vickers hydraulic pump repair manual quotation

vickers vane pump repair manual pdf comes to you after months of searching and searching for the best possible place to get this book. In this website, many questions about this author and their products are answered so that you can be sure to find what you are looking for. Let’s share this page in social networks such as Facebook, Twitter and Reddit.

After removing the pump from the system and before disassembly, cap or plug all ports and disconnected hydraulic lines. Clean the outside of the unit thoroughly to prevent entry of dirt into the system.

Absolute cleanliness is essential when working on a hydraulic system. Always work in a clean area. The presence of dirt and foreign materials in the system can result in serious damage or inadequate operation. Periodic maintenance of the pump will generally not require disassembly to the extent described here.

Troubleshooting is one of the best virtues to acquire if you are an industrial pump repair technician. All in all, troubleshooting is a process. Firstly, you have to define the problem, gather information, and analyze data that will help you solve the problem, implement the solution and check if it worked for you or not. This form collects vickers vane pump problems, symptoms, and solutions!

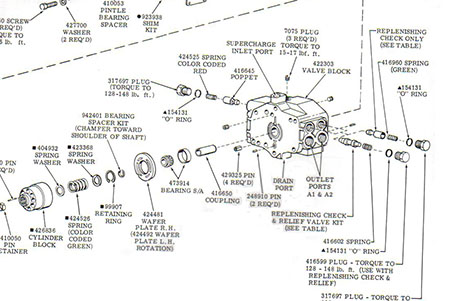

4.Install gasket (2) in place in the face of compensator body (11). Cover the compensator body with clean Kraft pa- per and set aside for final assembly of the pump.

19.Remove retaining ring (44) then press shaft seal (45) from pump housing (27).If yoke (56) and front shaft bearing (61) were not defective, perform the following step.

a. Install a nine inch piece of 1 1/2” heavy wall tubing over drive shaft (48) within the housing. The end of the tub- ing will rest against the inner race of tapered roller bearing (61) and extend out beyond the end of the pump housing. Place the complete unit with tubing into an arbor press with drive spline up. Press the drive shaft through the bearing and out of the unit. A 0.001 press exists between the shaft and bearing so considerable force is required to remove the bearing. See Figure 17 (PVE19/21).

c. Press drive shaft (48) into shaft bearing (61) as follows: Use a short piece of 1 1/2” inch heavy wall tubing (approximately 6” long) over the drive spline of the shaft. The tubing must be long enough to go through the shaft seal end of the pump and make contact with the inner race of the front bearing. Press the shaft through the bearing with an arbor press until the bearing bottoms against the shoulder of the shaft (snap ring on the PVE12). See Figure 18.

d. Place spherical washer (41) on top of the three pins, then install shoe plate (42) with nine piston and shoe subassemblies (43) over spherical washer (41) and into cylin- der block. Wobble shoe plate (42) to make sure that each piston is free within its bore in the cylinder block.e. Set housing (27) on its side and hold pump shaft (48) horizontal. Slide rotating group into the housing. Rotate the shaft to match the shaft splines to the cylinder block and spherical washer.

5.Inspect valve block (26) for burrs, nicks, plugged body passages, flatness of the pump wafer plate area and porosity. Inspect check valve seat (64). Make sure the seat is tight with- in the valve block and does not protrude above the valve block face. Repair or replace the valve block if defective.

Lubricate all moving parts of the piston pump with system fluid to facilitate assembly and provide initial lubrication. Pour system fluid liberally over the rotat- ing group and wafer plate as these parts are without lubrication until the pump primes.

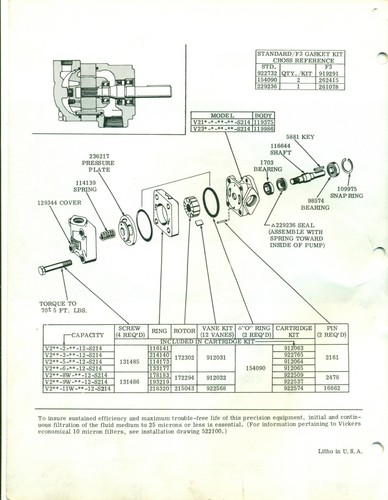

This article will provide you with tips and tricks when it comes to finding gaskets, seals and other quality components for your vickers vane pump repair manual.

tags: {vickers hydraulic pump repair manual,vickers hydraulic pump repair,vickers piston pump repair,3 stage vickers hydraulic pump repair georgia,vickers hydraulic pump repair parts,vickers hydraulic pump repair manual v201p6p1c11,vickers hydraulic pvb 10 pump repair manual,vickers hydraulic pvm pump repair manual,simplicity vickers pump repair parts,vickers pump repair santa ana,repair parts gpc vickers pump,how-to repair vickers hydraulic pump repair manual,vickers vane pump repair,3 stage vickers hydraulic pump repair

Precision Fluid Power provides repair for virtually any hydraulic component, including hydraulic pumps, hydraulic motors, servo valves, actuators, and cylinders. We serve all industries, large or small. Regardless of what equipment you operate – industrial, mobile, agriculture, construction – the precision fluid power team can provide solutions to handle all your hydraulic needs. Click here to find a Hydraulic Repair Shop Near Me.

All hydraulic units received in our facility for repair are completely disassembled and cleaned for a thorough inspection. Want a quote for your hydraulic pump repair? Contact us here: Hydraulic Pump Repair Services

After your approval for us to proceed, the unit to be repaired is cleaned again, tolerances are re-certified and the unit is made ready for necessary repairs.

Where a part proves to be obsolete or is beyond repair or reconditioning, our in-house machine shop can reduce cost and create fast turnaround by manufacturing replacements that meet or exceed OEM specs.

After reassembly, the unit is ready to be tested. If you have questions about our warranty or want to inquire about how to send in your part for repair please contact us.

But we service customers all over the globe. If you are looking for Hydraulic Pump Repair Services or you would like to order a part please contact us today for a quote.

If it is determined that the unit is covered under warranty, we will repair or replace it at no charge. If the unit cannot be replaced, you will receive full credit. Refer to the Return Authorization number (RGA#) when returning the item, freight prepaid.

This warranty does not cover units that have been disassembled or repaired by anyone other than Precision Fluid Power, Inc, nor failure due to misuse, abuse, neglect, accident, or tampering, and does not cover any customer loss or expense resulting from the unit being out of operation. The unit must be operated according to the original manufacturer’s specifications, otherwise, this warranty is null and void. Material that has been painted will be subject to an additional restocking charge.

A busted piston pump within your company’s hydraulic system is nothing short of frustrating. Instead of stressing about downtime and replacing the entire unit, choose Global Electronic Services. Our technicians ensure quick hydraulic piston repair services to increase your operation’s uptime and keep everything working at a smooth pace.

After understanding the issues your hydraulic pistons are facing, we replace broken, damaged or worn components and repair failed parts as necessary. Once we make crucial repairs and replacements, we test the hydraulic system to ensure it runs at its highest operating level.

While some faults are more accessible to detect than others, our specialists use top-of-the-line tools in combination with their extensive line of experience to recognize a variety of piston pump complications. Delivering fast, effective and efficient piston pump repair services allows us to provide top-quality solutions.

Hydraulic piston pump repairs from Global Electronic Services help you feel confident in your company’s operations. We pinpoint the hydraulic system’s issues and make fast turnaround times to keep you moving.

Competitive pricing: Before we start any repairs, we give you an accurate estimation that’s at least 10 percent better than our competitor’s, so you can get the most value.

Quick turnarounds:Using efficient methods with our years of experience, Global Electronic Services experts can repair your hydraulic piston issues within one to five days. We help ensure your company’s uptime and productivity remain high.

Top-notch repairs:Global Electronic Services offers an 18-month, in-service warranty — giving you peace of mind that you can rely on the equipment. We can tackle any piston faults and other hydraulic concerns.

The first step of repairing your hydraulic piston pump is disassembly. We take apart the axial piston pump for inspection and measurement, recording the dimensions of each part. Once we look through the entire unit and determine its issues, we prepare a quotation to give you an idea of what to expect.

When we get the go-ahead to move on with our repairs, we start by cleaning the unit. We lap the rotary parts and end cover, then make sure the bearing and shaft fit. Our technicians also ensure the pump’s play is within tolerance.

We make the appropriate repairs and replacements of critical parts, then reinstall the rotary components. After we complete the entire process, our specialists test the hydraulic piston pump. If it’s working at peak levels, we calibrate it, then send it off to painting and finishing. If it’s still not up to par, we go back and make corrections.

Repairing and replacing these essential hydraulic piston pump parts is a more economical solution than replacing the entire unit. Although the source of a pump’s failure can come from a multitude of sources, many fall into a few areas, such as:

In many cases, wear and tear cause problems. However, excessive heat, cavitation, extreme pressure and contamination can also cause premature failure of your piston pump. Another reason for failure is from incorrect installation — all of which we can fix on the spot.

We use sophisticated software, digital controls and integrated electronics to restore your company’s piston pumps. Global Electronics Services works with the increasing complexity of hydraulic systems. Our technicians can inspect, repair, test and calibrate a range of piston pump issues.

Global Electronic Services can answer any questions you have about hydraulic piston pumps as well as our services. Here are some commonly asked questions about piston pump repair and maintenance:

First, reference the manufacturer’s manual to see which areas require attention. Most commonly, you should grease the plunger center and the plunger slot corners for proper lubrication.

Check to make sure the piston pump hasn’t lost grease lubrication in the plunger slot. A contaminated environment and water hitting the pump can also cause it to be noisy. Even inlet plumbing that results in air leaks can create a loud noise.

Hydraulic pump upkeep depends on your company’s application, so check the unit’s manual to see how long specific parts can last before needing replacement. Regular and preventative maintenance can help increase the lifespan of the pump and decrease massive overhauls down the road.

Many factors can cause a hydraulic piston pump to pulse. For example, abnormal inlet conditions, fixed outlet plumbing and an undersized bypass hose can contribute to the fault. Other reasons can include a non-working regulating valve or stuck/damaged pump valves.

Global Electronic Services is your go-to for hydraulic and pneumatic maintenance service and repair. We offer superior solutions at competitive prices to ensure you receive valuable and dependable repairs.

Receive a free quote online or call us at 877-249-1701 to see how we can support your company. Our experts can handle whatever’s going on with your hydraulic piston pump unit to maximize uptime.

Advanced Fluid Systems is proud to offer hydraulic repair services for hydraulic pumps and motors, from gear pumps to vane pumps to the largest radial piston pumps, regardless of brand. Our inventory includes seals, parts and re-manufactured pumps available for immediate shipment.

100HP programmable variable frequency drive (VFD) test system for mineral oil and water glycol fluids that allows us to test pumps with electronic controls.

We are Expert & Specialist for Repairing of All types of Hydraulic Pumps & Motors used in All Earth Moving Machineries. We do Repairing work since last 37Years. We have total facilities for Repairing & Testing of pump with us.

We can supply what you need or repair what you have. Before purchasing, there may be a good chance that your current hydraulic pump, motor, valve or cylinder can be repaired. Danfoss hydraulics pump repairs, including motors, valves & cylinders come with our two-year warranty.

When purchasing, consider Danfoss hydraulics remanufactured or aftermarket hydraulic units. Best of all they can get you back up and running for less than the cost of a new hydraulic unit. We will give you a free quote so you can compare costs for a new, repaired or reman Danfoss unit.

Mads Clausen founded Danfoss on September 1, 1933, in Denmark. The name changed from the Danish Refrigeration Controls and Apparatus Manufacturer to Danfoss in 1946. They developed their first hydraulic product in 1964. Danfoss continued to expand until their merger with Sauer-Sundstrand, which formed Sauer-Danfoss. Later, in April 2013, the company officially became Danfoss, as they brought the remaining shares from Sauer-Sundstrand. Now, Danfoss is one of the largest companies in the hydraulics industry.

Danfoss Piston Pumps and Motors come in a wide range of displacements, pressures, shaft and flange combinations and control options. They have the ability to combine multiple units, allowing for comfortable operation and efficient fuel consumption.

H1 Series Pumps and Motors: specially designed for medium and high power needs, the H1 Series feature a functional design that provides more freedom and flexibility. The H1 Series offers higher output speeds and lower input speeds while reducing overall costs. It is available in a variety of displacements and sizes.

Closed Circuit Low Power Pumps and Motors: offer reliability, flexibility and easy installation and their featured high efficiency, low noise levels and the ability to customize interfaces meet any needs!

The Closed Circuit Medium Power Pumps and Motors are available in a variety of configurations, displacements and control options and high-quality performance, power density, and functionality are guaranteed features of these medium power pumps.

Closed Circuit High Power Pumps and Motors offers high power density in a simple, compact design. The Danfoss high power series is proven to perform in the toughest situations and increase productivity.

Open Circuit Axial Piston Pumps: are available in a wide range of configurations, displacements and control options. They are compatible with many fluid types and a wide range of mounting flanges for easy installation.

eaton aerospace hydraulic pump eaton axial piston pump pdf eaton hydraulic motor breakdown eaton hydraulic motor catalogue pdf eaton hydraulic motor char-lynn eaton hydraulic motor for brush cutter eaton hydraulic motor for sale eaton hydraulic motor manual eaton hydraulic motor near me eaton hydraulic motor numbers eaton hydraulic motor pdf eaton hydraulic motor price eaton hydraulic motor rebuild eaton hydraulic motor rebuild kit eaton hydraulic motor repair eaton hydraulic motor repair manual eaton hydraulic motor seal kit eaton hydraulic motor seal replacement eaton hydraulic motor service manual eaton hydraulic motor shaft seal replacement eaton hydraulic motor specifications eaton hydraulic motor specs eaton hydraulic motor speed sensor eaton hydraulic motor with brake eaton hydraulic orbit motor eaton hydraulic parts catalog eaton hydraulic piston pump eaton hydraulic pump eaton hydraulic pump 26001-rzg eaton hydraulic pump 26004-rzc eaton hydraulic pump 26007-rzc eaton hydraulic pump 70423-rbt eaton hydraulic pump 72400-rmp-04 eaton hydraulic pump dealers eaton hydraulic pump dealers near me eaton hydraulic pump distributors in india eaton hydraulic pump manua eaton hydraulic pump motor eaton hydraulic pump parts eaton hydraulic pump pdf eaton hydraulic pump pressure adjustment eaton hydraulic pump pvq32-b2r eaton hydraulic pump qatar eaton hydraulic pump rebuild kit eaton hydraulic pump repair eaton hydraulic pump repair near me eaton hydraulic pump seal kit eaton hydraulic pump uae eaton hydraulic pump uk eaton hydraulic pump yuken eaton hydraulic pump zf eaton hydraulic pumps and motors eaton hydraulic pumps canada eaton hydraulic pumps edmonton eaton hydraulic pumps for sale eaton hydraulic steering pump eaton hydraulic vane pump eaton hydraulic winch motor eaton hydraulics pump singapore eaton hydrostatic hydraulic pump eaton load sensing hydraulic pump eaton make hydraulic pump eaton piston pump distributors eaton piston pump pdf eaton pto hydraulic pump eaton tandem hydraulic pump eaton variable displacement hydraulic pump eaton vickers hydraulic pump

Moore Pumps is a second generation, family owned business that believes in going the extra mile in order to meet or exceed the needs of their customers. We know that every second counts when a critical piece of machinery goes down and we do whatever it takes to get your part to you as fast as possible.

ETS is committed to providing our customers with the most reliable and genuine Bosch Rexroth, Parker, Calzoni, Vickers (Eaton), Atos & Hydac pump and motor units, valves and parts possible.

8613371530291

8613371530291