derrick floor versus kelly bushing price

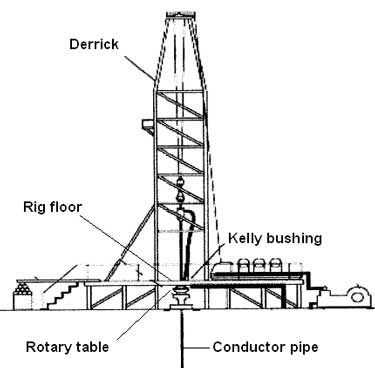

Every signed oil well drilling contract includes some form of conditions and agreements. For example, the drilling rig contractor will agree to a specific drilling depth, financial obligations, or where the well will be drilled. Once everything has been agreed upon, the drilling rig will be moved in to prepare for drilling. This is most commonly referred to as the MIRU, or the “Move In and Rig Up”; and in most cases, will include drilling with a jackknife rig instead of the derricks that are built in place. Other important personnel often comprise of:

Commonly referred to as the derrick man, a derrick worker cannot be afraid of heights. This position requires working high above the floor, and is used during regular operations to help when the pipe is being pulled or run. In many of the modern rigs, a rack will vertically hold various sections of drill pipe along the side of the derrick. Each is then added to the drilling string as the bit makes it way deeper and deeper into the ground.

One of the common duties of derrick workers is to add (or remove) sections of pipe from the drill string. During drilling, the pipe is added the deeper into the ground they drill; while sections are removed from the drill string and pulled out of the ground once the drilling has been complete. Sections of pipe are also removed for replacement, or to deal with any drilling issues.

While running and pulling pipe, there are always two floor workers. These two personal are generally referred to as either roughnecks or floor hands, with the more experienced worker being referred to as the lead. The lead operates the lead tong, while the other floor worker operates the back-up tong (or back-up). In most cases, these workers are the most inexperienced members of the rig crew.

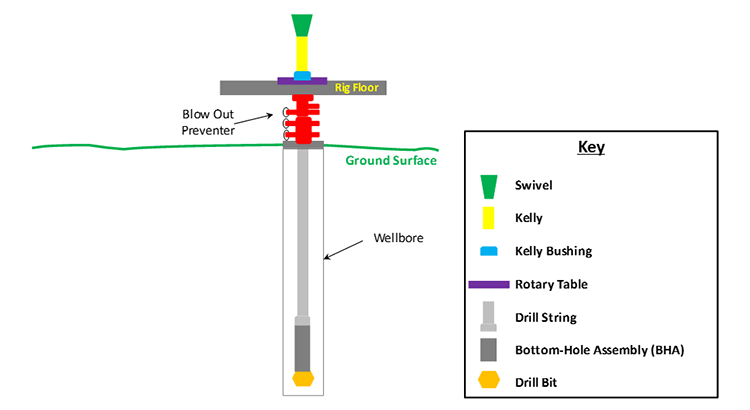

As the crew drills the well, the distances are calculated starting from the top of kelly bushing (refers to the sliding bushing located on the drilling rig floor on top of the rotary table that permits the drill kelly to go down through it when the pipe is turning and the hole is drilled.

Once the casing pipe is permanently cemented into the hole (or set) and either the braiden head or wellhead installed, the measurements from the top of the wellhead to the top of the kelly bushing are calculated and subtracted from all drilling records. This allows precise well records for once the drilling rig is no longer there.

Figure 8.06 shows a schematic diagram of a typical top-drive rig. In a top-drive drilling rig, the top-drive (Item 6 in Figure 8.06) is suspended from the traveling block (Item 5 in Figure 8.06) and attached to a guide system (gear train and rail system) on the derrick. The top-drive is an electrical motor that has the ability to travel vertically up and down and to impart torque to the drill pipe. These drilling rigs began to appear in the late 1990s. Although the top-drive supplies the torque for the system, a rotary table is still used to supply stability to the drill string and as a redundant (back-up) rotary system.

As we saw in our discussion of a Conventional Rotary Table Rigs, the next 30-foot joint of drill pipe to be added to the drill string is temporarily stored in the mousehole on the rig floor. This joint of drill pipe is added to the drill string when drilling ahead or tripping into the wellbore. Tripping is the process of running drill pipe into or out of the hole for purposes other than drilling ahead. For example, if a drill bit needs to be changed due to wear, then the entire drill string needs to be pulled from the wellbore (tripping out of the hole), the drill bit needs to be replaced, and the drill string needs to be run back into the wellbore (tripping into the hole) to resume normal drilling operations. You can imagine how much ineffective rig time (in terms of not drilling ahead) is used tripping into or out of the wellbore and making or breaking connections in the drill string–particularly if the well"s TD (Total Depth) is 10,000–15,000 feet (or a shallower well has a 10,000-foot horizontal section).

The improved efficiencies coming from a top-drive is that an entire 90-foot stand (or triple) of drill pipe can be connected to the drill string rather than a single 30-foot joint. This is because the top-drive can go to the full height of the derrick using the traveling block to connect to the entire stand of drill pipe. Note, however, that not all top-drives use a triple when connecting drill pipe; some use a Double (two joints), while others use a single joint from a mousehole.

Figure 8.07: Rig Components - showing Kelly, Kelly Bushing, Rotary Table, Mousehole, and Rat Hole (screen capture at 9 seconds of the Drilling Training video)

In the screen capture shown in Figure 8.07, we see many of the components discussed in this lesson: the kelly, kelly bushing, rotary table, mousehole, and rat hole. Throughout the video, you can see these components of the rig used in action.

In the screen capture shown in Figure 8.09, we see the mechanical tongs (red). As shown in the video, the mechanical tongs are used to grip the kelly and drill string to aid in uncoupling (unscrewing) the two.

At around 2:52 into the video, it appears that while two of the roughnecks were trying to remove the slips from the master bushing, the hoist system on the derrick was attempting to assist them by lifting the kelly and drill pipe to release pressure from the slips. Instead of freeing the slips, the hoist appears to have lifted the entire section of the rig floor covering the rotary table, along with the two roughnecks. You can hear someone laughing in the video.

At around 3:31 into the video, one of the roughnecks and the hoist appear to use a piece of drill pipe to tamp the section of rig floor back into place. This piece of drill pipe is then placed into the mousehole as the next piece of drill pipe to be connected to the drill string. This is not a standard operating procedure on the rig floor. After this incident, you can see the rotary table and kelly bushing rotating in the manner discussed in these lesson notes.

The Making a connection on a top drive triple from the derrick YouTube clip (3:26) is of a Derrickman (discussed earlier in this lesson) making connections on a top-drive rig from the perspective of the monkey board (Item 4 in Figure 8.06).

In this video, the derrickman appears to be connecting Triples (I think that I count three joints of drill pipe looking downward to the rig floor). As I mentioned, this video is taken from the monkey board on the top of the derrick.

n: a large load-bearing structure, usually of bolted construction. In drilling, the standard derrick has four legs standing at the corners of the substructure and reaching to the crown block. The substructure is an assembly of heavy beams used to elevate the derrick and provide space to install blowout preventers, casingheads, and so forth.

n: all members in the assembly used for rotary drilling from the swivel to the bit, including the kelly, the drill pipe and tool joints, the drill collars, the stabilizers, and various specialty items. Compare drill string.

n: the column, or string, of drill pipe with attached tool joints that transmits fluid and rotational power from the kelly to the drill collars and the bit. Often, the term is loosely applied to include both drill pipe and drill collars.

A pit in the ground to provide additional height between the rig floor and the well head to accommodate the installation of blowout preventers, ratholes, mouseholes, and so forth. It also collects drainage water and other fluids for disposal.†

A small enclosure on the rig floor used as an office for the driller or as a storehouse for small objects. Also, any small building used as an office or for storage.†

A device fitted to the rotary table through which the kelly passes. It is the means by which the torque of the rotary table is transmitted to the kelly and to the drill stem. Also called the drive bushing.†

A portable derrick capable of being erected as a unit, as distinguished from a standard derrick, which cannot be raised to a working position as a unit.†

The derrickman"s working platform. Double board, tribble board, fourable board; a monkey board located at a height in the derrick or mast equal to two, three, or four lengths of pipe respectively.†

Shallow bores under the rig floor, usually lined with pipe, in which joints of drill pipe are temporarily suspended for later connection to the drill string.†

A hole in the rig floor 30 to 35 feet deep, lined with casing that projects above the floor. The kelly is placed in the rathole when hoisting operations are in progress.†

Shallow bores under the rig floor, usually lined with pipe, in which joints of drill pipe are temporarily suspended for later connection to the drill string.†

The hose on a rotary drilling rig that conducts the drilling fluid from the mud pump and standpipe to the swivel and kelly; also called the mud hose or the kelly hose.†

The principal component of a rotary, or rotary machine, used to turn the drill stem and support the drilling assembly. It has a beveled gear arrangement to create the rotational motion and an opening into which bushings are fitted to drive and support the drilling assembly.

Wedge-shaped pieces of metal with teeth or other gripping elements that are used to prevent pipe from slipping down into the hole or to hold pipe in place. Rotary slips fit around the drill pipe and wedge against the master bushing to support the pipe. Power slips are pneumatically or hydraulically actuated devices that allow the crew to dispense with the manual handling of slips when making a connection. Packers and other down hole equipment are secured in position by slips that engage the pipe by action directed at the surface.†

A vertical pipe rising along the side of the derrick or mast. It joins the discharge line leading from the mud pump to the rotary hose and through which mud is pumped going into the hole.†

The top drive rotates the drill string end bit without the use of a kelly and rotary table. The top drive is operated from a control console on the rig floor.†

Because wells are not always drilled vertically, there may be two “depths” for every given point in a wellbore: the measured depth (MD) measured along the path of the borehole, and the true vertical depth (TVD), the absolute vertical distance between the datum and the point in the wellbore. In perfectly vertical wells, the TVD equals the MD; otherwise, the TVD is less than the MD measured from the same datum. Common datums used are ground level (GL), drilling rig floor (DF), rotary table (RT), kelly bushing (KB) and mean sea level (MSL). [1]

Kelly Bushing Height (KB):The height of the drilling floor above the ground level. Many wellbore depth measurements are taken from the Kelly Bushing. The Kelly bushing elevation is calculated by adding the ground level to the Kelly bushing height.

Driller’s Depth below rotary table (DDbrt): The depth of a well or features within the wellbore as measured while drilling. The measured length of each joint of drillpipe or tubing is added to provide a total depth or measurement to the point of interest. Drillers depth is the first depth measurement of a wellbore and is taken from the rotary table level on the rig floor. In most cases, subsequent depth measurements, such as those made during the well completion phase, are corrected to the wellhead datum that is based on drillers depth (reference: Schlumberger Oilfield Glossary).

Mast: A portable metal tower that is raised into working position as a unit, rather than assembled as a derrick. A mast is used as a component of the hoisting system of a drilling rig.

Top Drive: A power swivel which rotates the drill string without the use of a rotary table or kelly. It is efficient due to its ability to drill three joints deep before another connection must be added.

Rotary Table: A motorized, circular platform in the floor of the rig which rotates the kelly bushing and the kelly when the top drive is not in use. Turning the kelly turns all the pipe, therefore drilling the hole.

Mousehole: A hole in the drilling floor, seven to ten inches wide, located near the rotary table. It is used to store a piece of drill pipe until it is pulled up and attached to the drill string.

Iron Roughneck: A hydraulic powered wrench which can make up or break out pipe joints by applying correct torque. Most of the manual pipe handling operations previously performed by the drilling crew on the rig floor have been replaced by this piece of equipment.

Doghouse: A small building on the rig floor which is used as the driller’s office. It also serves as a shelter for the drilling crew and storage for tools and small equipment.

BOP Stack: Stands for Blowout Preventer Stack. This piece of equipment is attached to the well head under the rig floor and utilizes vertically arranged closing elements to either close off the well or control the release of fluids to and from the well bore.

Substructure: The steel platform and supports on which the mast and all drilling floor equipment sit. It also provides space for well control equipment and storage by elevating drilling floor components.

RFRMRD89–Oklahoma City, Oklahoma, United States of America - January 18, 2017. Portable drilling derrick in Devon Oil and Gas Exploration Park in Oklahoma City

RFRMRD8D–Oklahoma City, Oklahoma, United States of America - January 18, 2017. Drilling rigs and derricks located in Devon Oil and Gas Exploration Park in Okla

8613371530291

8613371530291