volumetric efficiency hydraulic pump in stock

In a condition-based maintenance environment, the decision to change out a hydraulic pump or motor is usually based on remaining bearing life or deteriorating efficiency, whichever occurs first.

Despite recent advances in predictive maintenance technologies, the maintenance professional’s ability to determine the remaining bearing life of a pump or motor, with a high degree of accuracy, remains elusive.

Deteriorating efficiency on the other hand is easy to detect, because it typically shows itself through increased cycle times. In other words, the machine slows down. When this occurs, quantification of the efficiency loss isn’t always necessary. If the machine slows to the point where its cycle time is unacceptably slow, the pump or motor is replaced. End of story.

In certain situations, however, it can be helpful, even necessary, to quantify the pump or motor’s actual efficiency and compare it to the component’s native efficiency. For this, an understanding of hydraulic pump and motor efficiency ratings is essential.

There are three categories of efficiency used to describe hydraulic pumps (and motors): volumetric efficiency, mechanical/hydraulic efficiency and overall efficiency.

Volumetric efficiency is determined by dividing the actual flow delivered by a pump at a given pressure by its theoretical flow. Theoreticalflow is calculated by multiplying the pump’s displacement per revolution by its driven speed. So if the pump has a displacement of 100 cc/rev and is being driven at 1000 RPM, its theoretical flow is 100 liters/minute.

Actualflow has to be measured using a flow meter. If when tested, the above pump had an actual flow of 90 liters/minute at 207 bar (3000 PSI), we can say the pump has a volumetric efficiency of 90% at 207 bar (90 / 100 x 100 = 90%).

Its volumetric efficiency used most in the field to determine the condition of a hydraulic pump - based on its increase in internal leakage through wear or damage. But without reference to theoretical flow, the actual flow measured by the flow meter would be meaningless.

A pump’s mechanical/hydraulic efficiency is determined by dividing thetheoretical torque required to drive it by the actual torque required to drive it. A mechanical/hydraulic efficiency of 100 percent would mean if the pump was delivering flow at zero pressure, no force or torque would be required to drive it. Intuitively, we know this is not possible, due to mechanical and fluid friction.

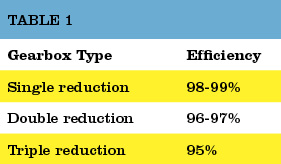

Table 1. The typical overall efficiencies of hydraulic pumps, as shown above, are simply the product of volumetric and mechanical/hydraulic efficiency.Source: Bosch Rexroth

Like theoretical flow, theoretical drive torque can be calculated. For the above pump, in SI units: 100 cc/rev x 207 bar / 20 x p = 329 Newton meters. But like actual flow, actual drive torque must be measured and this requires the use of a dynamometer. Not something we can - or need - to do in the field. For the purposes of this example though, assume the actual drive torque was 360 Nm. Mechanical efficiency would be 91% (329 / 360 x 100 = 91%).

Overall efficiency is simply the product of volumetric and mechanical/hydraulic efficiency. Continuing with the above example, the overall efficiency of the pump is 0.9 x 0.91 x 100 = 82%. Typical overall efficiencies for different types of hydraulic pumps are shown in the Table 1.

System designers use the pump manufacturers’ volumetric efficiency value to calculate the actual flow a pump of a given displacement, operating at a particular pressure, will deliver.

As already mentioned, volumetric efficiency is used in the field to assess the condition of a pump, based on the increase in internal leakage due to wear or damage.

When calculating volumetric efficiency based on actual flow testing, it’s important to be aware that the various leakage paths within the pump are usually constant. This means if pump flow is tested at less than full displacement (or maximum RPM) this will skew the calculated efficiency - unless leakage is treated as a constant and a necessary adjustment made.

For example, consider a variable displacement pump with a maximum flow rate of 100 liters/minute. If it was flow tested at full displacement and the measured flow rate was 90 liters/minute, the calculated volumetric efficiency would be 90 percent (90/100 x 100). But if the same pump was flow tested at the same pressure and oil temperature but at half displacement (50 L/min), the leakage losses would still be 10 liters/minute, and so the calculated volumetric efficiency would be 80 percent (40/50 x 100).

The second calculation is not actually wrong, but it requires qualification: this pump is 80 percent efficient at half displacement. Because the leakage losses of 10 liters/minute are nearly constant, the same pump tested under the same conditions will be 90 percent efficient at 100 percent displacement (100 L/min) - and 0 percent efficient at 10 percent displacement (10 L/min).

To help understand why pump leakage at a given pressure and temperature is virtually constant, think of the various leakage paths as fixed orifices. The rate of flow through an orifice is dependant on the diameter (and shape) of the orifice, the pressure drop across it and fluid viscosity. This means that if these variables remain constant, the rate of internal leakage remains constant, independent of the pump"s displacement or shaft speed.

Overall efficiency is used to calculate the drive power required by a pump at a given flow and pressure. For example, using the overall efficiencies from the table above, let us calculate the required drive power for an external gear pump and a bent axis piston pump at a flow of 90 liters/minute at 207 bar:

As you’d expect, the more efficient pump requires less drive power for the same output flow and pressure. With a little more math, we can quickly calculate the heat load of each pump:

No surprise that a system with gear pumps and motors requires a bigger heat exchanger than an equivalent (all other things equal) system comprising piston pumps and motors.

Whether we have your unit in stock or not, repair is always an option. In fact, it may be your BEST option for obsolete and hard to find hydraulic pumps and motors. Letting us repair your unit can also be drastically cheaper than replacing it, especially if parts are hard to come by.

Hydraulic pumpsconvert mechanical energy into hydraulic energy. A high-performance piston pump can make this conversion with an overall efficiency of 92%. If this pump drives a piston motor, then the motor can convert this hydraulic energy back into mechanical energy with an overall efficiency of 92%. The total, overall efficiency of this hydraulic drive, without considering losses in valves and conductors, is 85% (0.92 x 0.92 x 100 = 85).

The inefficiencies or losses in a hydraulic drive can be divided into two categories: hydraulic-mechanical, which comprises flow and mechanical friction losses, and volumetric, which comprises leakage and compressibility losses.

The hydraulic pump is usually the hardest working component of a hydraulic system. As the pump wears in service, internal leakage increases and therefore the percentage of output flow available to do useful work (volumetric efficiency) decreases. If volumetric efficiency falls below a level considered acceptable for the application, the pump will need to be changed out. In a condition-based maintenance environment, the decision to change-out the pump is usually based on remaining bearing life or deterioration in volumetric efficiency, whichever occurs first.

Put simply, volumetric efficiency is the percentage of theoretical pump flow available to do useful work. In other words, it’s a measure of a hydraulic pump’s volumetric losses through internal leakage and fluid compression. It is calculated by dividing the pump’s actual output in liters or gallons per minute by its theoretical output, expressed as a percentage. Actual output flow is determined using a flowmeter to load the pump and measure its flow rate.

Because internal leakage increases as operating pressure increases and fluid viscosity decreases, these variables should be stated when stating volumetric efficiency. For example, a hydraulic pump with a theoretical output of 100 L/min and an actual output of 94 L/min at 350 bar and 40 centistokes is said to have a volumetric efficiency of 94% at 350 bar and 40 centistokes. In practice, fluid viscosity is established by noting the oil temperature at which actual pump output flow is measured and reading the viscosity off the temperature/viscosity graph for the grade of oil in the hydraulic system.

When calculating the volumetric efficiency of a variable displacement pump, internal leakage must be expressed as a constant. This is best illustrated with an example. I was recently asked to give a second opinion on the condition of a large, variable displacement pump. My client had been advised that its volumetric efficiency was down to 80% and based on this advice, he was considering having the pump overhauled.

The hydraulic pump in question had a theoretical output of 1,000 L/min at full displacement and maximum RPM. Its actual output was 920 L/min at 300 bar and 25 centistokes. When I advised my client that the pump’s volumetric efficiency was in fact 92%, he was alarmed by the conflicting assessments. To try to explain the disparity, I asked to see the first technician’s test report.

After reviewing this test report, I realized that the results actually concurred with mine, but had been interpreted incorrectly. The test had been conducted to the same operating pressure and at a fluid temperature within one degree of my own test, but at reduced displacement. The technician had limited the pump’s displacement to give an output of 400 L/min (presumably the maximum capacity of his flow-tester) at maximum RPM and no load. At 300 bar the recorded output was 320 L/min. From these results, volumetric efficiency had been calculated to be 80% (320/400 x 100 = 80).

To help understand why this interpretation is incorrect, think of the various leakage paths within a hydraulic pump as fixed orifices. The rate of flow through an orifice is dependant on the diameter (and shape) of the orifice, the pressure drop across it, and fluid viscosity. This means that if these variables remain constant, the rate of internal leakage remains constant, independent of the pump’s displacement.

Note that in the above example, the amount of internal leakage in both tests was 80 liters per minute. If the same test were conducted with pump displacement set to 100 liters per minute at no load, pump output would be 20 liters per minute at 300 bar–all other things equal. This means that this variable pump has a volumetric efficiency of 20% at 10% displacement, 80% at 40% displacement, and 92% at 100% displacement. As you can see, if actual pump output is measured at less than full displacement (or maximum rpm), an adjustment needs to be made when calculating volumetric efficiency.

Of course, in considering whether it’s necessary to have the pump in the above example overhauled, the important number is volumetric efficiency at 100% displacement. And this was within acceptable limits. If my client had based their decision on volumetric efficiency at 40% displacement, they would have paid thousands of dollars for an unnecessary rebuild.

About the Author: Brendan Casey is the founder of HydraulicSupermarket.com and the author of Insider Secrets to Hydraulics, Preventing Hydraulic Failures, Hydraulics Made Easy and Advanced Hydraulic Control. A fluid power specialist with an MBA, he has more than 20 years experience in the design, maintenance and repair of mobile and industrial hydraulic equipment. Visit his website www.HydraulicSupermarket.com.

Hydraulic pump and motor efficiency can have a significant effect on your hydraulic system. It influences the power demand and therefore running costs of a hydraulic system. It determines the amount of heat generation and dictates the requirement for cooling. It can also effect the operating speed of a hydraulic system.

It is for these reasons that an understanding of pump and motor efficiency can assist greatly in understanding and diagnosing issues with a hydraulic system. The three most considered efficiencies are volumetric efficiency, hydro-mechanical efficiency and total efficiency.

Volumetric efficiency is a measurement of the actual flow from a pump, expressed as a percentage of the theoretical flow. Actual flow can be measured using a flow meter. Theoretical flow is easily calculated for a pump by multiplying the displacement by the drive speed and converting units as required. For instance, a 20cc/rev pump being driven at 1500rpm will have a theoretical flow of 30 litres per minute (in this case the product is divided by 1000 to convert cubic centimetres to litres). The volumetric efficiency of a motor is a measurement of the actual rotation speed for a given flow rate, expressed as a percentage of its theoretical speed.

Reduction in volumetric efficiency over time is considered a reliable indicator of pump and motor wear or degradation. For pumps and motors with case drains, flow from these drain lines can also be used to monitor changes in volumetric efficiency due to degradation as these components often leak into their casings. As the volumetric efficiency of a pump drops, the speed of actuators in the system will be reduced accordingly as they receive less flow. Eventually, a hydraulic system may become inoperable and pumps and motors showing symptoms of degradation as determined using volumetric efficiency will likely require hydraulic repair or replacement to restore proper system functionality.

Hydro-mechanical efficiency is a measurement of the theoretical torque required to drive a pump, expressed as a percentage of the actual torque required. For a motor, hydro-mechanical efficiency is a measurement of the actual torque output, expressed as a percentage of the theoretical torque output. This torque difference is caused largely by internal fluid and mechanical friction within pumps and motors. Theoretical torque can be calculated for a pump or motor by multiplying the displacement (in cc/rev) by the pressure drop (in Bar) and dividing by 20π, the resulting answer in Newton meters (Nm). For instance, the theoretical output torque of a motor with a displacement of 20 cc/rev, a pressure of 200 Bar would be 63.7 Nm.

Actual torque is relatively difficult to measure as it requires a dynamometer or other specialised and calibrated equipment. As a result, hydro-mechanical efficiency is most useful in estimating the actual output torque of a hydraulic motor having already calculated the theoretical torque. Using a high efficiency motor, such as a Char-Lynn geroler motor, will result in a high output torque for a given displacement and pressure.

Finally, total efficiency is a measurement of the theoretical power required to drive a pump (or developed by a motor), expressed as a percentage of the actual power requirement. It considers both losses due to leakage or bypass (volumetric efficiency) as well as losses due to internal friction (hydro-mechanical efficiency). It can be calculated by multiplying these two efficiencies together. Total efficiency is used to calculate the power demand of a hydraulic pump. Power (in kW) is equal to pressure (in Bar) multiplied by flow (in litres per minute) divided by 600 and the total efficiency. For instance, a pump with an output of 30 litres per minute and 200 Bar, with a total efficiency of 80%, would require 12.5kW of input power.

A hydraulic system whose pump has a higher total efficiency will require less power to produce the same pressure and flow. This difference in power will be reflected in lower running costs. However, total efficiency can often have a much larger bearing on the cooling requirements of a hydraulic system. The power lost through total efficiency will take the form of heat energy transferred into the hydraulic fluid, raising its temperature and at times necessitating a heat exchanger to dissipate this energy.

Hydraulics are essential in many industrial applications; they use mechanical energy to force liquid into a system. Within the category of hydraulics, there are many different types of hydraulic pumps that accomplish various tasks within industrial fields. Let’s take a look at some of them.

An axial piston hydraulic pump is also a positive displacement pump. Axion pumps have cylinders that are assembled around a central axis (cylinder block). Within each cylinder, there are pistons which will attach to a swashplate or wobble plate. These swashplates then connect to the rotating shaft, which moves the pistons and pulls them in and out of the cylinders.

Axial piston pumps can also be made into variable displacement piston pumps, which provide more control over speed. In variable pumps, the swashplate is used to set the depth of the pistons, which creates a length variation to affect the discharge volume. This design helps maintain constant discharge rates in industrial applications.

Another hydraulic pump type is the radial piston pump. As the name suggests, the pistons are arranged along the radius of the cylindrical block, which includes the pintle and rotor. The rotor powers the pistons through the cylinders and forces hydraulic fluid in and out of the cylinder.

Both axial and radial piston pumps are used for high-operating pressures as they can withstand much higher pressures than hydraulic pump types. They are often used in ice and snow control applications, as well as on truck-mounted cranes.

A rotary vane pump is also a type of positive displacement pump. It uses rigid vanes rather than the rotor hubs. These vanes are placed around an eccentric rotor device, which moves around the inside wall of the housing container. This movement forces the hydraulic fluid through the discharge port, and, in some applications, can be adjusted to align with the rotational axis of the motor.

Vane pumps are often used in utility vehicles but have lost popularity over the years in favor of gear pump hydraulic systems. However, they used to be very common in aerial buckets and ladders along with other mobile, truck-mounted hydraulic applications.

Gear pumps have become the most common hydraulic pump type that’s used in industrial applications today. The gear pump has fewer moving parts than piston or vane pumps, which makes it easy to service and relatively inexpensive compared to other hydraulic pumps. They are also less likely to be contaminated during use.

An external gear pump uses two gears on the outside of individual shafts to aid in movement and push both thin and thick fluids through the gears. These external pumps are commonly used in fixed-displacement applications and high-pressure environments.

Internal gear pumps place gears on the insides of the shafts rather than on the outside as found in external gear pumps. That makes them self-priming and non-pulsing, and can even be run without liquid for short periods of time—although they can’t be left dry for too long.

Additionally, internal gear pumps are bi-rotational, meaning that one can be utilized to both unload and load devices. And, with only two moving parts, they are considered to be one of the most reliable types of hydraulic pumps.

Volumetric efficiency is the amount of output the pump actually produces as a percentage of its theoretical production.The higher the percentage the more efficient the pump.

Among the factors affecting volumetric efficiency are leakage and fluid compressibility (ability for volume to be reduced under pressure). These issues can cause the pump to lose efficiency and waste energy as that energy converts to heat.

Still have questions about hydraulic pumps or their parts and repairs? Contact Panagon Systems today. We’ve been a leading hydraulic pump manufacturer in the U.S. for over two decades, and can help you find the best solution for your application. You can view our full line of pumps here. To request a consultation or quote, please fill out our online form.

Volumetric efficiency accounts for the leakage of fluid in the pump that doesn"t do any work. Mechanical/hydraulic efficiency accounts for friction losses. Total efficiency is volumetric efficiency X mechanical/hydraulic efficiency.

Depending on what you"re calculating, one of these efficiencies will be important. For flow rate and speed, volumetric efficiency is important. For displacement, pressure rise, and torque, mechanical efficiency is important. Finally, for input power, total efficiency is important.

Your final drive includes a hydraulic motor and that motor has a certain level of efficiency associated with it. Over time, that efficiency can drop -- so find out how efficiency is measured, what the source of losses are, and how to minimize them.

No system, no matter how well it’s designed, is going to be 100% efficient. High-quality, well-maintained radial piston motors are about 95% efficient while axial piston motors are about 90% efficient--which is likely why you see these two types of hydraulic motors used in the vast majority of final drive motors.

The definition of efficiency depends on what type of system you’re talking about, and even then there can be some variations. For a hydraulic motor, there are three ways efficiency can be measured or estimated: volumetric, mechanical/hydraulic, and overall efficiency.

Volumetric efficiency looks at the theoretical flow rate and the actual flow rate and provides information about leakage and wear. The theoretical flow rate is pretty easy to calculate: theoretical flow = (pump displacement per revolution) x (revolution speed).

This works much better in SI units, too. If the displacement is in cc/rev and the speed is in rpm, the results will be in liters/minute. Actual flow is then measured using a flow meter. The efficiency is then actual flow / theoretical flow x 100 to get efficiency as a percent.

Mechanical efficiency is based on actual work done and theoretical work done, both per revolution. This is based on theoretical torque and the actual torque, and in most hydraulic motors it’s about 0.9 (or 90%). Actual torque can be measured with a dynamometer, but is rarely done. The losses related to mechanical efficiency are directly tied to mechanical friction between mating parts.

Overall efficiency combines volumetric and mechanical efficiency. It"s simply the product of these two values: overall efficiency = mechanical efficiency x volumetric efficiency, and gives you an overall idea of how efficient your hydraulic motor is.

Some degree of internal leakage is normal and actually beneficial, but past a certain point it becomes a problem. Excess internal leakage most often results from wear. For example, the size of key clearances in a hydraulic motor can, over time, become larger because of abrasive wear and lead to internal leakage. That type of wear usually results from contaminated hydraulic fluid but can also result from normal wear and tear.

Friction is another major source of losses. Rough surfaces where they should be smooth cause friction issues with the hydraulic fluid, reducing the amount of power that can be transferred. There are other ways that friction can be introduced, however. For example, anti-friction bearings or plane bearings that are wearing out will be a source of friction.

One of the keys to preventing hydraulic motor losses relates to good maintenance practices, such as keeping the hydraulic fluid clean, replacing hydraulic filters, and not ignoring hydraulic leaks. It"s also important to look for symptoms of potential problems with the bearings, such as new noises, excessive vibration, and overheating.

?I just love this newsletter. As a Hydraulics Instructor for Eaton, I make copies and distribute them to my students as I address various topics. Please keep "em coming.?

Even the best-performing hydraulic pumps from top hydraulic gear pump suppliers need to be replaced eventually. Because work and environmental conditions are different on every work site, it can be difficult to place an exact timeframe on how long a pump will last. In order to stay on top of the condition and remaining lifespan of hydraulic pumps, and hydraulic systems overall, it’s important to consider two things: 1) remaining seal life 2) how fast a pump’s efficiency is deteriorating.

Efficiency is the easier of these two criteria to keep track of. If a pump’s performance has been steadily deteriorating or has suddenly declined, then it is probably reaching the end of its lifespan and will need to be replaced to sustain a reliable hydraulic system. The easiest way to judge the deterioration in a pump’s performance is to monitor and compare cycle times (i.e., the speed at which the machine operates).

However, sometimes it is necessary to take exact measurements of a pump’s performance efficiency, which can be quantified by three different categories: volumetric efficiency, mechanical/hydraulic efficiency, and overall efficiency:

• Volumetric flow: Determined by dividing the actual flow delivered by a pump at a given pressure by its theoretical flow. Actual flow is measured using a flow meter. To calculate theoretical flow, multiply the pump’s displacement per revolution by its driven speed. The result will give you the volumetric efficiency at a particular pressure so it will be necessary to take these readings over a range of pressures as the pump may be very efficient at low pressure but very inefficient at higher pressures.

• Mechanical/hydraulic efficiency: Determined by dividing theoretical torque required to drive the pump by the actual torque required to drive the pump. Theoretical torque is measured in Newton meters. Measuring actual drive torque requires a dynamometer.

Volumetric efficiency helps assess the pump’s condition in the field. If there is wear or damage increasing internal leakage, this measurement can help identify whether pump maintenance is required. In addition to mechanical performance, overall efficiency helps determine if hydraulic pump replacement is necessary. To help calculate the drive power the pump requires at a given flow and pressure, you need to know its overall efficiency. If the drive power required increases or decreases, the pump is probably operating less efficiently.

A hydraulic pump system must be properly maintained to ensure it remains reliable, but there are other factors that impact reliability. These include temperature; a hydraulic pump is most stable in cooler temperatures. Overheated hydraulic oil will lose its lubricity and become oxidized, causing increased wear on metal parts and potentially hydraulic pump overheating. The ambient temperature of the operating environment needs to be considered as well and regulated using equipment such as forced-air coolers or a liquid-to-liquid cooler.

Any hydraulic pump installation requires a clean environment. Particle contamination is a common cause of equipment failure; high-pressure flow can impact particles in a way they ordinarily wouldn’t react. Therefore, specialized filtration systems are required, such as kidney-loop filtration systems that circulate oil through a filter to maintain a particulate-free flow. Water contamination is another threat; water intrusion and even the slightest amount of moisture and humidity can affect hydraulic fluid and components. Desiccant breathers, absorbent filters, and vacuum dehydrators may be used in a plant to control moisture levels.

For more information on maintaining hydraulic pumps and motors, or to order hydraulic pumps, and other hydraulic component supplies, contact White House Products Ltd. today at +44 (0) 1475-742500.

Although many detractors sneer at the idea of hydraulic efficiency, right-sizingcomponents, proper system design and moderntechnology can go a long way to achieving system efficiency.

“Hydraulic efficiency”is a term alluding similar sentiments to “exact estimate” or “scientific belief.” It’s not that hydraulic efficiency is an oxymoron, per se, but these aren’t traditionally two words that make sense shoulder to shoulder. If efficiency was your top benefit on the list of machine requirements, fluid power wouldn’t have been on your short list of options, at least in the past half-century or longer.

Efficiency is a word now more commonly familiar to us, thanks to the escalation of green values—especially those defining the way we use natural resources. No longer can we take a limitless and inexpensive source of energy for granted, nor can we abuse the dirty sources of inexpensive energy at the expense of our precious environment. We must take full advantage of our energy resources to achieve the work required for maintaining our standard of living, while reducing associated waste along the way.

What is efficiency?I define efficiency as work-in minus work-out. Essentially, it’s the differential between the energy your process requires and the energy input required to achieve that process. Your process could be stamping, rolling, injecting, moving, pressing or any other mechanical function capable of being achieved in a rotational or linear motion. If you’re running a punch press, for example, the machine efficiency is defined as the current draw of the pump’s motor minus the combined force and velocity of the punch die.

Most machines are designed to convert energy from one form to another, which can sometimes occur multiple times. Because of the Laws of Thermodynamics, you cannot change energy from one form to another without creating waste energy, and this is a fact regardless of the energy transformation taking place. In the case of a hydraulic machine, you must convert electrical energy to mechanical energy within the electric motor, resulting in partial waste. Then you must convert mechanical energy into hydraulic energy within the pump, resulting in partial waste. Then you must convert hydraulic energy back into mechanical energy at your cylinder or hydraulic motor, resulting in partial waste.

The amount of energy wasted in the above example could be staggering, especially if you’re using an old machine with old components. Let’s say you have a 10-hp electric motor—and keep in mind electric motors are rated on power consumption, not power output. Your old motor might have an efficiency of 85%, meaning it will produce 8.5 hp at its shaft, the other 1.5 hp being wasted as pure heat.

In your old power unit, you have a worn and tired gear pump. When new, a gear pump is lucky to have 80% efficiency, so I’ll be generous to throw 75% at this example, since gear pumps become less efficient over their lifetimes. So this pump can convert only 6.4 of the motor’s 8.5-hp shaft output into usable hydraulic energy. The rest of the energy is, you guessed it, wasted as pure heat. We’ve now lost 36% of the electrical energy inputted, and we haven’t even done anything yet.

Just to be intentionally derisive, I’m going to choose a hydraulic motor as our actuator; a gerotor motor to be exact. These motors come at a modest price and perform at a modest level. They were a clever design back in the day, but have high leakage to lubricate the myriad components, and they leak even more if you operate them outside their optimum torque and speed curve. Leakage, I should note, is a designed element of most hydraulic components, based on gaps and clearances with internal moving parts, which is required to lubricate that component. More moving parts or higher clearances means more leakage, and I should further note, any fluid lost to leakage carries with it pure heat equal to the pressure and flow of the leakage.

Now that I’ve blasted gerotor motors, I’ll back it up by saying they’re often incapable of reaching 80% efficiency. There are some versions of these “orbital” motors, like the disc valve variant, which can be close to 90% efficient, but it would be only within a tiny window of flow and pressure. I’ll stick with 80% for this example, which is generous. With the 6.4 hydraulic horsepower we havein our system, we’re left with 5.1 hp at the hydraulicmotor’s shaft.

So with barely half of our input energy making its way to the output stage, it’s easy to see why I’m dubious of “hydraulic efficiency.” So why use hydraulics when we could have powered our machine straight from the electric motor and take advantage of 8.5 hp instead of 5.1? In that answer lies the reason hydraulics are awesome; with $300 worth of valving, you can infinitely vary torque and speed, and reverse direction. Our electric motor would require sophisticated electronic control to achieve the same features.

To be fair, I’m using one of the worst-case examples for hydraulic efficiency. Not only are there more efficient components available than gear pumps and orbital motors, there are ingenious approaches to using hydraulic components. Furthermore, recent advances in electronic control have not ignored the fluid power industry, and there are some tricks to further improve hydraulic efficiency.

Pressure compensated pumps are set to a particular standby pressure, and when this pressure is reached, the pump reduces flow until downstream pressure drops below that standby pressure. Image courtesy of CD Industrial Group

I can’t stress enough that a hydraulic machine is really just an energy conversion device, and when you can convert your input energy into usable force with as little heat waste as possible, you’re on the right track. A pump converts the mechanical energy of the prime mover into hydraulic energy in the form of pressure and flow. If I were to recommend one component you blow the bankroll on, it would be the pump.

A piston pump, especially a high-quality one, can be 95% efficient at converting input energy into hydraulic energy. Not only does this pump provide 27% more available hydraulic energy than our old gear pump, it creates 80% less waste heat than it, reducing or eliminating cooling requirements.

Not only does an efficient pump help, an efficient design works wonders. If you have a fixed displacement pump on a flow control, any unused fluid is wasted as heat. For example, take even our 95% efficient fixed piston pump, giving us 9.5 gpm out of a theoretical 10 gpm. If your downstream priority flow control valve is set to 5 gpm, 4.5 gpm is bypassed to tank. However, all of the 9.5 gpm is still being created at full system pressure, and what’s dumped to tank is lost as heat. So now our 95% efficient pump is helping create a 50% inefficient system.

A load-sensing pump will provide only the pressure and flow required of the circuit and actuator, with only a few hundred psi worth of pressure drop as the waste by-product. Image courtesy of CD Industrial Group

To get around this, pressure compensation was created. A pressure compensated pump is set to a particular standby pressure, and when this pressure is reached, the pump reduces flow until downstream pressure drops below that standby pressure. For example, if you have a 10 gpm pump set at 3,000 psi, and flow is restricted below 10 gpm, the pump will reduce its displacement to exactly match the downstream flow and pressure drop at 3,000 psi. Essentially, the pump only produces the flowbeing asked for, no more, but always at 3,000 psi.

But what if we only want 1,000 psi for a particular operation? Well, you could use a pressure-reducing valve, but the pump is still producing 3,000 psi, so you’re not saving any energy. To remedy this, the load-sensing pump was invented. A load sensing pump has an additional compensator that is plumbed downstream of the metering valve. This configuration allows it to measure load pressure and compare it to compensator pressure. The result is the pump will provide only the pressure and flow required of the circuit and actuator, with only a few hundred psi worth of pressure drop as the waste by-product.

The use of variable speed technology can dramatically increase hydraulic efficiency. Here, the new Green Hydraulic Power units use Siemen’s SINAMICS variable speed servo pump drive to increase efficiency by up to 70%.

Recent advancements in control technology have resulted in a similar concept of pressure and flow management, but using a combination of fixed displacement pumps, servo or VFD motors and pressure transducers. The pressure transducers measure pressure after the pump and after the metering valves, and PLC gives the signal to rotate the pump at a speed only fast enough to achieve the desired pressure and flow. It’s quite an advanced technology, and has progressed to the point a pump could hold a stationary load and rotate fractional speed just to compensate for leakage. Another advantage to this technology is that the motor doesn’t even turn when no energy is required, and then again only with the energy required by demand of the hydraulic system.

Aside from choosing efficient pump designs, using efficient hydraulic actuators is the next best place to continue. Not much can be said of hydraulic cylinders, because most are close to 100% efficient already, depending on sealing technology. But just like with your hydraulic pump, the hydraulic motor has many variations, each with their own contribution to overall efficiency.

So for the most part, hydraulics is not an efficient technology. But neither are gasoline-powered cars, and millions of those are sold every day, because there is no better option for their task. Regardless, efficiency in hydraulics is progressing, and advancements in materials and technologies will further that. As long as you are aware of what it takes to create “hydraulic efficiency,” the term won’t seem curious like “seriously funny” or “virtual reality.”

8613371530291

8613371530291