variable hydraulic pump supplier

The displacement of a pump is defined by the volume of fluid that the gears, vanes or pistons will pump in one rotation. If a pump has a capacity of 30 cm3, it should treat 30 ml of fluid in one rotation.

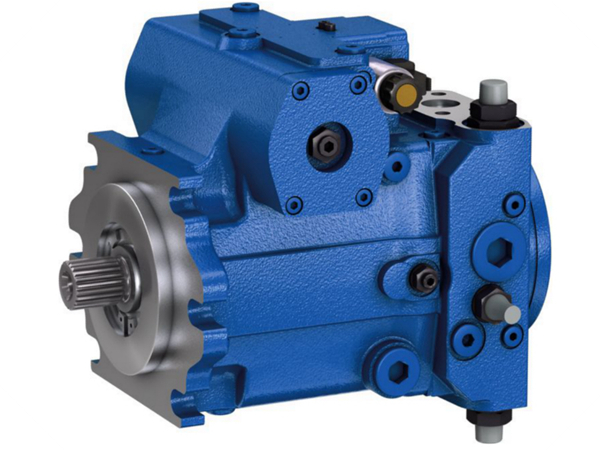

In axial piston variable pumps, the flow is proportional to the drive speed and the displacement. The flow can be steplessly changed by adjusting the swivel angle. Axial piston variable ...

... axial piston pump type V60N is designed for open circuits in mobile hydraulics and operate according to the swash plate principle. They are available with the option of a thru-shaft for operating additional ...

Variable displacement axial piston pumps operate according to the bent axis principle. They adjust the geometric output volume from maximum to zero. As a result they vary the flow rate ...

... piston pump type V30D is designed for open circuits in industrial hydraulics and operate according to the swash plate principle. They are available with the option of a thru-shaft for operating additional ...

... circuit axial piston pumps are used as hydrostatic transmission components in self-propelled machines and for rotary drives in both fixed and mobile equipment of all kinds.

Axial piston twin flow pump. With a very high performance in all job conditions. Due to its twin flow configuration this pump allows a great variety of solutions in different job applications.

Air hydraulic pump, double pneumatic motor, double effect, foot operated with lock-up function, lever distributor valve (4/3), 10L tank, oil flow 8.5 / 0.26 l / min

... customer system options for mechanical, hydraulic and electric input solutions are available. Further special regulating features like torque control and pressure cut-off are also available. The reliable ...

... needs of truck hydraulics, the TXV variable displacement pumps with LS (Load Sensing) control allow flow regulation to suit the application requirements. The pump ...

... rev. displacements, these pumps are designed to operate in both directions of rotation (clockwise or counter-clockwise). Only one reference regardless of direction of rotation. The TXV indexable pumps ...

... PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design ...

Variable displacement pumps in closed loop; 3 basic design units and 8 max. displacement sizes of 14, 18, 21, 28, 35, 46, 56, 64 cc/rev; various control options; max. ...

Parker P2/P3 High Pressure Axial Piston Pumps are variable displacement, swashplate piston pumps designed for operation in open circuit, mobile hydraulic ...

... Series pump offers variable displacement axial piston pumps for open-circuit applications. Featuring a compact footprint and continuous operating pressure ...

ISO 9001:2000 certified custom manufacturer of variable displacement axial piston pumps. Specifications of pumps include 3600 rpm maximum speed & 350 psi maximum pressure. Optional electronic control units provide proportional control, automotive control, control with feed-back for speed, displacement & steering angle, power limiter & customized software. Also available are hydraulic, mechanical & electric servo controls. Optional pump features include front & rear lever bypass, electrical bypass with brake release, reinforced roller bearings, suction filter, SAE flanges, UNF threads, cut-off pressure valve, pressure inlet & purge valve. Other products include gearboxes, drivelines, axles, electric wheel drives, hydraulic motors & pumps.

Manufacturer of standard and custom metering equipment and systems. Products include precision meter mix systems, metered dispensing systems, meter mix dispensing systems, precision gear metering pumps, prototype test systems and pump skid systems. Precision gear metering pumps such as extrusion/discharge metering pumps, hazardous/toxic materials metering pumps, high/low viscosity metering pumps, high pressure metering pumps, multiple streams metering pumps, spraying/coating metering pumps, dosing pumps, drum metering pumps, submersible metering pumps and platen based drum metering pumps are available. Capabilities include repairing, rebuilding, upgrading and preventive maintenance. Consulting and on-site training services are available. Markets served include aerospace, aviation, packaging, building and construction, medical, pharmaceutical, electronics, textiles, personal care products and food manufacturing industries.

VDP pumps are variable displacement axial piston pumps designed to use in open circuits. They are available from 40 to 120 cm3/rev and with a maximum pressure of 450 bar. They can be assembled directly into the PTO´s with support. They come standard with 1 1/4″ DIN shaft and BSP threaded ports for high pressure applications.

APPLICATIONS: Combined with any of our wide range of PE series eaton fuller PTO, PIM series Volvo I-Shift/Mack mDrive PTO, PA series hot shift PTO for AISIN and ALLISON automatic transmissions, PDT series PTO for the Detroit DT12, it can power your PTO hydraulic pumps wet kit or equipment on high pressure application such as truck mounted hydraulic cranes.

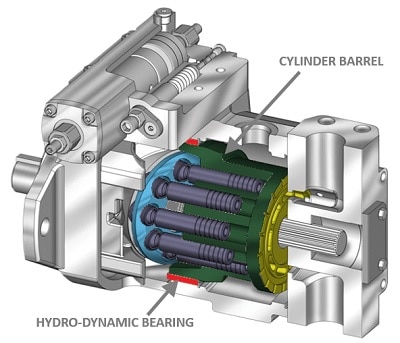

A common variable displacement pump used in vehicle technology is the axial piston pump. This pump has several pistons in cylinders arranged parallel to each other and rotating around a central shaft. A swashplate at one end is connected to the pistons. As the pistons rotate, the angle of the plate causes them to move in and out of their cylinders. A rotary valve at the opposite end from the swashplate alternately connects each cylinder to the fluid supply and delivery lines. By changing the angle of the swashplate, the stroke of the pistons can be varied continuously. If the swashplate is perpendicular to the axis of rotation, no fluid will flow. If it is at a sharp angle, a large volume of fluid will be pumped. Some pumps allow the swashplate to be moved in both directions from the zero position, pumping fluid in either direction without reversing the rotation of the pump.

Piston pumps can be made variable-displacement by inserting springs inline with the pistons. The displacement is not positively controlled, but decreases as back-pressure increases.

Designed for power and speed, the Oilgear PVV open-loop axial-piston hydraulic pumps can handle large, heavy-duty systems. Manufactured with advanced engineering and computer-optimized, the PVV pump range delivers up to 450 Bar / 560 horespower which equates to four times the horsepower at less than half the cost of other manufacturers pumps.

With it"s compact design available in several displacements, the PVV pumps offer a large selection of readily interchangeable controls. With improved response controls and reduced noise levels, its rugged cylinder design enhances performance.

The patented, pressure lubricated swashblock design offers high performance for high-cycling operations. It also contributes to the pump’s ability to run on low-viscosity fluids, including high water content, fire-resistant and other special fluids.

Zeus Hydratech fully supports the Oilgear PVV pump product line and is the only valid source for OEM parts. All Oilgear repairs are machined and tested per our original factory specifications.

Designed for power and speed, the Oilgear PVV open-loop axial-piston hydraulic pumps can handle large, heavy-duty systems. Manufactured with advanced engineering and computer-optimized, the PVV pump range delivers up to 450 Bar / 560 horespower which equates to four times the horsepower at less than half the cost of other manufacturers pumps.

With it"s compact design available in several displacements (200-540cc/rev), the PVV pumps offer a large selection of readily interchangeable controls. With improved response controls and reduced noise levels, its rugged cylinder design enhances performance.

The patented, pressure lubricated swashblock design offers high performance for high-cycling operations. It also contributes to the pump’s ability to run on low-viscosity fluids, including high water content, fire-resistant and other special fluids.

Zeus Hydratech fully supports the PVV pump product line and is the only valid source for OEM parts. All Oilgear repairs are machined and tested per our original factory specifications.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

Quiet operation, high efficiency and compact design — all available at a competitive price. That’s what Oilgear PVWC closed-loop, hydrostatic axial-piston hydraulic pumps bring to the table. All designed around our proven rotating group.

Quiet operation, high efficiency and compact design — all available at a competitive price. That’s what Oilgear PVWC closed-loop, hydrostatic axial-piston hydraulic pumps bring to the table. All designed around our proven rotating group.

Quiet operation, high efficiency and compact design — all available at a competitive price. That’s what Oilgear PVWC closed-loop, hydrostatic axial-piston hydraulic pumps bring to the table. All designed around our proven rotating group.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids—and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Extremely effective across numerous industrial applications that require quick response in extreme environments, the XD5 series of pumps offer lightning-fast control response on both low-viscosity fluids and standard hydraulic oil. Engineered to handle the most challenging environments, they have been designed to be a high-performance solution for demanding mobile applications.

In the variable displacement pump category, customers can find this variable displacement axial piston pump that is mainly used as a stand-alonepump. The other type of axial piston pump is constant pump. This type of pump can be identified by parallel arrangement of many pistons to the drive. It is possible to adjust the flow rate of fluid when using such pump. The variable flow rate is possible as the pump can adjust its geometric output volume. This type of pump finds use in hydraulic motors and cylinders for controlling their speed.

Another variable displacement pump is the piston, which is a quick compressor and has a low-pressure pressure. The piston is tendential and is more affordable than the other one because hydraulic technology is more affordable than reciprocating pumps.

Variable displacement pumps vary in the number, types, and sizes. One variable displacement pumps vary in the number, one, and many others. A piston type is compressed, and it has a low-pressage capacity compared to other variable displacement pumps. The piston type is compressed and has a low-pressure capacity.

Many hydraulic pumps are variable displacement, such as piston hydraulic pumps, variable displacement hydraulic pumps, variable displacement pumps, and hydraulic piston pumps, variable displacement pumps have a number of pumps. Among various types of hydraulic displacement pumps, variable displacement pumps are one of the best.

Variable displacement hydraulic pumps can be found for many purposes. Whenalling hydraulic pumps, the variable displacement of the hydraulic pumps is one for a considerable period of time, and it saves time and effort by installing hydraulic piston pumps.

6430 hydraulic pump variable displacement products are offered for sale by suppliers on Alibaba.comAbout 80% % of these are hydraulic pumps, 6%% are pumps, and 3%% are hydraulic motors.

A wide variety of hydraulic pump variable displacement options are available to you, such as new, used.You can also choose from piston pump, gear pump and vane pump hydraulic pump variable displacement,as well as from 1 year, 6 months, and 1.5 years hydraulic pump variable displacement, and whether hydraulic pump variable displacement is hydraulic power units, fittings, or hydraulic accumulators.

In a hydraulic system, fluid is conveyed through the various components by the activity of a pump. Pumps work by converting mechanical energy—e.g., the turning of a gear—into hydraulic (i.e., fluid) energy. Hydraulic pumps may be either fixed displacement (conveys a precise, unchangeable amount of fluid during each rotation) or variable displacement (can be altered to change the amount of fluid conveyed). Of these two types, variable displacement pumps are more complicated in design and, therefore, tend to be more expensive.

Hydraulic pumps are used in a wide range of industrial equipment and, for this reason, they exist in a broad assortment of designs, including the following:

Vane pumps – Vane pumps feature a rotating shaft with a number of thin vanes protruding from it. The vanes effectively separate the housing into distinct compartments, each of which conveys fluid from the input to the output as the central rotor turns. Because the rotor is positioned eccentrically, its motion first steadily increase the volume of space in each compartment as the compartments fill and then decreases them as they empty when the fluid is forcefully expelled through the output.

Gear pumps – The typical gear pump has two interlocking gears, one of which is connected to a drive shaft. As the shaft turns, the two gears are put into motion, conveying the hydraulic fluid around the outer perimeter of the housing and finally through the outlet.

Piston pumps – A piston pump is characterised by the presence of one or more pistons, consisting of a cylinder inside a cylinder. The up-and-down motion of the piston conveys hydraulic fluid to the output. These pumps are available in axial and radial designs.

In addition to supplying all types of hydraulic pumps, from stock White House Products can also manufacture piston gear and vane pumps to order. For gear pumps consult the Tailor Made gear pump section of our catalogue. For Vane pumps see the available options in the Vane pump and mtors section of the catalogue. For Piston pumps see the available options in the Standard Piston Pumps section.

If your hydraulic pump requires new parts or to be repaired White House Products can assist with a wide range of spare parts and full repair and test facilities for all types and styles of hydraulic pump. So if you need to replace the entire system, a component or need a component repair, you can count on White House Products for the exact part numbers. Parts for Cessna, Kayaba, Saeur Danfoss, Vickers, and other pump brands are available from stock.

Sometimes, it is a challenge to find an exact match to your application. If a particular hydraulics system manufacturer does not produce a pump for your requirements, we can help. You can have one built to your own specifications, which sets our operation apart from other hydraulic pump suppliers. Register to access this feature, but not before conducting a complete search of our catalogues, as this is the world’s largest selection of hydraulic pumps.

Search filters and the “Quick Find” feature simplify the process of browsing thousands of products from a leading pump system supplier. Your search can be as simple as entering a keyword or part number. By registering, instantly see stock availability and hydraulic pump pricing, and use instant online ordering; for help, our technical support team is always standing by.

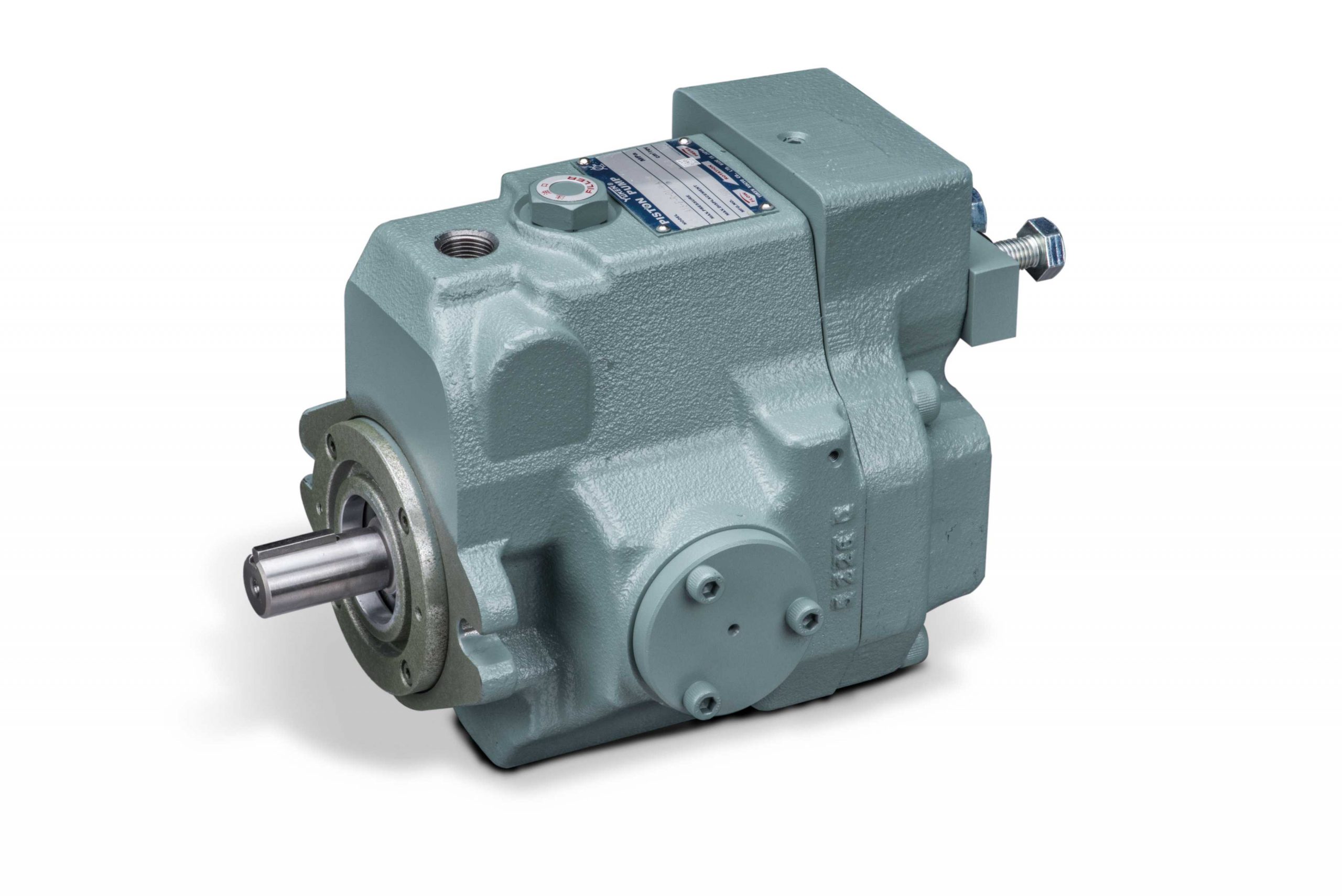

We are manufacturer and supplier of high efficiency Variable Displacement Pump suitable for engineering machines, industrial machinery, boats, and others. Open loop axial design of this pump increases its efficiency and makes it suitable for various industrial works. Furthermore, our Variable Displacement Pump consists of drive shaft that can endure extensive load. Its oil absorption facility is highly appreciated in the market. The Variable Displacement Pump that we offer maintains constant pressure and attains proportional displacement as well as drive speed.

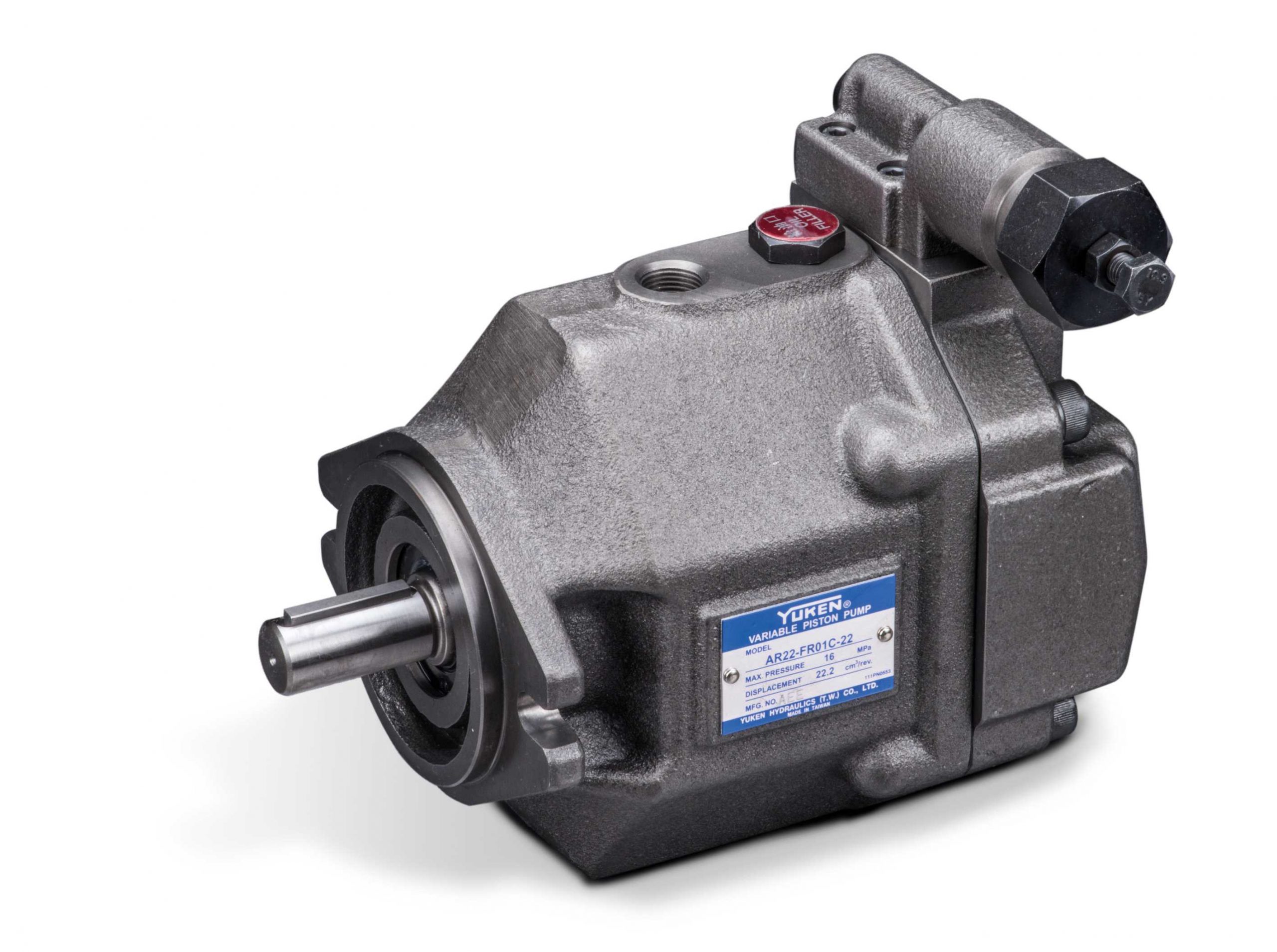

Piston Pump And MotorLeading Manufacturer of yuken piston pumps, parker axial piston variable pump, parker variable piston pump, hydraulic piston pump, rexroth hydraulic piston pump and mild steel hydraulic piston pump from New Delhi.

CML variable vane pump pressure can be adjusted in the range of 5 - 140 bar, and the flow adjust range is 8-40 L/min. Before inquiring, you can inform the working pressure and flow, as well as the working conditions of the machine, and we will select the most suitable model for you.

CML has been specializing in the development and manufacture of vane pumps for over 40 years. There is a diversified and complete range of styles, as well as combinations of vane pumps and gear pumps for customers to choose.

For requirements different from the standard products, CML also has an experienced R&D team that can perform customization or assist hydraulic circuits design for industrial applications according to customer demands.

Piston cylinder axis of rotation between the shoe and the variable because the head Using a hydro static equilibrium structures with oil pan and cylinder block as compared with other types of pumps.

8613371530291

8613371530291