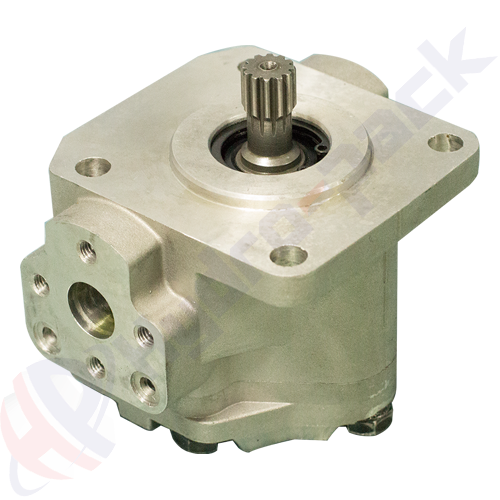

yanmar tractor hydraulic pump factory

Yanmar is a registered trademark of YANMAR Co. Ltd. Any appearance of the Yanmar name, Yanmar logo, or Yanmar part numbers are for reference purposes only and does not imply that the part is a genuine Yanmar part.

I think that my hydraulic pump is consuming itself. My 2610 has 56hrs on the meter and in the last 10 hrs or so I have been experiencing a lack of performance; the front bucket basically will not pick up more than maybe 10 lbs (my guess). I decided to change the Hyd Fluid this morning and after letting it drain for a while I noticed small particulates on the internal filter. since there is a small amount that remains within the "drainpan" I inserted a small magnet and moved it around the remaining fluid and boy was it covered with large, curly-Q metal shavings. Large meaning that if i straightened them out they would range between 1/4 and 3/8 inch.

Once I find the culprit (I think it is the Hyd pump) I still need to flush the entire system to remove any large shavings that may still be floating around in the system.

Bottom line to me is metal shavings in transmission case and possibly in hydraulic lines cannot be tolerated. There is a post just down from here from GAPAWN concerning flushing out his hydraulic system. Good reading if you haven"t and you will see different opinions. Here is my opinion on your situation. 1. If you are right and pump is bad (sounds likely to me) I would disconnect hydraulic lines as much as possible to facilitate blowing thru them. This may be a messy situation but with a little thought surely you could make a way to blow into a container with a lid on or something to catch most of the flushed material. Those metal shavings could only get to your case thru these lines if it is the pump. Once this process was complete I would fill the transmission case with diesel, drain out, take long air nozzle and blow around in case as much as is possible, thinking of going thru the dipstick hole. I would then run a quart or two of your fluid of choice thru there. Then I would intall new filter, clean strainer, fluid of choice and go for it. "If" it"s not your pump the whole senerio changes! Don Meredith once told Howard Cosell "if ifs and buts were candy and nuts, we"d all have a Merry Christmas". You guys are probably to young to remember those two.

Blah Blah blah!!! With that size and amount of metal don"t waste you time trying to make it work. If 10 pounds is all it will lift then the pump Most likely is already Gone and you will just be wasting your time. If you go pouring Diesel ( Bad Advice opinions are like a holes) into Your hydrolic system you are going to Screw something else up.

I"m certainly NO guru, but if you do decide to disconnect your hydraulic lines, let me pass along a tidbit that I learned in college about 30 years ago. Yeah, that makes me way old enough to remember Meredith & Cosell!

I took a course in "Hydraulics and Pneumatics" that was 90% hands-on lab work stuff. On the first day we were warned by the professor to always wear old clothes to class because the question was WHEN, not IF, we would disconnect a line with a load on it and spray ourselves plus a few nearby buddies with hydraulic fluid! I made it halfway thru the quarter before I took a bath in fluid, and I guarantee you that not a single one of us didn"t screw up at least once before we got out of that class.

Make sure that your front end loader bucket and three point hitch are lowered all the way to the ground and/or supported before you start pulling those hoses! Hydraulic fluid can squirt a LONG way, and make a Major mess if you disconnect a hose that has a load on it! Been there, done that, more than once!

I had planned to change my hydraulic fluid/wannabe-milkshake this weekend, but I forgot it was Easter, so I"ll have to update ya"ll on that later.....

Good luck getting to the bottom of your problem, are you sure you didn"t just have a low fluid situation or blocked filter? It may be wishful thinking, but those are very likely answers, and the shavings could possibly be left over from the manufacturing process? Or even from the gears in your tranny? It"s a long shot, but if your filter is working properly, none of the particles should have entered the system (ie: lines) unless the particles came directly from your pump.

Oh, and for what it"s worth, I have decided to drain the white, water contaminated fluid, clean the screen, then refill with hydraulic fluid, run it for a few hours, then see if I still have a milkshake mess. If so, I"ll repeat the process. I decided 2+ gallons of diesel is ~$5~ vs. ~$12~ for the 303 hydraulic fluid. It just ain"t worth screwing up a bunch of seals trying to save $7 by flushing the system with diesel. Yeah, I know, I often come up with some pretty dumb ways to save money!

Organic seals on a 75-80 Model tractor I doubt it. As for the fuel bowl that is the only seal I have had to replace when I changed my filter and tried to reuse it. I change both at the same time now it"s happened twice

I am still leaning towards the hydraulic pump as opposed to the tranny. I have no problems with any of the drive gears Creeper through 4th... In fact right now the only thing I can use is the back hoe, since it is a separate system. I can use the tractor to pull around a trailer for hay rides....if i had a trailer, and hay and grand kids....

It"s not likely those particles came from the pump. That means they would have to travel through the loader, pto, and the entire system to get back to the screen, which is the last stop before the pump.

Still Leaning that way myself. Back to clean you Screen and Hyd. fluid and go from there. I doubt that much metal came from the pump also but could be possible.

Well, it will be another couple of weeks before I can get to it, but I can drain the fresh fluid. I think that i will take the time to purge the hydraulic lines as well. I have ordered the pump, seals, etc....

Got it all put back together today and it is working like a champ. I looked at the hydraulic pump and i believe that it just has a serious amount of hours on it. I did notice that after I cleaned it up that the pump had a coat of OD green paint and not the gray that the motor has been painted.

Hydrocap is a Bulgarian company, manufacturer of mini-units and stations for industry. The company also offers a huge range of hydraulic products, spare parts and accessories.

The vast majority of subcompact, compact and larger compact utility tractors in the North America market are equipped with front end loaders. Many, if not most, come from the factory with the loader already installed.

When you look more closely at how tractor owners are putting front end loaders to work, you see that manufacturers are taking many steps to make the very popular front loader option more versatile and easier to use. Scooping stuff with the loader bucket is just not enough anymore. Tractor owners want pallet forks, bale spears, grapples and a host of other loader attachments.

To boost ease of use and versatility, manufacturers build loaders with quick attach systems making changing loader attachments fast and easy. With Yanmar tractor loaders, quick attach is standard on all Yanmar loaders. For the subcompact SA Series tractors, it is a Yanmar quick attach sized to the capabilities of the subcompact tractors. On the loaders for the larger YT2 and YT3 Series tractors, the loaders have an industry-standard, skid-steer style loader quick attach as standard equipment. That opens up the universe of loader attachments for skid-steers and tractors that all use the skid-steer style quick attachment. Some tractor brands use a proprietary quick attach design that does not allow “open – sourcing” your loader attachments.

If you’ll pardon the expression, let’s dig a little deeper into what is being done to make front end loaders more versatile and powerful tools. Loaders have long been about hydraulics to lift the loader and dump and return the bucket or other attachment. But when you move into the wider world of loader attachments, you find things like the increasingly popular grapples that need a 3rd function hydraulic circuit to operate the opening and closing of the grapple. Another 3rd function example would be attaching a hydraulic-turn snow blade to the loader. Still another example is using a 4-in-1 bucket that provides an attachment able to scoop, grapple and more in one attachment operated by the 3rd function hydraulic circuit. 3rd function circuits are usually an optional feature. They can be both factory installed and field installed by tractor dealers.

Because the universe of loader attachments is large and diverse, there are attachments that demand more than what 3rd function hydraulic circuits are designed to supply. Now we enter the world of “power – beyond” hydraulic systems. What is a front-end loader power beyond kit and how is it different from a 3rd function valve?

Power beyond kits let you use loader attachments that require high-flow hydraulics to power the attachment. Popular examples are snowblowers and rotary brooms for snow removal and grounds care work. On compact tractors, this is often accomplished by attaching an auxiliary hydraulic power unit to the 3-point hitch which is powered by the tractor’s rear power take off (PTO). The higher flow required to operate more demanding attachments like snowblowers or brooms is provided by this PTO-driven power pack that includes a hydraulic pump and hydraulic oil reservoir large enough to power a blower or broom through a long work day. The high hydraulic flow is routed through larger dedicated tubes and hoses to the front of the loader where it is delivered to the high flow attachment.

Equipping your tractor with a front power beyond kit makes the tractor even more versatile. Owners can quickly change from a hydraulic snowblower to a snow blade or back to the loader bucket. The loader stays on the tractor.

Snowblowers, brooms and other high-flow-required front attachments come in many sizes and specifications. Compare your loader lift capacity specifications, your hydraulic power pack specifications and the total attachment weight and flow requirements before you take the plunge on assigning your tractor and loader to run one of these tools. Your tractor dealer can help you make a correct match among tractor, power pack, loader and attachment.

Adding a power beyond kit to your tractor/loader package is different from another popular front attachment solution for subcompact and compact tractors. This other solution requires removing the loader arms and installing a front hitch specifically designed to operate blades, snowblowers and brooms. Front attachments on dedicated front hitch kits are a highly effective and affordable way to add from attachment versatility to your tractor but you have more steps to follow to switch between front attachments and using your loader.

Already today the tasks you can accomplish with a front-end loader have expanded far beyond scooping material with a bucket. New tractor and skid-steer loader attachment inventions appear every year. Selecting 3rd function and power beyond hydraulic kit options for your tractor and loader opens up all these possibilities.

I have a Yanmar 1600 and the hydraulics quit working. The pump started making a whinning noise and now the lift want work. Also is the rear end fluid the same fluid that the hydraulic pump uses? What kind of fluid would I need?

2003-05-27 55755I"ll let somebody who knows Yanmars make the oil call. Most compact tractors have a single case for transmission, differential and hydraulic reservoir. For most tractors it"s all from the same place and for many tractors most any oil sold as transmission/hydraulic oil works. There are issues of petro vs synthetic and winter vs summer blends though. I"m not aware of any compact that requires a special oil like the automotive F-type automatic transmission fluid issue but somebody who knows Yanmars could say.

A whining sound often is the pressure relief valve rather than the pump. The relief opens to relieve high pressures that can result from heavy loads, obstructed or disconnected lines. If the tractor has a loader, on many hookups, the lift won"t work if a loader valve is open or the inlet or outlet are disconnected. If the tractor doesn"t have a loader, changing the position of a diverter valve from the remote to auxiliary position will open the relief.

A pump can whine as a result of failing bearings etc. but I don"t believe it"s that all that common. A more common pump problem is cavitation from an obstructed, broken suction line or clogged filter. The sound usually is more of a rattle or buz. The lift on a tractor with a clogged filter usually works for a while, the power deteriorates and then it quits until it sits for awhile. It might be good to change the filter on general principal. It"s also important to cure this type problem before running a tractor much.

2003-05-28 55795I think Tom is on the right track, a whine in the hydraulic system is usually the pressure relief valve cycling very rapidly.

If that was the case then it may have been caused by spring failure, the whine was caused by the valve as it failed, the total loss of hydraulic power would be because the relief valve is now open and the fluid gets dumped directly back to the reservoir by the open valve.

2003-05-28 55827Ref:Yanmar problem is common to smaller Yanmar tractors. It is a sticking valve in the control located under the seat. A temporary solution is to take the valve apart and slightly sand the plunger. Yanmar sent a factory rep to my home many years ago when I was having the same problem. (Under weight the lift stops or freezes up and will not work, but makes a hissing sound, as if it is trying to work) If this is the case the solution is what I told you. You will have to replace the valve, but the method I gave you might get you by for a while. I replaced at least three valves. Good luck. flealine ....

I think it"s important to figure out where the whining is coming from, where the system relief valve is (it there is one in addition to one that"s normally in the 3ph) and exactly how the hitch isn"t working. The whining could be hydraulic noise due to fluid flow through a small orifice, but it"s important to know if the tractor has a relief valve that"s open.

2003-06-01 56142Usually the pump whines because it is starved. If you haven"t cleaned the pickup screen , I"d recommend it. It is the easiest & cheapest thing to do. Use a Universal hydraulic/transmission fluid = > to JD303. ....

TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday"s Tractor Co. products and within the Yesterday"s Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday"s Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

MASSEY FERGUSON TRACTOR: 175-Perkins 236 Diesel Engine, 180-Perkins 236 Diesel Engine, 255-Perkins 236 Diesel Engine, 265-Perkins 236 Diesel Engine, 270 275-Perkins 248 Diesel Engine, MF31-Perkins 236 Diesel Engine, MF50C-Perkins 236 Diesel Engine, MF50D

If you do not feel that you understand these steps, or can perform them safely, consult your tractor dealer or local mechanic. Also always consult your tractor owner’s manual for model-specific information.

If you need any further help, or have any questions about hydraulic systems, tractors, or anything else, please contact your dealer, local mechanic, or call us at 602-734-9944. Please ask about our current new and used tractor supply.

Team Tractor and Equipment- #1 Tractor Dealer in Arizona. We sell and service most major brands of tractors including Yanmar, Kubota, John Deere, TYM, Mahindra, Kioti, Case, New Holland, Massey Ferguson, Ford, Deutz, Case IH, Farmall, International Harvester, Branson Tractors, LS, Shibura, Claas Tractor, McCormick Tractors, Valtra, Solis, YTO, Montana, and Nortrac.

8613371530291

8613371530291