle all fluids, including mineral oil and water-glycol hydraulic fluid, while axial piston pumps are preferred for extremely high-pressure applications.

Although piston pumps are highly efficient and reliable, contamination, over-pressurization, and inlet blockages can cause the pump to fail. If and when this happens, you’ll need to replace your pump as soon as possible.

When choosing a replacement pump, you’ll have to choose between a direct OEM replacement and a remanufactured pump. Unfortunately, direct OEM replacement pumps and services can be a significant investment. Additionally, if you have outdated equipment, you may not be able to find thepump partsneeded to restore your equipment.

If you’re looking for a quick and relatively inexpensive solution, a remanufactured pump is your best choice. However, if time and money aren’t an issue, a direct OEM replacement will most likely be the best option if the manufacturer hasn’t discontinued the pump.

Do you need help finding the right piston pump? Turn to Panagon Systems. Founded over 25 years ago, we’re an industry-leading remanufacturer of hydraulic piston pumps and motors. We specialize in remanufacturing pumps from brands like Vickers/Eaton, Rexroth, and Caterpillar, and we also carry. All pumps and motors are remanufactured in-house in the United States, guaranteed to meet OEM specifications, and are backed by a one-year warranty.

Piston design - Solid, hollow, or with piston rings. The design and weight of the pistons will have a major effect on pump efficiency. The Parker F11 design with its lightweight head and retained balls can reach significantly higher speeds than swashplate pumps with their longer, heavier pistons.

Some pumps and motors can run over-centre, which means they can provide flow or rotate their drive shaft in both directions. These are commonly used in closed circuit, mobile vehicle drives systems.

Bent axis designs tend to have much heavier duty shaft bearings than swashplate pumps. This is because they are more commonly used as motor drive units and have to take the wheel loads against their shaft. Swashplate pumps, on the other hand, tend to be driven through flexible couplings that will remove any side loads, so the internal bearing is sized just to take the internal loads from the dynamic and pressure loading forces.

Noise level can be an issue with piston pumps. The noise is generated by the discontinuities in the flow e.g. as the pistons move forward and backward they create a pulsating flow that passes into the complete hydraulic system and vibrates or radiates from other components further down the circuit. This flow discontinuity is further complicated by the supply port which connects and disconnects each piston as it rotates. The timing of the opening and closing can create other, higher frequency flow discontinuities. Often different timing plates are available for different operating conditions e.g. fixed speed or variable speed applications.

Case leakage line pressures are critical for controlling the pressure balance of the slipper against the suction pressure. Care should be taken with some pump controllers as the valves exhaust into the pump casing and can create dangerous pressure spikes. Make sure case drain lines are sufficiently sized. One possible solution may be to use a more compliant, clear plastic hose for the case leakage line which will have the effect of damping out these peaks before damage the slippers. Case leakage line temperatures are also a good way of monitoring the health of the pump as discussed in the vane pump section.

If you are in doubt about the most appropriate pump to use in your application then always talk to manufacture or distributor who should be able to offer the most appropriate pump range and advise the expected service life.

The Muncie PV Series Piston Pumps is warranted against any defect in material and workmanship which existed at the time of sale by Muncie, according to the following provisions, subject to the requirements that the Valve must be used only in accordance with catalogue and package instructions. The Valve is warranted for a period of one year from date of installation. If during the warranty period the Valve fails to operate to Muncie’s specifications due to a defect in any part in material or workmanship that existed at the time of sale by Muncie, the defective part will be repaired or replaced, at Muncie’s election, at no charge, if the defective part is returned to Muncie with transportation prepaid.

An irregular performance of a mechanical-type constant power regulator is considered. In order to find the cause of an irregular discharge flow at the cut-off pressure area, modeling and numerical simulations are performed to observe dynamic behavior of internal parts of the constant power regulator system for a swashplate-type axial piston pump. The commercial numerical simulation software AMESim is applied to model the mechanical-type regulator with hydraulic pump and simulate the performance of it. The validity of the simulation model of the constant power regulator system is verified by comparing simulation results with experiments. In order to find the cause of the irregular performance of the mechanical-type constant power regulator system, the behavior of main components such as the spool, sleeve, and counterbalance piston is investigated using computer simulation. The shape modification of the counterbalance piston is proposed to improve the undesirable performance of the mechanical-type constant power regulator. The performance improvement is verified by computer simulation using AMESim software.

The pressure regulators of swashplate-type variable displacement axial piston pumps (VDAPP) control the swivel angle, which changes the amount of flow rate to hydraulic circuits. The pressure regulator is operating in accordance with the dynamic response of the discharge pressure, and it supplies pilot flow rate to the control piston which regulates the swivel angle of swashplate. The pressure regulator is mainly divided into the three types depending on the operating method, that is, a flat cut-off type, a differential cut-off type, and a constant power type.

The pressure regulators are usually used to save energy of hydraulic systems in the industrial field. As the hydraulic power unit used for movable equipment has increased, the pressure regulators have been applied in such systems in order to protect prime mover. Most movable hydraulic power unit consist of motor, pumps and reservoir (MPR). An overload of the pump can cause damage to the electric motor and its circuits under a variety of load conditions. To avoid these problems, power regulation of the pump is needed in order to respond to wide varieties of loads without exceeding the maximum power range of the prime mover. In this study, we applied the constant power regulator to the VDAPP so that the angle of the swashplate is automatically decreased according to an increase of the load pressure.

Recently, electronic regulators have been studied and commercialized [1–4]. However, the mechanical regulators are mainly applied in the industrial field because a proportional reducing pressure valve which is used as main part of the electronic regulator has relatively poor durability than mechanical regulator. In recently developed hydraulic regulator systems, both the electrical and mechanical regulators are applied to hydraulic regulator system. In those hydraulic regulator systems, the mechanical regulator is used as emergency equipment so that it only works when the electronic regulator fails. Due to the relatively exceptional durability, the mechanical regulator system is especially adopted to construction equipment and combat vehicles, which are used for long periods in poor conditions.

A schematic diagram of a swash plate VDAPP with a constant power regulator is shown in Figure 1. Figure 2 represent hydraulic circuit of the constant power regulator system. The constant power regulator system consists of five parts, that is, a regulator assembly (A), a control cylinder assembly (B) which controls the angle of the swash plate, a counterbalance assembly (C), a swash plate (D), and a piston (E). As shown in Figure 3, the regulator assembly consists of a spool and sleeve. A flow area of the regulator system is determined by relative displacement between spool and sleeve. Figures 4 and 5 show the detailed structure of the control cylinder and counterbalance.

As shown in Figure 8, the swash plate is held in a certain swivel angle. In this area, the discharge pressure of the pump does not feed back into the control cylinder. This causes the swash plate to rotate in a maximum angular displacement. As a result, the pump can supply the maximum flow rate to a load system unless the discharge pressure of VDAPP is sufficiently increased to a certain level by a load. At the maximum flow rate section shown in Figure 9, the discharge flow rate cannot be feed into the control cylinder because the spool blocks the path of the sleeve.

In the constant power area shown in Figure 11, the spool is moved by the pilot pressure which is equal to load pressure, and the spool displacement makes the flow path to the control cylinder open. Then, the flow is supplied to the control cylinder. Therefore, the swivel angle is decreased, and the discharge flow rate of the pump is reduced. When the swivel angle is decreased, the sleeve reduces or blocks the flow to the control cylinder by the movement of the counterbalance piston. Therefore, the displacement of the control cylinder is adjusted according to the load variation. Consequently, the increase of the load pressure decreases the discharge flow rate of VDAPP, and that makes output power of VDAPP constant because the output power of VDAPP is determined by the product of load pressure and discharge flow rate.

As previously described, these characteristics of the pump-regulator assembly are determined by the interaction of the spool and sleeve. The pilot pressure generated by the load pressure of the system affects the spool.

In the VDAPP, the displacements of the control cylinder and the counterbalance piston are the same due to kinematic constraint. Therefore, (2) can be expressed as

where is the pressure in control cylinder, is the pressurized area of the control cylinder, is the mass of the control cylinder, is the viscous friction coefficient between the control cylinder and a sleeve, is the spring constant, is the initial displacement, is the displacement of control cylinder, and is the spring constant of the reaction spring for the sleeve of the constant power mechanical regulator.

where is the effective bulk modulus, is input flow rate to control cylinder, is output flow rate from control cylinder to reservoir, is the pressurized area of control cylinder, and is leakage coefficient of the control cylinder. At mechanical-type constant power regulators, the control flow varies according to the relative displacement between the spool and sleeve. Thus,

where is flow coefficient of orifice, and represent the orifice areas, is discharge pressure of the hydraulic pump, and is density of working fluid.

The displacement of the control cylinder, in (4), is determined by the resultant force on the swash plate as shown in Figure 15. The various forces are expressed in the form of a complex nonlinear model. In this study, in order to derive more accurate results, the VDAPP was also implemented using AMESim software.

A VDAPP with a mechanical regulator system was established using AMESim simulation software, which allows a very accurate implementation of the response of a nonlinear system. In the field of hydraulic component design, AMESim is widely used to optimization and performance improvement as a review of the actual system [5]. Figure 16 shows an AMESim diagram for the analysis of the system performance of an MPR system that consists of nine pistons.

The maximum swivel angle was set to 16°, which is the same as in the real component, and the exclusion volume was set to 11.6 cm3/rev. All parameters of the VDAPP are the actual design values used in the experimental equipment. The experimental equipment was modeled by considering the nonlinear behavior of the MPR pump system.

If the pump is composed of an odd number of pistons, the number of discharging pistons is determined by the rotation angle of the piston, which located at regular intervals on the plate as follows [11]:

Figure 17 shows the simulation result when the pump is driven at 4500 rpm under no-load condition. The discharge flow rate is the sum of the flow rate of each piston. The pulsation in flow rate is observed in simulation result as shown in Figure 17. This simulation results also show that the average value of the discharge flow rate 49.8 L/min is less than the theoretical one 52 L/min because the internal leakage through the gap between the piston and cylinder block is considered in computer simulation.

Figure 19 shows the hydraulic circuit of test rig for VDAPP. The angular velocity of the electric motor is regulated as 4500 rpm, and the load pressure is adjusted by adjustable relief valve which installed in the discharge line of the VDAPP. The discharge pressure is slowly increased during 45 seconds. The load pressure, the discharge flow rate, and the angular velocity and the torque of the electric motor are acquired by data acquisition board in real time.

Also, the displacement of the counterbalance piston in this simulation is shown in Figure 24. This result is in good agreement with the designed dimension of the real system.

On the other hand, an irregular fluctuation in displacement of the counterbalance piston causes pulsation of the discharge flow rate of the VDAPP. As discussed in previous section, the displacements of the control cylinder and the counterbalance piston are the same due to kinematic constraint. The pressures in the control cylinder affects to the displacement of it. The pressure in control cylinder is regulated by the balance of inlet/outlet flow rate in the volume of control cylinder. In addition, the inlet flow rate to the control cylinder is decided by the relative displacement between the spool and sleeve. Therefore, the discharge flow rate of the VDAPP is influenced by the relative displacement between the spool and sleeve in the constant power regulator.

Figure 25 shows the simulation results of the displacements of the spool and sleeve versus time. The simulation results in Figure 24 show that the displacement of the sleeve and spool is distinguished at about 35 seconds. This means that the orifice is open on this point, but counterbalance piston does not move until 44 seconds. This phenomenon can be explained as follows. Though the pilot flow rate is supplied to the control cylinder at about 35 seconds, the amount of inlet flow rate is less than that of leakage from control cylinder. Therefore, the pressure in control cylinder does not rise. The relative displacement between spool and sleeve becomes sufficiently larger at around 44 seconds. At this time, the inlet flow rate is larger than the leakage from control cylinder. Therefore, the pressure in control cylinder is rising and the counterbalance piston starts to move and a constant output control begins.

The fluctuation in displacement of the spool and sleeve remarkably appears in the pressure cut-off area from 56 to 58 seconds. At this period, the displacement of the counterbalance piston also oscillates, and the irregular discharge flow rate of the VDAPP is observed. This phenomenon seems to be accrued due to the discontinuous shape at the edge of the counterbalance piston because the reacting spring force of the sleeve acting on the counterbalance piston disappears immediately at this region.

In this study, the constant power mechanical regulator system with variable displacement axial piston pump is considered. The constant power mechanical regulator with VDAPP has a problem of pulsation in the discharge flow rate at the cut-off area. In order to solve the problem, the internal behavior of the constant power regulator with VDAPP is analyzed by modeling the system using the AMESim software. The theoretical analysis of constant power regulator is induced for precise modeling, and the internal dynamics of un-measurable components are studied. The validation of the simulation model is confirmed by comparing the simulation results with the experimental output of the real system. By analyzing the dynamics of the unmeasurable internal components, it is found that the irregular discharge flow rate is caused by the discontinuous shape at the edge of the counterbalance piston. Therefore, we proposed the rounded shape for the edge of the counterbalance piston. The effect of the redesigned shape is implemented by AMESim simulation, and the validation is verified by computer simulation. The future work is experimental confirmation of the redesigned shape.

The Inline variable displacement pump type V60N works according to the swash plate principle usually driven via the ancillary drive. It is intended for open circuit operation in mobile hydraulics. In optional thru shaft enables direct mounting of additional variable displacement pumps or a feed pump. These pumps are suited for a wide range of applications due to their low running noise and various pump controllers. The direct mounting at the gear box is either via a SAE-flange or a flange conforming ISO 7653. The flange area at the suction port enables optimized hose connection with little back pressure. Main benefits of these pumps are the sturdy design, the good performance/weight ratio and long service life due to oversized bearings.

Designed to be cost effective, stable and low-maintenance, the PVWJ is a variable displacement axial piston pump with a medium control response. Like all Oilgear pumps, it thrives on low viscosity fluids and comes in a variety of frame sizes and available displacement rates.

PVWJ pumps were design and manufactured in such a way that we can offer customers greater flexibility to selectively match pressure and capacity for their specific application.

We offer 3 frame sizes and a total of 10 displacement rates, coupled with a variety of optional controls. The PVWJ family of pumps provides easy field interchangeability.

All Oilgear pumps are designed to thrive on low-viscosity fluids such as high water content and fire resistant fluids, like Skydrol™, Stack Magic™, Erifon™ and 98/2.

As with all Oilgear pumps, all contact surfaces such as the cylinder surface running on the valve plate and the pistons running on the swashblock surface are all hardened for incredible durability.

The PVWJ range provides a broad range of controls and porting options to take on your most demanding applications. For low to medium horsepower equipment, the PVWJ pumps are uniquely designed for enhanced stability and less maintenance. Further to that, they’re also a much quieter option for your operations (achieved with the use of static seals (O-rings) to reduce control noise.

Quiet in operation, super high efficiency, compact design, competitive pricing and impressive lead time are the key attributes of the Oilgear PVWJ open loop piston pump. Available in 10 displacement sizes, the PVWJ pumps offer a large selection of readily interchangeable controls. With improved response controls and reduced noise levels, its rugged cylinder design enhances performance.

The patented, pressure lubricated swashblock design offers high performance for high-cycling operations. It also contributes to the pump’s ability to run on low-viscosity fluids, including high water content, fire-resistant and other special fluids.

Zeus Hydratech fully supports the Oilgear PVWJpump product line and is the only valid source for OEM parts in the South of the UK. All Oilgear repairs are machined and tested per our original factory specifications.

Designed for power and speed, the Oilgear PVV open-loop axial-piston hydraulic pumps can handle large, heavy-duty systems. Manufactured with advanced engineering and computer-optimized, the PVV pump range delivers up to 450 Bar / 560 horespower which equates to four times the horsepower at less than half the cost of other manufacturers pumps.

With it"s compact design available in several displacements, the PVV pumps offer a large selection of readily interchangeable controls. With improved response controls and reduced noise levels, its rugged cylinder design enhances performance.

The patented, pressure lubricated swashblock design offers high performance for high-cycling operations. It also contributes to the pump’s ability to run on low-viscosity fluids, including high water content, fire-resistant and other special fluids.

Zeus Hydratech fully supports the Oilgear PVV pump product line and is the only valid source for OEM parts. All Oilgear repairs are machined and tested per our original factory specifications.

Gear Pump – Small to Medium Displacement Sleeve, Hydraulic Bushing Pumps, 4.5 – 17 GPM. The 197 series bushing pump has a minimum operating speed of 600 rpm, continuous operating speed 2400 rpm. Drive shaft PL factor; Integral up to 10000, Continental 6000. Built from cast iron for robust applications. Single and multiple units are […]

Gear Pump – Medium Displacement Sleeve Bushing Pump. The 257 Series pump is a heavy-duty sleeve bushing design in medium frame size. Working Pressure up to 4500 psi. Cubic inch displacements from 1.29 through 6.43 with speeds up to 2400 RPM and flows up to 65 GPM. The bushing pump is also available with outboard bearing options […]

Large Gear Pump – Sleeve Bushing Design, Large Frame Size. A large displacement sleeve bushing pump, in a large frame size, with working pressures up to 3500 psi, cubic inch displacements from 1.80 – 9.00, speeds up to 2400 RPM and flows up to 93 GPM. The 360 Series cast iron gear pumps are primarily […]

Gear – Medium Displacement Roller Bearing Gear Pump, 5.5 – 28 GPM. The P5000/P5100 series is a medium displacement, roller bearing gear pump. This pump is a cast iron pump ensuring a strong and long-lasting product able to withstand robust applications. Single and multiple units are available upon request. The pressure loaded wear plates of […]

The Series AP product range includes single pumps 05-100-212-212HP-250HP-300-312HP (corresponding with the common group denominations: 05-1-2-2.5-3) and several combinations of double pumps, triple pumps, and so on, that can be assembled together according to versions of displacement, flanging, and auxiliary valves.

External Gear Pump, Aluminum, 4.4 – 27.1 Displacement cm³/rev. The AP212 family has made it possible to achieve high operating pressures, excellent volumetric and mechanical efficiency and on specially developed units (LN – Low Noise) even lower noise levels. This is made possible by: The new design of gear teeth and balancing areas Use of […]

External Gear Pump, Cast Iron, 15.1 – 34.1 Displacement cm³/rev. Maintaining all the basics AP212 project characteristics, the AP212HP series is improving the reliability of the complete product, strongly increasing the mechanical resistance of the pump body. This important feature, reached through the use of cast iron material and dedicated body shape, allows the life […]

External Gear Pump, Aluminum, Single and Multiple, 40.0 – 75.0 Displacement cm³/rev. The product range of SpA includes single pumps 05-100-212-212HP-250HP-300-312HP (corresponding with the common group denominations: 05-1-2-2.5-3) and several combinations of double pumps, triple pumps, and so on, that can be assembled together according to versions of displacement, flanging, and auxiliary valves. Gear Pumps […]

External Gear Pump, Aluminum, 27.0 – 93.0 Displacement cm³/rev. The Series AP product range includes single pumps 05-100-212-212HP-250HP-300-312HP (corresponding with the common group denominations: 05-1-2-2.5-3) and several combinations of double pumps, triple pumps, and so on, that can be assembled together according to versions of displacement, flanging, and auxiliary valves. External gear pumps are widely […]

External Gear Pump, Cast Iron, Single and Multiple, 40.0 – 75.0 Displacement cm³/rev. The product range of SpA includes single pumps 05-100-212-212HP-250HP-300-312HP (corresponding with the common group denominations: 05-1-2-2.5-3) and several combinations of double pumps, triple pumps, and so on, that can be assembled together according to versions of displacement, flanging, and auxiliary valves. Thanks […]

Aluminum-Body, Low-Power, Oil-Operated Pumps for Auxiliary Services, 1.1 – 8 Displacement cm³/rev. The Pumps Series A 1P gear pump usually consists of a gear pair supported by two aluminum bushes, a body, a securing flange and a cover. The shaft of the driving gear projecting beyond the flange mounts a twin – lip seal ring […]

Cast Iron Flanges, Aluminum Body, High-Performance Single Pumps, 1.4 – 87 Displacement cm³/rev. The Pumps GHP are high-performance single gear pumps with an aluminum body, and a cast iron flange and cover. Displacements range from 1.4 up to 87 cc/rev (Group 1, 2 and 3). Available in different configurations (European, SAE, German standard) in a […]

Aluminum-Body, Low-Power, Oil-Operated Pumps for Auxiliary Services, 1.4 – 200 Displacement cm³/rev. The Pump ALP Series (where groups named ALP1, ALP2, ALP3, and ALP4) are suitable for the most different application in both industrial and mobile sectors. Produced in four different groups. Within each of them, the different displacements (between 1.4 and 200 cm³/rev) are […]

High-Pressure, Short Multiple Pumps,1,4 -35,2 Displacement cm³/rev. The ALPC & GHPC pumps are well designed to fit applications where multiple pumps are required to be driven by just one motor and space is too narrow for standard multiple pumps. Available displacements vary from 1.4 to 13.8 cm3/rev for group 1 and from 4.5 to 35.2 […]

Variable Displacement Axial Piston Pump, Pressure Rating of 6,090 psi. The C Series Variable Displacement Axial Piston Pumps are engineered for heavy-duty mobile equipment applications. Pumps offer a pressure rating of 6,090 psi, durable construction and a compact footprint. C Series variable displacement piston pumps have been designed for use in closed circuit hydrostatic applications. […]

Fixed Cast Iron Gear Pump, Integrated Relief Valve, and Load Hold Valve, 5,1-6,4. Displacement. The C101/C102 series combination pump valves (fixed gear pump) provide the most reliable, trouble-free performance in the industry for the dump truck and trailer applications. Operating pressures up to 138 bar (2,000 psi) speeds up to 2,400 rpm, flows up to […]

Fixed Aluminum Gear Pump, 1.87-10.50 cc/rev Displacement. The Aluminum Pump D Series fixed displacement gear pump offers high performance and high power density due to its aluminum construction, making it an ideal selection for the Aerial, Agriculture, Construction, Forestry, Material Handling, and Turf Equipment markets. It is available as a standard pump or a pump […]

Axial Piston Fixed Displacement Hydraulic Motor – Large Frame. The F12 hydraulic motor series has operating pressures up to 480 bar (7,000 psi) and speeds up to 7300 rpm. The F12 motor is a robust design motor and can be used in numerous applications in both open and closed loop circuits. Sizes from 30-250cc. The […]

Fixed Cast Iron Gear Pump, Integrated Relief Valve, and Load Hold Valve, 5,1-6,4. Displacement. The G101/G102 fixed displacement gear pumps offer high performance and high endurance due to its cast iron construction, making it an ideal selection for the Vocational & Municipal Equipment market. It is available as a standard pump with an integrated valve […]

Fixed, Two-Piece, Cast Iron, 23-80cc. Displacement. These truck gear pumps are ideal for operators of light trucks for their hydraulic power needs. The Cast Iron Pump GP1 Series fixed displacement gear pump offers high performance and high power density dues to its two-piece cast iron construction, making it an ideal selection for the Aerial and […]

Low Noise, Low Ripple, High-Efficiency, High-Pressure Gear Pumps, 7 – 200 Displacement cm³/rev. ELIKA® pumps are extremely silent gear pumps that can be applied in situations where low noise levels are required. Using a low noise ELIKA® gear pump will eliminate harmful noises for persons and their surroundings. ELIKA® gear pumps are fully interchangeable with […]

Double Pumps and Multiple Pumps, 7 – 35 cm³/rev. ELIKA, being low-noise and low-ripple, ELI2 Multiple Series Gear Pumps is a perfect fit for all those applications that require low noise levels. The use of ELIKA gear pump eliminates adverse noise effects on humans and on the surrounding environment. The ELIKA reduces the noise level […]

Pumps with Flange and Cover in Cast Iron, 1,4 – 87 cm³/rev Displacement. These range of products have a new series of pumps named GHP, where groups named GHP1, GHP2, and GHP3 are suitable for the most different application in both industrial and mobile sectors. Available in different configurations (European, SAE, German standard) in a […]

Gear Pump, High-Performance Version, Hydraulic Drive, 6 (1.5) GPM. The GP0 gear pump with displacements up to 3,2 cm³ (0.20 inch³), Pmax 260 bar (3800 PSI), Speed from 500 to 8000 RPM. Flange, cover, and body are made of a high-quality aluminum alloy. These pumps are characterized by high-efficiency and low-noise levels through the entire rotation […]

Gear Pump, Light-Line Version, Hydraulic Drive, 6 (1.59) GPM. The GP0L Fixed Displacement gear pump, with displacements up to 2 cm³ (0.12 inch³), Pmax 250 bar (3600PSI), and speeds from 500 to 7000 RPM. Technical Features: Operating pressure 200 bar, Peak pressure 250 bar Cost-Effective design or circuits with a lower operating pressure High-quality aluminum alloy […]

Gear Pump, High-Performance Version, Hydraulic Drive, 21 (5.55) GPM. The GP1 gear pump with displacements up to 31 cm³ (1.89 inch³), Pmax 310 bar (4500 PSI), and speeds from 500 to 4000 RPM. Technical Features: Operating pressure 280 bar, Peak pressure 310 bar High-strength quality aluminum alloys pump with axial play compensation Low noise level […]

Fixed, Aluminum, 8-19cc., Displacement. These truck gear pumps are ideal for operators of light trucks for their hydraulic power needs. The Aluminum Pump GPA Series fixed displacement gear pump offers high performance and high power density dues to its aluminum construction, making it an ideal selection for Truck applications. The GPA/GP1 series gear pumps are […]

Gear Pump, High-Performance Version, Hydraulic Drive, 67 (17.65) GPM. The GP2 gear pump with displacements up to 31 cm³ (1.89 inch³), Pmax 310 bar (4500 PSI), and speeds from 500 to 4000 RPM. Technical Features: Operating pressure 280 bar, Peak pressure 310 bar High-strength quality aluminum alloys pump with axial play compensation Low noise level […]

Fixed, Aluminum, Pressure-Loaded Gear Pump, 9.88 – 36.50 cc/rev Displacement. Aluminum Pump H Series fixed displacement gear pump offers high performance and high power density due to its aluminum construction, making it an ideal selection for the Aerial, Agriculture, Construction, Forestry, Material Handling, and Turf Equipment markets. It is available as a standard pump, a […]

Gear Pump, Light-Line Version, Hydraulic Drive, 65 (17.17) GPM. The GP2L gear pump with displacements up to 30 cm³ (1.83 inch³), Pmax 300 bar (4350 PSI), and speeds from 400 to 4000 RPM. Technical Features: Operating pressure 270 bar, Peak pressure 300 bar Cost-effective design or circuits with a lower operating pressure High-quality aluminum alloy […]

Gear Pump, High-Performance Version, Hydraulic Drive,177 (16.76) GPM. The GP3 gear pump with displacements up to 100 cm³ (6.10 inch³), Pmax 320 bar (4600 PSI), and speeds from 350 to 3200 RPM. Technical Features: Operating pressure 290 bar, Peak pressure 320 bar High-strength quality aluminum alloys pump with axial play compensation Low noise level in […]

Gear Pump, Light-Line Version, Hydraulic Drive, 177 (46.76) GPM. The GP3L gear pump with displacements up to 71 cm³ (4.30 inch³), Pmax 280 bar (4060 PSI), and speeds from 400 to 3500 RPM. Technical Features: Operating pressure 250 bar, Peak pressure 280 bar Cost-effective design or circuits with a lower operating pressure High-quality aluminum alloy […]

Fixed, Tandem Pressure-Loaded Gear Pump, 30.18/10.5 cm³/rev Max. Displacement. The Aluminum Pump HD Series fixed displacement gear pump offers high performance and high power density dues to its aluminum construction, making it an ideal selection for the Aerial, Agriculture, Construction, Forestry, Material Handling, and Turf Equipment markets. It is available as a standard pump, a […]

Variable Displacement Closed Circuit Axial Piston Pumps, Displacement 17 to 28 cm³ (1,04 to 1,71 in³), Continuous 280 bar (4060 psi), Pressure Intermittent 300 bar (4350 psi), (Power-Transmission Hydrostatic Transmission). The axial piston pumps series HM P1A are designed to operate in a closed circuit. The available control systems make it easy to use these […]

Double Stage Pumps with Unloading Valves, 1st Stage- 1,4 – 4,1, 2nd Stage – 4,1 – 13,8 cm³/rev Displacement. The 1HL, 1PHL, and 2HL High/Low hydraulic gear pumps are special double-stage pumps with special integrated valves. The first stage, low displacement, high pressure. The second stage, high displacement, low pressure. RPM pump range 1,000 to […]

Gear Pump, Light-Line Version, Hydraulic Drive, 16 (4.31) GPM. The GP1L fixed displacement gear pumps, with displacements up to 8 cm³ (0.49 inch³), Pmax 270 bar (3900 PSI), and speeds from 600 to 6000 RPM. Technical Features: Operating pressure 230 bar, Peak pressure 270 bar Cost-effective design or circuits with a lower operating pressure High-quality […]

Variable Displacement Pump for Closed Loop Operation, Displacement 54.7 to 281.9 CC/Rev, Max. Operating Speed 2400 RPM to 3900 RPM, Max. Pressure 500 Bar, Nominal Pressure 450 Bar, Power Take-Off (PTO) Flange, Internal Gear Pump (IGP) and External Gera Pump (EGP) Available. The HPV-02 variable pump is an axial piston pump designed for high pressure […]

Fixed, Iron and Aluminum Gear Pump, 16-64cc, Displacement. The Iron and Aluminum Pump P16 Series fixed displacement gear pump offers high performance and high power density due to its part aluminum construction. The P16 fixed displacement gear pump offers a combination of high performance and lightweight due to combining a rugged cast iron pumping section […]

Variable Displacement Axial Piston Pump, Operating Pressure of 4,060. Variable, swashplate piston pumps designed for operation in open circuit, mobile hydraulic systems. The perfect choice when it comes to cost-saving installation as well as high productivity and power density. Displacement from 60 to 145 cc/rev. The P2/P3 Series has been designed to meet the specific […]

Medium Pressure Super Charged Pumps, Pressure Rating 3,000 psi. The PAVC Medium Pressure/Super Charged Pumps provide reliable high-speed operation. With a pressure rating of 3,000 psi, they are ideal for a variety of medium pressure mobile and industrial applications. Featuring a flexible, compact design, Pavc Medium Pressure Pumps deliver a reliable,easy-to-use solution for a wide […]

Variable Displacement Closed Circuit Axial Piston Pumps, Displacement 28 to 36 cm³ (1,71 to 2,20 in³), Continuous 280 (4060 psi), Pressure Intermittent 300 bar (4350 psi), (Power-Transmission Hydrostatic Transmission). The axial piston pumps series HM P1M is designed to operate in a closed circuit. The available control systems make it easy to use these pumps in […]

Bent-Axis Axial Piston Pumps, Fixed Displacement 10 | 12 | 16 cm³ (0,61 | 0,732 | 0,976 in³), Continuous 350 bar (5075 psi), Pressure Intermittent 400 bar (5800 psi), (Power-Transmission Hydrostatic Transmission). The HM PF 10 | 12 | 16 fixed displacement axial piston pump is designed to work in an open circuit. The system […]

Bent-Axis Axial Piston Pumps, Fixed Displacement 107 | 125 cm³ (6,63| 7,63 in³), Continuous 350 bar (5075 psi), Pressure Intermittent 400 bar (5800 psi), (Power-Transmission Hydrostatic Transmission). The HM PF 107 | 125 fixed displacement axial piston pump is designed to work in an open circuit. The system is designed in order to obtain 40° […]

Bent-Axis Axial Piston Pumps, Fixed Displacement 45 cm³ (2,75 in³), Continuous 350 bar (5075 psi), Pressure Intermittent 400 bar (5800 psi), (Power-Transmission Hydrostatic Transmission). The HM PF 45 fixed displacement axial piston pump is designed to work in an open circuit. The system is designed in order to obtain 40° angle of inclination of the […]

Bent-Axis Axial Piston Pumps, Fixed Displacement 56 | 63 cm³ (3,42 | 3,84 in³), Continuous 350 bar (5075 psi), Pressure Intermittent 400 bar (5800 psi), (Power-Transmission Hydrostatic Transmission). The HM PF 56 | 63 fixed displacement axial piston pump is designed to work in an open circuit. The system is designed in order to obtain […]

Variable Displacement Closed Circuit Axial Piston Pumps, Displacement 7 to 18 cm³ (0,43 to 1,10 in³), Continuous 250 | 230 bar (3625 | 3335 psi), Pressure Intermittent 280 | 250 bar (4060 | 3625 psi), (Power-Transmission Hydrostatic Transmission). The axial piston pumps series HM PO is designed to operate in a closed circuit. The available control systems […]

Variable Displacement Closed Circuit Axial Piston Pumps, Displacement 17 to 34 cm³ (1,04 to 2,07 in³), Continuous 280 bar (4060 psi), Pressure Intermittent 300 bar (4350 psi), (Power-Transmission Hydrostatic Transmission). The axial piston pumps series HM PS is designed to operate in a closed circuit. The available control systems make it easy to use these pumps […]

Variable Displacement Closed Circuit Axial Piston Pumps, Displacement 9+9 to 16+16 cm³ (0,55+0,55 to 0,97+0,97 in³), Continuous 280 bar (4060 psi), Pressure Intermittent 300 bar (4350psi), (Power-Transmission Hydrostatic Transmission). The axial piston pumps series HM PX is designed to operate in a closed circuit. The available control systems make it easy to use these pumps in any application for industrial and […]

Variable Displacement Closed Circuit Axial Piston Pumps, Displacement 7 to 18 cm³ (0,43 to 1,10 in³), Continuous 250 | 230 bar (3625 | 3335 psi), Pressure Intermittent 280 | 250 bar (4060 | 3625 psi), (Power-Transmission Hydrostatic Transmission). The axial piston pumps series HM PZA have been designed to operate in a closed circuit. The available control systems […]

Variable Displacement Piston Pump, Operating Pressure of 4,060 psi. The PD Series pump offers variable displacement axial piston pumps for open-circuit applications. Featuring a compact footprint and continuous operating pressure of up to 4,060 psi, PD pumps provide quiet operation and efficient control. The PD Series of Open-Circuit Piston Pumps boost productivity in medium pressure […]

Bent-Axis Axial Piston Pumps, Fixed Displacement 80 | 90 cm³ (4.99 | 5,49 in³), Continuous 350 bar (5075 psi), Pressure Intermittent 400 bar (5800 psi), (Power-Transmission Hydrostatic Transmission). The HM PF 80 | 90 fixed displacement axial piston pump is designed to work in an open circuit. The system is designed in order to obtain […]

Variable Displacement Closed Circuit Axial Piston Pumps, Displacement 14 to 23 cm³ (0,85 to 1,40 in³), (Swashplate 14,5 | 19 | & 18), Continuous 250 bar (3625 psi), Pressure Intermittent 280 bar (4060 psi), (Power-Transmission Hydrostatic Transmission). The axial piston pumps series HP P2 is designed to operate in a closed circuit. Control Systems are available […]

Closed Circuit Axial Piston Pumps, Variable Displacement , Max. Displacement from 17cc to 34 cc, SAE B Flange, (Swashplate 18 | 19 | 18 | 18 | 18°), Pressure Intermittent 300 (bar), 4350 (psi). The axial piston pumps series HP P4 34•46•50•58•65 is designed to operate in a closed circuit, for applications at medium pressure. Control […]

Variable Displacement Closed Circuit Axial Piston Pumps, Displacement 55 to 78 cm³ (3,35 to 4,76 in³), (Swashplate 16,3 | 17,3 | 17,7 °), Continuous 420 | 400 bar (6090| 5800 psi), Pressure Intermittent 450 | 420 bar (6525 | 6090 psi), (Power-Transmission Hydrostatic Transmission) The axial piston pumps series HP P6 series is designed to operate […]

Variable Displacement Closed Circuit Axial Piston Pumps, Displacement 82 to 125 cm³ (5,0 to 7,6 in³), (Swashplate 18,0, 16,5, 20,0°), Continuous 400 bar (5800 psi), Pressure Intermittent 420 bar (6090 psi), (Power-Transmission Hydrostatic Transmission). The axial piston pumps series HP 8 82•100•125 is designed to perform in closed circuit for high pressure operations. The various control […]

Gear Pumps, Cast Iron Body, 4,cm³/rev. to 90,5 cm³/rev., up to 320 Bar. The HP Hydraulic series HPG (Series G) gear pumps are supplied in size group 2, 3 and 4. The series of products is even further completed with a full range of flanges, shaft ends, and available multiple pumps with or without valves […]

Gear Pumps, Fixed Displacement, Aluminum Body, 0,19 cm³/rev. to 88 cm³/rev., up to 310 Bar. The HP Hydraulic series L (HPL..0, HPL..1, HPL..2, HPL..2 SG Version, HPL..3, HPL..3 SG Version, HPL..4 SG Version) pumps have aluminum bodies and are suitable for a wide range of applications. Available in five different sizes: Group 0, Group 1, Group 2, […]

Fixed, High-Speed, Low Torque, Gerotor Pump, 16-64cc, Displacement. The Aluminum Pump PGG Series fixed displacement High-Speed Low Torque Gerotor pump offers high performance and high power density dues to its aluminum construction, making it an ideal selection for the Aerial, Agriculture, Construction, Forestry, Material Handling, and Turf Equipment markets. • Flows from .95 GPM to […]

Fixed, Cast Iron Gear Pump, Single, and Multiple, 16.2-64.6 cc/rev, Displacement. The PGP031 fixed displacement gear pumps offer high performance and high endurance due to its cast iron construction. • Flow range to 38.4 gpm (145.4 lpm) per section • Displacements from .985 to 3.94 cir (16.2 to 64.6 cc/rev) • Operating pressures up to […]

Swash Plate Variable Displacement Axial Piston Pump. The K3VG Series are variable displacement axial piston pumps of swash plate design for industrial equipment. The K3VG Series are available in size ranging from 63 to 560 cm³/rev with various control options including a highly precise electro-hydraulic servo regulator “ILIS”. Main features of the K3VG Series includes […]

Variable Displacement Swash Plate Design, Open Loop. The K3VL Series – medium pressure, open circuit, axial piston pumps are designed for mobile, industrial, and marine applications. The pump’s rotating groups are based on the proven design of the K3V and K3VG pumps. K3VL pumps are available in nominal displacements ranging from 1.71 to 12.20 in³/rev […]

Variable Displacement Swash Plate Design, Open Loop, Displacement 50 (cm³) to 150 (cm³). The K3VLS series are variable displacement axial piston pumps of swash plate design, suitable for use in mobile applications and industrial vehicles with medium pressure hydraulic systems. The K3VLS pumps enable flexible configuration in a wide range of applications with their compact […]

Low Noise Variable Displacement Axial Piston Pump. The K7V Series are variable displacement axial piston pumps of swashplate design, suitable for use in mobile applications. A long life is obtained by adopting large capacity of bearing and thicker shaft which reduces the load on the edge of bearing rollers. The power density if 1.5 times […]

Swash-plate Axial Piston Pump The K7VG high-pressure swashplate pump developed for general industrial machinery use and is based on long and rich experience. The adoption of the high-load bearing and friction-free contacting mechanism of shoes has achieved high reliability and long life. The unique compact rigid housing construction in addition to the semi-cylindrical swash-plate and […]

Variable Displacement Swash Plate Design, Closed Loop. The K8V series with a range in pump size from 71 to 130 cm3/rev are equipped with electric or hydraulic pilot displacement control. The K8V series pumps, having the integrated components required for a closed system, such as a charge pump, high and low-pressure relief valves, and a […]

Fixed Displacement Axial Piston Pump. The LX/LV series are fixed displacement axial piston pumps of bent axis design. They can operate for long periods of time under severe conditions. such as high-pressure continuous drive, use of fire-resistant fluids, ect. The series is suitable for the heavy duty application in press machine and steel making plants.

Gear – Small Frame, High-Pressure Bushing Gear Pump, 2.5 – 10.5 GPM. The P124 is a small frame hydraulic bushing gear pump with high-pressure capabilities, the 424 series has the same capabilities as the P124, but is capable of higher pressures. Cast Iron construction, built to with-stand robust applications. Compatible with mineral oil, water glycol, […]

Bent Axis Variable Displacement Axial Piston Pump. The LVP 017 Series are manual variable displacement axial piston pumps of bent axis design for high-pressure jacks. The bent axis type axial piston pumps have features such as high efficiency and long life. They can operate for long periods under severe conditions: high-pressure continuous drive, use of […]

Variable Displacement Axial Piston Pump The LXV/LZV series are variable displacement axial piston pump of bent axis design and have heavy duty bearings to achieve long life. They can operate for long periods of time under severe conditions: high-pressure continuous drive, use of fire-resistant fluid, etc.

Bent-Axis Axial Piston Pumps, Fixed Displacement 23 | 28 | 32 cm³ (1,4 | 1,71 | 1,95 in³), Continuous 350 bar (5075 psi), Pressure Intermittent 400 bar (5800 psi), (Power-Transmission Hydrostatic Transmission). The HM PF 23 | 28 | 32 fixed displacement axial piston pump is designed to work in an open circuit. The system […]

Fixed, Cast Iron Gear Pump, 16.2-64.6 cc/rev, Displacement. The 020 series fixed displacement gear pumps offer high durability & resistance to oil contamination due to their cast iron, roller bearing construction making them an ideal selection for the Vocational Truck, Winch, and Oil & Gas markets. They are available as single, or multi-section pumps. and […]

Fixed, Cast Iron Gear Pump, Multiple, 21-105 cc/rev, Displacement. The PGP051 fixed displacement gear pumps offer high performance and high endurance due to its cast iron construction. The 051 series fixed displacement gear pumps offer high durability & resistance to oil contamination due to their cast iron, roller bearing construction making them an ideal selection […]

Fixed, Cast Iron Gear Pump, Multiple, 50-202 cc/rev, Displacement. The PGP076 fixed displacement gear pumps offer high performance and high endurance due to its cast iron construction. • Flow range to 121.4 gpm (459.5 lpm) per section • Displacements from 3.07 to 12.3 cir (50 to 202 cc/rev) • Operating pressures up to 200 bar […]

Fixed, Cast Iron Gear Pump, Multiple, 50-202 cc/rev, Displacement. The PGP130 fixed displacement gear pumps offer high performance and high endurance due to its cast iron construction, making it an ideal selection for the construction equipment market in particular mini-construction equipment. Available with industry standard output shafts, ports and mounts, these pumps deliver up to […]

The 315 series fixed displacement gear pumps offer high-pressure durability due to their cast iron construction, making them ideal for high duty cycle mobile applications for the Construction, Forestry, and Oil & Gas markets. They are available as a standard pump, clutch pump, and tandem pump. • Flow range to 32 gpm (121 lpm) […]

Variable Displacement Closed Circuit Axial Piston Pumps, Displacement 21 to 37 cm³ (1,28 to 2,26 in³), (Swashplate 18°), Continuous 250 bar (3625 psi), Pressure Intermittent 300 bar (4350 psi), (Power-Transmission Hydrostatic Transmission). The axial piston pumps series M4 PV is designed to operate in a closed circuit. Control systems actually available are making easy to […]

Fixed, Cast Iron Gear Pump, Multiple, 21-105 cc/rev, Displacement. The 350 series fixed displacement gear pumps offer high-pressure durability due to their cast iron construction, making them ideal for high duty cycle mobile applications for the Construction, Forestry, and Oil & Gas markets. They are available as a standard pump, clutch pump, and tandem pump. […]

Variable Displacement Closed Circuit Axial Piston Pumps, Displacement 7 to 18 cm³ (0,43 to 1,10 in³), Continuous 210 bar (3045 psi), Pressure Intermittent 230 bar (3335 psi), (Power-Transmission Hydrostatic Transmission). The axial piston pumps series HM PLB is designed to operate in a closed circuit. Displacement range 7cc thru 18cc, R or L hand rotation, single […]

Fixed, Cast Iron Gear Pump, Multiple, 44-147.5 cc/rev, Displacement. The 365 series fixed displacement gear pumps offer high-pressure durability due to their cast iron construction, making them ideal for high duty cycle mobile applications for the Construction, Forestry, and Oil & Gas markets. They are available as a standard pump, clutch pump, and tan

8613371530291

8613371530291