volvo excavator hydraulic pump in stock

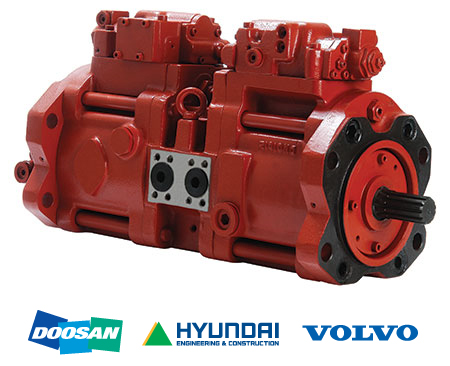

Plant Parts are pleased to support this ease of maintenance with a wide range of genuine, OEM and quality replacement Volvo excavator parts: hydraulic pump, final drive, swing motor, recoil spring and slew ring that are guaranteed to fit and perform to specification.

Investigate below the stock availability for your Volvo excavator or mini excavator part. If a unit is available and you order before 3pm we despatch worldwide the same day.

The ec290 hydraulic pump can be used in various industries, such as construction works, machinery & shops, energy & mining, and building material shops. The pumping volumes of ec290 are also used as pumping for various materials, such as farms, manufacturing plants, and construction works.

There are various types of hydraulic pumps available on Alibaba.com. Including various hydraulic pushes such as the vol290 hydraulic pump, for example, is a type of high-pressure hydraulic pump. They have different properties and functions suitable for different types of hydraulic pushes, such as the vol290 hydraulic pump, and the ec2 pump catalogues work well.

There are various types of sizes, including example volcanic pumps, high-pressure pumps, and mini vol290 hydraulic pumps at great prices. They have a wide range of pressure and pump functions, such as the vol290 hydraulic pumps, or ec290 hydraulic pumps, are available at Alibaba.com. These pumps work in volcanic conditions and have a low-pressure capacity.

There are also variations of the pressure-sensitive pumps such as volV ec290 hydraulic pumps and volV ec290 hydraulic pumps, they are a great option for smaller clients. They are ideal for work with minimal hydraulic pumps, such as volV ec290 and high voltage hydraulic pumps, depending on the type of pump. They have reduce hydraulic oil consumption and alsoize the pressure of the pump with a pressure range of 50 to ec290, depending on the size of the pump. Ec290 hydraulic pumps with ec290 positive pressure, reduce the hydraulic oil consumption, and reduce the hydraulic oil balance of gravity.

Hydraulic piston pumps are mainly used in construction, including they-reed and self-propelled hydraulic pumps, mainly for construction work, they are a common choice of pumps for construction, and they are mainly used in construction plants. Both hydraulic piston pumps and pneumatic piston pumps are the most common and used in construction sites. The pneumatic piston pumps usually have a piston pressure and the pressure is the same as those used in construction. Pumps, such as pneumatic piston pumps, are air-cooled hydraulic pumps, which are mainly for construction work and they are used with gravity pumps, are air-cooled pumps, and mini hydraulic pumps for construction work. They are smaller and heavier than high-pressure pumps, but they are not used in heavy-duty construction.

When hydraulic pumps work with pressure, they are more adaptable to all types of concrete, such as pumps for trucks, excavators. There are many different kinds of hydraulic pumps available on Alibaba.com, such as electric hydraulic pumps for sale, and hydraulic concrete pumps for sale. They are also great for construction projects, such as large excavator pumps for sale, used excavator pumps for sale, and hydraulic concrete pumps for sale.

The hydraulic pumps on construction equipment are critical components of the machines and even though they are often designed to work under vigorous and intense conditions, no pump will last forever. Discovering a problematic pump can be complicated as the effects might seem to originate in other connected parts, and, if failures are gradual, the cascading effects of a pump failure can spread throughout a machine.

To help in your diagnosis — and with a small dash of preventive maintenance — we’ve put together this basic, short list of common pump problems and their causes.

Not every hydraulic pump on a machine is simple to inspect, but this Volvo main hydraulic pump on a EC220B-LC excavator sits behind a quick access door so an operator can check it often.

A failing hydraulic pump can be a long and subtle process, a sudden and catastrophic calamity, and all shades in-between, but often a perceptive operator will notice the signs of a pump failure in advance. It might take a few minutes of stopping and inspecting, but knowing what to watch for and taking the time to inspect your hydraulic pumps can often pay off in the long run and lead to fast and simple fixes, instead of prolonged and labor-intensive downtimes.

A hydraulic pump is often secured behind a door or guard or integrated deeply into the body of a machine, but taking the time to inspect the pump for the presence of oil (or oil and dirt clumping) can lead to the early discovery of problems. If the issue is simply a loose connection, a quick tightening can often stop a small issue from growing.

Since a hydraulic pump has both seals to prevent fluid from exiting the pump and also fluid from prematurely entering from one chamber to the next, failing seals can be both internal and external. Spotting an exterior leak is, of course, simpler, but being aware of where seals exist inside the pump can also help you diagnose a failing internal seal.

The most frequently noticed indication of a failing pump is often the start of a new sound coming from the hydraulic pump. An experienced operator will often immediately know and recognize a pump that is indicating issues through sounds, but for many it can be harder to pinpoint.

A problem with a pump can cause it to simply become louder in its operations, develop a whining sound, or even create a knocking sound. The sounds can indicate a number of problems, but often the cause is either cavitation or aeration in the pump.

Over long spans of work and under intense conditions, a hydraulic pump will often heat up, but excessive heating is often a sign of internal issues in the hydraulic pump. Checking a hydraulic pump for excess heat should always be done with safety in mind and with a secure machine and proper protective equipment. Periodically ensuring a hydraulic pump isn’t overheating allows an operator to discover if the pump is under undue strain and on a path to failure.

Overheating in a hydraulic pump can also cause fluid to thin, cause internal components to more rapidly degrade, and introduce dangerous working conditions to the machine. Overheating in a pump is both a sign of current trouble and a cause of other growing problems.

Unexpected and non-fluid movement of parts can be caused by issues with the hydraulic pump, but since the culprit can be a number of other parts in the system, diagnosing pump issues from these movements isn’t always simple. Still, if you do notice non-uniform movements in your machine, taking time to rule out the hydraulic pump is important.

A main hydraulic pump, like this one from a Komatsu PC400LC-6 excavator, comes with a working life and will need to be replaced or rebuilt at some time. This one is fresh from an H&R Recon and Rebuild shop and is headed to a customer.

Knowing some of the common causes of hydraulic pump failures is a proven way of proactively discovering developing issues and correcting them before they become disastrous to the pump and the machine.

The internals of a hydraulic pump are designed to work with fluid that meets exacting specifications. When hydraulic fluid is contaminated it can lead to issues developing in the pump, force the pump to work harder, and cause the pump to work erratically. One common culprit for contamination is water, and it can quickly lead to increased corrosion, changes in viscosity that lead to inefficiencies, and the inability to properly regulate heat in the pump.

Other debris, either introduced from outside or from the degradation of internal elements, can also lead to issues in the pump and signal failing seals or other parts.

A hydraulic pump is often containing a high level of pressure and as this pressure exerts force on seals in the pump, the seals can begin to leak or fail. Even minor leaks in seals can lead to loss of fluid and create issues in the system. Leaks can be both external and internal. For an internal leak, fluid will move from one part of the pump to another in unintended ways and force inefficiencies into the pump as it has to work harder to compensate.

While many hydraulic pumps are built to stand up to tough and continuous working conditions, every hydraulic pump is designed with an upper limit. Every time a hydraulic pump is subjected to overpressuring and overloading beyond what the manufacturer has specified, the pump is more prone to damage.

All hydraulic oil has a defined amount of air dissolved in it, but increases to this amount can lead to inefficiencies in the pump and force the pump to work harder or erratically. An increase in air can also happen inside the pump and create similar problems. Even though the pump and hydraulic system have mechanisms in place to regulate air in the system, if excess air is introduced the system should be returned to a balanced system before prolonged use of the pump.

The hydraulic system on a construction equipment machine is designed to work within defined parameters. Operating a machine with too little oil or too much oil for even the briefest amount of time can cause the pump to overwork, lead to increases in working temperatures, or create conditions for non-uniform movement. The exact type of oil used — matched to the machine and the working environment — can also impact how the hydraulic pump operates.

The operator’s guide of your machine will define the hydraulic oil change schedule and adhering to that schedule can extend the life of your hydraulic pump. When oil is changed, take time to examine the spent oil for signs of debris

Keeping a pump on a hard-working machine looking new every day is nearly impossible, but routinely peeling back dirt, grime, and oil can help catch issues early.

No one wants to take a machine out of work for cleaning, but keeping the machine clean and ensuring pumps are not covered in mud, dirt, or other debris can allow them to be inspected more easily and avoid contamination and overheating.

The hydraulic hoses connected to a hydraulic pump can wear out over time and ensuring they are well-maintained can help you avoid the introduction of debris and even catastrophic issues in the case of sudden failures.

If a hydraulic pump fails on your machine, taking time to ensure you properly diagnose why and how the failure occurred will help you avoid repeating the failure with your replacement pump. Even if the pump failed simply from prolonged use and age, taking time to confirm that can lead to insights about how to extend the life of the next pump.

A hydraulic pump on an excavator, wheel loader, dozer, or articulated truck can be an often ignored component of the machine — until it starts to act up and cause issues. If problems have brought a pump to the forefront of your mind, hopefully, this short guide has helped simplify your pump problem solving.

If you find yourself in need of a replacement hydraulic pump, our Parts Specialists are always here to help. As a supplier of new, used, and rebuilt hydraulic pumps and with our deep inventory of parts, our Parts Specialists can often find the perfect solution to get a customer back up and running quickly. Simplify your search and give them a call.

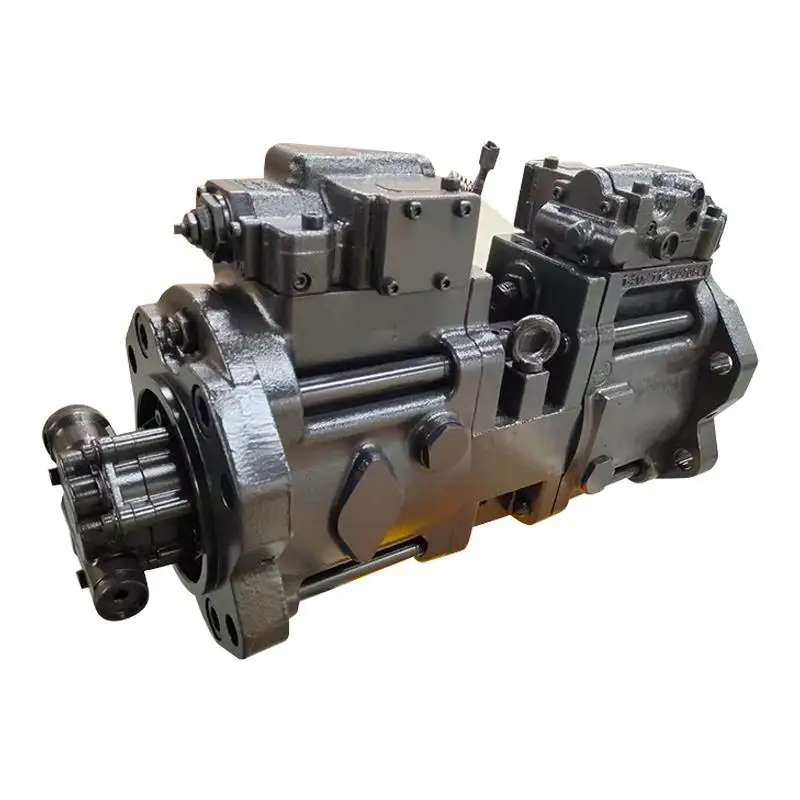

The look and design of a hydraulic pump is customized to fit the machine and the available space. This main hydraulic pump is freshly reconditioned from a Kobelco SK160LC-VI excavator.

Hydraulic pumps come in a wide range of shapes and sizes. This large Volvo main hydraulic pump requires assistive overhead cranes and forklifts to move around the warehouse.

Gear pump is the most common type of hydraulic pump. It is commonly used in tractors, forklifts and other types of watermelon equipment. It uses the meshing of two or more gears to replace the fluid in the cavity to generate power to work. Because of its simple working principle and simple structure, the gear pump in general tractors will be replaced after a problem occurs.

1. The company has more than 70 technical R&D team members, of which more than 90% have accumulated more than ten years of hydraulic product technology, and have become the main force for the company to develop new products.

3. The company has more than 80 invention patents for existing technologies, among which “bi-metal sintering of ductile iron and copper”, “surface hardening nitriding heat treatment of hydraulic parts”, “hardening carbonitriding heat treatment” and other technologies are second to none in the industry.

Are you looking for hydraulic repair services for a Volor EC530E or EC440E excavator? Volvo recently launched these 50-ton excavators, and we offer a full line of hydraulic services for all Volvo heavy machines, including pump repair, motor repair, final drive repair, and on-site visits. Get in touch with us today for a repair estimate, or P and D on a new or remanufactured pump or motor.

For loading and transportation convenience, the EC530E shares the same 10-foot, 10-inch width as Volvo’s 48-ton EC480E. The end result is an EC530E with 22,884 pounds of lift capacity, while the bigger and wider EC550E raises that to 29,674 pounds at reach height.

As one of North Americas leading suppliers of excavator hydraulic pumps. Leemar effectively stocks new, used, and rebuilt pumps for a wide range of heavy equipment. Specializing in John Deere, Hitachi, Link Belt, Caterpillar (CAT) and Madill.

Our Brand-New Aftermarket Korean built hydraulic pumps have been carefully designed, tested, and set up to OEM specifications and carry a full one-year warranty on almost all models. We work directly with the manufacturers to ensure the highest standard is upheld and this is what makes us unique in the industry.

Alongside our new aftermarket product line, we also carry remanufactured OEM main hydraulic pumps that have been disassembled, cleaned, measured, and inspected by our accredited in-house hydraulic shop. Out of spec parts are replaced and these pumps are carefully re-assembled and tested, carrying industry leading warranties.

Volvo offers a variety of variable displacement pumps which provides the highest levels of performance, reliability, and ease of maintenance. With Volvo optimized pumps you will benefit from improved fuel economy and lower exhaust emissions, both of which are central to Volvo’s sustainability objectives.

8613371530291

8613371530291