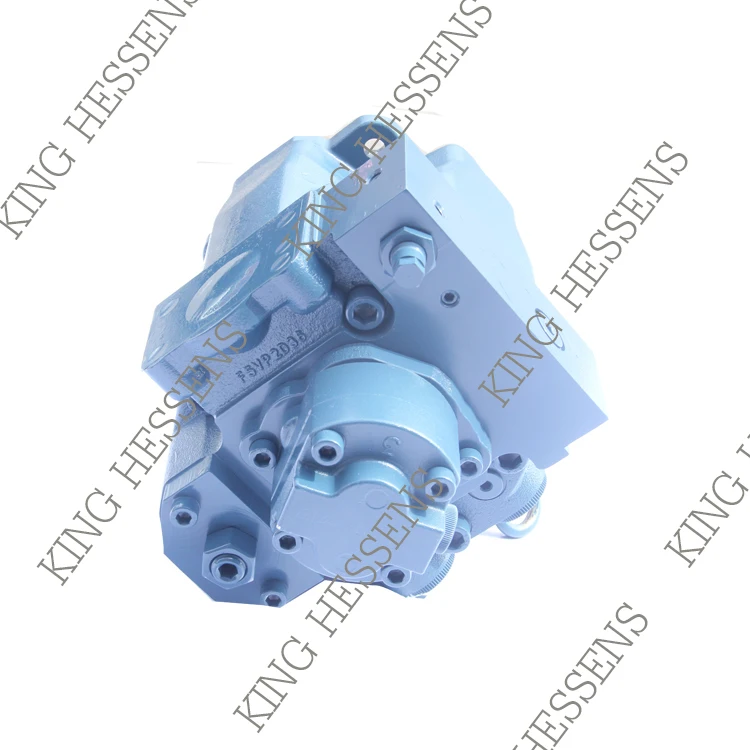

western hydraulic pump made in china

The hydraulic power pumps are ideal for small, high-pressure applications. They have a positive lifplacementpan and a variety of hydraulic power pumps, ideal for those who want to save energy on rotating pumps.

The lifespan of the hydraulic pump is good because they can maintain more pressure, and with a higher volume, it don"t need to worry about the lifespan of the hydraulic pump system.

If you are looking for ideal hydraulic pumps, there are a wide range of them, on Alibaba.com. These high-pressure pumps are ideal for hydraulic pumps, such as electric hydraulic pumps, and many other variable pumps. Check out Alibaba.com"s wide range of cheap hydraulic pumps, ideal hydraulic pumps for high-pressure applications, and choose the ones that are ideal for these pumps.

When hydraulic pumps are available, Alibaba.com offers a wide range of hydraulic pumps for sale in different sizes, you can choose from one of the different types of hydraulic pumps for sale.

Hydraulic systems are in general members of the fluid power branch of power transmission. Hydraulic pumps are also members of the hydraulic power pack/hydraulic power unit family. Hydraulic units are encased mechanical systems that use liquids for hydraulics.

The hydraulic systems that hydraulic pumps support exist in a range of industries, among them agriculture, automotive manufacturing, defense contracting, excavation, and industrial manufacturing. Within these industries, machines and applications that rely on hydraulic pumps include airplane flaps, elevators, cranes, automotive lifts, shock absorbers, automotive brakes, garage jacks, off-highway equipment, log splitters, offshore equipment, hydraulic motors/hydraulic pump motors, and a wide range of other hydraulic equipment.

When designing hydraulic pumps, manufacturers have many options from which to choose in terms of material composition. Most commonly, they make the body of the pump–the gears, pistons, and hydraulic cylinders–from a durable metal material. This metal is one that that can hold up against the erosive and potentially corrosive properties of hydraulic fluids, as well as the wear that comes along with continual pumping. Metals like this include, among others, steel, stainless steel, and aluminum.

First, what are operating specifications of their customer? They must make sure that the pump they design matches customer requirements in terms of capabilities. These capabilities include maximum fluid flow, minimum and maximum operating pressure, horsepower, and operating speeds. Also, based on application specifications, some suppliers may choose to include discharge sensors or another means of monitoring the wellbeing of their hydraulic system.

Next, what is the nature of the space in which the pump will work? Based on the answer to this question, manufacturers will design the pump with a specific weight, rod extension capability, diameter, length, and power source.

Manufacturers must also find out what type of substance does the customer plan on running through the pumps. If the application calls for it, manufacturers can recommend operators add other substances to them in order to decrease the corrosive nature of certain hydraulic fluids. Examples of such fluids include esters, butanol, pump oils, glycols, water, or corrosive inhibitors. These substances differ in operating temperature, flash point, and viscosity, so they must be chosen with care.

All hydraulic pumps are composed in the same basic way. First, they have a reservoir, which is the section of the pump that houses stationary fluid. Next, they use hydraulic hoses or tubes to transfer this fluid into the hydraulic cylinder, which is the main body of the hydraulic system. Inside the cylinder, or cylinders, are two hydraulic valves and one or more pistons or gear systems. One valve is located at each end; they are called the intake check/inlet valve and the discharge check/outlet valve, respectively.

Hydraulic pumps operate under the principle of Pascal’s Law, which states the increase in pressure at one point of an enclosed liquid in equilibrium is equally transferred to all other points of said liquid.

To start, the check valve is closed, making it a normally closed (NC) valve. When the check is closed, fluid pressure builds. The piston forces the valves open and closes repeatedly at variable speeds, increasing pressure in the cylinder until it builds up enough to force the fluid through the discharge valve. In this way, the pump delivers sufficient force and energy to the attached equipment or machinery to move the target load.

When the fluid becomes pressurized enough, the piston withdraws long enough to allow the open check valve to create a vacuum that pulls in hydraulic fluid from the reservoir. From the reservoir, the pressurized fluid moves into the cylinder through the inlet. Inside the cylinder, the fluid picks up more force, which it carries over into the hydraulic system, where it is released through the outlet.

Piston pumps create positive displacement and build pressure using pistons. Piston pumps may be further divided into radial piston pumps and axial piston pumps.

Radial pumps are mostly used to power relatively small flows and very high-pressure applications. They use pistons arranged around a floating center shaft or ring, which can be moved by a control lever, causing eccentricity and the potential for both inward and outward movement.

Axial pumps, on the other hand, only allow linear motion. Despite this, they are very popular, being easier and less expensive to produce, as well as more compact in design.

Gear pumps, or hydraulic gear pumps, create pressure not with pistons but with the interlocking of gear teeth. When teeth are meshed together, fluid has to travel around the outside of the gears, where pressure builds.

External gear pumps facilitate flow by enlisting two identical gears that rotate against each other. As liquid flows in, it is trapped by the teeth and forced around them. It sits, stuck in the cavities between the teeth and the casing, until it is so pressurized by the meshing of the gears that it is forced to the outlet port.

Internal gear pumps, on the other hand, use bi-rotational gears. To begin the pressurizing process, gear pumps first pull in liquid via a suction port between the teeth of the exterior gear, called the rotor, and the teeth of the interior gear, called the idler. From here, liquid travels between the teeth, where they are divided within them. The teeth continue to rotate and mesh, both creating locked pockets of liquid and forming a seal between the suction port and the discharge port. Liquid is discharged and power is transported once the pump head is flooded. Internal gears are quite versatile, usable with a wide variety of fluids, not only including fuel oils and solvents, but also thick liquids like chocolate, asphalt, and adhesives.

Various other types of hydraulic pumps include rotary vane pumps, centrifugal pumps, electric hydraulic pumps, hydraulic clutch pumps, hydraulic plunger pumps, hydraulic water pumps, hydraulic ram pumps, portable 12V hydraulic pumps, hydraulic hand pumps, and air hydraulic pumps.

Rotary vane pumps are fairly high efficiency pumps, though they are not considered high pressure pumps. Vane pumps, which are a type of positive-displacement pump, apply constant but adjustable pressure.

Centrifugal pumps use hydrodynamic energy to move fluids. They feature a rotating axis, an impeller, and a casing or diffuser. Most often, operators use them for applications such as petroleum pumping, sewage, petrochemical pumping, and water turbine functioning.

Electric hydraulic pumps are hydraulic pumps powered by an electric motor. Usually, the hydraulic pump and motor work by turning mechanisms like impellers in order to create pressure differentials, which in turn generate fluid movement. Nearly any type of hydraulic pump can be run with electricity. Most often, operators use them with industrial machinery.

Hydraulic clutch pumps help users engage and disengage vehicle clutch systems. They do so by applying the right pressure for coupling or decoupling shafts in the clutch system. Coupled shafts allow drivers to accelerate, while decoupled shafts allow drivers to decelerate or shift gears.

Hydraulic ram pumps are a type of hydraulic pump designed to harness hydropower, or the power of water, to elevate it. Featuring only two moving hydraulic parts, hydraulic ram pumps require only the momentum of water to work. Operators use hydraulic ram pumps to move water in industries like manufacturing, waste management and sewage, engineering, plumbing, and agriculture. While hydraulic ram pumps return only about 10% of the water they receive, they are widely used in developing countries because they do not require fuel or electricity.

Hydraulic water pumps are any hydraulic pumps used to transfer water. Usually, hydraulic water pumps only require a little bit of energy in the beginning, as the movement and weight of water generate a large amount of usable pressure.

Air hydraulic pumps are hydraulic pumps powered by air compressors. In essence, these energy efficient pumps work by converting air pressure into hydraulic pressure.

Hydraulic pumps are useful for many reasons. First, they are simple. Simple machines are always an advantage because they are less likely to break and easier to repair if they do. Second, because fluid is easy to compress and so quick to create pressure force, hydraulic pumps are very efficient. Next, hydraulic pumps are compact, which means they are easy to fit into small and oddly shaped spaces. This is especially true in comparison to mechanical pumps and electrical pumps, which manufacturers cannot design so compactly. Speaking of design, another asset of hydraulic pumps is their customizability. Manufacturers can modify them easily. Likewise, hydraulic pumps are very versatile, not only because they are customizable, but also because they can work in places where other types of pump systems can’t, such as in the ocean. Furthermore, hydraulic pumps can produce far more power than similarly sized electrical pumps. Finally, these very durable hydraulic components are much less likely to explode than some other types of components.

To make sure that your hydraulic pumps stay useful for a long time, you need to treat them with care. Care includes checking them on a regular basis for problems like insufficient fluid pressure, leaks, and wear and tear. You can use diagnostic technology like discharge sensors to help you with detect failures and measure discharge pressure. Checking vibration signals alone is often not enough.

To keep yourself and your workers safe, you need to always take the proper precautions when operating or performing maintenance and repairs on your hydraulic pumps. For example, you should never make direct contact with hydraulic fluid. For one, the fluid made be corrosive and dangerous to your skin. For two, even if the pump isn’t active at that moment, the fluid can still be pressurized and may potentially harm you if something goes wrong. For more tips on hydraulic pump care and operation, talk to both your supplier and OSHA (Occupational Safety and Health Administration).

Pumps that meet operating standards are the foundation of safe and effective operations, no matter the application. Find out what operating standards your hydraulic pumps should meet by talking to your industry leaders.

The highest quality hydraulic pumps come from the highest quality hydraulic pump manufacturers. Finding the highest quality hydraulic pump manufacturers can be hard, which is why we have we listed out some of our favorites on this page. All of those whom we have listed come highly recommended with years of experience. Find their information nestled in between these information paragraphs.

Once you have put together you list, get to browsing. Pick out three or four hydraulic pump supply companies to which you’d like to speak, then reach out to each of them. After you’ve spoken with representatives from each company, decide which one will best serve you, and get started on your project.

Wenzhou Johames Technology Co.,Ltd mainly manufacture and export industrial pumps with good reputation around home and abroad. Product is exported to Europe, North America, South America, Asia, Africa, more than 45 countries and regions.

mission magnum, mission 2500 supreme, mcm250 centrifugal pump, mechanical seal, demco butterfly valve, kemper hammerseal union, varco tong dies, demco mud gate valve and oteco pressure gauge

Kunming Kunshui Industrial Pump Co., Ltd("Kunshui pump" for short) is a professional manufacturer of pump specialized in manufacturing slurry pumps with more than10 years experience in China.

GREENTECH was founded in 2000, The company is professional blower and vacuum pump manufacturer specializing in producing and supplying full range of 2BV and 2BE series liquid ring vacuum pump, vacuum compressor etc.

air operated diaphragm pump,including metal and non-metal series, widely applied in chemical, paints & coatings, food processing, pharmaceutical, construction, mining, utilities, pulp & paper, metal finishing

BLDC PUMP produces excellent small electric DC water pumps for cooling, circulation system in the various device, for fish tank aquarium, small fountains and other applications. We are a magnetic DC water pump manufacturer located in Shenzhen of China.

Shanghai Shenbao Industrial Pump Co., Ltd. is located in Minhang Development Zone in Shanghai, occupying an area of over 45,000sq.m .Shenbao has become a multi-industry enterprise and specialist in research and manufacture pump...

Slurry pumps, Vertical slurry pumps, slurry pumps, Gravel sand pumps, Dredging pumps, Paper pulp pumps, Molten Salt Pumps, End suction pumps, Double suction pumps, Multistage pumps, Boiler feed water pumps...

Wuhan EvenWall Machinery Co., Ltd. specialized in even wall thickness stator and hollow rotor for progressive cavity pump, even wall thickness stator for mineral oil transportation(artificial lift), multi lobe power section for downhole drilling motor(mud motor).

Shijiazhuang Jiurun Pump Co., Ltd is a pump engineering, manufacturing and distribution company for industrial, municipal and dewatering applications. With over 60 years’ expertise, we have developed great reputation by serving the mining, power, metallurgy, dredging, petroleum

we are a professional pump manufacturer in China with many years experience. We mainly produce slurry pump, spare parts and OEM wear resistance casting.

APK, A Pump that Keeps water moving, is the brand name of Zhengzhou Shenlong Pump Industry Co., Ltd. APK Submersible pumps is short as APK Pump. We are a large scale submersible pump manufacturer officially registered on Apr 25, 1996. Our factory is in Henan Province

Established in the year 2000, we have become one of the most supposed organizations engaged in manufacturing and supplying high grade High Pressure Piston Pump. The range of our products offered by us includes : Industrial Pumps & Motors, Rexroth Axial Piston Motor, Piston Variable Pumps, A4VSO Series Piston Pump, A11V Series Piston Variable Pump, Axial Piston Pumps, China Hydraulic Piston Pump Parts, External Gear Pump, Fixed Displacement Hydraulic Motor, Hydraulic Engine, Hydraulic Motor Wheel, Hydraulic Piston Pump, and Hydraulic Pump for Engineering and Orbital Motors. These pumps and systems are expansively used for meeting pumping various fluids and dangerous material in varied industrial purposes. Some of the exclusive features of our products are robustness, high tensile strength, sturdy construction, corrosion resistance and consistent serviceability. Further, clients can avail our complete variety in variegated shapes & sizes, depending upon their needs and application related necessities.

The Li family had ethnic Han origins, and it belonged to the northwest military aristocracy prevalent during the Sui dynasty.paternally descended from the founder of Taoism, Lao Tzu (whose personal name was Li Dan or Li Er), the Han dynasty general Li Guang, and Li Gao, the founder of the Han-ruled Western Liang kingdom.Longxi Li lineage (Li lineage[zh]; 隴西李氏), and it included the prominent Tang poet Li Bai. Aside from traditional historiography, some modern historians have suggested that the Tang imperial family might have modified its genealogy to conceal Xianbei heritage.Xianbei maternal ancestry, from Emperor Gaozu of Tang"s part-Xianbei mother, Duchess Dugu.

Map of the major protectorates of the Tang dynasty c.660, following the campaigns against the Eastern Turks (629), the Western city-states (640-648) and the Western Turks (657).

The Tang dynasty further led the Tang campaigns against the Western Turks. Early military conflicts were a result of the Tang interventions in the rivalry between the Western and Eastern Turks in order to weaken both. Under Emperor Taizong, campaigns were dispatched in the Western Regions against Gaochang in 640, Karasahr in 644 and 648, and Kucha in 648. The wars against the Western Turks continued under Emperor Gaozong, and the Western Turkic Khaganate was finally annexed after General Su Dingfang"s defeat of Qaghan Ashina Helu in 657 CE.

Although these natural calamities and rebellions stained the reputation and hampered the effectiveness of the central government, the early 9th century is nonetheless viewed as a period of recovery for the Tang dynasty.Jiangnan region to the south, such as Yangzhou, Suzhou, and Hangzhou prospered the most economically during the late Tang period.government monopoly on the production of salt, weakened after the An Lushan Rebellion, was placed under the Salt Commission, which became one of the most powerful state agencies, run by capable ministers chosen as specialists. The commission began the practice of selling merchants the rights to buy monopoly salt, which they would then transport and sell in local markets. In 799 salt accounted for over half of the government"s revenues.Tangshu (Old Book of Tang) compiled in the year 945 recorded that in 828 the Tang government issued a decree that standardized irrigational square-pallet chain pumps in the country:

In the second year of the Taihe reign period [828], in the second month... a standard model of the chain pump was issued from the palace, and the people of Jingzhao Fu (d footnote: the capital) were ordered by the emperor to make a considerable number of machines, for distribution to the people along the Zheng Bai Canal, for irrigation purposes.|

Some of the kingdoms paying tribute to the Tang dynasty included Kashmir, Nepal, Khotan, Kucha, Kashgar, Silla, Champa, and kingdoms located in Amu Darya and Syr Darya valley.Shabolüe Khan (d. 658) was put down at Issyk Kul in 657 by Su Dingfang (591–667), Emperor Gaozong established several protectorates governed by a Protectorate General or Grand Protectorate General, which extended the Chinese sphere of influence as far as Herat in Western Afghanistan.

Although they were formerly enemies, the Tang accepted officials and generals of Goguryeo into their administration and military, such as the brothers Yeon Namsaeng (634–679) and Yeon Namsan (639–701). From 668 to 676, the Tang Empire would control northern Korea. However, in 671 Silla broke the alliance and began the Silla–Tang War to expel the Tang forces. At the same time the Tang faced threats on its western border when a large Chinese army was defeated by the Tibetans on the Dafei River in 670.Unified Silla.

The Sui and Tang carried out successful military campaigns against the steppe nomads. Chinese foreign policy to the north and west now had to deal with Turkic nomads, who were becoming the most dominant ethnic group in Central Asia.marriage alliances with Turkic clan leaders, in 597, 599, 614, and 617. The Sui stirred trouble and conflict amongst ethnic groups against the Turks.a major militarized force employed by the Chinese. When the Khitans began raiding northeast China in 605, a Chinese general led 20,000 Turks against them, distributing Khitan livestock and women to the Turks as a reward.fubing Chinese conscripts, the majority of the troops led by Turkic generals were of non-Chinese origin, campaigning largely in the western frontier where the presence of fubing troops was low.desinicized people.

While the Turks were settled in the Ordos region (former territory of the Xiongnu), the Tang government took on the military policy of dominating the central steppe. Like the earlier Han dynasty, the Tang dynasty (along with Turkic allies) conquered and subdued Central Asia during the 640s and 650s.Göktürks, but also separate campaigns against the Tuyuhun, the oasis city-states, and the Xueyantuo. Under Emperor Gaozong, a campaign led by the general Su Dingfang was launched against the Western Turks ruled by Ashina Helu.

Although the Silk Road from China to Europe and the Western World was initially formulated during the reign of Emperor Wu (141–87 BC) during the Han, it was reopened by the Tang in 639 when Hou Junji (d. 643) conquered the West, and remained open for almost four decades. It was closed after the Tibetans captured it in 678, but in 699, during Empress Wu"s period, the Silk Road reopened when the Tang reconquered the Four Garrisons of Anxi originally installed in 640,

There were many other mechanical inventions during the Tang era. These included a 3 ft (0.91 m) tall mechanical wine server of the early 8th century that was in the shape of an artificial mountain, carved out of iron and rested on a lacquered-wooden tortoise frame. This intricate device used a hydraulic pump that siphoned wine out of metal dragon-headed faucets, as well as tilting bowls that were timed to dip wine down, by force of gravity when filled, into an artificial lake that had intricate iron leaves popping up as trays for placing party treats.

Midway up the southern side of the mountain was a dragon... the beast opened its mouth and spit brew into a goblet seated on a large [iron] lotus leaf beneath. When the cup was 80% full, the dragon ceased spewing ale, and a guest immediately seized the goblet. If he was slow in draining the cup and returning it to the leaf, the door of a pavilion at the top of the mountain opened and a mechanical wine server, dressed in a cap and gown, emerged with a wooden bat in his hand. As soon as the guest returned the goblet, the dragon refilled it, the wine server withdrew, and the doors of the pavilion closed... A pump siphoned the ale that flowed into the ale pool through a hidden hole and returned the brew to the reservoir [holding more than 16 quarts/15 liters of wine] inside the mountain.

Wechsler, Howard J. (1979). Sui and T"ang China, 589–906. Part 1. Cambridge, England: Cambridge University Press. p. 151. ISBN 978-1139055949. This genealogy claimed by the T"ang royal house established its claim to be descended from a notable Han clan and to be members of a prominent north-western lineage. However, there is some reason to believe that this line of descent, presented as solid fact by the T"ang histories, was in fact a deliberate fabrication.... Two of the men who, it has been suggested, were among the ancestors of Li Hu [grandfather of Li Yuan] were the generals Li Ch"u-ku-pa and Li Mai-te, whose names show that they had either adopted or been granted the Chinese surname Li, but retained alien, perhaps Hsien-pei, personal names.

We realize that the longer your snow plow is out of commission, the less money you make. Our goal is to keep you up and running so your customers are pleased with the job you do. However, we all know that cold weather can wreak havoc on outside equipment and you can only make money if your snow plow is in working order. Most of the time it is a quick fix like a cracked hose, or a broken spring; but this is not always the case and you can count on Mill Supply to help you in those harder times too. Mill Supply has been selling snow plow parts since 1986. Many in our sales staff have been on-the-job for over 30 years. With that kind of knowledge you can be assured that we can assist you with your questions and get the right parts sent out right away. Most orders placed before 3:00 PM EST will get shipped out the same day. So if your Meyer, Western, Boss, Fisher, or other snow plow needs some maintenance, order today! If you"re unsure as to what exactly you need, you can either contact us via email or give us a call at 800-888-5072 between 8:00 a.m. - 5:00 p.m. E.S.T. and one of our experienced representatives will be happy to help you.

Our staff are usually in the spirit of "continuous improvement and excellence", and while using the top-quality high-quality items, favorable value and superior after-sales services, we try to acquire each and every customer"s belief for China Hydraulic Travel Motor, Electric Winch 10 Ton Double Drum Electric Winch, Micro Electric Winch, Excavator Swing Motor Assy,Marine Electric Hydraulic Crane. Welcome all prospects of residence and abroad to visit our organization, to forge a outstanding potential by our cooperation. The product will supply to all over the world, such as Europe, America, Australia,Estonia, Albania,Panama, Vietnam.As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

8613371530291

8613371530291