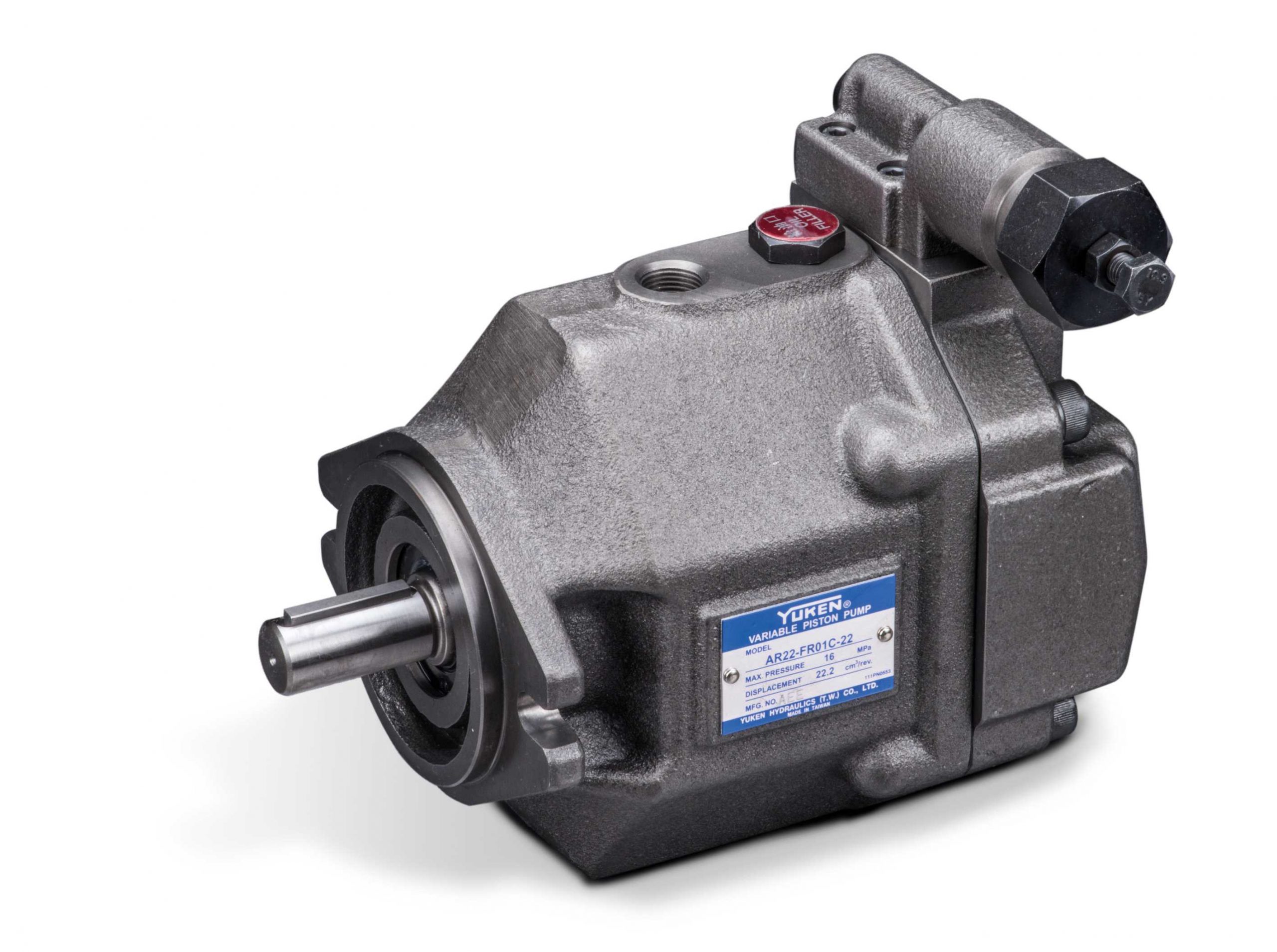

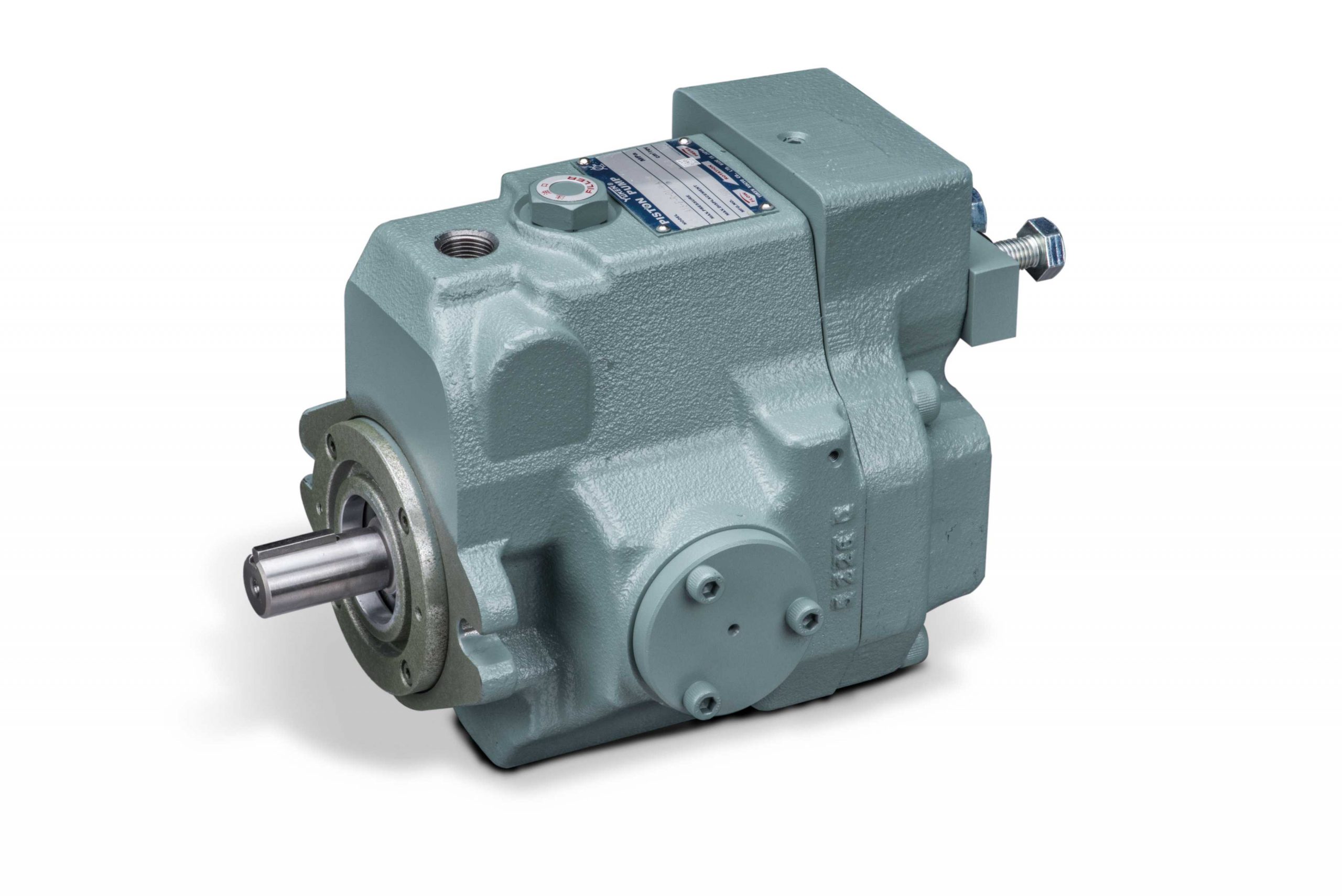

variable swash plate hydraulic pump brands

The displacement of a pump is defined by the volume of fluid that the gears, vanes or pistons will pump in one rotation. If a pump has a capacity of 30 cm3, it should treat 30 ml of fluid in one rotation.

In axial piston variable pumps, the flow is proportional to the drive speed and the displacement. The flow can be steplessly changed by adjusting the swivel angle. Axial piston variable ...

... axial piston pump type V60N is designed for open circuits in mobile hydraulics and operate according to the swash plate principle. They are available with the option of a thru-shaft for operating additional ...

Variable displacement axial piston pumps operate according to the bent axis principle. They adjust the geometric output volume from maximum to zero. As a result they vary the flow rate ...

... piston pump type V30D is designed for open circuits in industrial hydraulics and operate according to the swash plate principle. They are available with the option of a thru-shaft for operating additional ...

... circuit axial piston pumps are used as hydrostatic transmission components in self-propelled machines and for rotary drives in both fixed and mobile equipment of all kinds.

Axial piston twin flow pump. With a very high performance in all job conditions. Due to its twin flow configuration this pump allows a great variety of solutions in different job applications.

Air hydraulic pump, double pneumatic motor, double effect, foot operated with lock-up function, lever distributor valve (4/3), 10L tank, oil flow 8.5 / 0.26 l / min

... customer system options for mechanical, hydraulic and electric input solutions are available. Further special regulating features like torque control and pressure cut-off are also available. The reliable ...

... needs of truck hydraulics, the TXV variable displacement pumps with LS (Load Sensing) control allow flow regulation to suit the application requirements. The pump ...

... rev. displacements, these pumps are designed to operate in both directions of rotation (clockwise or counter-clockwise). Only one reference regardless of direction of rotation. The TXV indexable pumps ...

... PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design ...

Variable displacement pumps in closed loop; 3 basic design units and 8 max. displacement sizes of 14, 18, 21, 28, 35, 46, 56, 64 cc/rev; various control options; max. ...

Parker P2/P3 High Pressure Axial Piston Pumps are variable displacement, swashplate piston pumps designed for operation in open circuit, mobile hydraulic ...

... Series pump offers variable displacement axial piston pumps for open-circuit applications. Featuring a compact footprint and continuous operating pressure ...

The axial piston pump type V60N is designed for open circuits in mobile hydraulics and operate according to the swash plate principle. They are available with the option ...

Variable displacement axial piston pumps operate according to the bent axis principle. They adjust the geometric output volume from maximum to zero. As a result they vary the flow rate ...

The K3VG series are swash-plate type axial piston pumps which give excellent performance in high flow industrial applications in a compact and cost-effective package.

Closed circuit axial piston pumps are used as hydrostatic transmission components in self-propelled machines and for rotary drives in both fixed and mobile equipment of all kinds.

Twin flow axial piston pumps offers two different flows. In addition, we find several advantages such as lower weight or standar system solutions. BZT are available in ISO and SAE version.

Our variable volume, pressure compensated axial piston pumps continuously match output flow to the system demands. They’re designed to closely match the Eaton-Vickers PVB and PVQ and ...

The PFBA is a fixed displacement pump, axial-piston pump. It’s proven itself in a variety of operations—including die casting and injection molding machines, high-pressure ...

PMH high pressure axial piston pumps for closed loop are specifically designed to be used on heavy duty machines for traction and auxiliary functions, providing efficiency and durability.

Variable displacement pumps in closed loop; 3 basic design units and 8 max. displacement sizes of 14, 18, 21, 28, 35, 46, 56, 64 cc/rev; various control options; max. nominal pressure 300 bar, 350 bar peak; driving speed: ...

"C"" Axial Piston Pumps for high accuracy fluid metering with precision flow controls and high-pressure capability. Specifically designed for the Polyurethane Industry. Capacities from ...

Rotork offers a range of high quality hydraulic pumps for applications in the upstream and downstream oil and gas industries. These include an extensive range of axial piston ...

... Parker’s hydraulic truck pump series F1 featuring high self-priming speed and high efficiency and is one of the leading truck pumps in the market. The F1 pump provide ...

Parker P2/P3 High Pressure Axial Piston Pumps are variable displacement, swashplate piston pumps designed for operation in open circuit, mobile hydraulic ...

... Series pump offers variable displacement axial piston pumps for open-circuit applications. Featuring a compact footprint and continuous operating pressure ...

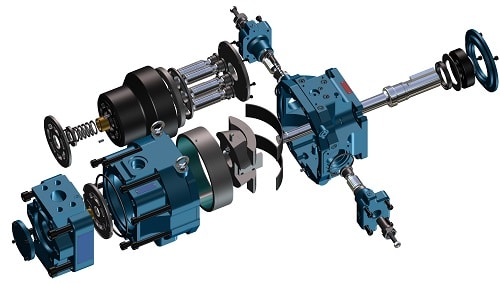

Swashplate hydraulic pumps have a rotating cylinder containing pistons. A spring pushes the pistons against a stationary swash plate, which sits at an angle to the cylinder. The pistons suck in fluid during half a revolution and push fluid out during the other half. The greater the slant the further the pump pistons move and the more fluid they transfer.

Electro-Hydraulic Controls for Model (A)A4VSO (Sizes 40...1,000), Model A4VSH (Sizes 40...250), Model (A)A4VSG (Sizes 40...1000) and Model (A)A4CSG (Sizes 250...750) Swashplate pumps

Piston pumps are typically much more complicated and are often available in wither fixed or, commonly, variable displacement configurations and with pressure compensation. These are big words that mean that piston pumps can usually adapt to the system pressure, providing maximum efficiency and flexibility. They are often used in “closed center” systems where the pump displacement varies to meet the needs of the work being done. Piston pumps use a “swashplate” to move the pistons and the angle of the swashplate & bore of the pistons determines the displacement. Pressure compensation regulates outputs in response to variations in the system. Piston pumps are typically the most efficient type of hydraulic pumps.

In an axial-piston pump, the pistons and cylinder rotate around the center, longitudinal axis. The pistons and shoes move in and out of the cylinder because they are sliding upon a stationary, variable angle, swashblock.

Designed for power and speed, the Oilgear PVV open-loop axial-piston hydraulic pumps can handle large, heavy-duty systems. Manufactured with advanced engineering and computer-optimized, the PVV pump range delivers up to 450 Bar / 560 horespower which equates to four times the horsepower at less than half the cost of other manufacturers pumps.

With it"s compact design available in several displacements (200-540cc/rev), the PVV pumps offer a large selection of readily interchangeable controls. With improved response controls and reduced noise levels, its rugged cylinder design enhances performance.

The patented, pressure lubricated swashblock design offers high performance for high-cycling operations. It also contributes to the pump’s ability to run on low-viscosity fluids, including high water content, fire-resistant and other special fluids.

Zeus Hydratech fully supports the PVV pump product line and is the only valid source for OEM parts. All Oilgear repairs are machined and tested per our original factory specifications.

The K3VLS series are axial piston, swash-plate type pumps, designed for open loop systems. They are suitable for mobile and industrial applications with medium duty pressure requirements. The K3VLS pumps are a compact, light-weight design with performance and reliability to suit many medium duty applications. With many control options, mounting and thru drive configurations, the K3VLS pumps offer excellent flexibility for system design considerations.

Fixed Displacement High Pressure. Fixed displacement motors for open and closed circuits with displacement size from 28 to 135 cc. Axial piston motor in swash plate design for high pressure open and closed circuit systems. Design characteristics HMF-02/HMA-02: Motor set to a fixed, customer-specific displacement ex-works. Displacements 135 thru 280.

Variable Displacement Motors for Open and Closed Circuit Operation. High-pressure hydrostatic Hydraulics HMV-02 variable displacement motors. Displacement size from 55 to 280 cc. Axial piston motor in swash plate design for high pressure closed and opened circuit systems. Jerk-free low-speed, high starting torque, large conversion range, zero angles possible, dynamic response, PTO through-drive motor, compact […]

Torque Transmission | PTO Through-Drive Motor. Based on a standard Series 02 variable hydraulic motor with single shaft end, the PTO Through-Drive Motor features two shaft ends for torque transfer. This enables the hydraulic motor to be installed directly in the driveline without a transfer gearbox, reducing noise emission and fuel consumption. At the same […]

Bent-Axis Axial Piston Motors, Variable Displacement 108 cm³ (6,6 in³), (Swashplate 25°), Continuous 350 bar (5075psi), Pressure Intermittent 400 bar (5800 psi), (Power-Transmission Hydrostatic Transmission). The HP BA 160 variable displacement axial piston motor is designed in order to obtain a high angle of inclination of the pumps with respect to the axle of the […]

Bent-Axis Axial Piston Motors, Variable Displacement 110 cm³ (6,65 in³), (Swashplate 26°), Continuous 350 bar (5075 psi), Pressure Intermittent 400 bar (5800 psi), (Power-Transmission Hydrostatic Transmission). The HP BA 110 variable displacement axial piston motor has been designed in order to obtain a high angle of inclination of the pumps with respect to the axle […]

Bent-Axis Axial Piston Motors, Variable Displacement 160 cm³ (9,77 in³), (Swashplate 25°), Continuous 380 bar (5510 psi), Pressure Intermittent 400 bar (5800 psi), (Power-Transmission Hydrostatic Transmission). The HP BA 160 variable displacement axial piston motor has been designed in order to obtain a high angle of inclination of the pumps with respect to the axle […]

Bent-Axis Axial Piston Motor, Variable Displacement 60 cm³ (3,66 in³), (Swashplate 25°), Continuous 380 bar (5510 psi), Pressure Intermittent 400 bar (5800 psi), (Power-Transmission Hydrostatic Transmission). The HP BA 60 variable displacement axial piston motor has been designed in order to obtain a high angle of inclination of the pumps with respect to the axle […]

Bent-Axis Axial Piston Motors, Variable Displacement 80 cm³ (4,88 in³), (Swashplate 25°), Continuous 350 bar (5075 psi), Pressure Intermittent 400 bar (5800 psi), (Power-Transmission Hydrostatic Transmission). The HP BA 80 variable displacement axial piston motor has been designed in order to obtain a high angle of inclination of the pumps with respect to the axle […]

Variable Displacement Open or Closed Circuit Axial Piston Motors, Displacement 34 to 65 cm³ (2,08 to 3,97 in³), (Swashplate 18 | 19 | 18 | 18 | 18°), Continuous 250 bar (3625 psi), Pressure Intermittent 330 | 300 bar (4785 | 4350 psi), (Power-Transmission Hydrostatic Transmission). The HP M4 MV series axial piston motors have […]

Variable Displacement Axial Piston Motors, Displacement From 75 cm³ to 115 cm³, (Swashplate 17 | 18 | 17 | 19 °), Pressure Intermittent 400 bar (5800 psi), (Power-Transmission Hydrostatic Transmission). The HP M5 MV series variable displacement axial piston motors feature a swashplate-system and can operate in either a closed or open circuit. Control systems […]

Fixed Displacement Open & Closed Circuit Axial Piston Motors, Displacement 77 to 125 cm³ (4,7 to 7,6 in³), (Swashplate 17 | 18 | 20 | 17 | 18 | 20°), Continuous 400 bar (5800 psi), Pressure Intermittent 420 bar (6090 psi), (Power-Transmission Hydrostatic Transmission). The HP M8 series axial piston motors have been designed to work […]

Variable Displacement Axial Piston Motors, Swashplate, Displacement From 34 cm³ to 115 cm³, Pressure up to 420 bar, Plug-In. Applications: Closed circuit axial piston motors are used as hydrostatic transmission components, in conjunction with closed circuit pumps, and found consequently in the widest imaginable range of mobile equipment. Key Features: Axial piston motors can be […]

Variable Displacement Axial Piston, Displacement From 34 cm³ to 65 cm³, (Swashplate 18 | 19 |18 | 18 | 18°), Continuous 250 bar (3625 psi), Pressure Intermittent 330 | 300 bar (4785 | 4350 psi), (Power-Transmission Hydrostatic Transmission). The HP V4 series axial piston motors have been designed to work both in an open and […]

Variable Displacement Axial Piston Motors, Swashplate, Displacement From 34 cm³ to 115 cm³, Pressure up to 420 bar, Plug-In. Applications: Closed circuit axial piston motors are used as hydrostatic transmission components, in conjunction with closed circuit pumps, and found consequently in the widest imaginable range of mobile equipment. Key Features: Axial piston motors can be […]

Fixed Displacement Swash-Plate Axial Piston Motor, Displacement 3.91 in³ (64.0 cm³) to 6.77 in³ (110.9 cm³). This motor series has proven high reliability in construction machinery applications. The low noise is achieved by the optimum valve plate design and casing rigidity. High-Efficiency with a spherical valve plate surface and full balancing mechanism provide excellent cylinder […]

High-Performance Motors for Swing Applications. Complete with swash-plate, fixed displacement, and axial piston type motors, the M2X and M5X motors are specifically designed for excavator swing operation. The M5X series are fixed displacement axial piston motors of swash plate design. The motor has built-in relief valve and make-up valve elements to achieve swing function by […]

Axial Piston Motors, Variable Displacement, Swash Plate. This series consists of variable displacement axial piston motors of swash plate design for winch application. These motors have a good self-priming capability and high starting efficiency developed based on our many years of experience and technology obtained in swash plate type pumps and motors. By combining the […]

Axial Piston Motors, Dual Displacement, Swash Plate. This motor series are dual displacement axial piston motors of swash plate design for mobile applications. The M3X series are newly developed motors for construction machinery, industrial machinery or other applications. The design based on technology and experience of the current MX series is more compact and enables […]

Axial Piston Motor with Reduction Gear, Fixed/Variable Displacement. The M3X/M3B-RG series motors are Fixed/Variable Displacement Axial Piston Geared type motors with a reduction gear for applications requiring multiplied torque at lower speeds. The M3X series are fixed displacement axial piston motors of swash plate design for applications. The M3B series are variable displacement axial piston […]

Fixed Displacement Open & Closed Circuit Axial Piston Motors, Displacement 21 to 37 cm³ (1,28 to 2,26 in³), (Swashplate 18°), Continuous 250 bar (3625 psi), Pressure Intermittent 300 bar (4350 psi), (Power-Transmission Hydrostatic Transmission). The M4 MF series axial piston motors are designed to work both in an open and in a closed circuit. Control systems […]

Fixed Displacement Open & Closed Circuit Axial Piston Motors, Displacement 34 to 65 cm³ (2,08 to 3,97 in³), (Swashplate 18 | 19 | 18 | 18 | 18°), Continuous 250 bar (3625 psi), Pressure Intermittent 330 | 330 | 330 | 330 | 300 bar (4785 | 4785 | 4785 | 4785 | 4350 psi), (Power-Transmission […]

Axial Piston Motors, Variable Displacement, Swash Plate, Size: 85, 112,160, Nominal Pressure: 49 Mpa (5,800 psi), Max. Pressure: 45 MPA (6,500 psi). The M7V / M7X series are variable/fixed displacement motors of swash plate design that can be used in high pressure and high-speed condition. By developing and utilizing the accumulated Kawasaki technologies for swash […]

There are typically three types of hydraulic pump constructions found in mobile hydraulic applications. These include gear, piston, and vane; however, there are also clutch pumps, dump pumps, and pumps for refuse vehicles such as dry valve pumps and Muncie Power Products’ Live PakTM.

The hydraulic pump is the component of the hydraulic system that takes mechanical energy and converts it into fluid energy in the form of oil flow. This mechanical energy is taken from what is called the prime mover (a turning force) such as the power take-off or directly from the truck engine.

With each hydraulic pump, the pump will be of either a uni-rotational or bi-rotational design. As its name implies, a uni-rotational pump is designed to operate in one direction of shaft rotation. On the other hand, a bi-rotational pump has the ability to operate in either direction.

For truck-mounted hydraulic systems, the most common design in use is the gear pump. This design is characterized as having fewer moving parts, being easy to service, more tolerant of contamination than other designs and relatively inexpensive. Gear pumps are fixed displacement, also called positive displacement, pumps. This means the same volume of flow is produced with each rotation of the pump’s shaft. Gear pumps are rated in terms of the pump’s maximum pressure rating, cubic inch displacement and maximum input speed limitation.

Generally, gear pumps are used in open center hydraulic systems. Gear pumps trap oil in the areas between the teeth of the pump’s two gears and the body of the pump, transport it around the circumference of the gear cavity and then force it through the outlet port as the gears mesh. Behind the brass alloy thrust plates, or wear plates, a small amount of pressurized oil pushes the plates tightly against the gear ends to improve pump efficiency.

A cylinder block containing pistons that move in and out is housed within a piston pump. It’s the movement of these pistons that draw oil from the supply port and then force it through the outlet. The angle of the swash plate, which the slipper end of the piston rides against, determines the length of the piston’s stroke. While the swash plate remains stationary, the cylinder block, encompassing the pistons, rotates with the pump’s input shaft. The pump displacement is then determined by the total volume of the pump’s cylinders. Fixed and variable displacement designs are both available.

With a fixed displacement piston pump, the swash plate is nonadjustable. Its proportional output flow to input shaft speed is like that of a gear pump and like a gear pump, the fixed displacement piston pump is used within open center hydraulic systems.

As previously mentioned, piston pumps are also used within applications like snow and ice control where it may be desirable to vary system flow without varying engine speed. This is where the variable displacement piston pump comes into play – when the hydraulic flow requirements will vary based on operating conditions. Unlike the fixed displacement design, the swash plate is not fixed and its angle can be adjusted by a pressure signal from the directional valve via a compensator.

Vane pumps were, at one time, commonly used on utility vehicles such as aerial buckets and ladders. Today, the vane pump is not commonly found on these mobile (truck-mounted) hydraulic systems as gear pumps are more widely accepted and available.

Within a vane pump, as the input shaft rotates it causes oil to be picked up between the vanes of the pump which is then transported to the pump’s outlet side. This is similar to how gear pumps work, but there is one set of vanes – versus a pair of gears – on a rotating cartridge in the pump housing. As the area between the vanes decreases on the outlet side and increases on the inlet side of the pump, oil is drawn in through the supply port and expelled through the outlet as the vane cartridge rotates due to the change in area.

Input shaft rotates, causing oil to be picked up between the vanes of the pump which is then transported to pump outlet side as area between vanes decreases on outlet side and increases on inlet side to draw oil through supply port and expel though outlet as vane cartridge rotates

A clutch pump is a small displacement gear pump equipped with a belt-driven, electromagnetic clutch, much like that found on a car’s air conditioner compressor. It is engaged when the operator turns on a switch inside the truck cab. Clutch pumps are frequently used where a transmission power take-off aperture is not provided or is not easily accessible. Common applications include aerial bucket trucks, wreckers and hay spikes. As a general rule clutch pumps cannot be used where pump output flows are in excess of 15 GPM as the engine drive belt is subject to slipping under higher loads.

What separates this pump from the traditional gear pump is its built-in pressure relief assembly and an integral three-position, three-way directional control valve. The dump pump is unsuited for continuous-duty applications because of its narrow, internal paths and the subsequent likelihood of excessive heat generation.

Dump pumps are often direct mounted to the power take-off; however, it is vital that the direct-coupled pumps be rigidly supported with an installer-supplied bracket to the transmission case with the pump’s weight at 70 lbs. With a dump pump, either a two- or three-line installation must be selected (two-line and three-line refer to the number of hoses used to plumb the pump); however, a dump pump can easily be converted from a two- to three-line installation. This is accomplished by inserting an inexpensive sleeve into the pump’s inlet port and uncapping the return port.

Many dump bodies can function adequately with a two-line installation if not left operating too long in neutral. When left operating in neutral for too long however, the most common dump pump failure occurs due to high temperatures. To prevent this failure, a three-line installation can be selected – which also provides additional benefits.

Pumps for refuse equipment include both dry valve and Live Pak pumps. Both conserve fuel while in the OFF mode, but have the ability to provide full flow when work is required. While both have designs based on that of standard gear pumps, the dry valve and Like Pak pumps incorporate additional, special valving.

Primarily used on refuse equipment, dry valve pumps are large displacement, front crankshaft-driven pumps. The dry valve pump encompasses a plunger-type valve in the pump inlet port. This special plunger-type valve restricts flow in the OFF mode and allows full flow in the ON mode. As a result, the horsepower draw is lowered, which saves fuel when the hydraulic system is not in use.

In the closed position, the dry valve allows just enough oil to pass through to maintain lubrication of the pump. This oil is then returned to the reservoir through a bleed valve and small return line. A bleed valve that is fully functioning is critical to the life of this type of pump, as pump failure induced by cavitation will result if the bleed valve becomes clogged by contaminates. Muncie Power Products also offer a butterfly-style dry valve, which eliminates the bleed valve requirement and allows for improved system efficiency.

It’s important to note that with the dry valve, wear plates and shaft seals differ from standard gear pumps. Trying to fit a standard gear pump to a dry valve likely will result in premature pump failure.

Encompasses plunger-type valve in the pump inlet port restricting flow in OFF mode, but allows full flow in ON mode lowering horsepower draw to save fuel when not in use

Wear plates and shaft seals differ from standard gear pumps – trying to fit standard gear pump to dry valve likely will result in premature pump failure

Live Pak pumps are also primarily used on refuse equipment and are engine crankshaft driven; however, the inlet on a Live Pak pump is not outfitted with a shut-off valve. With a Live Pak pump, the outlet incorporates a flow limiting valve. This is called a Live Pak valve. The valve acts as an unloading valve in OFF mode and a flow limiting valve in the ON mode. As a result, the hydraulic system speed is limited to keep within safe operating parameters.

Outlet incorporates flow limiting valve called Live Pak valve – acts as an unloading valve in OFF mode and flow limiting valve in ON mode restricting hydraulic system speed to keep within safe operating parameters

8613371530291

8613371530291