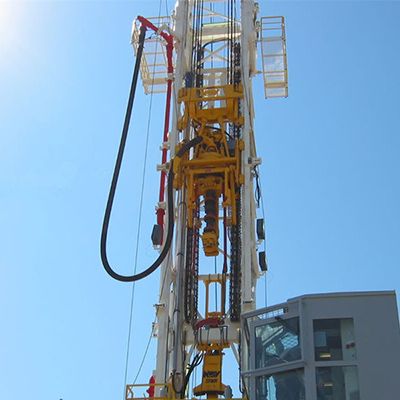

kelly hose drilling rig in stock

Flexible drilling rubber hoses play an important role in petroleum extraction. They should suffer high operating pressure, extreme operating temperature, abrasion and other inferior elements. Our special compounded synthetic rubber has been proven an effective and economical way to reject these problems. All our oilfield drill hoses are manufactured as API 7K or other related specifications.

Steel cable reinforcement loads most working pressure up to 15,000psi. The wires are usually zinc-plating or copper platting to improve steel wire resistant against rust and corrosion. Due to the thick reinforcement, the hoses should be handled or stored in correct way to avoid kicking or crushing. They will substantially decrease their rated operating pressure.

Rotary hose, Kelly hose, cement hose, mud hose, jumper hose and vibrator hose and choke & kill hoses are the most popular oilfield rubber hoses. They convey high-pressure drilling fluid from one place to another. Many end fittings are provided to satisfy different applications. Most end fittings are made according to API standards. Special order is also available.

Kelly hose is used to connect the standpipe to the swivel. It allows the drill string to be raised and lowered while the drill fluid is pumped through it. Kelly line usually contains two layers of plated steel cables to reach 5000 psi operating pressure. Inside tube is made of special NBR to improve abrasion and corrosion capability. Rubber cover is compatible with the ozone, sunlight and oils for a long time. It is supplied with multiple end fittings – API flanges, threads, butt-welded union and other as specified.

Flexible connection between standpipe and swivel (Rotary Drilling) or between pump and standpipe (Rotary Vibrator) for pumping mud at extra high pressure in oil drilling and exploration work. Meets the high demands of directional drilling and down linking with negative pressure pulses and elevated temperatures. This hose can also be used as a Motion Compensator hose for stabilization of rotary drilling and pumping equipment against vertical wave action on offshore drill platforms. The Motion Compensator hose is not recommended for phosphate ester fluids.

A large-diameter (3- to 5-in inside diameter), high-pressure flexible line used to connect the standpipe to the swivel. This flexible piping arrangement permits the kelly (and, in turn, the drillstring and bit) to be raised or lowered while drilling fluid is pumped through the drillstring. The simultaneous lowering of the drillstring while pumping fluid is critical to the drilling operation.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Reinforcing our capability to meet the growing demand forLarge Diameter Hose (LDH), JGB Enterprises, Inc. has decided to expand our production capabilities to include 12” crimping.

With our continued development and support of the energy exploration market, JGB Enterprises, Inc. has invested in the Techmaflex PES-500 Large Bore Hose Assembly Machine.

We feel this investment will lead the energy exploration market to the next level. We also look forward to this investment opening more opportunities in markets where the need for safety of crimped large diameter hoses exists.

Drilling hose also called Oilfield drilling hose, rotary drilling hose, is hollow, thin-walled, steel or aluminium alloy piping that is used on drilling rigs. It is hollow to allow drilling fluid to be pumped down the hole through the bit and back up the annul-us. It comes in a variety of sizes, strengths, and wall thicknesses, but is typically 27 to 32 feet in length (Range 2). Longer lengths, up to 45 feet, exist (Range 3).

Oilfield drilling hoses have found their wide application in the extraction of minerals such as oil & gas drilling. With the help of the drill pipe, a drilling mud is injected into the well at a very high pressure, most often technical water, hydrogel solution or clay-based solutions. The drill hose is also used between oil tankers and drilling wells in the sea. Drilling hoses can be used on stationary and mobile drilling rigs, for drilling wells in the sea.

The drilling rotary hose is suitable for flexible connection between the top of the drilling riser and the swivel which can move vertically. It resists corrosion of hydrogen sulfide and can deliver water, oil, mud high‐pressure media.

Rotary drilling hose is mainly used for conveying water-based or oil-based mud and other fluids in the working temperature of -30 °C to +82 °C. It is often used for oil fields, cement repairing, geological exploration and water conveyance for coal excavation. It is composed of three parts: tube, reinforcement and cover. The tube is made from NBR, which is resistant to abrasion, corrosion and oils. The reinforcement is made from 2-8 layers of high tensile and high strength spiraled steel wire, making the hose have solid structure and resistant to high pressure. The cover is made from high quality synthetic rubber, mainly chloroprene rubber, making the hose resistant to abrasion, corrosion, cut, weather, ozone, aging and sunlight. The hose has longer service life as a result.

Cover: high quality synthetic rubber, mainly chloroprene rubber, making the hose resistant to abrasion, corrosion, cut, weather, ozone, aging and sunlight.

As drilling operation methods evolve, become deeper, with increasing pressure and higher temperatures, JYM can provide a range of drilling and cementing hose solutions to meet these challenging conditions. Our key offering includes rotary drilling / vibrator hose grade D and E, choke and kill, cement and sour hoses. The JYM range supports the pumping of mud at very high pressure during drilling and exploration campaigns.

JINYUAN RUBBER CO., LTD. has been an important partner of many famous customers including America, East Asia, Africa and other countries and regions in the world. Oilfield drilling hoses are vital components for rig drilling systems. Rotary drilling hose, mud hose, cement hose, Kelly hose, vibrator hose are working under high-pressure. Once the hose failure, it will cause catastrophic damage to the equipment, body health and property. Our professional engineers can help you solve any problem in safe storage, handling and other technical problems. Our drilling hoses are equipped with API end fittings – flanges, NPT threads and butt-weld unions to meet requirements on the market. Bespoke end fittings are also available. Hose quality is our life. It is our aim to provide constantly high level of quality. All production processes and procedures have been strictly inspected. The final inspection before shipment is the strictest and any inferior products are not allowed in our company. When you purchase our products, we will provide considerable after-sales service. If the drill rotary hoses fail in warranty time, they can be returned without costing you one cent of shipment.

Kelly drilling hoses are big inside diameter (3" to 4" ID) high pressure flexible lines used to between the standpipe and the swivel. This flexible piping permits the kelly to be raised and lowered while drilling fluid is pumped through the drill string. The simultaneous lowering of the drill string while pumping fluid is very important to the drilling operation.

We stock, fabricate, and assemble Rotary/Kelly, Vibrator, Choke & Kill and BOP Hoses right at our facility in Newcomerstown, OH. After assembly, we test each hose to 10,000 or 15,000 before it goes out the door.

In addition to the Texcel Oilfield and Hydraulic Hose lines, Buckeye BOP is proud to distribute Texcel for all of your Industrial Hose needs. With walk-in service available, it’s never too late to give us a call or stop in.

Whether you’re out on a drilling rig, hauling water and sand or a local farmer in need of a few parts, we maintain a vast stock of supplies to be ready when you need us. From lubricants and fluids to trash bags and wire brushes, we’re here to help.

When time becomes an issue, or you just want quality, custom work done, call Buckeye BOP for you fabrication needs. We build custom water tanks, fuel tanks, mud pits, mud pump packages, skidded centrifugal pump packages and skids. We will even put together your custom Drilling Rig Package. Everything we do has a focus on Quality. With a CAD design services available, you know how the project will look before any wire is burned. Call us today to realize your project.

In addition to selling and renting Sioux units, we can also provide service. Since we already deliver our products to you in the field, we are available to assess your service needs right where you are. And, since we offer 24 hour service, we’re always ready to work.

High Pressure Drilling Rotary Hoses is used in drilling and exploration work. Suitable for hydraulic fluids, such as hydraulic oil, fuel oil, lubricants, emulsion, glycol and water.Drilling hose is also used to adjust the installation mistake between drilling pipe line and stand pipe to avoid shake. To transmit high pressure oil or water based mud.

Meets the severe demands of today’s drilling methods including directional drilling, pressure pulses and elevated temperatures. Tube is designed to handle abrasive, corrosive and oil based drilling muds. The cover is designed to handle external damage from abrasion, corrosion, gouges, oil and weather.

Recommended For:Flexible hose between the riser and manifold or around the ball joint of offshore drilling rigs, specially designed to withstand high pressure.Meets the high demands of directional drilling and down linking with negative pressure pulses and elevated temperatures. This hose can also be used as a Motion Compensator hose for stabilization of rotary drilling and pumping equipment against vertical wave action on offshore drill platforms. The Motion Compensator hose is not recommended for phosphate ester fluids.

The main advantage of a kelly hose is that it helps you move water from one point to another without much struggle. Hose pipes are also versatile and can be used for various activities in your home or at your workplace. Moreover, rubber horse pipes are durable since rubber is a strong material. This means that you won’t need to replace it often. Additionally, rubber hoses are less prone to cuts and abrasions. Another advantage of this hose pipe is that it absorbs shocks and vibrations. Also, there is no need for specialized bending or brazing since it can bend easily. Lastly, it reduces pressure surges and lubricates itself.

When buying a kelly hose, there are several factors that you need to consider, including length, couplings, thickness, and price. The length of the kelly hose is an important factor to consider. If you are taking the water to the furthest corner of your compound, consider getting a longer pipe for convenience. Also, if you are watering a large garden, a longer pipe will serve you better. Couplings or horse pipe fittings are also another important consideration. These are the accessories that help you connect your pipe to the water source. They can either be made from brass or plastic. Some people prefer plastic couplings since they are lightweight, but they can break easily. Brass fittings are heavier but long-lasting. Lastly, consider the thickness of the pipe. This refers to the number of layers used to make the kelly hose. Thickness determines the weight of the pipe and ease of bending.

For a wholesale kelly hose, visit Alibaba.com. This online shopping platform offers a wide range of rubber hoses that suits your needs. Visit the website at any time and place your order.

8613371530291

8613371530291