what causes hydraulic pump cavitation in stock

The second leading cause of hydraulic pump failure, behind contamination, is cavitation. Cavitation is a condition that can also potentially damage or compromise your hydraulic system. For this reason, understanding cavitation, its symptoms, and methods of prevention are critical to the efficiency and overall health of not just your hydraulic pump, but your hydraulic system as a whole.

The product of excessive vacuum conditions created at the hydraulic pump’s inlet (supply side), cavitation is the formation, and collapse of vapors within a hydraulic pump. High vacuum creates vapor bubbles within the oil, which are carried to the discharge (pressure) side. These bubbles then collapse, thus cavitation.

This type of hydraulic pump failure is caused by poor plumbing, flow restrictions, or high oil viscosity; however, the leading cause of cavitation is poor plumbing. Poor plumbing is the result of incorrectly sized hose or fittings and or an indirect (not straight or vertical) path from the pump to the reservoir. Flow restrictions, for example, include buildup in the strainer or the use of an incorrect length of hose or a valve that is not fully open. Lastly, high oil viscosity—or oil that is too viscous—will not flow easily to the pump. Oil viscosity must be appropriate for the climate and application in which the hydraulic pump is being used.

The greatest damage caused by cavitation results from the excessive heat generated as the vapor bubbles collapse under the pressure at the pump outlet or discharge side. On the discharge side, these vapor bubbles collapse as the pressure causes the gases to return to a liquid state. The collapses of these bubbles result in violent implosions, drawing surrounding material, or debris, into the collapse. The temperature at the point of implosion can exceed 5,000° F. Keep in mind that in order for these implosions to happen, there must be high vacuum at the inlet and high pressure at the outlet.

Cavitation is usually recognized by sound. The pump will either produce a “whining” sound (more mild conditions) or a “rattling” sound (from intense implosions) that can sound like marbles in a can. If you’re hearing either of these sounds, you first need to determine the source. Just because you hear one of these two sounds doesn’t guarantee that your hydraulic pump is the culprit.

To isolate the pump from the power take-off (PTO) to confirm the source, remove the bolts that connect the two components and detach the pump from the PTO. Next, run the PTO with no pump and see if the sound is still present. If not, it is safe to assume your hydraulic pump is the problem.

Another sign you may be experiencing cavitation is physical evidence. As part of your general maintenance, you should be inspecting and replacing the hydraulic oil filter"s elements at regular intervals based on the duty cycle of the application and how often it is used. If at any time during the inspection and replacement of these elements you find metallic debris, it could be a sign that you’re experiencing cavitation in the pump.

The easiest way to determine the health of your complete hydraulic circuit is to check the filter. Every system should have a hydraulic oil filter somewhere in-line. Return line filters should be plumbed in the, you guessed it, return line from the actuator back to tank—as close to the tank as possible. As mentioned earlier, this filter will have elements that should be replaced at regular intervals. If you find metallic debris, your pump could be experiencing cavitation. You’ll then need to flush the entire system and remove the pump for inspection.

Conversely, if you’ve already determined the pump to be damaged, you should remove the filter element, cut it open, and inspect it. If you find a lot of metal, you’ll need to flush the entire system and keep an eye on the other components that may be compromised as a result.

Once cavitation has been detected within the hydraulic pump, you’ll need to determine the exact cause of cavitation. If you don’t, cavitation can result in pump failure and compromise additional components—potentially costing you your system.

Since the pump is fed via gravity and atmospheric pressure, the path between the reservoir and the pump should be as vertical and straight as possible. This means that the pump should be located as close to the reservoir as is practical with no 90-degree fittings or unnecessary bends in the supply hose. Whenever possible, be sure to locate the reservoir above the pump and have the largest supply ports in the reservoir as well. And don"t forget, ensure the reservoir has a proper breather cap or is pressurized (3–5 PSI), either with an air system or pressure breather cap.

Be sure the supply line shut-off valve (if equipped) is fully open with no restrictions. This should be a “full-flow” ball valve with the same inside diameter (i.d.) as the supply hose. If feasible, locate a vacuum gauge that can be T’d into the supply line and plumb it at the pump inlet port. Activate the PTO and operate a hydraulic function while monitoring the gauge. If it reads >5 in. Hg, shut it off, and resume your inspection.

A hose with an inner bladder vulcanized to a heavy spiral is designed to withstand vacuum conditions as opposed to outward pressure. The layline will also denote the size of the hose (i.d.). You can use Muncie Power’s PPC-1 hydraulic hose calculator to determine the optimal diameter for your particular application based on operating flows.

Another consideration, in regards to the inlet plumbing, is laminar flow. To reduce noise and turbulence at the pump inlet, the length of the supply hose should be at least 10 times its diameter. This means that any type of shut-off valve or strainer at the reservoir should be at least 10 diameters from the pump inlet. A flared, flange-style fitting at the pump inlet can also reduce pump noise by at least 50 percent compared to a SAE, JIC, or NPT fitting.

Selecting the proper viscosity of hydraulic fluid for your climate and application is also critical. Oil that is too viscous will not flow as easily to the pump. Consult your local hydraulic oil supplier for help selecting the optimal fluid viscosity.

By maintaining a regular maintenance schedule, remaining vigilant for any signs or symptoms, and taking preventative measures, the good news is that you should be able to prevent cavitation and experience efficient operation for the duration of your pump’s lifespan.

Poor plumbing is the leading cause of cavitation and can be prevented by selecting a properly sized hose, choosing the appropriate fittings, ensuring the most direct, straight routing from the pump to the reservoir, etc.

Cavitation is the term used to describe the formation of gas cavities within a liquid. In a hydraulic system, this is normally taken to mean formation of vapor bubbles within the oil. But it can also mean dissolved air coming out of solution in the oil.

In a hydraulic system, the formation of gas cavities is usually, but not always, associated with the presence of a vacuum (negative gauge pressure). And the presence of vacuum-induced, mechanical forces can be far more damaging to hydraulic components than pressure-induced bubble implosion.

Whatever the cause, cavitation is detrimental to the long-run reliability of any hydraulic system. Which means tolerating its occurrence is a costly mistake.

Although cavitation can occur anywhere in a hydraulic system, it commonly occurs within the suction line of a pump. This will cause excessive noise in the pump – generally a high pitched “whining” sound. However, this excessive noise is only the tip of the iceberg! The real result of this phenomenon is severe pump damage and a decrease in pump life. I have personally seen many instances where a customer was replacing pumps frequently, thinking they were receiving defective pumps from their vendor. In reality, the pump failures were not due to poor pump quality – the failures were occurring because of cavitation.

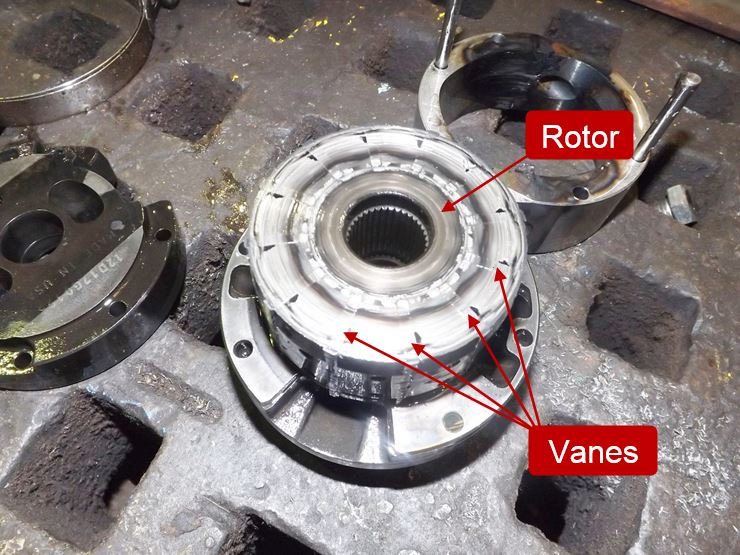

Simply put, cavitation is the formation of vapor cavities in the hydraulic oil. In hydraulic pumps, cavitation will occur any time the pump is attempting to deliver more oil than it receives into the suction (inlet) line. This is commonly referred to as “starvation” and results from a partial vacuum in the suction line. To fully illustrate what is happening when this occurs, we need to discuss vapor pressure. Vapor pressure is the pressure below which a liquid at a given temperature will become a gas, and this pressure varies significantly depending on the liquid. Generally, as the temperature of a liquid rises, the vapor pressure will proportionally increase. Likewise, as the temperature decreases, the vapor pressure will decrease. Most of us know that water will boil (turn to vapor) at 212°F (100°C) at 14.7 PSI (atmospheric pressure at sea level). In other words, the vapor pressure of water at 212°F is 14.7 PSI. If the pressure is reduced, the temperature at which the water boils will be reduced. If the temperature is lowered, the vapor pressure will decrease. In fact, water will boil at room temperature if the pressure is sufficiently reduced! The same principle applies to hydraulic oil, although the vapor pressure will be somewhat different than that of water. The vapor pressure of hydraulic oil is somewhere between 2 and 3 PSI at normal temperatures. In ideal conditions, the pressure in the suction line of the pump will be around 14.7 PSI at sea level. Of course, this pressure decreases with altitude, but sufficient pressure will normally be maintained in the suction line to prevent cavitation of the oil. However, if the pressure in the suction line of the pump is sufficiently reduced to the vapor pressure of the oil, vapor cavities will form. As the oil passes from the suction line to the outlet of the pump, the pressure will increase and the vapor cavities will implode violently. These extremely powerful implosions will cause erosion and premature failure of the pump components. In fact, a brand-new pump can be destroyed in a matter of minutes if the cavitation is severe enough. The picture below shows a rotor and cam ring from a vane pump that had failed due to severe cavitation.

In my 35-plus years of troubleshooting hydraulic components, this is the worst case of cavitation damage I have ever seen. In addition to the usual erosion of the parts, the vanes were actually fused to the rotor slots! Although this is an extreme example, it shows the potential damage to a pump due to cavitation. The good news is that cavitation is preventable and we will look at several conditions that can trigger this phenomenon.

Cavitation is the second leading hydraulic pump failure cause, behind contamination. As this can potentially cause damage and compromise your hydraulic system, it is important to understand what it is as well as its symptoms.

Cavitation is the product of excessive vacuum conditions created at the hydraulic pump’s inlet. This causes high vacuums to create vapour bubbles within the hydraulic oil, these are then carried to the discharge side before they then collapse - causing cavitation to occur.

These high vacuums and cavitation are often caused by poor plumbing, flow restrictions, or high oil viscosity. Poor plumbing is often the main cause of this and is due to an incorrectly sized hose or fittings and/or an indirect (not straight or vertical) path from the pump to the reservoir.

The easiest way to identify cavitation is through noise. The hydraulic pump will either emit a “whining” or a “rattling” sound. If you hear either or both of these sounds you will need to isolate the pump to make sure that this is where it is coming from.

As part of your general maintenance, you should be inspecting and replacing the hydraulic oil filter"s elements at regular intervals based on the duty cycle of the application and how often it is used. If when replacing the filter you come to find metallic debris this could be a sign that cavitation is occurring within the pump. In this case it is best to flush the entire system and detach the pump for closer inspection.

When replacing the filter you find that it is damaged, this could be due to cavitation. To find out if this is the case, remove the filter element of the hydraulic system and inspect for metallic debris. If there is some present then flush the system to prevent damage being caused elsewhere. Now that you have identified cavitation has been occurring within the hydraulic pump, you’ll need to determine the exact cause of cavitation.

As there are so many causes and damage results from cavitation, it is important to regularly check your hydraulic pump for signs of cavitation. By simply checking the pump and filter you can prevent your hydraulic system from failing when you most need it.

Hydraulic pumps come in a variety of sizes, styles and fuel types, so if you are having issues with your pump browse our great range for a replacement or get in contact with our expert team for advice on any hydraulic issue.

A variety of factors within the system could produce such a vacuum. When fluid enters the hydraulic pump and is compressed, the small air bubbles implode on a molecular level. Each implosion is extremely powerful and can remove material from the inside of the pump until it is no longer functional. Cavitation can destroy brand new pumps in a matter of minutes, leaving signs of physical damage including specific wear patterns. The process of cavitation destroying a hydraulic pump also has a distinctly audible sound similar to a growl.

The good news is that cavitation need not be a common problem in hydraulic systems. A few design flaws are largely responsible for causing cavitation: improper configuration of pump suction lines and the use of suction-line filters or strainers. To prevent these causes of cavitation and ensure the creation of a quality hydraulic system with a long, productive life, seven design elements must be properly executed:

In addition to improper pump suction-line configurations, suction-line filters or strainers can be a leading cause of cavitation. These filters are often placed under the oil reservoir, and thus are rarely serviced properly due to their inconvenient location. With this configuration, the entire reservoir has to be drained and disassembled in order to the reach the filter, so this necessary task is often neglected. As the filter becomes increasingly full of debris over time due to a lack of regular maintenance, not enough fluid will flow to the pump, and cavitation will occur.

Such causes of cavitation can be prevented using a series of correct design practices based on the specific needs and functions of a hydraulic system. Many systems are unique, so an experienced engineer with a firm grasp on each of these concepts must ensure the proper installation and maintenance of a hydraulic system.

Air bubbles in hydraulic fluid first originate is in the reservoir. New oil being introduced into the reservoir can cause turbulent flow, stirring up the oil and introducing air into the fluid, which can lead to cavitation. A correctly designed reservoir tank will prevent this issue.

The size of the tank and the amount of fluid that needs to rest before being extracted depends on the amount of system flow. However, a minimum 4 to 1 tank capacity to flow rate ratio is recommended — four times the oil available in the reservoir at any given time than is needed for extraction to send to the pump. This ensures that the pump will receive clean oil and the oil spends enough time in the reservoir for air bubbles and impurities to work their way out.

Beyond properly designing the reservoir itself, it’s important to include the correct accessories to ensure proper functionality. The breather filter is perhaps the most important accessory for maintaining the correct conditions for the hydraulic fluid in the tank.

When fluid is drawn from the reservoir by the pump, and an equal amount isn"t returned, the oil level will drop. To regulate the pressure and prevent forming a vacuum, air needs to be introduced to the tank to occupy the extra volume created upon removal of the oil. A breather filter performs this function, which helps avoid cavitation.

Incorrect design and configuration of suction lines is the primary cause of cavitation in hydraulic systems. For this reason, it’s crucial to use correct design practices when designing the suction lines, such as using the proper line size, minimizing fittings on the line, and properly sizing the ball valve to handle the amount of flow through the line.

The size of a suction line should be large enough for the liquid’s area to flow through at the correct rate and in the correct amount. Because the pump needs to be constantly supplied with oil, it becomes obvious how a line that’s too small could prevent this essential function. The exact specifications of a suction line in terms of length and width can’t be determined in a general sense — it requires a skilled engineer with a firm grasp of the process to make the correct decision on this specification.

Another best practice to consider when configuring suction lines is to include a lock on the suction ball valve, preventing it from being accidentally closed or left partially closed during the pump’s operation. Shutting off the flow of a suction line during pump operation will have cataclysmic effects on the system.

For example, the oil can be filtered upon entering the reservoir tank rather than when leaving the tank. Or a off-line (kidney loop) filtration system can be used to pull the oil out of the tank, filter it, and reinsert it before it’s extracted and sent to a hydraulic pump. These solutions allow for greater ease of maintenance and lower the chance of system failure.

A key aspect of a hydraulic system is a pump that’s properly sized to handle the flow rate and amount of fluid in the system. Again, this decision must be made by an experienced engineer with a good understanding of the entire process. A pump’s size can be determined by incorporating several variables of the process into a standard equation while also considering unique application conditions.

Another key element within a hydraulic system is to maintain the proper fluid temperature. If the hydraulic fluid gets too cold, it can become too viscous, increasing pressure drop in fluid lines and eventual cavitation in the pump. On the other hand, overheated hydraulic fluid can become too thin, compromising its ability to lubricate the hydraulic pump.

To regulate the temperature of the fluid, electric heating elements can be placed in the reservoir to keep the fluid at the ideal temperature of 110°F. Hydraulic systems often heat themselves naturally, so it’s also important to monitor for temperatures in excess of 110° and provide a heat exchanger or operate the system at reduced capacity.

Most systems use a flooded suction design, meaning that the pump is placed below the oil level to achieve net positive suction. The oil comes out of the reservoir above the location of the pump, which means gravity is used to assist in creating pressure into the pump and suction line. This represents the ideal configuration for a pump in a hydraulic system.

The alternative to this layout is non-flooded suction, in which the pump is placed on top of the tank. This configuration is often used to save space in a system with a limited footprint, but results in several disadvantages. For instance, the pump has to perform the extra work of pulling the oil up against gravity to create a vacuum and then pump the fluid out, which inherently creates restrictions by working against gravity. Also, certain types of pumps will function poorly in a non-flooded suction layout. In these cases, a charge pump can be used to provide positive pressure in the pump suction line.

If each of these design elements is carefully considered while engineering a hydraulic system, the risk of cavitation damaging or destroying hydraulic pumps should decrease significantly. Latest from Valin"s Blog

Two leading causes why hydraulic pumps usually fail are: (1) contamination and (2) cavitation. In order to prevent any potential damage to your entire hydraulic system, it’s imperative to understand cavitation, the indications or symptoms from your system it is occurring, as well as the preventive measures.

How does cavitation happen exactly? It starts when vapor bubbles in the oil are created due to high vacuum. When these vapor bubbles are carried and collapsed on the pump outlet (discharge side), cavitation happens.

Make Sure Oil flow Paths are Straight – Hydraulic pumps are being supplied via atmospheric pressure and gravity, so it’s ideal to place the reservoir above it. Make sure that the path is as straight and vertical as possible. Keep an eye on bent or twisted supply hose.

Check Laminar Flow – If you’re hearing turbulence or noise in pump inlet, make sure that the supply hose length is the correct ratio to its diameter. A flange-style, flared fitting in the pump inlet can also help in eliminating pump noise.

Check Proper Viscosity – It"s important to choose the hydraulic fluid with appropriate viscosity for your application and climate. Consult with your supplier for professional help in choosing the optimal fluid viscosity.

With regular maintenance, keeping an eye on symptoms, and taking preventive measures, you’d be able to avoid cavitation and expect efficient operation from your hydraulic pumps.

When designing a hydraulic system, it is important to understand the difference between cavitation and aeration—and understand the damage they can create.

As previously discussed in our April issue, it is critical to maintain proper fluid levels in the reservoir to ensure the Net Positive Suction Head Available (NPSHA) is greater than the Net Positive Suction Head Required (NPSHR) by the pump.

Anytime the NPSHA is equal to the NPSHR, the flow instabilities in the fluid moving to and through the pump will be affected to the point cavitation can (and will be) generated.

Aeration is a process where air is circulated with, mixed with or dissolved in the hydraulic fluid. It is created when air leaks into the system through the pump seals, pipe fittings and unions, which are all areas where air leakage is common.

Although you can not see cavitation, a demonstration at Eaton’s training facility in Maumee, Ohio, shows an extreme example of the effects of excessive air in hydraulic fluid.

Cavitation, on the other hand, is the formation of gas bubbles that create vapor cavities in a liquid. It occurs when the gas bubbles in the liquid are subjected to rapid changes of pressure. This higher pressure causes the air bubbles to implode, which generates an intense miniature water hammer (shock wave). This shock wave creates significant wear as the gas bubbles implode on or near a metal surface, causing cyclic stresses through repeated implosions.

Cavitation occurs when the volume of fluid demanded by any part of a hydraulic circuit exceeds the volume of fluid being supplied. This causes the absolute pressure in that part of the circuit to fall below the vapor pressure of the hydraulic fluid. This will result in the formation of gas bubbles.

The difference between the two is in how the air is getting into the system. Cavitation is caused by NPSHA, and can be stopped by simply slowing the fluid flowing through the system. If the problem is aeration, on the other hand, you have to locate and isolate the air leaking into the system, so resolving the problem can be more time-consuming. The damage by both is equal, however.

Abnormal noise in hydraulic systems is often caused by aeration and/or cavitation. Air in the hydraulic fluid makes a banging or knocking noise when it experiences high and low system pressures as it circulates through the system.

In addition to damaging seals and reducing the service life of the hydraulic fluid, high fluid temperature can cause damage to system components through boundary lubrication as a result of excessive thinning of the oil film (lower viscosity index), which in turn causes full film lubrication loss.

Slow operation, or a reduction in system performance, is often the first indication that there is something wrong. In a hydraulic system, flow controls speed and response. Therefore, a loss of speed indicates a loss of flow.

Consequences of cavitation in a hydraulic system can be serious. Cavitation causes metal erosion, thus damaging the system components and contaminating the fluid. Cavitation can also cause mechanical failure of system components.

Cavitation can occur anywhere within the hydraulic circuit; however, hydrodynamic cavitation commonly occurs at the pump. The pump suction line between the reservoir and pump should be open and not restricted. If the pump has an inlet strainer or filter, it is important to prevent it from becoming clogged. A partially closed suction valve or restricted intake line will cause the velocity of the fluid in the intake line to increase, causing the boiling temperature of the fluid to decrease as the fluid pressure goes below vapor pressure. This will vaporize some of the fluid molecules.

The damage caused by unresolved cavitation to a hydraulic system can be extremely expensive and cause extensive downtime. Prevent this problem with proper system design and maintenance. And always, listen to your hydraulic system. A rattling or knocking noise is not the sound of a welcome visitor.

Pump cavitation is one of the most searched topics on fluid power, which is justified, because cavitation is unfortunately an all-too-common cause of pump failure on mobile equipment. Liquids are able to hold dissolved gasses in solution, and the gas saturation level within any liquid is dependent upon the pressure, the temperature and the type of liquid itself, among other things. Cavitation is literally the bubbles spontaneously formed during conditions that prevent the liquid from holding that gas in saturation, such as a drop in relative pressure.

The best example to explain the gas saturation concept and the cavitation principle can be found for a couple bucks at the convenience store—a trusty bottle of soda pop. To ensure the pop is fizzy when it hits your lips, carbon dioxide is super-saturated within the delicious beverage, and pressure maintains that artificial level of fizz until you open the bottle. Upon opening the bottle, you can see cavitation at work, as bubbles seem to form out of nowhere, and other than the fact hydraulic fluid simply has common air dissolved within itself, the principle is the same.

The problem with my example is in trying to translate some harmless bubbles that tickle your taste buds into the damage that can eat away at solid metal. Cavitation bubbles themselves do little damage just floating around in your hydraulic oil, but it’s when the bubbles reach the pressure side of your pump that they do their harm.

Cavitation bubbles would rather form within the imperfections on the surface of the metal parts of your pump, such as the lens plate of a piston pump, or the gear of a gear pump, rather than just popping into existence in the middle of the fluid. The damage from cavitation occurs when the bubbles make their way around to the pressure size of the pump, where they implode under pressure, creating super-hot jets of fluid that pierce the bubble. Because the bubbles are most often located on metal parts, these little implosion jets heat up the surface of the metal, and you end up with little pits that destroy the pump’s efficiency until it just can’t pump at all.

Cavitation is difficult to detect on mobile equipment because of the noise of the engine or the machine itself, but if it ever sounds like someone threw a bag of marbles into your pump, it’s probably a result of cavitation. However, a diesel engine knock sounds not-unlike cavitation, making it difficult to distinguish cavitation noise, especially from inside the cab. Also, cavitation can be unnoticeable even in quiet ambient conditions if it’s not severe, and damage may not be discovered until the pump fails.

Because cavitation is bad, and cannot be corrected or repaired by your dentist, I’m going to give you seven tips on how to avoid cavitation in your hydraulic system. If these tips are heeded, I promise you cavitation will be a thing of your past, like your plaid grunge look or that weekend in Bangkok.

1 – Don’t use a suction strainer. Suction strainers are installed in the reservoir on the suction line of the hydraulic pump. They are intended to protect the pump from ingesting dirt and filth, which should subsequently protect the pump. However, think about the method in which a suction strainer prevents dirt from entering the pump; it collects it across its flow path. Larger particles and other junk get trapped in the suction strainer, but over time it gets clogged.

Most often, maintenance personnel don’t know the power unit even has a suction strainer, so it can get overlooked during routine maintenance, especially because most mobile reservoirs have no clean-out panel. Don’t get me wrong, it could take an easy decade to clog a suction filter, but when it does clog, it will cause slowly increasing levels of cavitation. You might as well have a clamp over the suction hose that you tighten at regular intervals. The biggest problem I have with suction strainers is that they’re redundant anyway if your hydraulic system is designed and maintained well to begin with.

2 – Ensure pumps have flooded suction. A pump can create vacuum at the inlet port to pull up fluid a short distance, but excessive pump head height will cause cavitation. A flooded suction condition uses the force of gravity and atmospheric pressure to push fluid into the pump, rather than the pump having to draw it in. A flooded suction is easy for PTO-mounted pumps because the pumps sit so low in the chassis, but with pumps driven off the engine, you may want to consider mounting your tank high on the machine to compensate for the long run to the front of the truck. With a pump mounted below or to the side of the reservoir, cavitation is nearly impossible unless something catastrophic occurs, like a rag being thrown into the reservoir and blocking the suction line.

3 – Don’t leave rags in the reservoir. It may sound ridiculous for me to offer that as a suggestion, but every hydraulic technician worth their weight in oil counts the number of rags they show up to and leave a job with. The best tools for cleaning out reservoirs are rags, and you will have to trust me when I say that it’s more common than you’d think to leave them in the reservoir. And if you leave a rag in the reservoir, it will most definitely find its way to the suction tube of the pump(s), starving them and causing cavitation.

While we’re at it, be considerate of more than just rags when maintaining a hydraulic machine. I’ve heard of tools, cell phones and dead animals finding their way into reservoirs, not all of which can clog a suction strainer or pump inlet, but their existence there is cause for concern. For a possum to make its way into a tank for a nap, a cover must have been left off, and this lack of consideration for the hydraulic system is unacceptable. Reservoirs are buttoned up for a reason, so I recommend keeping it that way if you care about the health of your machine.

4 – Properly size inlet plumbing. The recommended maximum velocity for suction lines is only a few feet per second, and because the relative action of fluid being “pulled” into the pump already causes a drop in suction pressure, the condition of sucking too much fluid through a small straw will cause cavitation. By simply sizing suction plumbing large enough, especially if you’re running a pump far from the reservoir, you can reduce the chance of cavitation.

5 – Use high quality hydraulic fluid. The quality of hydraulic fluid is often overlooked, and unfortunately, the good stuff is very expensive. Synthetic hydraulic fluid has many properties making it superior to standard dino oil, which has limited capacity to work well outside a narrow window of operating conditions. Speaking on viscosity alone, thicker oil is harder to pump and is more prone to cavitation.

Problems occur during machine start-up, such as on a cold morning, when standard hydraulic fluid is rather thick, making it difficult to pump. If cold and thick oil is not given time to warm before the machine is run at full pressure, cavitation could result. Even if the period of cavitation is short, because oil can heat quickly, the damage can accumulate during every cold start. By switching to synthetic fluid with a high viscosity index, you help ensure cold starts provide little drama. Viscosity index is the quality of oil to maintain its tested viscosity over a wide temperature range, and the bigger the number, the better. So even with a 46 cSt oil which could be prone to cavitating a pump at 20° below if it were normal oil, a high quality oil will still be relatively thin and easy to pump.

6 – Heat your hydraulic oil. Odd as it may sound, because heating oil in mobile machinery is rare, heating the oil before machine start-up can also help prevent cavitation due to cold-related high-viscosity. You wouldn’t fire up your rig and drive off without letting the engine warm up, so the same consideration should be paid to the hydraulic system. Oil doesn’t need much time to come up to temperature in most cases, so just running the pump to circulate oil through the system and operating some low pressure functions could heat up the oil before the serious work begins.

7 – Keep your oil dry. This recommendation comes from a specific example of pump cavitation, which could have been prevented by considering a few of these tips. This brutal past winter broke down more than one hydraulic machine, and this particular example occurred on a half-dozen machines powered by a 12 VDC electric power unit. Excessive water saturation within these power units caused ice to form on the suction strainers, both cavitating the pumps and imploding the strainers.

By following these tips, your chances of experiencing pump cavitation are slim to none. Mobile hydraulic systems already have so much to worry about; creating conditions conducive to cavitation should not be one of them.

Hydraulic cylinder cavitation is a nightmare for any hydraulic system, leading to a cascading series of damaging issues that will eventually destroy critical (and costly) components within your hydraulic system. While most people associate cavitation issues with pumps and motors, cavitation can also be a problem for hydraulic cylinders. In order to minimize or eliminate cavitation damage, knowledge of how it works and what kind of damage it leads to are good starting points. However, the wisest approach to dealing with cavitation issues is to take preventative measures.

The simplest explanation of cavitation is the presence of gas entrapped within bubbles in a liquid. In the case of hydraulic systems and components like pumps or cylinders, the liquid involved is the hydraulic fluid transmitting pressure. In hydraulic cylinders, the pressure transmitted by the fluid is used for linear actuation that can move thousands of pounds at the press of a button. Obviously, very high pressures are involved.

When these bubbles collapse on themselves (or implode), the result is noise, heat, serious surface damage, and a negative impact on efficiency and productivity. Essentially, the bubbles generate a powerful mechanical shock that results in microjets impacting nearby metal. That implosion occurs when the bubbles reach an area of low pressure that causes the vapor within them to condense. The metal begins to wear away in a process known as cavitation erosion, cavitation wear, or cavitation pitting.

Cavitation can also occur when air is trapped within the hydraulic fluid (a phenomenon known as aeration). As pressure increases (e.g., as the rod closes in on the end cap in a hydraulic cylinder) the bubbles violently burst. In a hydraulic cylinder, cavitation most often occurs on the cap side of the piston when it is extending quickly, and especially when it is attempting to stop an over-running load. It also occurs when the rod is pointing downward while supporting a heavy tensile load on the end. Some experts would argue that this is not true cavitation, but its effects are the same.

One of the easiest ways to detect cavitation in a hydraulic cylinder is by sound: when cavitation bubbles implode, you can hear them in the form of an intense rattling sound. You will also notice pitting on the surface of parts affected by cavitation; in the case of hydraulic cylinders, it can be found on the surface of the rod and the inside surface of the cylinder.

Cavitation can lead to multiple problems within a hydraulic system as a whole, as well as hydraulic cylinders. These include accelerated wear of critical surfaces, seal failure, generation of unwanted heat, reduction in hydraulic oil quality, and lubrication issues.

One of the most serious problems caused by cavitation is surface wear, sometimes known as pitting. Keep in mind that the vapor bubbles implode at an almost molecular level, releasing a tremendous amount of force over an incredibly small area. That leads to high stresses — stresses high enough to remove metal from surfaces adjacent to those bubbles. The result is highly accelerated wear in the form of surface pitting and internally generated contamination. The metal particles removed from the surface will stay within the system and can cause the formation of even more cavitation bubbles.

Also, keep in mind that surface finish can be an important factor in many applications, and especially with hydraulic cylinders. When selecting an appropriate seal for a hydraulic cylinder, the surface finish of the rod is critical. If the rod is experiencing pitting due to cavitation, it will cause premature wear of the seal. As the seal begins to wear, hydraulic fluid can leak out (reducing performance) and environmental contaminants such as dust and moisture can make their way inside.

The bubble implosions also lead to high temperatures, sometimes reaching up to 5,000°F. In addition, as the surface is damaged, there will be increased friction as fluid flows over. That friction results in not only system losses and lower efficiency but also unwanted heat generation. This is one of the reasons why excessive heat can also be a strong indicator of cavitation.

Because of the high temperatures that can result from cavitation, the hydraulic fluid is very likely to suffer degradation (an overall reduction in fluid quality). Excessive heat and high temperatures will cause the fluid to age more rapidly than normal, seriously affect the additives present, and reduce the viscosity of the fluid.

The presence of bubbles within the hydraulic fluid can also cause a lack of lubrication, resulting in metal-to-metal contact and premature wear. This type of wear takes on a different form than that resulting directly from cavitation implosion and explosion: it will look like abrasions in a pattern consistent with the movement of the metal parts rather than pitting.

One of the means of preventing cavitation lies in temperature control. If the hydraulic fluid is too viscous, pressure drops will become more of a problem; this increase in viscosity can be the result of hydraulic fluid at a less than ideal temperature. In addition, high temperatures combined with low pressures can also cause cavitation, so care needs to be taken to ensure that the hydraulic fluid is as close as possible to an ideal operating temperature. In some instances, this can be as simple as insulating hydraulic pipes against direct sunlight.

Piping losses can contribute to cavitation and result from issues such as the use of too many fittings, a collapsed pipe liner or suction pipe, a gasket protruding into the pipes, a replacement pump that has too much capacity for the system, or the buildup of solids on the interior surface of the pipes.

Another way to prevent cavitation that is especially applicable to hydraulic cylinders is to prevent air from entering the hydraulic system. For example, hydraulic systems and some components should be bled properly after they are filled (or refilled) to release the air trapped within the system. When additional fluid is added to the system, it should be introduced gently to prevent splashing and agitation — both of which can allow air to be entrained with the fluid. In addition, improperly designed hydraulic reservoirs can inadvertently encourage the entrapment of air within the hydraulic fluid.

The presence of contaminant particles within hydraulic fluid can serve as a starting point for cavitation bubbles to form, so keeping the hydraulic fluid clean and the system free of contaminants can be an excellent starting point. This involves changing hydraulic filters as needed, filtering any hydraulic fluid that enters the system, and addressing leaks as soon as they are detected.

When parts have experienced surface damage due to cavitation, repairs are often a lost cause. For parts with a circular geometry, such as rods and cylinders, the pitting damage is often too deep by the time it is discovered for polishing to work because rods and cylinders must meet very strict surface conditions and geometric tolerances. Unless the damage was discovered quickly, it would be wiser to replace the damaged components. For seals that have been damaged as a side-effect of cavitation, replacing the lip of the seal may be enough.

Cavitation causes so much damage: accelerated surface wear in the form of pitting, premature seal failure, generation of unwanted heat, compromised hydraulic fluid quality, and lack of lubrication leading to additional wear. The best way to deal with cavitation is to take measures to prevent it because once it wreaks havoc on the surfaces of equipment (including hydraulic cylinders), it can be extremely difficult if not impossible to repair. Preventative measures against cavitation are the wisest course of action and can often include basic maintenance principles (e.g., bleeding air out of the system, filtering hydraulic fluid). As soon as hydraulic cylinders start making rattling noises or become hotter than normal, it is time to get them checked out.

At MAC Hydraulics, our highly skilled team can maintain, troubleshoot, and repair hydraulic systems and components, including hydraulic cylinders. Our repair services include replacing seals, polishing rods, and honing tubes — and we also have a 24-hour resealing pick up and delivery service. MAC Hydraulics can manufacture custom cylinders, tubes, and rods with our state-of-the-art fabrication facilities and service any brand equipment from industries including construction, recycling, manufacturing, rental, aviation, and waste handling. If you are experiencing symptoms that are consistent with cavitation, we will help you track down the cause and keep it from happening again.

Most modern hydraulic pumps are reliable, robust pieces of equipment that will withstand years of constant service. However, any hydraulic pump can suffer from mechanical issues. Aeration and cavitation are two serious problems that can affect a hydraulic pump, and either problem can cause serious damage if the issue is ignored.

However, it can be difficult to figure out if a malfunctioning pump is suffering from aeration or cavitation, as the two problems tend to produce similar symptoms. Despite these similarities, aeration and cavitation have different causes and require different solutions, so knowing the difference between the two problems is vitally important knowledge for any hydraulic pump user.

All hydraulic pumps contain a small amount of air, which provides space for the pump"s hydraulic fluid to expand into as it heats up. However, excessive amounts of air in a hydraulic system can cause serious problems.

Aeration in hydraulic pumps occurs when air is drawn into the pump"s hydraulic fluid supply. Air can infiltrate your system through perished pump seals, damaged pipe connectors, leaking suction lines, and other forms of damage. This unwanted air mixes with and dissolves into the hydraulic fluid supply.

Hydraulic fluid that has been contaminated by exposure to air loses many of its functional properties. For example, hydraulic fluid containing excess air cannot conduct heat as efficiently, so aeration can cause rapid overheating in affected pumps and other hydraulic systems. Serious aeration can also impede the pump"s stroke cycle, causing a significant drop in usable power.

For a hydraulic pump to function properly, the flow of fluid from the pump"s reservoir to the pump itself must remain constant and unimpeded. If this flow speeds up or slows down for any reason (such as improper pressure settings or a block in the suction line), this can lead to a potentially catastrophic problem known as cavitation.

When a running hydraulic pump does not receive hydraulic fluid at the proper rate, fluid pressure in the pump"s suction line can drop dramatically. This causes the formation of bubbles inside the hydraulic fluid, which contain air and vaporized hydraulic fluid. These bubbles subsequently collapse, creating an incredible amount of force and heat.

The shockwaves created by these imploding bubbles can do an incredible amount of damage to a hydraulic pump in a short space of time. The pump"s impellers and interior surfaces tend to be particularly badly affected by cavitation, and a pump that has suffered from extensive cavitation may need a complete rebuild before it can be used again.

While cavitation and aeration have different causes, they can produce similar problems, making proper diagnosis difficult. High hydraulic fluid temperatures, lowered pumping rates, and visibly damaged valve seals can all be caused by either cavitation or aeration.

Generally, the easiest way to tell the difference is by listening to the malfunctioning pump, as both types of problem usually produce distinct noises. A cavitating pump tends to produce a steady, rhythmic pattern of knocking or whining noises. Unusual noises produced by aeration are more erratic and random and tend to sound more like rattling than knocking.

However, it is important to note that cavitation and aeration are not mutually exclusive problems, and a poorly maintained hydraulic pump may suffer from both problems simultaneously. Combined aeration and cavitation can lead to a particularly damaging form of cavitation, known as gaseous cavitation.

If your hydraulic pump is suffering from any signs of cavitation or aeration, calling in a professional hydraulic repair service is usually the fastest way to get to the bottom of the problem. These services have access to specialized testing tools and equipment that can quickly detect cavitation and aeration and will be able to provide rapid and effective solutions.

If your hydraulic pumping system is not functioning as it should, and you think cavitation or aeration may be the cause, contact the hydraulic experts at Quad Fluid Dynamics, Inc., for professional advice.

When a reliable hydraulic system suddenly starts exhibiting problems, one of the first types of components most technicians assume may need to be replaced are hydraulic pumps, yet the pump should be the last component evaluated since it is often very time-consuming to replace.

There are all sorts of “warning” symptoms a hydraulic system will exhibit long before pump failure. Some of the most common types are changes in the sounds the system makes while it is in operation. If the system suddenly starts sounding different from how it has before, this could indicate various types of problems.

Two of the more common changes in sound are a banging noise, much like water banging in plumbing pipes, and or a very high pitched shrieking noise, similar to the sound sticky car brakes make. These sounds indicate aeration and cavitation in the system, which we will discuss in more detail shortly.

Another thing to check if you notice the system is not working correctly is to verify the pump is turning. Some systems are designed so that you have to manually engage or switch the pump on. You would be surprised by how many system problems are due to the pump not being turned on!

The last thing to check before getting into troubleshooting the pump is the hydraulic fluid level. If the fluid level is too low, it will allow air into the system and cause operational problems. If you discover air in the system, you will need to remove it first to avoid pump failure.

Aeration occurs when air is introduced into the hydraulic system. This can be due to defective seals, through low tank fluid level allowing air into the pump inlet line, damaged inlet hoses and connections. It is easy to check to find out if there is air in the system as the fluid returning to tank will be foamy and the oil in the tank full of bubbles.

Operating the system when air is present may result in the pump being unable to reach the pressures required to operate the system. A by-product of this problem is the generation of excessive heat. Excessive heat is of course another reason in itself for pump failure, in this case secondary to aeration but demonstrates how the primary cause can set off a vicious circle, in this case aeration, leading to excessive heat, leading to lack of lubrication, leading to contamination issues, possible partial or full bearing seizure before complete pump failure.

The opposite of aeration is cavitation. Instead of air being added to the fluid, it is removed very rapidly. Cavitation is where air bubbles form quickly and collapse inward on each other within the fluid. This occurs due to a vacuum at the pump inlet as a result of an insufficient fluid supply. As in excess of 10% by volume of hydraulic fluid is dissolved air when there is an excessive vacuum at the pump inlet it is this air that is being drawn out of the oil.

The effects of cavitation can be seen around the internal pump inlet surfaces as the air is drawn out the oil it causes the removal of tiny amounts of material from the internal pump surfaces on the inlet side. This is always particularly evident in aluminum gear pumps as it leaves a slightly pock marked or frosty looking surfaces on the bearing blocks and inside of the gear housing on the inlet side.

Every hydraulic pump has a maximum design pressure level. If you attempt to operate the pump at a higher pressure than it was designed for, it will cause premature pump failure. The pump simply cannot handle the excessive pressure.

Contaminants are one of the biggest reasons for hydraulic pump replacement. Contaminants can enter into the hydraulic system through a variety of entry points. One of the most common ones is through the hydraulic fluid reservoir.

As contaminant levels grow, they can get stuck in between key surfaces such as between gear end faces and bearing block or pressure plate or between piston barrel and valve plate in a piston pump. This then leads to further wear and the generation of more contaminant and heat. The more contaminant induced wear there is to these surfaces the larger the gap becomes between these critical surfaces leading to loss of pressure capability, overheating and failure.

The viscosity of the hydraulic fluid moving through the system could lead to premature pump failure if it is not properly maintained. Having a fluid of a higher viscosity level than specified for the pump can result in cavitation within the hydraulic pump.

On the other hand, when fluid viscosity is too low, it can lead to excessive leakage between critical surfaces leading to an increase in heat generation. As such, the fluid can become too hot, overheating the entire system, and ultimately causing premature pump failure.

Extreme heat is often caused as a byproduct of other hydraulic system problems. If you notice your system seems to be operating at a higher temperature than it normally does, take it as a warning sign that something is wrong. Continuing to operate the system can lead to more costly repairs.

Excessive heat levels not only cause parts and components to fail but also can damage drive shafts, housings, and other metal components. Additionally, damaged parts and components may not properly seal leading to fluid leaks. Furthermore, inside pumps, misalignment of moving parts could occur, causing internal damages that introduce contaminants into the system.

Many types of hydraulic pump system failures could easily be avoided with regular pump maintenance. Regular maintenance requires checking and inspecting the entire hydraulic system prior to using it. Some of the more common things you should do include:

Another vital part of maintenance is replacing worn out hoses, valves, and related parts and components when they show signs they need to be replaced. It is better to replace hydraulic system parts and components before they fail. Doing so will result in low overall maintenance and repair costs. When replacing components always make certain they are clean of dust and dirt before fitting to avoid unwanted contamination entering the system.

Furthermore, hydraulic fluid should be changed periodically as it starts to slowly break down from extended use. Your objective is to ensure the fluid provides the right viscosity level required for your hydraulic operations. Always flush the system and replace the hydraulic fluid when replacing a pump or motor and be especially vigilant in removing contaminant from every nook and cranny of the system when component failure has been due to contamination damage and the source of contamination has been ascertained.

For further help troubleshooting hydraulic pump system failures, as well as all of your hydraulic system motors, pumps, parts, and component needs, please contact White House Products, Ltd. at +44 (0) 1475 742500 today!

While it’s common for people to think of a pump’s inlet as sucking in oil, in reality, it is atmospheric pressure doing the work. In essence, the weight of the atmosphere pushes the oil out of the reservoir and into a region of lower pressure—the inlet. Once the oil is forced from the reservoir and through the inlet, it then moves the volume of liquid into a region of decreasing volume to create flow. For this process to begin, there must be minimum pressure at the inlet of a hydraulic pump, as shown in the diagram below.

As you can see, the inlet of a pump plays a large role in how well it operates. Unfortunately, those designing and maintaining pump systems can become so focused on downstream flow that they overlook proper inlet maintenance. This can result in degradation of inlet function and serious problems such as cavitation.

Cavitation occurs when the absolute pressure on the inlet side of the pump is too low and air is drawn out of the solution, creating bubbles in the oil. As these bubbles get pushed around to the high-pressure outlet side of the pump, they collapse. This creates localized shock waves that blow bits of material out of the pump. It can also result in excessive heat and reduced lubrication that leads to friction and wear over time.

Cavitation can cause pump failure and it can damage other components of your system, which is why it is critical to examine the condition of the pump"s inlet on a regular basis.

PSI versus PSIA. What’s the difference? PSI, or pounds per square inch, is a unit of measurement for pressure used in the United States. PSIA describes the absolute pressure in psi, including the pressure of the atmosphere. Absolute pressure is also referred to as total pressure.

The energy it takes to lift oil through the suction line (including pressure drop due to flow). We refer to this action as Phase 1 pressure, because it represents the amount of energy it takes to accelerate the fluid through the pumps internal pathways and keep the pump full.

In order for a pump to function, atmospheric pressure must be greater than Phase 1 pressure + NPSH. Every pump has its own specifications regarding acceptable minimum/maximum inlet pressure, but we can use the example below to illustrate how to calculate it.

To begin, assume that you are maintaining an 18 GPM hydraulic pump. The NPSH is equal to 12 PSIA with standard hydraulic oil and 1800 RPM per manufacturer’s specifications.

If we apply the same numbers to a variable-volume pump, the result will be less acceptable. Here’s why: Imagine the pump is not in demand and is therefore being held off stroke, meaning there is no flow. When the pump is suddenly needed, it will come on stroke, requiring the column of oil in the suction line to accelerate. This sudden change in demand requires the pump pressure to accelerate from static to a pressure that is strong enough to move the oil and prevent cavitation.

Assume the pump strokes on in 70 milliseconds (msec). The volume of liquid that has to accelerate is 1.5in^2 x 18.1” = 27.1 cubic inch (cu. in.). Note: Since the entire column of oil in the pipe has to accelerate, we used a measurement of 18.1” instead of 12.1”.

These calculations reveal that the system is fine, because the pump requires a minimum 12 PSIA at its inlet to operate effectively. However, if this system was installed at 2,300 feet above sea level (13.4 PSIA), the pump would cavitate whenever it came on stroke.

The above example assumes no losses due to other plumbing, however, it is not uncommon to see elbow fittings on pump ports, which could add to losses in the inlet line.

In addition to maintaining good inlet conditions, any small leak on the inlet will entrain air, which is also bad for the pump. Small leaks will cause a pump to lose prime whenever the system is shut off, which means it will start dry and run dry until prime is re-established. For this reason, it is never a good idea to install hydraulic pumps above the fluid level. Rather, hydraulic systems designs should ensure that the pump inlet is flooded, i.e. the oil level is above the pump inlet. A ball valve can be used to isolate the pump from the reservoir in case it needs service, and a limit switch can be used on the ball valve to prevent the system from running if the ball valve isn’t fully open.

Bubbles might not seem very powerful, but the types of bubbles in pumping systems are nothing like the ones you make by waving a wand around with little kids. Tiny bubbles created by changes in pressure inside pumps collapse and create shock waves that occur over and over and the repeated shocks erode the components.

Pumps are designed to work with a full flowing water supply, but in some cases a flooded inlet is not enough to maintain pressure required to prevent cavitation. The inlet, or suction side of a pump is the point of lowest pressure in a given pump.For positive displacement pumps, the lowest pressure occurs just prior to rotor meshing; for centrifugal pumps, lowest pressure is near the eye of the impeller.

Cavitation is possible in all pump types and since its principles are essentially the same, we will focus on centrifugal pumps. The eye is where fluid is drawn into the impeller and where the rotation of the impeller begins to act on the fluid. When pressure acting on the liquid (Net Positive Suction Head Available) is too low, bubbles form, and as the liquid accelerates because of impeller rotation, pressure increases and the bubbles collapse.

Under normal atmospheric pressure conditions, fluids have predictable vapor pressure. As the pressure inside the pump falls below the liquid"s vapor pressure, bubbles form. The bubbles collapse when they reach areas of the liquid where the pressure is above the vapor pressure. In the case of cavitation, this formation and collapse is both rapid and violent.Disrupted or poorly executed processing lines can cause suction or discharge pressure to fall, which leads to cavitation.

At extremely high discharge pressure, some fluid circulates inside the pump instead of discharging. Fluid trapped between impeller and housing at very high velocity cause a drop in pressure, creating the same conditions as for suction cavitation.

Cavitation sounds like marbles or gravel circulating through the pump, pipes, or hoses. The effects of prolonged cavitation are visible on the pump impeller and other components.

Start by identifying the cause of the pressure drop. In many cases moving the pump closer to the fluid source and removing as many bends and valves as possible corrects the problem because each component causes additional pressure drop. When suction lift is too high to maintain pressure, move the pump closer to the fluid source or move the fluid source closer to the pump.

Enlarging suction lines can also be effective. In some obvious cases, a blockage occurs in piping or hoses near the pump. Clear those blockages to resolve the issue.Clean suction lines by clearing debris. Avoid blowing the debris back toward the fluid source because it’s likely to create a blockage again.

Don’t exceed your pump manufacturer’s performance guidelines. Pump curves tell you how much net positive suction head the pump requires, so check your pump’s performance curve to ensure it has the right specifications for your application.

The best way to prevent cavitation is to select the right pump for the application. Cavitation increases as pump head falls or as capacity increases, so selecting the correct pump to maintain a positive margin of NPSHa above NPSHr is the best first move.

NPHS at the inlet depends on atmospheric pressure, friction losses in the suction piping, and flow velocity. A good rule of thumb is for pressure at the pump inlet t

8613371530291

8613371530291