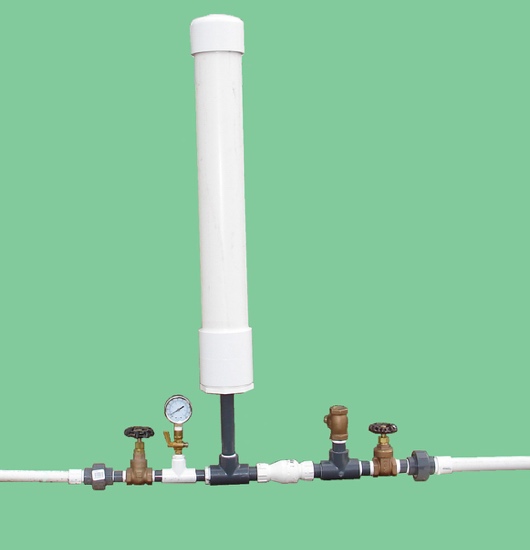

vertical shaft hydraulic pump free sample

600 gpm of water is pumped a head of 110 ft. The efficiency ofthe pump i s 60% (0.6) and the specific gravity of water is 1. The pump shaft power can be calculated as

The shaft power - the power required transferred from the motor to the shaft of the pump - depends on the efficiency of the pump and can be calculated as Ps(kW) = Ph(kW)/ η (3)

The Anderson Clamp Hubs can carry a large amount of torque with a very high thrust load; making it ideal for vertical applications where there is either a thrust load or a significant weight carried onto the shaft. With our unique Vertical Rigid Couplings, one-half of the coupling slides onto the driving shaft and clamps into place, and the other half clamps onto the driven shaft. After bolting the two flanges together, the coupling is complete and ready to run.

Vertical rigid couplings can be found in many other applications, including mixers, turbines, or any other equipment that spins on a vertical axis. If there is only a thrust bearing in the motor, but none in the pump, a rigid vertical coupling would be used. But in the cases where the pump has its own thrust bearing, a vertical flexible coupling is required. There are also many cases where a motor may be in a horizontal position driving into a right-angle gearbox. Then the gearbox output drives into a vertical pump. In this case, the type of coupling will still be dependent on whether or not the pump has a thrust bearing.

There are many other applications where you might find a vertical rigid coupling including connecting two pieces of shafting. The shafts could be transmitting torque or simply a vertical load. In either case, the vertical rigid coupling can handle a very large amount of torque load and vertical thrust load.

Hydraulic motors are rotary or mechanical actuators that operate by converting hydraulic pressure or fluid energy into torque and angular displacement.

Motor displacement is the volume of fluid required to turn on the motor’s motor output shaft through one revolution. Cubic inches and cubic centimeters per revolution are the common units that are used for motor displacement. Depending on the type of motor used and application, the displacement may be a fixed or variable quantity. In a fixed displacement motor the torque is constant. The speed of the motor can be varied when controlling the amount of input flow that gets into the motor. Variable torque and speed can be obtained if the motor used is a variable displacement motor.

Starting torque is the ability of a hydraulic motor to make a load start moving. The starting torque indicates the amount of torque that a hydraulic motor can develop to make a load start turning. It can be expressed as a fraction or percentage of the theoretical torque. The starting torque for piston, vane, and common gear motors is usually between 70% to 80% of the theoretical value.

Mechanical efficiency measures the effectiveness found in a machine or a mechanical system. This can be obtained from different variables and in hydraulic motors, torque usually is used. In hydraulic motors, mechanical efficiency refers to the ratio of the actual torque to be delivered to the theoretical torque.

Hydraulic motors work by converting hydraulic pressure or fluid energy into torque and angular displacement. Some components operate inside these motors to develop the required. Below is a list of the key components that are used in most hydraulic motors and their corresponding functions

In hydraulic motors, the rotor is the part that rotates after being triggered by a mechanism inside the motor. These mechanisms differ depending on the type of motor, for example in a gear-type hydraulic motor, the rotor starts rotating after meshing of the gears and fluid flow. In a vane type hydraulic motor, the rotor is triggered by the pressing of the vanes.

A driveshaft (also known as a propeller) is part of a hydraulic motor that is responsible for delivering or transferring the torque created inside the motor to the outside environment where it can be used for lifting loads and other applications. Most driveshafts are made of metals and have gear teeth on their ends.

Hydraulic motors operate by manipulation of the flow of fluid inside the motor. Directional control valves are designed to control fluid flow inside the motor. In most hydraulic and pneumatic systems these valves allow the fluids such as oil, water, air to flow from into different parts according to the control patterns and mechanisms of the system.

Hydraulic motors have a casing that protects and contains the components. They are made of different materials such as stainless steel, titanium, cast iron, low carbon steel, nickel, etc. Cases come in various shapes according to the arrangements of the components inside the motor.

A piston rod is a bar that is machined precisely and used to transmit a force created in a hydraulic or pneumatic system to a machine’s component performing the work. In hydraulic motors, piston rods are mainly used in piston-type motors to produce a turning movement.

Hydraulic motors use fluids to transmit energy from one point to another. Most hydraulic motors use water-based, petroleum-based, and synthetic fluids. The widely used is petroleum-based which is also known as mineral-based. This mineral-based product comes in many forms depending on the additives used and the quality of the crude oil used. Common fluid additives include anti-corrosion agents, demulsifiers, extreme pressure agents, rust, oxidation inhibitors, and defoamants.

Bearings are mechanical components that enable the rotation of parts by reducing friction and holding the load. In hydraulic motors the bearing is mainly used on the driveshaft to enable smooth and efficient rotation of the shaft. Many types of bearings are used on rotating shafts and the choice of one depends on many factors such as shaft speed, amount of load, the direction of the load, type of fluid used, etc.

It is important to know and understand how hydraulic pumps and motors differ from each other. Hydraulic pumps and motors operate similarly to each other to such an extent that some people do not know the differences. Some use the word pump when in effect they are talking about a motor and vice versa.

Hydraulic motors can operate in either direction. Hydraulic motors have mechanisms that allow them to rotate in either direction (negative or positive rotation) are required to have positive and negative rotation, which is why their internal structure is symmetrical, and hydraulic pumps generally rotate in a single direction, so that requirement is not necessary.

For example, in a vane motor, the blades can only be arranged in a radial manner. It can not be inclined like a vane pump, because this will cause the blades to be broken when reversing. The distribution plate in the axial plunger motor is supposed to have a symmetrical design, in that case, the axial plunger of the pump is not; the gear motor should have a separate leakage tube.

Hydraulic pumps are mainly used when they are connected with a prime mover and motors are connected with loads. The pump in essence has no radial loads such as pulleys, sprockets, belts which can be found in hydraulic motors.

High-speed low torque (HSLT) hydraulic motors are sometimes referred to as high revs per minute (RPM) motors are designed to operate at high speeds ranging from 1 000 rpm to 14 000 rpm. They are used when the load is light because they have a low torque range. They can be used for applications in the utility, earthmoving, forestry, material handling etc.

In this gear type, the hydraulic motor is made of two gears which are called the driven gear and the idle gear. The driven gear is connected to the output shaft usually by means of a key. Inside the motor is high pressure oil which flows into the sides around the gear tips and flows into the motor housing exiting through the outlet port. In the process, the gears mesh, and this will not allow oil coming from the outlet to flow back into the inlet side.

A small amount of this oil is used for lubrication of the gears. This oil is bled through the bearings (hydrodynamic), and the oil enters through the pressure side of the gears. The spur gears are popularly used in these types of hydraulic motors. If the gears are not manufactured to standards, they may become subject to vibration and may be noisy during the operation of the motor.

Internal gear motors have similar features and characteristics to external gear motors. The smooth operation of the gears characterizes the motors as compared to external gears where they are subjected to vibration causing noisy situations. They have one external gear that is used to mesh with the circumference of a larger gear. Internal gears are found in two versions namely the gerotor motor (mainly used in mobile systems and hydraulic technologies) and the gerotor motor.

In these gear motors a crescent vane is used to separate the discharge volume from the inlet volume between the two gears. When the hydraulic fluid enters through the inlet volume it causes the pressure to increase causing the volume to expand and this results in the gears rotating. The fluid will be forced out as the gears continue to rotate.

Hydraulic motors operate by creating an imbalance due to pressure which results in the rotation of the shaft. In vane motors, this imbalance is a result of the difference when the vane area is exposed to hydraulic pressure. Vane motors have a hydraulic balance which prevents the rotor from sideloading the shaft. The pressure difference develops the torque as the oil from the pump is forced to go through the motor.

Vane motors are usually made of a cartridge configuration of a motor housing. Their design is like that of a vane pump. They are characterized by two-port plates that separate the outlet and inlet ports as they put in between them the cam and rotor ring. Inside the cylindrical case of a vane motor is a ring mounted. This ring is made up of radial slots where there are sliding vanes. The vanes operate by pressing inside, against the wall of the cylindrical case. The ring rotates when the vanes are spring forced against the wall due to centrifugal force.

The radial-piston type hydraulic motor operates by transforming the energy created by the fluid pressure into mechanical energy (rotation). There is a directional valve, which is a fixed and central part of the configuration, it has two lines for fluid flow where one is for draining and another for fluid intake. The rotor is for turning in the directional valve which is fitted with radial bores. This will cause the free-floating pistons to operate.

When the hydraulic fluid, that is pressurized by the pump, gets into the bores it presses the pistons against the stator usually for half a revolution. In the following half revolution, the fluid is delivered into the draining line connected to the directional valve. If the motor is operating under pressure loading on the motor piston, the stator will exert stress on the piston, and this will make the pistons and the rotor rotate. When this happens the output shaft of the motor is driven. Most of these systems are fitted with rollers which reduce the losses caused by piston friction on the track.

Axial piston-type hydraulic motors are also known as barrel motors. In these motors the plate of the drive shaft is positioned at an angle with respect to the barrel of the motor, the intake of fluid in the cylinders results in the movement of the pistons, causing the drive to rotate. In each cylinder, there is 1 phase of output and of intake per rotation. The piston operates when it is applied to the inclined plate with a force proportional to the pressure. This force reduces the angle and creates a force that makes the plate rotate.

The direction of rotation of the drive shaft is associated with the angle of inclination of the plate of the drive shaft with respect to the axis on the barrel. In other assemblies which have axial pistons, they can change this inclination. If this axis can be changed, it means that the speed can/will be varied for a constant rate of flow, and in this case, a motor with two flow directions is created.

When choosing a hydraulic motor to use there are factors that one needs to consider when designing an efficient system. The motor used should match the system requirement and if it does not this might affect the whole system. Below is a list of some of the factors and questions to consider.

There are many applications that hydraulic motors can be used for. These motors are made of different materials meaning they respond differently to operating conditions. Some are strong enough to withstand vibrations and harsh conditions and these are mainly used for industrial applications.

Knowing the expected life of a motor and the bearing to be used can help to plan with regard to application and maintenance. There are some complicated machines where it does not make sense to fit a motor type that has a short life span. There are many bearings that can be used for the rotor and shaft. These will depend on the forces and torque produced because bearings are used according to the force that acts on their surface area.

Before one can choose a type of motor to use, they need to gather installation information as well. This is because other motor types require a lot of expertise and are complicated to install. It is essential to talk with professionals about the other costs that are involved before purchasing a hydraulic motor.

A closed-loop in a hydraulic system is also known as a hydrostatic drive and is commonly found in mobile systems and industrial machines such as conveyors. In a closed-loop, the fluid flows directly from the pump to the motor and then returns to the pump without entering a reservoir. The fluid flow determined the speed of the motor. In an open loop, the fluid flows from the motor to the pump through a reservoir. Before choosing the right motor for the system it is essential to understand the loop that will operate in the specific hydraulic system.

Hydraulic motors play a vital role in the engineering and automation of many systems in our everyday lives. Although some of them are complex, most of these motors use simple operating principles which are easy to understand and are user-friendly.

8613371530291

8613371530291