water glycol hydraulic pump in stock

Continental Hydraulics announced that it’s PVX vane pumps are now fire-resistant, as they are approved for water glycol to 2,500 psi. Water glycol fluids have proven to be an excellent fire-resistant hydraulic fluid option. This should open up new markets like food processing, steel manufacturing, automotive assembly or and other industry that typically use the water glycol fluids.

Excellent High-Pressure Performance - Shell Water Glycol S3 CX 46 has been tested to provide excellent performance in applications of 350 bar (5000 psi) by providing excellent antiwear for pump parts or motor components.

Fire Resistant - Recognized by FM Global as a less flammable industrial fluid Shell Water Glycol S3 CX 46 reduces fire hazards related to personal safety in storage, handling, and use which could help lower insurance premiums.

All Season Usage - A high viscosity index (VI) and a low pour point provided a wide temperature operating window meaning Shell Water Glycol S3 CX can be used year round.

Water Soluble, Easy Cleanup - Shell Water Glycol S3 CX 46 is 100 percent soluble in water making equipment and shop cleanups easier than with conventional hydraulic fluids.

Readily Biodegradable - Formulated with 35-40% water and specially selected additives, Shell Water Glycol S3 CX 46 is readily biodegradable thus helps minimize disposal problems.

Fire Resistant - A fire-resistant fluid may be used to avoid the risk of fluid ignition in the event of a leak. Fire-resistant fluids are specially formulated lubricants and greases that are more difficult to ignite and do not propagate a flame from an ignition source. Because of its water content, this product has the ability to prevent flame propagation when fire occurs. Recognized by FM Global as a less flammable industrial fluid Shell Water-Glycol S2 C 46 reduces fire hazards related to personal safety in storage, handling, and use which could help lower insurance premiums.

Heat Transfer Properties - Water based fluids such as Shell Water-Glycol S2 C 46 are excellent heat transfer media. Water glycol fluids in general have marked advantages over typical mineral oil based formulations in this respect. One of the most effective protection against fire and explosion is to prevent leakage with proactive servicing, and maintenance and care of the system.

Low Pump Wear - A high level of anti-wear protection is built into Shell Water-Glycol S2 C 46. Shell Water Glycol S2 C 46 is designed to be resistant to mechanical shear resulting in stable viscosity, helping to protect components against wear.

Corrosion Protection - Shell Water-Glycol S2 C 46 will afford corrosion protection to a wide variety of metals including aluminum, copper, brass, cast iron, steel and other metals commonly used in hydraulic circuitry.

Seal, O-Ring and Hose Compatibility - Shell Water-Glycol S2 C 46 can be used in systems that contain a wide variety of seal, gasket and hose materials. Elastomers such as natural rubber, Buna-N, Buna-S and Neoprene are compatible with the fluid. Other materials such as Viton and Teflon are also compatible. The only seal and gasket configurations that are not acceptable are leather, cork, cellulose or other substances that will absorb water and either swell or deteriorate as a result.

188409 Used; Eaton 02-125549-1 Vickers Vane Pump; 38GPM; 3000PSI; 2500RPM; Port type: Code 61 Flange; Inlet port size: 3" SAE; Outlet port size: 1-1/4" SAE; Shaft: 1.375" OD x 3" Length; 35VQTBS21A2203AA20R. Item shows signs of having been used - actual...

Castrol AnvolTM WG 46 is an HF-C type water-glycol fire-resistant hydraulic fluid, containing anti-wear additives and corrosion inhibitors. It provides excellent protection against rust and vapor phase corrosion. In hydraulic pump tests, Anvol WG 46 has shown high levels of anti-wear performance. Its foam resistance, low temperature flow, emulsion stability and storage stability are also excellent.

Anvol WG 46 is for use in hydraulic systems where, in the event of fluid leakage, there is a significant risk of ignition. Examples of applications include furnace doors, die-casting machines, forging machinery and mining equipment. It can be used in vane, gear or piston-type pumps with pressures up to 3000 PSI. As with any water containing fluid, continuous high temperature leads to excessive evaporation. The water content should be checked regularly in service and any corrections made by addition of distilled or de-ionized water. Occasional monitoring of alkalinity is recommended to ensure the correct level of corrosion inhibition. Care should be taken to ensure the hydraulic system is designed for using water glycol-based fluids. Care should also be taken to ensure the compatibility of Anvol WG 46 with paints, seals and metals, and also ensure that the hydraulic pumps and filters used are suitable. A thorough draining and flushing procedure should be followed when converting from other fluids to water glycol-based solutions. Anvol WG 46 is fully compatible with nitrile, neoprene, silicone, nylon, butyl rubber and fluropolymer seal materials. Anvol WG 46 meets the fire resistance requirements of: 7th Luxembourg Report FM Global 6930

The checkball pump’s ability to operate with a combination of high or low viscosity or lubricity fluids offers remarkable flexibility. Dynex hydraulic pumps operate within a wide range of recommended viscosities from 31.6 to 3,142 SUS (1,5 to 680 cSt). Dynex water glycol pumps are widely used in the offshore oil & gas industry.

Phillips 66® FR Fluid-Glycol is a water-glycol based fire-resistant HYDRAULIC FLUIDS developed for use in industrial hydraulic systems operating in areas subject to fire hazards. It contains sufficient water to snuff out a fire resulting from ignition of a fluid leak. It is suitable for use in hydraulic systems operating at 2,000 to 3,000 psi, and can withstand intermittent pressure spikes up to 5,000 psi.

1600 3000 4000 bar hand pumps – very high pressure hydraulic hand pumps produced in light aluminum alloy of aeronautical derivation to reduce as much as possible the weight. Available in 3 versions with maximum operating pressure:

Design studied to have high performances maintaining an optimal effort on the lever, a reduced weight and an excellent ergonomics. Robust hand pumps – heavy duty – with long maintenance intervals. Surface treatments to guarantee total reliability in the most difficult environments and maximum durability.

Tank capacity from 1,6 to 2 liters. Possibility of mounting manometric sockets, various types of quick couplings, high pressure flexible hoses. For a more accurate reading, the digital pressure gauge supplied with quick couplers is also available. The hand pump can be calibrated to different pressures upon customer request.

Hydraulic mineral oil operating fluid, models available on request with different fluids such as: water, glycol, glycerin, phosphoric esters. Custom made versions available for extreme operating temperatures.

Possibility to design and produce special 1600 3000 4000 bar hand pumps on request, with flow rates, performance and dedicated features. Available in stainless steel, with special fire painted colors and layouts designed and manufactured to customer specifications.

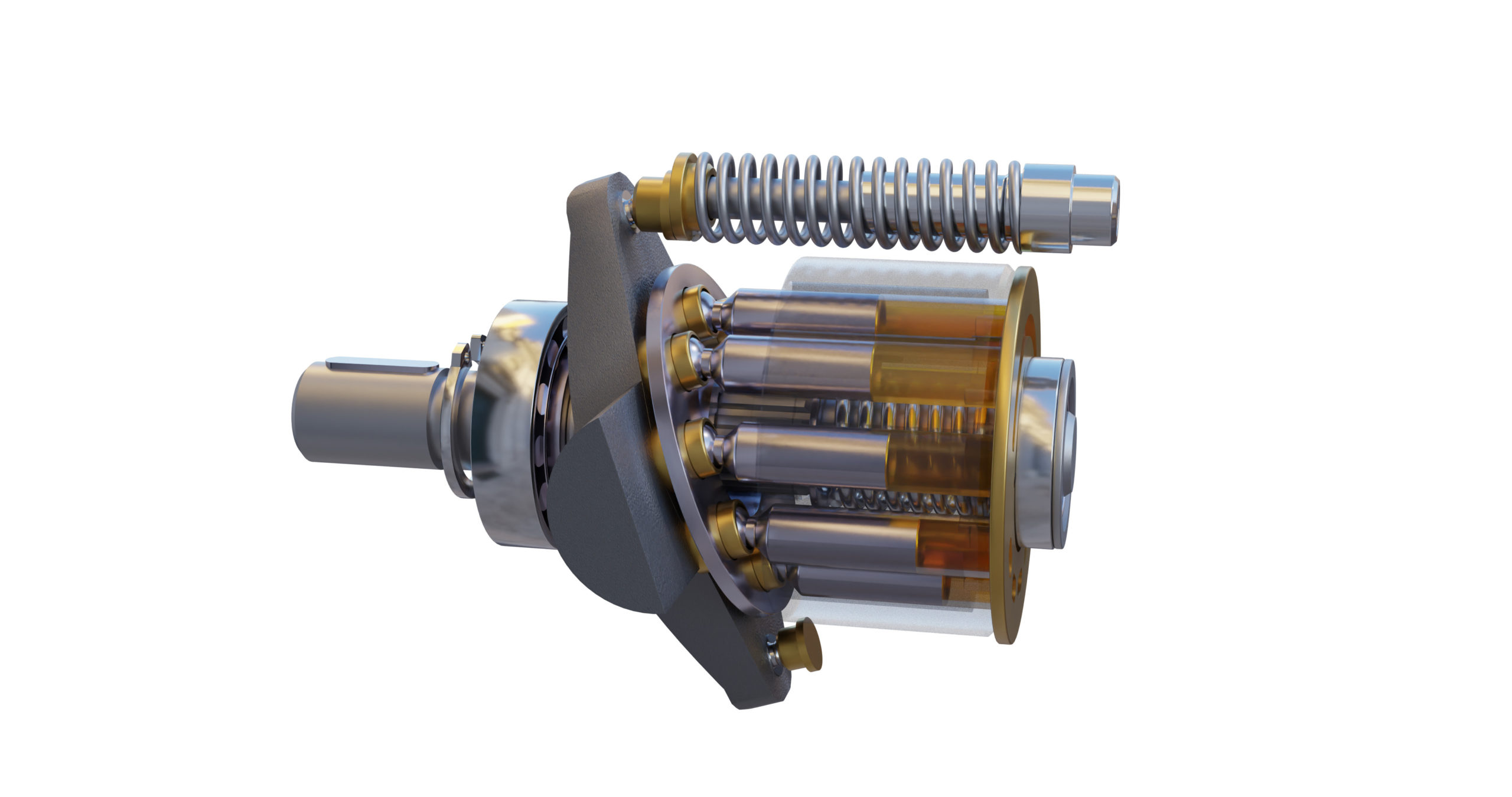

Advanced Fluid Systems is proud to offer hydraulic repair services for hydraulic pumps and motors, from gear pumps to vane pumps to the largest radial piston pumps, regardless of brand. Our inventory includes seals, parts and re-manufactured pumps available for immediate shipment.

100HP programmable variable frequency drive (VFD) test system for mineral oil and water glycol fluids that allows us to test pumps with electronic controls.

The fluid is green in color and was deliberately chosen to differentiate Kleen & Green from the current car wash industry standard and denote its eco-friendly nature. The fluid has a consistency of light syrup, a sweet amine odor, and if left open for extended periods of time; the water will evaporate increasing the viscosity.

Except for color and odor, the fluid has a consistency similar to mineral-based hydraulic oil at normal room temperatures. It is dissimilar to mineral-based hydraulic fluid at lower temperatures. As the temperature decreases mineral oil viscosity gets thicker and eventually will refuse to flow. Kleen & Green will continue to flow down to a -47° F. As the temperature increases, mineral oil-based fluid thins out where water-based glycols remain more viscous. The water glycol fluid does not mix with oil and will not emulsify. Being heavier than oil, the water glycol sinks and the oil floats. This feature allows recently converted systems to be fully purged of oils by the process of skimming.

In addition, even though Kleen & Green is a different formulation than standard water based car wash hydraulic fluids, it will readily mix with systems filled with older water glycol formulations. Therefore it can be used as a makeup fluid. Water glycol hydraulic fluids are usually a blend of three primary components; glycol, water, and an amine additive package. The glycol functions as the base component and provides the fluid viscosity and basic thermal characteristics.

Purified water is used to control the viscosity of the fluid and to provide the fire resistance. The additive package is blended into the fluid to enhance lubricity, and to provide anti-wear, anti-oxidation, anti-corrosion and anti-foaming properties.Because of water based fluids" higher bulk modulus, they transfer force more effectively than mineral based oils. Another advantage of the fluid"s high water content is that it transfers heat much better. This results in higher operating efficiencies and a cooler running system.

Traditional hydraulic fluids are not only toxic but are essentially non-biodegradable. The environmental impact of fluid releases is considered as hazardous requiring HAZMAT reporting and in some cases HAZMAT call outs. Mineral oil based hydraulic fluids are damaging to waste water treatment processes if they reach effluent systems easily overwhelming the natural degradation process. If allowed to reach wetlands, streams and rivers, lakes or the ocean; it becomes a toxic threat to wildlife and the overall health of the ecosphere into which it is released.

Traditional mineral oils, when released into the soil, can render the soil polluted and unusable. Remedial action often requires the exposed soil to be removed and incinerated. Kleen & Green is classified as a "readily biodegradable" fluid, which means it will degrade by 60% within 28 days of release. When compared to other car wash water glycol fluids is degrades even more rapidly.

The P5000 / 5100 series gear pump is built from cast iron ensuring a strong and long lasting product, which can stand the most robust applications. Single & multiple units are available as per your requirements.

We machine, build from stock and test the P5000 / 5100 gear pump on site, to ensure the highest quality and a workable product is delivered to you. The P5000 / 5100 gear pump also comes with a 12 month warranty.

The P5000 / 5100 can be supplied as an ATEX gear pump if required. ATEX Group I & II approval is required, if the product will be used in potentially explosive atmospheres.

Keeping equipment working at optimal performance with less downtime and supporting a longer life span are significant factors that make fire-resistant hydraulic fluids a safe and pragmatic choice. As in any hydraulic system, a strong maintenance strategy is vital to reduce component corrosion and thereby avoid the significant costs of replacing parts and unplanned repair downtime. Therefore, a disciplined maintenance regime for water-glycol (HFC) hydraulic fluids can help keep systems operating more effectively and efficiently — and for longer.

Standing at 50 to 55% market adoption, HFC is a water-based fluid that can be used in all industries where there are major fire risks. HFC hydraulic fluids remain the most widely used fire-resistant hydraulic fluids today because of their price ratio and combination of excellent fire-resistant properties with good lubrication performance.

Hydraulic fluids with HFC technology have low flammability. They can be used in the presence of a high-temperature heat source, such as high-pressure die casting (HPDC) foundries or steel-making shops. In addition to offering uncompromising fire resistance, other factors for choosing HFC include OEM endorsements.

Water-glycol fluid viscosity is directly related to its water content. The glycol and polyalkylene glycol (PAG) thickener in an HFC fluid are not volatile and remain in the hydraulic reservoir regardless of fluid temperature. As such, the fluid’s viscosity is expected to increase over time as water evaporates.

The viscosity increase rate depends on ambient temperature, reservoir temperature, airflow across the reservoir breather, the amount of make-up fluid added, and other factors. A knowledgeable hydraulic fluid supplier can provide a graph that directly relates the viscosity to the water content. The graph eliminates the need to run actual water contents and allows for easy maintenance.

Decreasing viscosity can be related to excess water in the water-glycol fluid. This excess water can only come from a leaking heat exchanger or an over-addition of water during a water adjustment.

If a water alteration is necessary, perform water suppletion gradually and use soft, distilled, or deionized water. Divalent metal ions, such as calcium and magnesium found in tap and spring water, will separate the lubrication additive from the fluid, resulting in performance issues.

The pH of the water-based HFC fluid must be above 8.0 to inhibit rust. A pH of less than 8.0 indicates that the system has been contaminated or diluted.

An alkaline reserve of 90 or above is needed to inhibit vapor phase rust in an HFC fluid. The alkaline reserve will drop with use because the vapor phase inhibitor is slowly removed from the fluid. The evaporation rate depends on reservoir temperature, ambient temperature, and airflow across the reservoir’s breather. Small additions of make-up fluid can significantly and positively impact the alkaline reserve of a water-glycol fluid. Depending on the amine used as the vapor phase corrosion inhibitor, the alkaline reserve of the fluid in service may never need to be adjusted.

Particle counts must be managed to maximize component life. Pump and valve OEMs recommend fluid particle counts depending on pump type, operating pressure, and whether servo or proportional valves are used. Therefore, users can set particle count targets for a given piece of equipment by identifying the critical hardware in a hydraulic system.

Typically, water-glycol fluid will have particle counts around 19/17/14 as determined using the ISO 4406:1999 standard. This applies to fluid supplied in drums and intermediate bulk containers.

8613371530291

8613371530291