what is kelly bushing pricelist

Start shopping at Alibaba.com to discover wholesale kelly bushing at incredible prices.Browse through kelly bushing for any type of vehicle.Bearings can be produced from a broad variety of materials, such as different steel, rubber, plastic, brass, and ceramic. These materials, each having their own benefits that render them appropriate to specific operations, including noise level, mass, weight, capacity, and resistance, and a series of options to match your individual needs and requirements.

This particular type of rolling component has had a lengthy lifespan, originally made popular in bicycles then, automobiles. It decreases spinning rubbing while withstanding axial and radial loads and has the potential to be used across a broad spectrum of different industries, of which aerospace, agricultural and machinery, wagons and other automobiles, skateboards, and of course fidget spinners!

However, getting a bushing that is properly functioning is critical to a comfortable and smooth ride, as they maintain the car in good conditions. We have variously available bushings including, grounding bushing, polyurethane bushings, energy suspension bushings, brass bushings, and even drill bushings.Buy our selection of kelly bushing now. For those of you who are looking for quality wholesale kelly bushing at a bargain price, well then you should look no further! At Alibaba.com, you may find a great array of quality automotive accessories and everything at an awesome price.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Buyer acknowledges and agrees that all equipment / parts are sold as is / where is without guarantee or warranty of any kind, either expressed or implied.

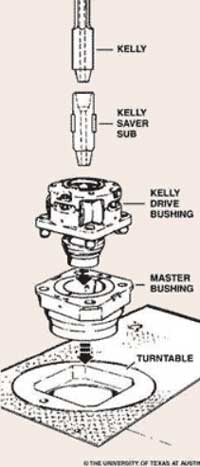

Kelly Bushing Height (KB): The height of the drilling floor above the ground level. Many wellbore depth measurements are taken from the Kelly Bushing. The Kelly bushing elevation is calculated by adding the ground level to the Kelly bushing height.

1. n. [Drilling] An adapter that serves to connect the rotary table to the kelly. The kelly bushing has an inside diameter profile that matches that of the kelly, usually square or hexagonal. It is connected to the rotary table by four large steel pins that fit into mating holes in the rotary table.

A Kelly bushing (some people call “rotary Kelly bushing”) engages a master bushing via four pins and rollers inside a Kelly bushing to allow a Kelly to move up or down freely while it is rotated or in a static mode. This video demonstrates how to make a connection via a Kelly system.

Kelly bushing is that elevated device positioned right on top of the rotary table and used to transmit torque from the rotary table to the kelly. The kelly bushing is designed to be the connection between the rotary table and the kelly.

1. n. [Drilling] An adapter that serves to connect the rotary table to the kelly. The kelly bushing has an inside diameter profile that matches that of the kelly, usually square or hexagonal. It is connected to the rotary table by four large steel pins that fit into mating holes in the rotary table.

The kelly is used to transmit rotary motion from the rotary table or kelly bushing to the drillstring, while allowing the drillstring to be lowered or raised during rotation.

1. adj. [Drilling] Referring to the condition that occurs when the kelly is all the way down, so drilling progress cannot continue. A connection must be made, which has the effect of raising the kelly up by the length of the new joint of drillpipe added, so drilling can resume.

This means that Top Drives can drill about 90 feet before making a connection, whereas with a Kelly System, you will make a connection at about 30 feet deep. Another difference between a Kelly and a Top Drive is that a Top Drive System allows rotation and circulation while back reaming out of a hole.

Kelly drive system is capable to drill with one single drill pipe. On other hand TDS is capable to drill with drill pipe stand. One drill pipe stand is made of three drill pipe joints together.

Kelly bars operate by transferring the torque and crowd force from a rotary drive tool to the drilling tool. Many kelly bars can be applied to any type of piling rig that is available on the market. Kelly bars can be divided into two main types: friction kelly bars and interlocking kelly bars.

The wear bushing is housed in the head or in the spool and is secured by means of two tie down screws to protect it against damage or wear during drilling. It is installed or retrieved with either a simple installation tool or with the HCC combined tool.

Kelly Saver Subs refer to a sub used between the Kelly or top head drive and the drill pipe. It is usually a pin to pin sub that takes the wear abuse to protect the drill pipe and the drive connection. Mills can furnish these subs along with the fluted, hex, or square Kelly Bar drive itself.

Measured Depth (MD) is the length of the wellbore measured along its length. True Vertical Depth (TVD), is the absolute vertical distance between a datum, such as the rotary table, and a point in the wellbore.

A mechanical device for rotating the kelly. The kelly spinner is typically pneumatic. It is a relatively low torque device, useful only for the initial makeup of threaded tool joints. It is not strong enough for proper torque of the tool joint or for rotating the drillstring itself.

This means that Top Drives can drill about 90 feet before making a connection, whereas with a Kelly System, you will make a connection at about 30 feet deep. Another difference between a Kelly and a Top Drive is that a Top Drive System allows rotation and circulation while back reaming out of a hole.

Kelly bars are key components in the execution of boreholes with hydraulic rotary drilling rigs. They transfer the torque of the rotary drive and the crowd pressure of the crowd system concurrently to the drilling tool.

A kelly drive is a type of well drilling device on an oil or gas drilling rig that employs a section of pipe with a polygonal (three-, four-, six-, or eight-sided) or splined outer surface, which passes through the matching polygonal or splined kelly (mating) bushing and rotary table.

A conventional rotary rig or rotary table rig or kelly drive rig is a drilling rig where the rotation of the drill string and bit is applied from a rotary table on the rig floor.

Kelly drive system is capable to drill with one single drill pipe. On other hand TDS is capable to drill with drill pipe stand. One drill pipe stand is made of three drill pipe joints together.

Kelly bars operate by transferring the torque and crowd force from a rotary drive tool to the drilling tool. Many kelly bars can be applied to any type of piling rig that is available on the market. Kelly bars can be divided into two main types: friction kelly bars and interlocking kelly bars.

An adapter that serves to connect the rotary table to the kelly. The kelly bushing has an inside diameter profile that matches that of the kelly, usually square or hexagonal. It is connected to the rotary table by four large steel pins that fit into mating holes in the rotary table. The rotary motion from the rotary table is transmitted to the bushing through the pins, and then to the kelly itself through the square or hexagonal flat surfaces between the kelly and the kelly bushing. The kelly then turns the entire drillstring because it is screwed into the top of the drillstring itself. Depth measurements are commonly referenced to the KB, such as 8327 ft KB, meaning 8327 feet below the kelly bushing.

The global kelly drive market was valued at $1.6 billion in 2021, and is projected to reach $2.3 billion by 2031, growing at a CAGR of 3.7% from 2022 to 2031.

Report Key HighlightersThe kelly drive market is consolidated in nature with few players such as NOV Inc., SANY Group, BAUER Maschinen GmbH (Subsidiary of BAUER Group), Jereh Global Development LLC (As a Subsidiary of Jareh Group) and Liebherr-International Deutschland GmbH. that hold significant share of the market.

The study covers in-depth analysis of 16 countries from different regions including North America, Europe, Asia-Pacific, and LAMEA. In addition, country-wise data of every country has been provided for better understanding of kelly drive market dynamics in every country.

A kelly drive is a particular kind of well drilling tool which uses a section of pipe with a polygonal or splined outer surface and feeds it through a rotary table and matching kelly (mating) bushing which have the same shape or splines. The Kelly is a long, four- or six-sided steel bar having a hole bored through the center to allow drilling fluid to pass through. The kelly bushing allows the drill string to be lifted or lowered while it rotates by transferring rotating motion from the rotary table or kelly bushing to the drill string. Crewmembers make up several attachments to the kelly. The attachments include the upper kelly cock, the lower kelly cock (drill pipe safety valve), and the kelly saver sub.

Kelly drilling is one of the most used dry rotary drilling techniques. The kelly drive is used to create large-diameter bored piles (from a size of approx. 500 mm). With the increasing drilling activities is booting the kelly drive market share in coming year. The kelly drive works with almost any kind of rock and soil. According to kelly drive market forecast, the demand for short rotary drilling instruments, such as augers, core barrels, buckets, and specialized drilling tools which are used to move the dirt will be more in the market. The drill rod which is also known as a kelly bar, is a typical component of this drilling technique. The strong kelly bars enables deep drilling and help in boosting the kelly drive market trend in forecast period.

Globally, there has been a surge in oil exploration activity, which is driving the demand for kelly drive in rig and drilling industry. Apart from the pandemic time, a boom in exploration has tripled over the last five years. Kelly drive market analysis showcase the owing to a global boom in exploration of oil reserves, several oil companies are getting into the rig sector. With the ongoing expansion in petroleum products, large oil extraction companies are contracting with drilling equipment manufacturers for the rent and sale of drilling equipment. Oil exploration companies and equipment companies collaborate to provide offshore support services that can increase production. Factor such as oil exploration activities is likely to boost the market for kelly drive in near future.

Advances in technology and equipment have enabled more oil and natural gas to be recovered from the length of each well, improving production and reducing the environmental footprint of energy production. Kelly drive is cheaper however, technology is slow, inefficient, and unsafe as compared to the other technology which are present or coming in the market. These factors may restrain customers from using kelly drive; thus, hampering the market growth.

With combination of seismic surveys and drilling wells, companies are doing the search of oil reserve and deposits beneath the surface of the earth. Exploration projects can be expensive, time-consuming, and risky, drilling a well may cost tens of millions of dollars. Several factors are considered the number of wells to be drilled, recovery method, type of installation to be used, separation systems for the gas & fluids, and how the oil and gas will be transported to a processing facility. High demand for the petroleum products in the market resulting into several new excavations projects in different regions. This factor is anticipated to increase the sales of kelly drive; thus, creating lucrative kelly drive market opportunities.

The kelly drive market is segmented into product type, and region. On the basis of product type, the market is bifurcated into cleaners, braking oil, grease and lubes, degreaser, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

In 2021, the square kelly segment was the largest revenue generator, and is anticipated to grow at a CAGR of 3.6% during the forecast period. With the increasing horizontal drilling operations result in increasing demand for square kelly in the market. To increase the output from a single well, drilling square kelly equipment are being used frequently in the market. Square Kelly is advantageous for end-users, however equipment can be used for both onshore and offshore drilling operations. Drilling activities are becoming more challenging which are demanding the high quality of kelly equipment. Several oil firms engage in new types of drilling on land, such as horizontal well drilling which covers a significantly larger area under the earth. With the increasing horizontal well drilling creates the opportunity for square kelly segment in global kelly drive market.

In 2021, the kelly bar segment was the largest revenue generator, and is anticipated to grow at a CAGR of 4.0% during the forecast period. With the increasing number of excavation projects and finding of deep oil reserves will increase the demand for kelly bars in the market. Companies are entering into the agreement for the drilling operations which is driving the kelly bars market. Today, reserves are found very deep under the land of sea which require the high strength bars for handling the pressure. Vertical and horizontal drilling activities are increasing which is increasing the demand for different shapes of kelly bars.

In 2021, the onshore segment was the largest revenue generator, and is anticipated to grow at a CAGR of 3.8% during the forecast period. The rise in production activities and decrease in non-productive time are anticipated to propel the market for the onshore segment during the coming years. The onshore oilfields in North America and LAMEA have witnessed a high market share, regions mainly focus on efficiency improvement, decline in non-productive drilling activity time, and enhancement in health, safety, and environment aspects while drilling.

The North America kelly drive market size is projected to grow at the highest CAGR during the forecast period. The region is experiencing more drilling activities of oil and gas extraction as the demand for oil-related goods rises worldwide. Kelly drive equipment is particularly helpful for drilling through hard rock and getting to the oil deposits. The Kelly Drive can be used to reduce operational expenses in drilling operations. For field operators and engineers, it ensures long-term project success and a high rate of return.

LAMEA was the second-largest contributor in terms of revenue in the global kelly drive market in 2021, and is anticipated to grow at a CAGR of 3.8% during the forecast period. Accelerated investment across the upstream sector along with crude oil price recovery will foster the drilling activities in the region. Robust growth in petrochemical products demand along with increase in industrial and commercial activities across the developing economies will boost the kelly drive market growth in LAMEA region.

For instance, The natural gas production in Saudi Arabia has been planned to increase by two-fold in the coming decade, which is expected to result in increased drilling activities related to gas production.

The leading players operating in the global kelly drive market include, NOV Inc., SANY Group, BAUER Maschinen GmbH (Subsidiary of BAUER Group), Jereh Global Development LLC (As a Subsidiary of Jareh Group) and Liebherr-International Deutschland GmbH, Bridges Equipment LTD, Lake Petro., TEXAS INTERNATIONAL OILFIELD TOOLS, LTD, Goldman, Tianhe Oil Group Co. Ltd., XI"AN KINGWELL OILFIELD MACHINERY CO.,LTD, El Didi Group.

Key benefits for stakeholdersPorter’s five forces analysis helps analyze the potential of buyers & suppliers and the competitive scenario of the industry for strategy building.

It outlines the current Kelly drive market trends and future estimations from 2021 to 2031 to understand the prevailing opportunities and potential investment pockets.

The invasion of Russia has further worsened an already precarious scenario for the energy and drilling markets, notably in Europe. To minimize the possibility of an interruption in Russian oil and gas supply, oil and gas corporations must collaborate with governments. In longer term, the sector needs to increase its adaptability and relevance in a rapidly evolving energy environment. The scenario brought about by the conflict between Russia and Ukraine influences the Kelly Drive market as well. Many projects that were previously underway in the nations are now on hold, and new projects are being delayed, which has slowed the market"s expansion in recent years.

Product Description: Roller Kelly Bushings can be classed as two types based on different ways of drive, square drive and pin drive. Also they can be classed as three types based on different style, heavy, medium and light-duty. They are used for 17.1/2 to 49.1/2inch rotary tables. They are designed and manufactured...

Buyer acknowledges and agrees that all equipment / parts are sold as is / where is without guarantee or warranty of any kind, either expressed or implied.

Heavy Duty Roller Kelly Bushings is designed for heavy duty drilling operations, high torque and high speed drilling conditions. Heavy Duty Roller Kelly Bushings is used with Den-Con Pin Drive Master-Casing Bushings for 23” through 49 1/2” Rotary Tables. The 27 RPH has 3 5/16 ” diameter drive pins (API) and 25 3/4” pin centers (API) and will handle Kelly sizes 3” to 6” square and 3” to 6” hex. DEN-CON 20 RPH Kelly Bushing is used with Den-Con Pin Drive Master Casing Bushings for 20 1/2” to 22 1/2” Rotary Tables. The 20 RPH has 2 1/2” diameter drive pins (API) and 23” pin centers (API). The 20 RPH uses the same roller assemblies, components and wiper assemblies as the 27 RPH.

Heavy Duty Roller Kelly Bushings is a square drive unit used with DEN-CON SSB Master Bushings and all Master Bushings having a drive square dimension of 13 9/16 ” (API). This bushing uses the same roller assemblies, components and wiper assemblies as the 27 RPH.

The FG Flex-Grip Power Slip System is a family of “flush” mounted power slips, designed for drilling and/or rental operations. The most recent addition to the family is the FG-5 which fits into 27 1/2” rotary tables and handles 9 5/8” - 2 3/8” pipe sizes. A hydraulic pipe centering device is available for the FG-5.

Safety Clamp is a safe and convenient tool to prevent dropping slick drill collars or flush joint pipe into the hole while making up or breaking out the string. Other popular uses include use when running large diameter surface casing, handling of drilling risers and casing heads during installation and lifting prepacked gravel liners.

The multi-link design provides uniform pressure around the pipe so the risks of crushing the pipe or damaging the surface are minimized. Each link, complete with tapered slip, is interchangeable as a unit and is readily adaptable to any diameter from 2 7/8” to 39 1/2”.

R-750 Master Bushing is available for 49 1/2” - 60 1/2” rotaries, and is rated for 750 tons. Master bushing is available for 37 1/2” and 49 1/2” rotary tables. Split insert bowls of various bore diameters are available to allow handling capability for 2 3/8 ” to 13 3/8 ” tubular products. The HMB can easily be removed from the drill string by removal of one hinge pin. The Den-Con 27 RPH Roller Kelly Bushing is the drive bushing used with HMB. 49 1/2” x 37 1/2”.

CL Casing Slips are designed to handle casing sizes from 6 5/8” to 48”. The multi-segment design provides even load distribution and full wrap-around gripping on all casing sizes. The CL Series Casing Slip have a 4” API taper to fit spiders and casing bushings of the same taper.

FCS Flush Casing Spider is a family of tools specifically designed for casing handling operations. All FCS tools mount inside the rotary and eliminate the need for special rig floor platforms when running casing.

Casing Elevator/Spider is available in 350 ton, 500 ton and 750 ton rated capacities. The 350 ton and 500 ton tools will handle 4 1/2” - 14” pipe sizes. A larger 500 ton tool handles 16” - 24 1/2” casing sizes. 750 ton casing tools are also available in two body sizes. One handles 6 5/8” - 14” pipe and the other size is for 16” - 24 1/2” pipe sizes. All Den-Con Elevator/Spiders are designed for pneumatic operation using the rig air supply. The system may be manually operated if the rig air supply is temporarily lost. All Elevator/Spider units are manufactured and tested according to the latest industry standards.

Rotary Slips is designed for use in API Bowls. The RDS Series has 11” of insert gripping length. The RD Series has 13 3/4” of grip length for medium depth well and drill string application. The RDL Series has 16 1/2” of grip length for all deep well and heavy duty string applications. The rugged design of the slip assembly provides a full load distribution throughout the length of the slip and prevents bottle-necking of the drill pipe. Den-Con slip inserts are machine-cut and interchange with Varco inserts.

79 CU, CUL AND CB Rotary Make Casing Casing Bushing Weight Table Size [inches] and Insert Bowl (P/N) [lbs/kg] CASING BUSHINGS Size [inches] CU, CUL and CB casing bushings are 17.1/2-20.1/2 ALL 11.3/4 and 13.3/8 CU (3102) 470 / 213 inserted directly into the rotary table and insure that the casing being run 9.5/8 and 10.3/4 W/bowl No. 2 (1902) 342 / 155 is perfectly aligned with the center 26 and 27.1/2 ALL 18.5/8 and 20 CUL (3103) 938 / 425.5 of the hole. Models CU and CUL are 16 W/bowl 20x16 (3104) 562 / 255 solid bushings and model CB is a split bushing. All of the bushings accept 11.3/4 and 13.3/8 W/bowl No. 1 (3105) 846 / 384 bowls of different sizes to accommodate 9.5/8 and 10.3/4 W/bowl No. 2 (1902) 342 / 155 a wide range of casing. Using CMS-XL 2.3/8 and 8.5/8 W/bowl No. 3 (1809) 464 / 210.5 or CP-S slips, since these bushings fit into the rotary table, the casing string 27.1/2 ALL 27.1/2 18.5/8 and 20 CB (6695) 713 / 323 can be easily rotated during cementing API 16 W/bowl 20 x 16 (6127) 572 / 259 operations. 11.3/4 and 13.3/8 W/bowl No. 1 (6126) 895 / 406 9.5/8 and 10.3/4 W/bowl No. 2 (6114) 252 / 114 37.1/2-49.1/2 NATIONAL 30 CB (V11763) 1100 / 499 26 CB (16454) 1100 / 499 24 CB (11253) 1200 / 544BUSHINGS / SLIPS / CLAMPS

CU Casing Bushing 24 CB (6170) 1260 / 571.5 18.5/8 and 20 CB (10188) 1670 / 759 16 W/bowl 20 x16 (6127) 572 / 259 11.3/4 and 13. 3/8 W/bowl No. 1 (6126) 895 / 406 9.5/8 and 10.3/4 W/bowl No. 2 (6114) 252 / 114 37.1/2-49.1/2 EMSCO 30 CB (11633) 1160 / 526 26 CB (89183-1) 1100 / 500 24 CB (16542) 1260 / 571.5 22 CB (11252-22) 1120 / 509 18.5/8 and 20 CB (11553) S/N 49 1610 / 730 and above for 37.1/2 only CUL Casing Bushing (10190) S/N 48 1820 / 825.5 and below for 37.1/2 only 16 W/bowl 20 x16 (6127) 572 / 259 11.3/4 and 13.3/8 W/bowl No. 1 (6126) 895 / 406 9.5/8 and 10.3/4 W/bowl No. 2 (6114) 252 / 114 37.1/2 IDECO 30 CB (12092) 1100 / 499 26 CB (74814-26) 1452 / 605 24.1/2 CB (74814) 1560 / 650 18.5/8 and 20 CB ( 10189) 1670 / 759 16 W/bowl 20 x16 (6127) 572 / 259 11.3/4 and 13.3/8 W/bowl No. 1 (6126) 895 / 406 9.5/8 and 10.3/4 W/bowl No. 2 (6114) 252 / 114

UC-3 CASING SLIPSMost casing strings’ weight and the relatively thin pipe wall make itimportant that the supporting slips provide full circumferential grip. The Baash Ross 200 Ton hinged casing spiderBaash Ross type UC-3 slips achieves this with many narrow segments.They are hinged together to wrap around the casing and exert a moreuniform pressure. With each segment carrying the same load, theyautomatically center the casing string within the bushing or spider.The UC-3 has a 3” taper. With changes in the number of segments andliners, it will handle strings from 16” OD to 42” OD. Liners are held inplace by a liner retainer key and cotter pins.

200 TON HINGED CASING SPIDERS, INSERT BUSHINGS AND UC-3 SLIPS Csg. Size UC-3 Slip No. Weight 30” Spider Weight 36” Spider Weight 42” Spider Weight

BUSHINGS / SLIPS / CLAMPS [lbs / kg] 7704-A-161 [lbs / kg] 7704-A-167 [lbs / kg] 7704-A-179 [lbs / kg] 1,200 1,100 1,525 16” 7704-5036 226 / 102 Bushing 7704- 975 / 442 A-165 Retainers 50012-148-8 18.5/8” 7704-5035 325 / 147 Bushing 7704- 900 / 408 Bushing 1135 / 514 A-164 Retainers 7704-A-172 50012-50-8 Retainers 50012-76-8 20” 7704-5034 283 / 128 Bushing 7704- 900 / 408 Bushing 1135 / 514 A-164 Retainers 7704-A-172 50012-50-8 Retainers 50012-76-8 22.1/2” 7704-5002 359 / 162 Bushing 7704- 750 / 340 Bushing 924 / 419 A-163 Retainers 7704-A-171 50012-38-C8 Retainers 900041-441 24” 7704-5001 312 / 141 Bushing 7704- 750 / 340 Bushing 924 / 419 A-163 Retainers 7704-A-171 50012-38-C8 Retainers 900041 -441 26” 7704-5006 325 / 147 Bushing 7704- 605 / 274 Bushing 817 / 370 A-162 Retainers 7704-A-170 50012-26-C8 Retainers 900042-186 30” 7704-5005 367 / 166 Use 30” Spider Bushing 640 / 290 Bushing 7704- 1400 / 635 7704-A-169 A-180 Retainers Retainers 900042-708 50012-32-C8 33” 7704-5008 410 / 185 Bushing 500 / 226 7704-A-168 Retainers 50012-20-C8 36” 7704-5007 437 / 198 Use 36” Spider Bushing 7704-A- 1226 / 556 178 Retainers 50012-36-C8 42” * 7704-5019 495 / 224 Use 42” Spider

81 ROLLER KELLY BUSHINGS HDP ROLLER KELLY BUSHING OPTIONAL LOCK ASSEMBLY Widely recognized as the standard of the industry. Locks for the kelly bushing in the master bushing for use For master bushings with 25.3/4" pin circle 27 HDP of offshore with motion compensators. Lock assembly may be 23" pin circle, 20 HDP. Unit comes with wrench, wiper ordered installed in 27-HDP only. To specify, add an"L" to and wear gauge. Weight 1,500 lbs / 680 kg. basic part number of unit. Lock assembly alone PN 3695.

27 XHDP ROLLER KELLY BUSHING For extreme high-torque drilling. Essentially two HDP bushings combined into one unit, this tool reduces wear 27" HDP Roller Kelly Bushing to kelly and itself through wider force distribution. For master bushings with 25.3/4" pin circle. Unit comes with wrench, wiper and wear gauge. Weight 2,850 lbs / 1,293 kg .

HDS ROLLER KELLY BUSHING For heavy duty square drive applications. Components are interchangeable with HDP. Unit comes with wrench, wiper and wear gauge. Weight 1,420 lbs / 644 kg.

Size/Type Part. No. Part. No. Part. No. Part. No. 3" Hex 3650-30 - - - 3 .1/2" Hex 3650-35 3690-35 - 3635-35 4.1/4" Hex 3650-42 3690-42 70947-1 3635-42 5" Spec. Hex 3650-50 - - - 5.1/4" Hex 3650-52 3690-52 - 3635-52 XHDP Roller Kelly Bushing 6" Hex 3650-60 - 70947-2 3635-60 2 .1/2" Sq - - - - 3" Sq 3651-30 - - 3636-30 3 .1/2" Sq 3651-35 3691-35 - 3636-35 4.1/4" Sq 3651-42 3691-42 - 3636-42 5.1/4" Sq 3651-52 3691-52 70947-3 3636-52 6" Sq 3651-60 - 70947-4 - Less Rollers 3653 3692 70947-BD 3637 ROLLER ASSEMBLIES COMPLETE HDS Roller Kelly Bushing Kelly HDP* HDS* Size/Type Part Weigth Part Weigth No. [lbs/kg] No. [lbs/kg] 3" Sq 3660 590/276 70474-5 176/80 3 .1/2" Sq 3661 562/255 70474-6 160/73 4.1/4" Sq 3662 512/232 70474-7 132/60 5.1/4" Sq 3665 438/199 - - 6" Sq 3666 374/169 - - 3" Hex 3667 612/278 70474-1 162/74 27.1/2" HDP Roller Kelly 3 .1/2" Hex 3668 584/265 70474-2 146/66 Bushing

82KELLY BUSHINGSKELLY WIPERS Kelly Size HDP, HDS Weight Hex Wt [inches] Square P/N [lbs/kg] P/N [lbs/kg] 3" API 8-0260 4 / 1.8 8-0320 4 / 1.8 3.1/2" API 8-0265 4 / 1.8 8-0285 4 / 1.8 4.1/4" API 8-0170 3.5 / 1.6 8-0275 3.5 / 1.6 5.1/2" API 8-0300 3 / 1.4 8-0305 3 / 1.4 6" API 8-0200 3 / 1.4 8-0240 3 / 1.4KELLY BUSHING SAFETY GUARDFits Rotary Tables with HDP-HDS kelly Bushings.For 17.1/2" - 27.1/2" Rotary Table P/N 15794For 37.1/2" Rotary Table P/N 16951For 49.1/2" Rotary Table P/N 16953

MPCH MASTER BUSHINGThe 37.1/2" MPCH pin drive hinged master bushing is specially designed for floating and semi-submersible drilling operations.With insert bowl No. 3 and optional insert bowls No. 1 and No. 2, the MPCH master bushing will

BUSHINGS / SLIPS / CLAMPShandle 2.3/8" to 13.3/8" OD drill collars, tubing and casing.Unit comes complete with No. 3 insert bowl, bit breaker adapter plate and 4 way lifting sling PN 6699.

Part P/N Weight [lbs/kg] Complete * 4200 / 1905 MPCH with # 3 bowl and SDXL slips Body only * 3200 / 1452 Insert Bowl No. 1: 13.3/8" to 11.3/4" 6610 336 / 152 Insert Bowl No. 2: 10.3/4" to 9.5/8" 6609 470 / 213 Insert Bowl No. 3: API 8.5/8" and smaller 6608 625 / 283 2 way lifting sling for insert bowls 1021 46 / 22* See selection chartMSPC MASTER BUSHINGThe 27.1/2" MSPC solid body pin drive master bushing designed for all drilling operations. Thepin drive allows the kelly bushing to ride on top of the rotary table and permits extended bowlsto be used for better slip back up. With the extended API insert bowl No. 3, the MSPC master MPCH with bit breaker adapter platebushing will handle 2.3/8" thru 8.5/8" OD drill pipe, drill collars, tubing and casing. Insert bowlNo. 2 can handle tubulars from 9.5/8" to 10.3/4" OD; while insert bowl No. 1 is good for 11.3/4"to 13.3/8" OD. Unit comes with No. 3 insert bowl, bit breaker adapter plate and 4 way lifting slingPN 6699.

MSP MASTER BUSHINGSMSP 27.1/2" split pin drive bushings*MSP 27.1/2 split pin drive bushings are also available. With the larger rotary opening the MSPstandard No. 3 extended API taper is used. This allows the use of extra-long SDXL slips requiredfor heavier loads. Weight 1600 lbs / 726 kg.* See selection chart

83 MASTER BUSHING SELECTION CHART Make Type MPCH MSPC MSP Compl. Body only Compl. Body only Compl. Body only Emsco T-2750 - - 1804-1 1808-1 5429-1 - G-27.1/2 - - 1804-5 1808-5 5429-5 - H-27.1/2 - - 1804-2 1808-2 - - K-27.1/2, KS, P1 - - 1804-3 1808-3 - - T-3750 (S/N 1-48) 6600-2A 6601-2A - - - - T-3750/T-4950 (49/UP) 6600-2 6601-2 - - - - Ideco 27.1/2 - - 1804-7 1808-7 5429-7 - 37.1/2 6600-4 6601-4 - - - - National MS-27 .1/2, A and B-27.1/2 - - 1804-5 1808-5 5429-5 - C-365 6600-5 - - - - - C-375 6600-1 6601-1 - - - - Oilwell 27 .1/2, 27.1/2 A - - 1804-9 1808-9 - - A-27.1/2 - - 1804-1 1808-1 5429-1 - A-37.1/2 6600-3 6601-3 - - - -BUSHINGS / SLIPS / CLAMPS

Wirth* 27.1/2 - - 1804-1 1808-1 5429-1 - 37.1/2 6600-6 6601-6 - - - - *WIRTH is a trademark of Wirth Maschinen- und; Bohrgeräte-Fabrik GmbH. The Wirth trademark and trade name referenced above are used solely for reference purposes and NOV is not affiliated with Wirth and Wirth does not endorse any of NOV"s products.

84MBH1250 HINGED MASTER BUSHINGFor the safe handling of heavy weight casing strings, including bit, in combination with thecorresponding landing strings, a new series of rotary equipment, having a dedicated rating andsafety factor, has been developed.• Casing sizes up to 24", for string weights up to 750 sTon.• 5.1/2" to 6.5/8" landing strings with dedicated drill pipe, string weights up to 1,250 sTon.• Dual upset drill pipe, string weight up to 1,250 sTon.• All standard pipe types and sizes with special #1, #2 and #3 master bushing bowls, string weights up to 750 sTon.• Standard bit breaker plates. Maximum bit diameter 29.1/2". MBH1250 with drilling bowl and slips

CASING BUSHINGSHeight and internal diameters/tapers of casing bushing are 100% identical to standard NOVVarco BJ 24" CB16542 casing bushing. Interfaces with standard 24" CMS-XL casing slips.

DRILLING BOWLS MBH1250 with casing bushing

BUSHINGS / SLIPS / CLAMPSInterfaces with standard API handslips featuring a 1: 6 taper.When removed from the MBH1250 bushing, a 29.1/2" diameter bit can pass through MBH1250,without the need to remove the MBH1250 from the rotary table, due to throat opening of 30".These bowls feature the standard MPCH bit breaker holes. Standard bit breaker plates, kellybushings, etc, fit into these holes. Interfaces with same torque backup blocks in the MBH1250as above mentioned casing bowls for torque backup an assembly.

MBH1250 with drilling bowlLSB1250 LANDING STRING BUSHINGTo handle 1,000 sTon capacity landing strings, the MBH1250 can be dressed with the LSB1000landing string bowl. Combined with the special design landing string hand slips, the landingstring can be run up to loads of 1,000 sTon. The landing string slips grip the pipe with standardinserts. Customers should always perform a crushing load calculation to determine the ultimatesafe working load of the system.

To handle 1,250 sTon capacity landing strings, the MBH1250 can be dressed with the LSB1250landing string bowl. Combined with the special design landing string hand slips, the landing MBH1250 with LSB1250 landing stringstring can be run up to loads of 1,250 sTon. The 1,250 sTon capacity can only be achived with bushing and LSS1250 landing string sliplanding strings with “dual upset” connections, i.e. the joint has two 18 degree tool joints. A 1,250sTon capacity BX style elevator will be connected to the upper tool joint, while the lower tooljoint is suspended in the LSB1250 with the special slips that have an 14 degree contour in theslips, rather then inserts.

TECHNICAL SPECIFICATIONS LSS1250 landing string slip Description Size Size Fits into 49.1/2" National rotary table (= 49.1/2" RST) as standard. Height 20" (equal to a standard 37.1/2" MPCH Master Bushing) Internal throat opening 30" Maximum backup torque 500,000 ft.lbs / 677,910 Nm Load Rating axial 1,250 sTon / 1,134 Tonne Load Rating axial w/ spreading load 1:6 taper 1,000 sTon / 907 Tonne Lifting slings Can be handled (lifted) with standard lifting slings with certified latching hooks or standard certified shackles.

85 MAIN PART NUMBERS MBH1250 MASTER BUSHING HINGED Part number Name 50005900-2 MBH1250 Emsco 50005900-3 MBH1250 National 50005900-4 MBH1250 Oilwell 50005900-6 MBH1250 Wirth** 50005900-7 MBH1250 Ideco

MBH1250 MASTER BUSHING HINGED W/ BOWL #3, + BIT BREAKER PLATE + LIFTING SLING Part number Name 50005900-200 MBH1250 Emsco 50005900-300 MBH1250 National 50005900-400 MBH1250 Oilwell 50005900-600 MBH1250 Wirth** 50005900-700 MBH1250 IdecoBUSHINGS / SLIPS / CLAMPS

CASING BUSHINGS Part number Description 50005905 Casing bushing for 24” 50005906 Casing bushing for 22” 50005907 Casing bushing for 20” 50005908 Casing bushing for 16”

LSS1250 LANDING STRING SLIPS Type Size [inches] Part number Insert Qty Weight [lbs/kg] LSS750* 5,1/2 50005925-1 50003937 60 640 / 290 LSS1250 5.7/8 50005929-1 50003937 60 620 / 281 LSS1250 6.5/8 50005935-1 50003937 60 581 / 263 LSS1250 6.906 50005939-1 50003937 60 565 / 256 LSS1250 7.5/8" 50005945-1 50003937 60 545 / 247 * higher rating impossible due to limitations of massive CMS-01 test mandrel which will break at higher ratings **WIRTH is a trademark of Wirth Maschinen- und; Bohrgeräte-Fabrik GmbH. The Wirth trademark and trade name referenced above are used solely for reference purposes and NOV is not affiliated with Wirth and Wirth does not endorse any of NOV"s products.

Kelly bushing is that elevated device positioned right on top of the rotary table and used to transmit torque from the rotary table to the kelly. The kelly bushing is designed to be the connection between the rotary table and the kelly. The kelly is a 4 or 6 sided steel pipe.

The purpose of the rotary table is to generate the rotary action (torque) and power necessary to rotate the drillstring and drill a well. The torque generated by the rotary table is useless if it is not transferred to the kelly (the drillstring is connected to the kelly).

Hence, through the kelly bushing the torque generated at the rotary table is transferred to the kelly. To achieve this connection, the inside profile of the kelly bushing matches the outer profile of the kelly so that the kelly fits or “sits” comfortably in the kelly bushing.

There are various designs for the kelly bushing including the split type, the pin-drive type and the square-drive type. Each of these designs has different ways in which they are connected and disconnected from the rotary table.

The internal diameter of the kelly bushing can be cut into the shape of a square (4-sided) or a hexagon (6-sided) depending on the outer shape of the kelly that will be used. The internals of a Kelly bushing is designed to resemble the outer shape of a Kelly just like the insides of a key lock is cut to exactly match the outer shape of the key.

The kelly bushing is not designed to hold tightly onto the Kelly; the kelly is still permitted to move up and down through the kelly bushing. This requirement is a must since drilling cannot progress if the kelly remains on a fixed spot. As the well is drilled deeper, the kelly also moves downward through the Kelly bushing.

The kelly bushing is sometimes used as a reference point from which depth measurements can be taken. All depths must be recorded with respect to a reference point; the kelly bushing (KB) is one of the depth references used in the oil and gas industry.

The top of the kelly bushing is normally used as the depth reference.For example, 7500ft KB means 7500ft below the kelly bushing or 7500ft measured from the top of the kelly bushing down to that point in the well.

In some other cases, depths could be recorded as 7500ft MDBKB meaning 7500ft measured depth below the kelly bushing. This is mostly used when the measured depth is different from the true vertical depth of the well, common with deviated and horizontal wells.

DEN-CON 27 RPH Kelly Bushing is used with Den-Con Pin Drive Master-Casing Bushings for 23" through 49 1/2" Rotary Tables. The 27 RPH has 3 5/16 " diameter drive pins (API) and 25 3/4" pin centers (API) and will handle Kelly sizes 3" to 6" square and 3" to 6" hex.

DEN-CON 20 RPH Kelly Bushing is used with Den-Con Pin Drive Master Casing Bushings for 20 1/2" to 22 1/2" Rotary Tables. The 20 RPH has 2 1/2" diameter drive pins (API) and 23" pin centers (API).

SSB Master Bushings and all Master Bushings having a drive square dimension of 13 9/16" (API). This bushing uses the same roller assemblies, components and wiper assemblies as the 27 RPH. All RH Series Parts & Components Interchange with Varco HD Series Bushing Parts.

8613371530291

8613371530291