kelly hose price

The main advantage of a kelly hose is that it helps you move water from one point to another without much struggle. Hose pipes are also versatile and can be used for various activities in your home or at your workplace. Moreover, rubber horse pipes are durable since rubber is a strong material. This means that you won’t need to replace it often. Additionally, rubber hoses are less prone to cuts and abrasions. Another advantage of this hose pipe is that it absorbs shocks and vibrations. Also, there is no need for specialized bending or brazing since it can bend easily. Lastly, it reduces pressure surges and lubricates itself.

When buying a kelly hose, there are several factors that you need to consider, including length, couplings, thickness, and price. The length of the kelly hose is an important factor to consider. If you are taking the water to the furthest corner of your compound, consider getting a longer pipe for convenience. Also, if you are watering a large garden, a longer pipe will serve you better. Couplings or horse pipe fittings are also another important consideration. These are the accessories that help you connect your pipe to the water source. They can either be made from brass or plastic. Some people prefer plastic couplings since they are lightweight, but they can break easily. Brass fittings are heavier but long-lasting. Lastly, consider the thickness of the pipe. This refers to the number of layers used to make the kelly hose. Thickness determines the weight of the pipe and ease of bending.

For a wholesale kelly hose, visit Alibaba.com. This online shopping platform offers a wide range of rubber hoses that suits your needs. Visit the website at any time and place your order.

From 2003, Letone has always been committed to manufacturing rubber hose for 14 years, which provides high-grade and high-end rubber hose for the field of spaceflight and maritime industry, petroleum industry and highway, and PLA etc. Just as careful and elaborate rubber hose, LETONE has now become a high-tech enterprise integrating research, production, sales and services after years of steady development, shining brilliantly in the international market as an iconic enterprise among China"s rubber hose.

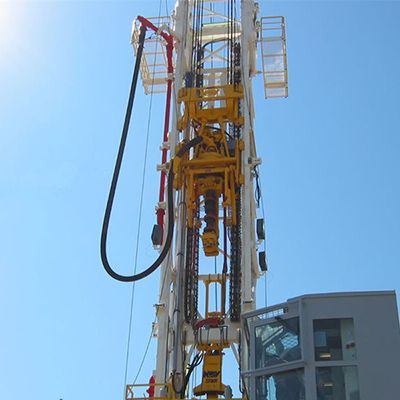

Flexible drilling rubber hoses play an important role in petroleum extraction. They should suffer high operating pressure, extreme operating temperature, abrasion and other inferior elements. Our special compounded synthetic rubber has been proven an effective and economical way to reject these problems. All our oilfield drill hoses are manufactured as API 7K or other related specifications.

Steel cable reinforcement loads most working pressure up to 15,000psi. The wires are usually zinc-plating or copper platting to improve steel wire resistant against rust and corrosion. Due to the thick reinforcement, the hoses should be handled or stored in correct way to avoid kicking or crushing. They will substantially decrease their rated operating pressure.

Rotary hose, Kelly hose, cement hose, mud hose, jumper hose and vibrator hose and choke & kill hoses are the most popular oilfield rubber hoses. They convey high-pressure drilling fluid from one place to another. Many end fittings are provided to satisfy different applications. Most end fittings are made according to API standards. Special order is also available.

Green Line G663 Kelly Hose is rated to 3600 psi with a full 4:1 safety factor. G663 is manufactured in long lengths of up to 164 ft to minimize remnants when long assemblies are required.

Six layers of spiral wire reinforcement make G665 our highest pressure Kelly hose. It has a full 4:1 safety factor and is supplied in lengths up to 50 metres (164 ft) to minimize scrap.

High Pressure Drilling Rotary Hoses is used in drilling and exploration work. Suitable for hydraulic fluids, such as hydraulic oil, fuel oil, lubricants, emulsion, glycol and water.Drilling hose is also used to adjust the installation mistake between drilling pipe line and stand pipe to avoid shake. To transmit high pressure oil or water based mud.

Recommended For:Flexible hose between the riser and manifold or around the ball joint of offshore drilling rigs, specially designed to withstand high pressure.Meets the high demands of directional drilling and down linking with negative pressure pulses and elevated temperatures. This hose can also be used as a Motion Compensator hose for stabilization of rotary drilling and pumping equipment against vertical wave action on offshore drill platforms. The Motion Compensator hose is not recommended for phosphate ester fluids.

Since 1898, Kelly Pipe Co., LLC has been the industry leader among carbon steel pipe suppliers in the United States and abroad. With sizable, diversified inventories and sales offices in the United States and Canada, Kelly is widely recognized as an unrivaled master distributor of line pipe and standard pipe. Visit our locations page to find Kelly in a city near you.

Contact one of our sales professionals now to get a competitive quote for any of your pipe needs. We pride ourselves as a reliable supplier of industrial pipe offering over 100 years of superior service. Trust Kelly to meet your needs and exceed your expectations while remaining competitive.

A more economical alternative to our polyurethane layflat hose. Warflex is reinforced with high–tenacity polyester yarn and coated through the weave with a 70% nitrile rubber / 30% PVC blend for good chemical resistance for produced water. Less abrasion resistance and puncture resistance. Custom hose color and branding available on big volume orders.

The new Midwest Hose Layflat Deployer completes our extensive water transfer portfolio. Our Direct Drive System makes our deployer one of the fastest, most powerful, and easy to use on the market with the capacity to deploy and retreive layflat hose up to 16″ in diameter.

Ideally suited for any high pressure hydraulic applications where there is a need for hoses to be Fire Rated and capable of working in extreme heat in the event of an emergency.

Hoses have a higher working pressure than normally available chemical hoses. CPE handles a wide variety of acids, alcohols, salt solutions, and petroleum based products.

Lightweight chemical transfer hose designed for almost every common industrial chemical used in industry today (98% of chemicals) without staining / contamination.

Designed for applications that required the hose to slide easily or require visual confirmation of material flow. Great for pumping water and light chemical solutions. Popular with pumping equipment because it handles suction discharge uses.

Lightweight, flexible, rugged suction/discharge hose that has good chemical resistance. Excellent for transferring fertilizer solutions, septic solutions, and pesticides. Hose remains flexible in sub-zero temperatures. Helix serves as a scuff strip.

Economical general service suction and discharge hose used for pumping water and light chemical solutions. PVC helix increases flexibility and abrasion resistance while the smooth interior provides maximum flow.

Designed for water discharge in construction, heavy duty equipment rental, and mines and quarries. Soft-wall hose construction provides similar performance to a layflat hose but a higher working pressure and more abrasion resistance.

Mud discharge hose designed for petroleum waste, drilling mud, diesel, and water. The standard to transfer liquid mud at high pressures from the mud pump.

Designed for use with push-on fittings for air tools, petroleum products, gasoline, mild chemicals or water. No clamps or special tools required. Hose reinforcement laid at the most effective angle for maximum strength and coupling holding ability.

Wire braid steam hose for saturated and superheated steam up to 250 PSI 450° F. Cover is pin pricked to allow venting to eliminate blistering and cover separation.

General purpose hoses for open end discharge. Non-absorbing, mildew proof, and rolls up flat for easy storage and handling. Common in construction, agriculture, irrigation, marine, and rental applications. PVC hoses resistant to oils, grease.

Designed to handle edible liquids, vegetable oils, salad dressings, vinegar, mustard and meat products requiring a sanitary hose which will not impair taste. Great for service with hot oil fat filters and fryers.

Designed as a hydraulic brake hose for vehicles and motorcycles. The average life of a brake hose is six years. Brake hoses swell with age and restrict flow. Generally all brake hoses on a vehicle deteriorate at the same rate.

Air Brake Tubing, Steel Brake Line Tubing Assemblies, Steel Brake Line Tubing Coils, Rubber Air Brake Hose, Silicone Coolant Hose, Silicone Heater Hose, GPR Radiator Hose, Rubber Heater Hose, Garage Exhaust Hose, Air Conditioning Hose

Camlocks, Petroleum Handling, Industrial and Oilfield Hose Ends, External Swage Hose Ends (Holedale), Crowsfeet Couplings, Sand Blast Couplings, Ground Joint Couplings, Bauer Style Quick Connects, Ringlock Fittings, Storz, Foot Valves and Strainers, Airline Accessories, Industrial Accessories, Clamps, Pressure Washer, Safety and Protection Products

Available in sizes 1/4″ – 12″. Operates in high/low temperatures. Fire safety up to 1200° F. No permeation of gases. Full vacuum. Annular is hydroformed, a process that enhances flexibility and extends the life of the hose. Suitable for oils, chemicals, gases, exhaust gases, water, steam, vacuum.

Plug Valves, Swivel Joints, J-55 and N-80 Pup Joints, Integral Fittings, Steel Hose Loops, Crossover Adapters and Swages, Blast Joints, Manifolds, Bull Plugs and Caps

37° JIC, Pipe, Pipe Swivel, O-Ring Kits, O-Ring, Split Flange, Face Seal, Hose Barb, Flareless Bite Type, Metric, BSPP, BSPT, Inline Live Swivel, 90° Live Swivels, 90° Dual Plane Live Swivels, Test Points, Thread ID Kits

Inverted Flare, SAE 45° Flare, Compression, Self Aligned, Polyline Flareless, Push-Connect, Push-Connect Air Brake, Compression for DOT, Compression for Air Brake Copper Tubing, Threaded Sleeve, Pipe Fittings, Needle Valves, Drain Cocks, Truck Valves, Ground Plugs, Multiple Shut-Offs, Hose Barbs, Push-On Hose Barbs, Garden Hose Fittings

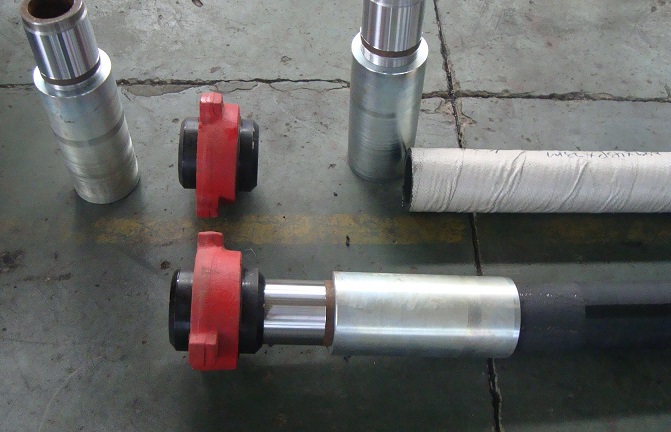

API 7K Rotary Drilling hoses also called oilfield drilling hoses, vibrator hoses, mud hoses, cementing hoses, kelly hoses, de-coking hoses, for the steady high pressure oilfield service. PME Grade D and Grade E rotary hose are designed and produced for mud delivery and cement service on the drilling rigs, by pumping mud at extra high pressure in oilfield drilling operation and exploration.

PME Rubber High Pressure Rotary Drilling Hoses, API 7K Certification, Grade A, Grade B, Grade C, Grade D, Grade E, Grade F.The rotary connection between mud pump and standpipe is called mud hose or kelly hose.

Drilling rotary and vibrator hoses (High Pressure Drilling Hoses) are designed as API 7K Spec as the flexible connection between the standpipe and swivel for pumping mud at a very high pressure in oil drilling and exploration. This hose features high strength spiral steel wire reinforcement which provides a very flexible connection capable of withstanding high pumping pressures at API working pressures, also called mud hose, cement hose, kelly hose or shock-resistant hose.

Our high pressure drilling hoses are often equipped with API end fittings. Connection type covers LP, NPT, TBG and BSPT thread, welding or integral forged union or flange.

8613371530291

8613371530291